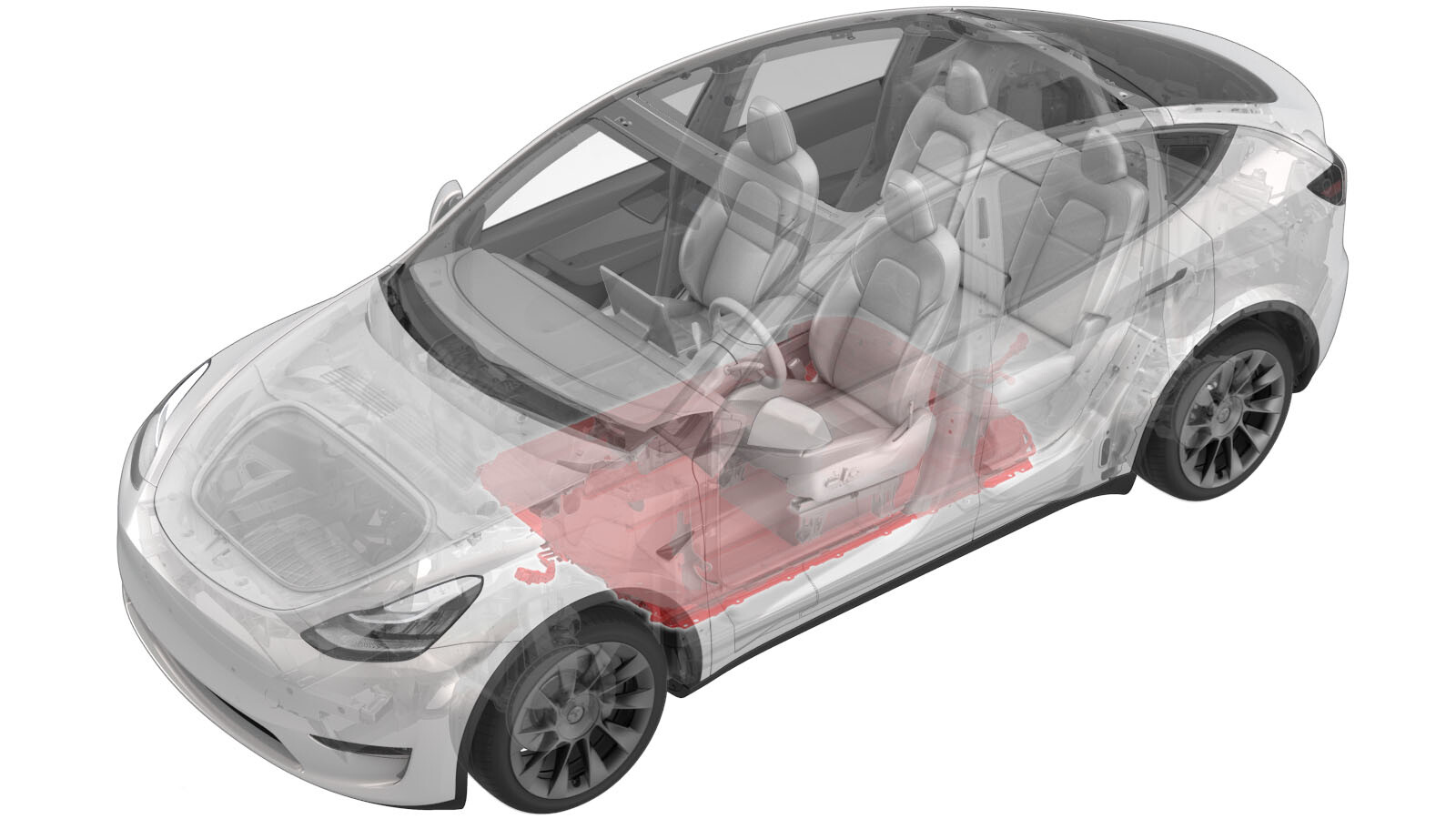

HV Battery (AWD) (Non-Structural Pack) (Remove and Replace)

Correction codes

16010202

5.40

NOTE: Unless otherwise explicitly

stated in the procedure, the above correction code and FRT reflect all of the work

required to perform this procedure, including the linked procedures. Do not stack correction codes unless

explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how they are created. To provide feedback on

FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when

performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

Correction codes

16010202

5.40

NOTE: Unless otherwise explicitly

stated in the procedure, the above correction code and FRT reflect all of the work

required to perform this procedure, including the linked procedures. Do not stack correction codes unless

explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how they are created. To provide feedback on

FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when

performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

- 2025-10-10: Changed procedure sequence for cleaning the HV busbar and HV header connector contact surfaces.

- 2025-05-28: Modified step for attaching pyrotechnic battery disconnect when shipping the HV battery.

- 2025-04-08: Added step for attaching pyrotechnic battery disconnect when shipping the HV battery.

- 2025-02-19: Added a note to replace the ancillary bay cover with a compatible part while removing the pyro disconnect, if necessary.

- 2025-01-08: Added images of HV battery alignment rods for clarification.

- 2025-01-03: Added notes regarding the potential absence of the ancillary bay cover volcano brackets and fasteners for newer Model 3/Y vehicle builds. Replaced pyro disconnect steps with pyro removal service manual link.

- 2024-12-19: Added a step to verify the front HV battery coolant passthrough fittings on the new HV battery to determine if the updated front HV battery coolant manifold hose 1734606-00-D is needed.

- 2024-12-18: Added step to determine if HV battery parameters are within safe limits before removing the pyro disconnect.

- 2024-11-07: Added 3-phase harness disconnect/connect steps.

- 2024-10-31: Updated HV battery discharge steps.

- 2024-09-11: Added step to support the LV system.

- 2024-06-13: Updated lift pad adapter PNs.

- 2024-06-10: Added pyro disconnect removal steps.

- 2023-11-21: Added new lift pad instructions.

- 2023-11-13: Add note to further clarify fasten the HV battery pack to crate before shipping.

- 2023-11-06: Updated UI steps.

- 2023-08-25: - Updated EPB Service Mode reference.

- 2023-05-22: Added conspicuous discharge warning table.

- 2023-05-22: Added caution for correct positive DC cable connection.

- 2023-03-16: Updated Discharge section and added steps to configure the HV battery.

Equipment:

- 1936724-00-A - Universal Lift Pad Adapters

- 1133787-00-A Key, Seat Belt Release, Model 3

- 1020566-00-F ASY, Battery Table, Manual Lift

- 1020566-99-A Top Plate, Battery Table, Manual Lift

- 1129166-00-A Hoist, H-Frame EMEA

- 1073363-00-A Gantry, Adjustable, Aluminum

- 1134523-00-A Kit, Alignment Rods, Battery, Model 3

- 1140311-00-A Lever Lock, HV Connector, Model 3

- 1053600-00-B Drive Unit Pressure Test Fixture

- 1130942-00-B Adapter, Coolant Reservoir Pressure Test

- 1132185-00-B Kit, Coolant Leak Test Adapters, Model 3

- 1133843-00-A Kit, Coolant Drain & Fill Adapters, M3

- 1135762-00-A Kit, Svc Plug, Cooling Hose, Model 3

- 1065131-00-A Kit, Battery Coolant Drain and Fill

- 1026636-00-A Pack Enclosure Leak Tester, HV Battery

- 1140501-00-A Pack Kit, Enclosure, Leak Test, HV Battery, Complete

- 1144879-00-A Kit, Encl Leak Test Adapters, HV Battery

- 1108272-00-B Cap, Logic Conn, Inv, 3DU

Only

technicians who have completed all required certification courses are permitted to

perform this procedure. Tesla recommends third party service provider technicians

undergo equivalent training before performing this procedure. For more information on

Tesla Technician requirements, or descriptions of the subject matter for third parties,

see HV Certification Requirements. Proper personal protective equipment (PPE) and insulating HV

gloves with a minimum rating of class 0 (1000V) must

be worn at all times a high voltage cable, busbar, or fitting is handled. Refer to Tech Note TN-15-92-003, High Voltage Awareness

Care Points

for additional safety

information.

Torque Specifications

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| LH front inner HV battery bolt |

136 Nm (100.3 lbs-ft) |

|

Reuse | |

| LH middle inner HV battery bolt |

66 Nm (48.7 lbs-ft) |

|

Reuse | |

| LH rear inner HV battery bolt |

66 Nm (48.7 lbs-ft) |

|

Reuse | |

| Bolt that secures the busbar cover access door |

9 Nm (6.6 lbs-ft) |

|

Reuse | |

| Bolts that attach the charge port busbar kit to the HV header |

9 Nm (6.6 lbs-ft) |

|

Reuse | |

| Nut that attaches the DCDC ground strap to the HV battery |

15 Nm (11.1 lbs-ft) |

|

Replace | PN - 1093060-00-A |

| Nut that attaches the positive 12V output to the PCS cable |

15 Nm (11.1 lbs-ft) |

|

Replace | PN - 1093060-00-A |

| Bolt that attaches the LH front wheel liner to the HV battery |

5 Nm (3.7 lbs-ft) |

|

Reuse | |

| Bolt that attaches the FDU HV harness to the FDU |

10 Nm (7.4 lbs-ft) |

|

Reuse | |

| Bolt that attaches the ground strap to the HV battery |

10 Nm (7.4 lbs-ft) |

|

Reuse | |

| Smaller bolts that attach the LH shear plate to the body |

35 Nm (25.8 lbs-ft) |

|

Reuse | |

| Larger bolt that attaches the LH shear plate to the body |

130 Nm (95.9 lbs-ft) |

|

Replace | PN - 1461657-00-A |

| Nut that attaches the RDU HV electrical harness bracket to the HV battery |

10 Nm (7.4 lbs-ft) |

|

Reuse | |

| Center bolts (x4) that attach the HV battery through the HV battery center rail ski cover |

35 Nm (25.8 lbs-ft) |

|

Reuse | |

| Bolts that attach the HV battery LH and RH support brackets to the vehicle |

110 Nm (81.1 lbs-ft) |

|

Reuse | |

| Bolts (x16) that attach the HV battery to the vehicle |

35 Nm (25.8 lbs-ft) |

|

Reuse |

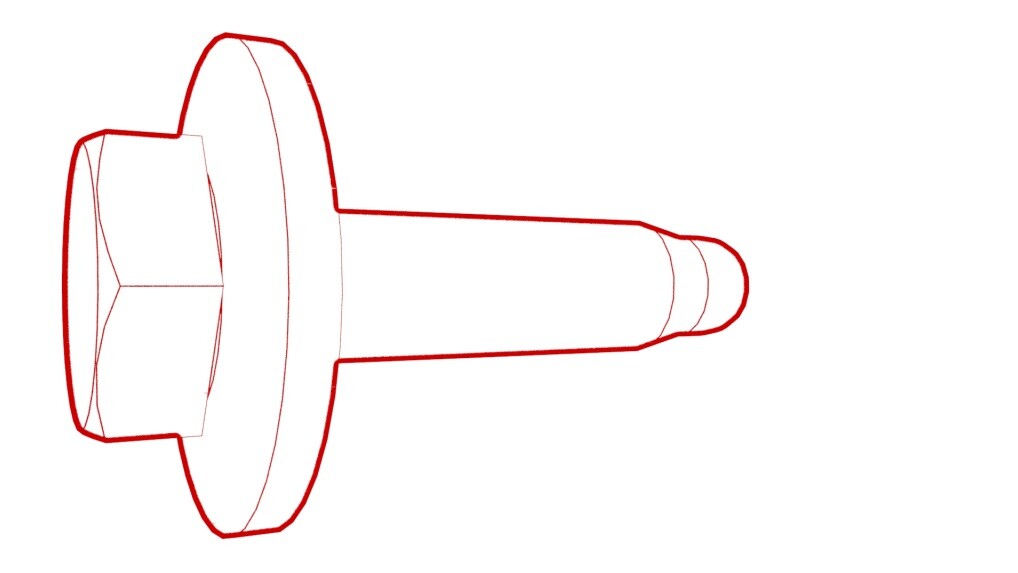

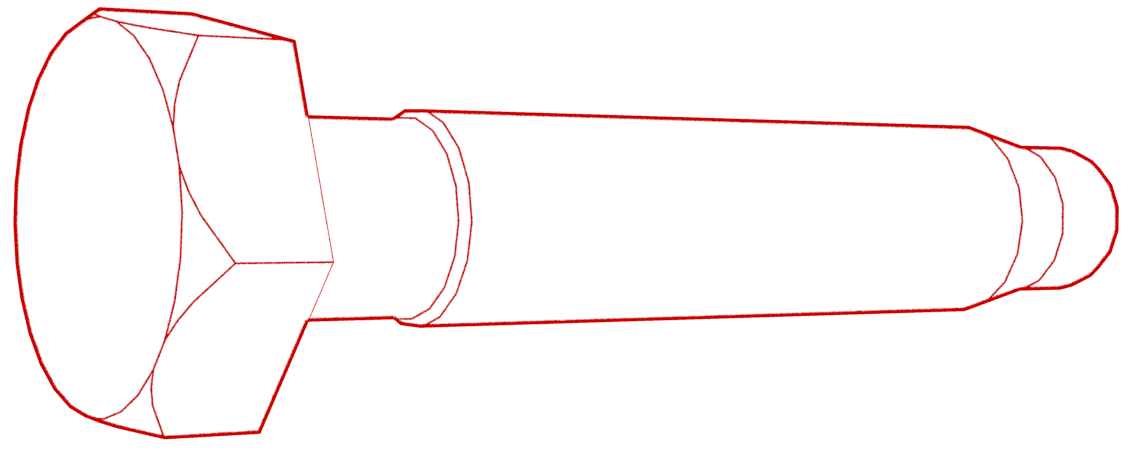

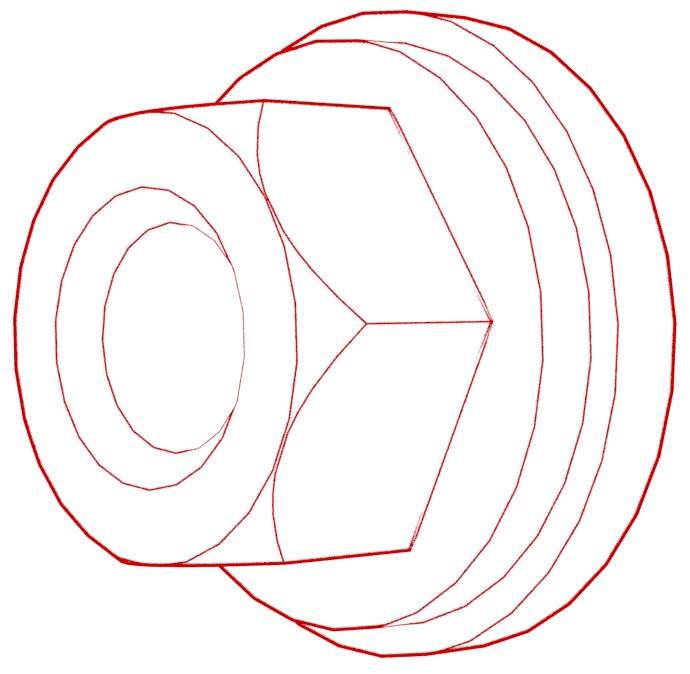

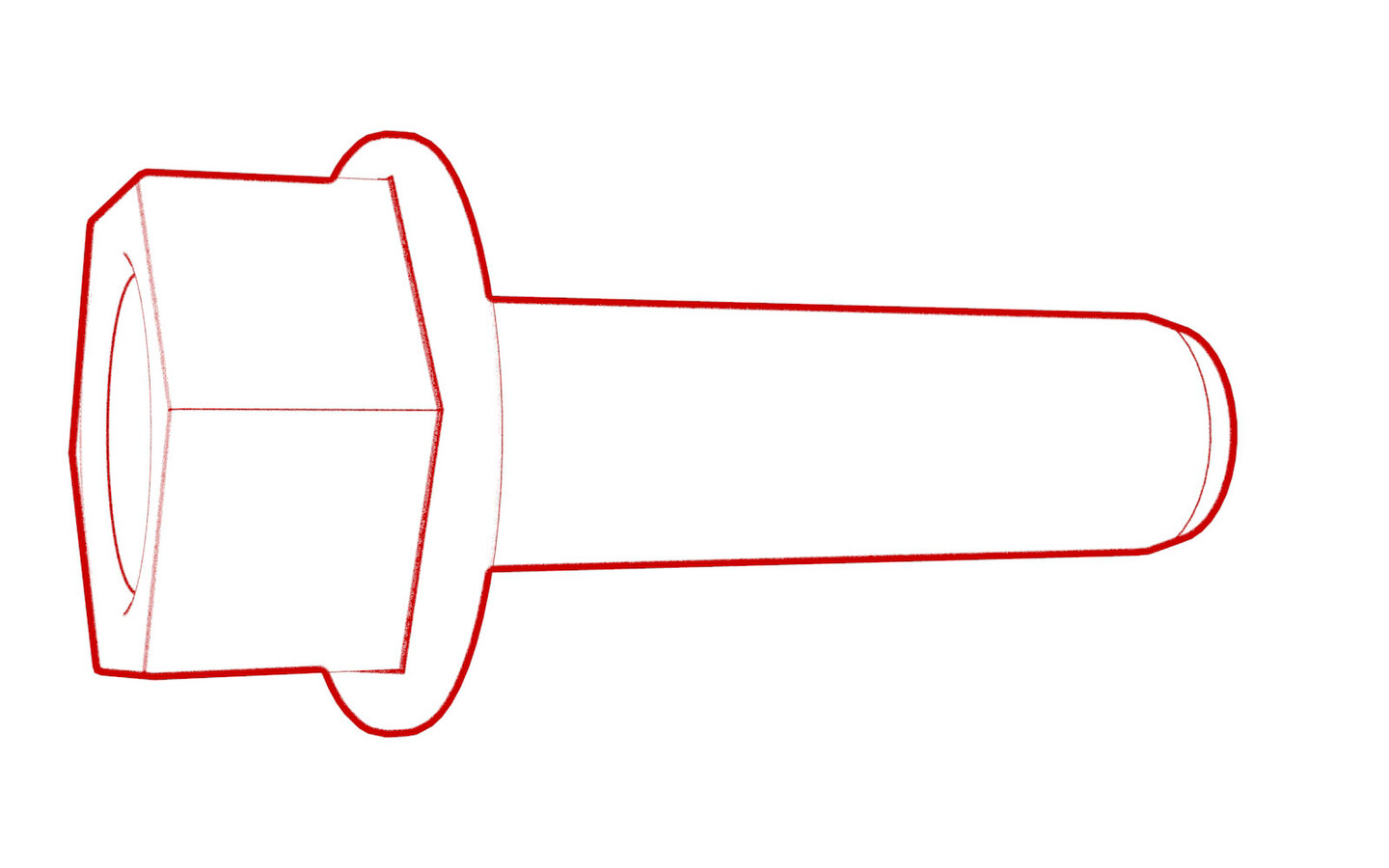

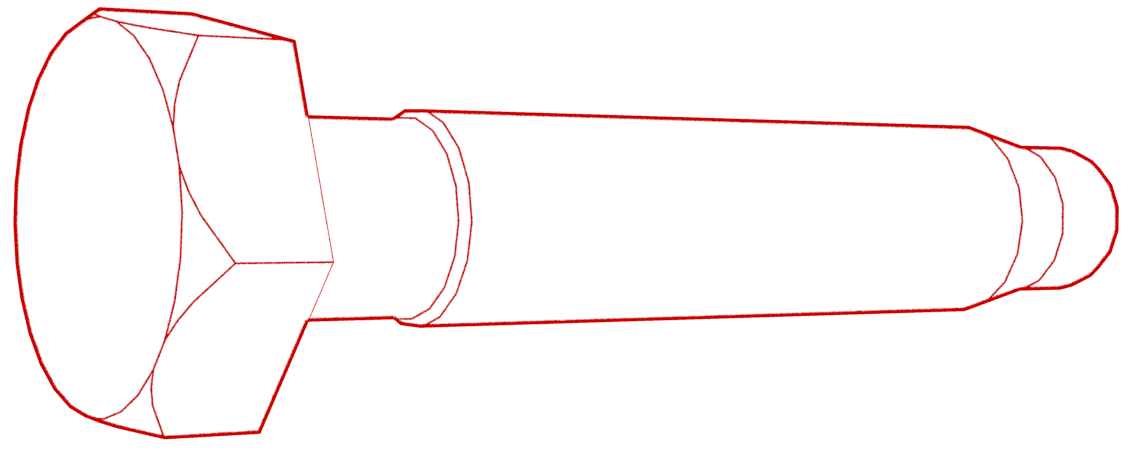

Note Some vehicles are

equipped with self-tapping bolts in bolt position #8-15 from the

factory. If the vehicle is equipped with a bolt with a hexagonal

indentation on the bolt head (1637725-00-A), the torque value is 64 Nm. |

Discharge

|

WARNING:

To conform with local laws, High Voltage Lithium Batteries must

be discharged before packing for shipment. Additionally, HV

batteries must be discharged before being put into storage. HV

batteries to be shipped must have a State of Charge (SoC) of

less than 25% or 45%, depending on the region. If the method of

shipment is unknown or uncertain, or the battery is to be

stored, it is recommended to discharge the HV battery to less

than 25%.

WARNING: After discharge, wait 20 minutes and verify that the SoC is less than the targeted value. This waiting period allows the open circuit voltage (OCV) to settle, which is critical for accurate measurements. Continue discharging if the SoC does not meet the required level. Make sure to collect all HV battery shipping data using the HV Battery Communication Tool, preferably before removing the HV battery from the vehicle. WARNING: Do not ship or store an HV battery that has a loss of high voltage isolation. Verify HV battery isolation before packing for shipment or storage. Use the HV Battery Communication Tool, described in Toolbox article #41977 or Customer Document CD-21-16-003, to determine if the HV battery parameters are within safe limits for shipment or storage. |

- Enable Service Mode Plus. See Service Mode Plus.

-

Identify the vehicle's current SOC Max: In the Service Mode Plus menu, touch , and then touch the large HV battery diagram to display the HV Battery information window.

- If the SOC Max is less than the SOC shipping threshold, skip to step 6 of this sub-procedure.

- If the SOC Max is greater than the SOC shipping threshold, continue to the next step.

- Move the vehicle to a location where the battery can be safely discharged unattended.

-

In the Service Mode Plus menu, touch .

-

In the Tools section, touch Start HV Discharge, and then in the window that opens, touch Run.

NoteThe discharge routine starts and will automatically stop when the SOC Max value for surface transport has been attained.

- After discharge is complete, use the HV Battery Communication Tool to collect HV battery shipping data, and then move the vehicle to the service bay.

Remove

- Verify that the vehicle software version is at 2023.20 or later, and if not, update to the latest version. See Software Update.

- Remove the LH lower rocker panel cover. See Cover - Rocker Panel - Lower - LH (Remove and Replace).

- Remove the LH rocker panel carrier. See Carrier - Rocker Panel - LH (Remove and Replace).

-

Remove the butyl patches that cover the LH rocker access hole.

- Repeat step 2 through step 4 for the RH side of the vehicle.

-

Install lift pad adapters.

- For EMEA only, install Adapter, Lift Pad, Model Y (1614078-00-A)

- For other regions, install Universal Lift Pad Adapters (1936724-00-A)

WarningDO NOT use any other lift pad adapters.NoteOutside of EMEA, Universal Lift Pad Adapters (1936724-00-A) replace Adapter, Lift Pad, Model Y (1614078-00-A). Discard any other versions of lift pad adapters.NoteIn EMEA, the Universal Lift Pad Adapters are not yet available. Make sure to use the rubber Model Y lift pads on Model Y and the Model 3 lift pads on Model 3.Instructions for Universal Lift Pad Adapters:

- Depending on the lift type, install

the correct thread adapter onto the lift adapter.

- Make sure the thread stop washer is

installed and tightened to the bottom of the lift adapter. If the thread stop washer

is not installed, do not

continue using the lift adapter.

- Install the lift adapters onto the

lift arms so that the black lift pad is toward the vehicle.WarningMake sure the adapter is install in the correct orientation.

- Position the lift arms so that the

lift adapters align with the datum hole on the vehicle.

- Lift the lift arms to fully seat the

lift pads into the vehicle.

- Make sure all 4 adapters are fully

seated into the vehicle.

-

Open all doors and lower all windows.

NoteLatch the rear doors to prevent accidental lockout.

- Enable the EPB Service Mode. See Parking Brake - Caliper - Rear - LH (Release)

- Remove the rear underhood apron. See Underhood Apron - Rear (Remove and Replace).

- Remove the LH instrument panel end cap. See End Cap - Instrument Panel - LH (Remove and Replace).

- Remove the LH middle A-pillar trim. See Trim - A-Pillar - Middle - LH (Remove and Replace).

- Remove the LH lower A-pillar trim. See Trim - A-Pillar - Lower - LH (Remove and Replace).

- Move the driver seat fully rearwards.

- Remove the driver footwell cover. See Cover - Footwell - Driver (Remove and Replace).

- Remove the LH center console side panel carpet. See Side Panel - Center Console - LH (Remove and Replace).

-

Remove the clip that attaches the LH front carpet to the vehicle, and then fold the carpet rearward.

-

Remove the foam plugs in the padding underneath LH front carpet, and then remove the LH front inner HV battery bolts (x2).

TIpUse of the following tool(s) is recommended:

- Torx Plus EP20 socket

- 6 in extension

- Raise the LH front seat fully.

- Repeat step 10 through step 18 for the RH side of the vehicle.

- Remove the 2nd row floor mat from the vehicle.

-

Lift the flap in the carpet underneath the RH front seat, and then remove the RH middle inner HV battery bolt that attaches the HV battery to the vehicle. Repeat this step for the LH side of the vehicle.

TIpUse of the following tool(s) is recommended:

- 16 mm socket

- Remove the 2nd row seat assembly.

- Remove the LH lower C-pillar trim. See Trim - C-Pillar - Lower - LH (Remove and Replace).

-

Remove the clip securing the LH lower B-pillar to body.

- Repeat steps 23 and 24 for the RH side of the vehicle.

-

Remove the clips (x3) that attach the rear carpet to the vehicle.

-

Position a folded shop towel underneath the rear cabin carpet to raise the carpet and allow access to the rear inner HV battery bolts, and then remove the LH and RH bolts.

TIpUse of the following tool(s) is recommended:

- 16 mm socket

- 6 in extension

- Disconnect 12V power. See 12V/LV Power (Disconnect and Connect).

-

Perform the Vehicle HV Disablement procedure.

- 5-seater vehicles

- 7-seater vehicles

-

Disconnect the logic electrical connector at the LH seat frame.

-

Release the clip that attaches the logic electrical harness to the LH seat frame.

-

Remove the bolt that secures the busbar cover access door.

TIpUse of the following tool(s) is recommended:

- 10 mm deep socket

-

Remove the bolts that attach the charge port busbar kit to the HV header, and then lift to remove the kit from the header.

TIpUse of the following tool(s) is recommended:

- 10 mm deep socket

-

If there is a 3-phase (AC) connection

between the charge port and HV battery, disconnect it:

-

Disconnect the HVC logic connector, and then install the logic cap.

-

Remove and discard the nut that attaches the DCDC ground strap to the HV battery, and then remove the strap from the battery.

TIpUse of the following tool(s) is recommended:

- 13 mm 12-point deep socket

- 4 in extension

-

Release the positive 12V output cover from the PCS cable, remove and discard the nut that attaches the positive 12V output to the PCS cable, and then move the cable aside.

TIpUse of the following tool(s) is recommended:

- 13 mm socket

- 3 in extension

- Use the HV Battery Communication Tool, described in Toolbox article #41977 or Customer Document CD-21-16-003, to determine if the HV battery parameters are within safe limits before proceeding.

-

Remove the pyrotechnic battery disconnect prior to shipping the HV battery. See Pyrotechnic Battery Disconnect (Remove and Replace).

NoteIf the old HV battery ancillary bay cover has volcano brackets, and the new ancillary bay cover does not have the same brackets or vice versa, replace the ancillary bay cover with a compatible part while removing the pyro disconnect.NoteReinstall the ancillary bay cover after removing the pyro battery disconnect. Newer built vehicles may be equipped with ancillary covers without volcano brackets and the bolts will not be present.

-

Close all doors.

NoteDoors will be unlatched at a later step.

- Remove the wheel chocks from the wheel.

-

With assistance, push the vehicle onto the lift, then re-chock the wheels when the vehicle is in position.

CAUTIONOnly push the vehicle for a very short distance and at less than 1 MPH.

-

Install lift pad adapters.

- For EMEA only, install Adapter, Lift Pad, Model Y (1614078-00-A)

- For other regions, install Universal Lift Pad Adapters (1936724-00-A)

WarningDO NOT use any other lift pad adapters.NoteOutside of EMEA, Universal Lift Pad Adapters (1936724-00-A) replace Adapter, Lift Pad, Model Y (1614078-00-A). Discard any other versions of lift pad adapters.NoteIn EMEA, the Universal Lift Pad Adapters are not yet available. Make sure to use the rubber Model Y lift pads on Model Y and the Model 3 lift pads on Model 3.Instructions for Universal Lift Pad Adapters:

- Depending on the lift type, install

the correct thread adapter onto the lift adapter.

- Make sure the thread stop washer is

installed and tightened to the bottom of the lift adapter. If the thread stop washer

is not installed, do not

continue using the lift adapter.

- Install the lift adapters onto the

lift arms so that the black lift pad is toward the vehicle.WarningMake sure the adapter is install in the correct orientation.

- Position the lift arms so that the

lift adapters align with the datum hole on the vehicle.

- Lift the lift arms to fully seat the

lift pads into the vehicle.

- Make sure all 4 adapters are fully

seated into the vehicle.

-

Raise and lock the vehicle at a comfortable working height.

CAUTIONVerify that the vehicle is stable on the lift.

- Remove the front aero shield panel. See Panel - Aero Shield - Front (Non-Structural Pack) (Remove and Replace).

-

Remove the bolt and clips that attach the LH front wheel liner to the HV battery and lower wheel well area. Repeat this step for the RH side of the vehicle.

TIpUse of the following tool(s) is recommended:

- 10 mm socket

- 4 in extension

- Remove the front HV battery skid plate. See Skid Plate - HV Battery - Front (Remove and Replace).

-

Remove the bolt that attaches the front drive unit HV harness to the front drive unit.

TIpUse of the following tool(s) is recommended:

- External Torx Plus EP10

-

Slide the release to unlock the front drive unit HV connector handle of the front drive unit to HV battery harness from the secured position.

-

Fully raise the handle on the front drive unit HV connector.

- Remove the front drive unit HV connector from the front drive unit HV header.

-

Remove the bolt that attaches the ground strap to the HV battery.

TIpUse of the following tool(s) is recommended:

- 10mm ratcheting combination flex head wrench

-

Release the bracket that secures the HV connectors to the bulkhead.

-

Disconnect the A/C compressor electrical connector from the HV harness.

-

Install bungee straps to pull the LH and RH front wheel arch liners away from the HV battery and expose the coolant hoses.

- Perform a rear powertrain coolant drain. See Powertrain Coolant (Drain and Refill).

- Perform a platter enclosure coolant drain. See Platter Enclosure Coolant (Drain and Refill).

- Remove the mid aero shield panel. See Panel - Aero Shield - Rear (Remove and Replace).

- Position the support stand underneath the front portion of the rear subframe.

-

Release the fir tree clips that attach the coolant hoses to the LH shear plate.

-

Remove the smaller bolts that attach the LH shear plate to the body.

TIpUse of the following tool(s) is recommended:

- 13 mm socket

- 3 in extension

-

Remove and discard the larger bolt that attaches the LH shear plate and rear subframe to the body, and then remove the LH shear plate.

TIpUse of the following tool(s) is recommended:

- 21 mm socket

- 6 in extension

-

Re-install the larger bolt, and hand-tighten the bolt to the rear subframe.

- Repeat step 60through 63 for the RH shear plate.

- Remove the support stand from underneath the rear subframe

- Remove the rear HV battery skid plate. See Skid Plate - HV Battery - Rear (Remove and Replace).

- Position the coolant drain under the rear LH side of the HV battery.

-

Release the clip and disconnect the rear drive unit inverter inlet hose from the rear of the HV battery, and immediately plug the male and female fittings.

- Position the coolant drain under the rear RH side of the HV battery.

-

Release the clip and disconnect the coolant outlet hose to rear powertrain return coupling, and immediately plug the male and female fittings.

- Remove the coolant drain from underneath the vehicle.

-

Remove the nut that attaches the rear drive unit HV electrical harness bracket to the HV battery.

TIpUse of the following tool(s) is recommended:

- 10 mm socket

- 4 in extension

-

Slide the release to unlock the HV battery rear drive unit connector handle of the rear drive unit to HV battery harness from the secured position.

-

Fully raise the handle on the HV battery rear drive unit connector.

- Remove the HV battery rear drive unit connector from the HV battery header.

-

With an assistant, put the battery table in position, and then lower the vehicle to support the HV battery.

NoteLine up the battery table so that the center 4 bolts of the HV battery are accessible through the opening in the battery table.

-

Remove the center bolts (x4) that attach the HV battery through the HV battery center rail ski cover.

TIpUse of the following tool(s) is recommended:

- External Torx Plus EP14

-

Remove the bolts (x8) that attach the HV battery LH and RH support brackets to the vehicle.

TIpUse of the following tool(s) is recommended:

- 16 mm socket

- 3 in extension

-

Remove the bolts (x16) that attach the HV battery to the vehicle.

NoteRecord the positions of any installed washers, as they will be reinstalled to the same locations during the installation procedure.TIpUse of the following tool(s) is recommended:

- 13 mm socket

- 3 in extension

- With an assistant, raise the vehicle and remove the HV battery from underneath the vehicle.

-

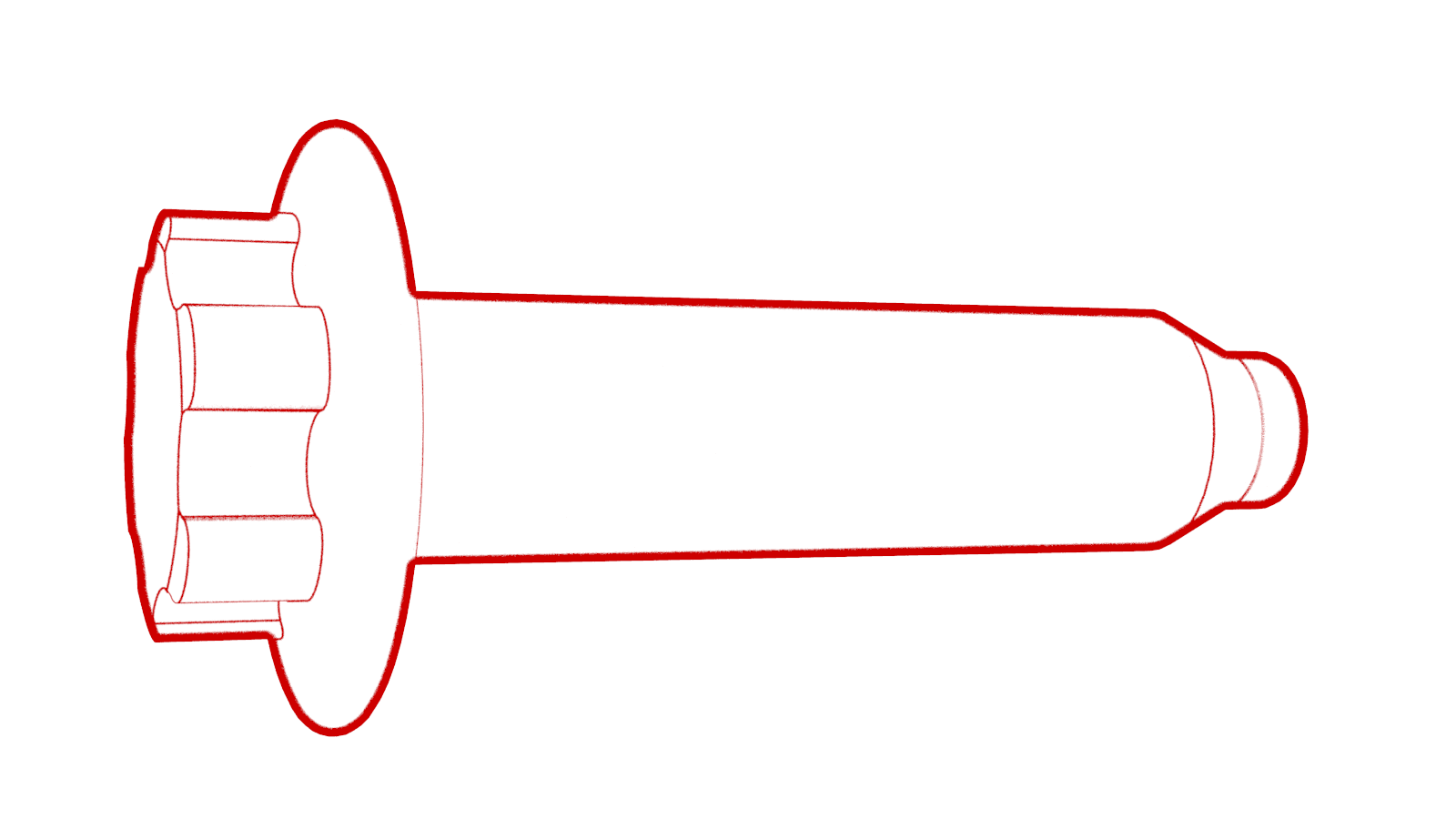

Turn the adjustable elements (x4) clockwise to remove them from the ancillary bay cover.

NoteKeep the adjustable elements so that they can be installed onto the replacement HV battery.

-

Release the clip and disconnect the LH inner HV battery supply hose fitting from the LH front of the HV battery platter enclosure.

-

Release the clip and disconnect the LH outer HV battery supply hose fitting from the LH front of the HV battery platter enclosure.

-

Release the clip and disconnect the RH inner coolant hose fitting from the RH front of the HV battery.

-

Release the clip and disconnect the RH outer HV battery supply hose fitting from the RH front of the HV battery platter enclosure, and remove the hose assembly from the HV battery.

-

Release the clips (x5) that attach the powertrain return (lower) hose to the RH side of the HV battery, and remove the hose from the HV battery.

-

Release the clip and disconnect the powertrain supply hose fitting from the RH rear underside of the ancillary bay.

-

Release the clips (x5) that attach the powertrain supply (upper) hose to the RH side of the HV battery, and remove the hose from the HV battery.

- Use the gantry and H-frame hoist to lift the HV battery from the manual lift battery table.

- Use the gantry and H-frame hoist to lower the HV battery into the shipping container.

-

Remove the logic cap from old battery.

NotePlease make sure correctly fasten the HV battery pack to the crate before shipping.

-

If the HV battery is being shipped,

attach the old pyrotechnic battery disconnect to the brackets on the ancillary bay cover

of the old HV battery using cable ties. If the ancillary bay cover is not equipped with

brackets, attach the old pyrotechnic battery disconnect to the RH rear corner of the old

HV battery using cable ties.

NotePut a piece of paper under the pyrotechnic battery disconnect. Use masking tape if necessary to prevent movement.

Figure 1. Pyrotechnic battery disconnect attached to brackets on the ancillary bay cover Figure 2. Pyrotechnic battery disconnect attached to RH rear corner of HV battery

Install

- Use the gantry and H-frame hoist to lift the new HV battery out of the shipping container.

-

Transfer all of the HV header and coolant port caps from the front and rear of the new HV battery to the old HV battery for return shipment.

NoteIf it is not possible to fit the caps onto the old HV battery, include the caps in the shipping crate.

-

With assistance, lower the HV battery onto the battery table.

NoteAlign HV battery onto center ski.

-

Inspect the top cover of the HV battery for the presence of NVH pads.

- If the HV battery does not have NVH pads, install the NVH pads. See NVH Pads - HV Battery (Install).NoteAdd correction code 16103101 to the Repair Order separately. The labor time to install the NVH pads is not included in this parent procedure.

- If the HV battery already has NVH pads, continue to the next step.

- If the HV battery does not have NVH pads, install the NVH pads. See NVH Pads - HV Battery (Install).

- Install the logic cap onto the new HV battery.

-

Install the powertrain supply hose to the upper clips on the RH side of the HV battery, fasten the clips (x5) and install a plug to the coolant hose.

-

Connect the RH outer coolant hose to the rear of the HV battery, and then fasten the clip.

NotePerform a push-pull test to verify that the hose is fully seated.NoteUse a shop towel to clean any residue coolant if necessary.

-

Install the powertrain return hose to the lower clips on the RH side of the HV battery, fasten the clips (x5) and install hose plugs.

-

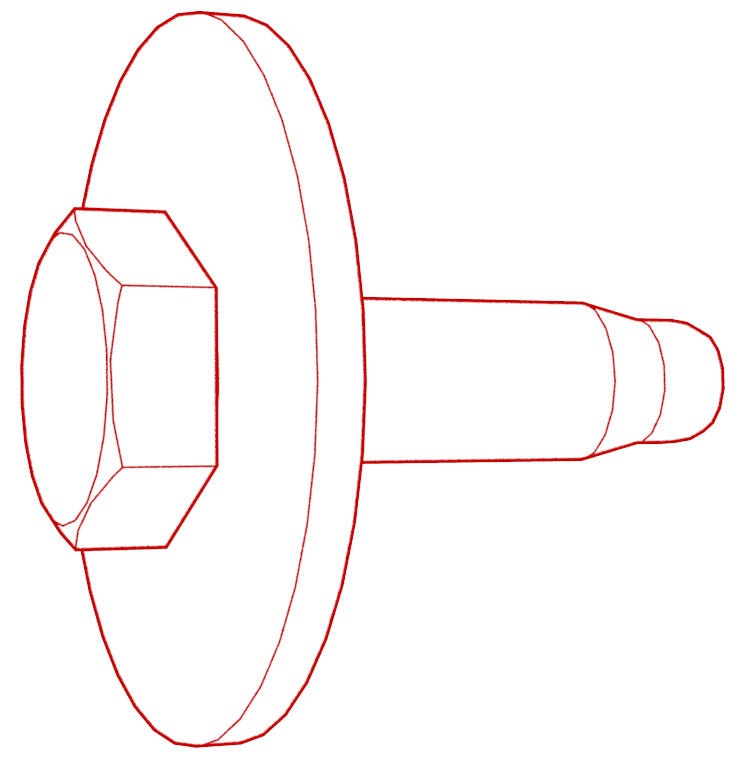

Verify if the new HV battery front

coolant passthrough fittings (x4) are male fittings or female fittings.

Figure 4. HV battery coolant passthrough fittings; Female -

Position the HV battery supply hose assembly onto the HV battery, connect the RH outer HV battery supply hose fitting to the RH front of the HV battery platter enclosure, and then fasten the clip.

NotePerform a push-pull test to verify that the hose is fully seated.NoteUse a shop towel to clean any residue coolant if necessary.

-

Connect the RH inner HV battery supply hose fitting to the RH front of the HV battery platter enclosure, and then fasten the clip.

-

Connect the LH outer coolant hose to the front of the HV battery, and then fast the clip.

NoteEnsure the locking clip is fully seated.NoteUse a shop towel to clean any residue coolant if necessary.

-

Connect the LH inner HV battery supply hose to the front of the HV battery platter enclosure, and then fasten the clip.

NoteEnsure the locking clip is fully seated.NoteUse a shop towel to clean any residue coolant if necessary.

-

Install and hand-tighten the adjustable elements (x4) on the ancillary bay cover counter-clockwise so that they are fully engaged.

CAUTIONHand-tighten only.

- Install a new HV battery cover gasket. See Seal - Perimeter - HV Battery (Remove and Replace).

-

Clean the busbar HV connector contact

surface of residual Penetrox.

NoteAllow one minute of drying time after removing Penetrox.

-

Clean the HV connector contact surface

of residual Penetrox.

NoteAllow one minute of drying time after removing Penetrox.

-

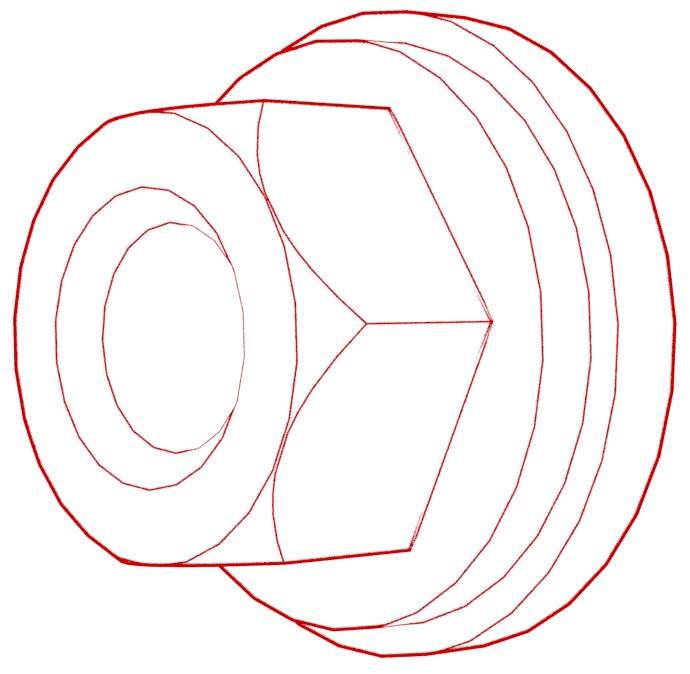

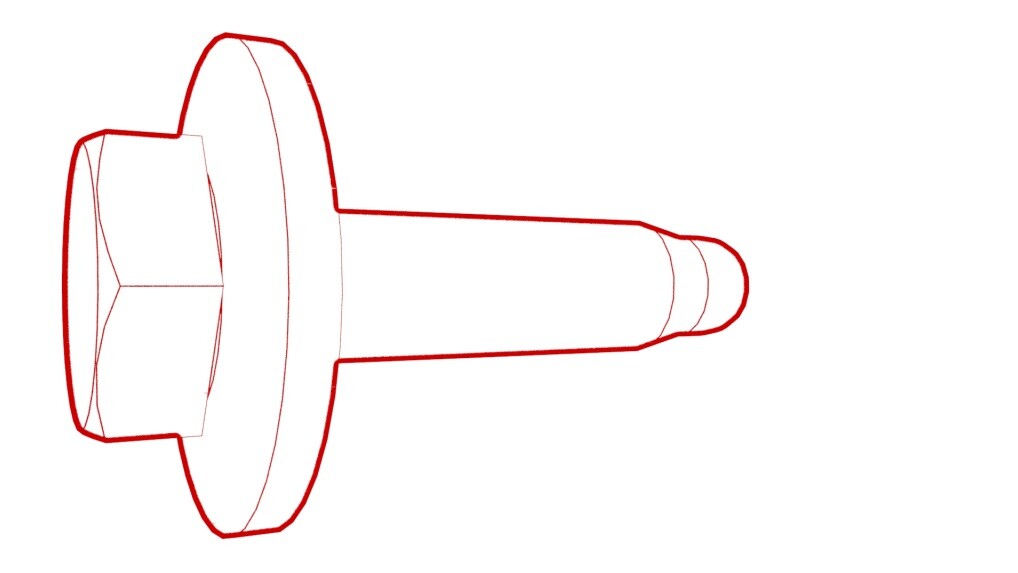

Install the HV battery alignment rods; 2 at the front of the vehicle and 2 at the HV battery near the ancillary bay.

Figure 5. RH front alignment rod shown; LH similar Figure 6. Rear alignment rods - With an assistant, position the HV battery underneath the vehicle.

-

Lower the vehicle to the HV battery, and with an assistant, align the holes with the alignment rods.

NoteDo not fully lower the vehicle onto the HV battery. The battery will still need to slightly move to install the bolts in the following steps.CAUTIONMake sure that the coolant hoses and HV harnesses are not caught on the alignment rods or sandwiched between the HV battery and the vehicle.

-

Install and hand-tighten the smaller bolts that would attach the LH and RH shear plates to the body.

NoteDo not install the shear plates at this time.

Figure 7. LH shown, RH similar -

Install and hand-tighten the LH and RH bolts (x16) that attach the HV battery to the body.

NoteInstall the washers to the locations recorded earlier during removal.

- Remove HV battery front alignment rods.

-

Install and hand-tighten the bolts (x8) that attach the HV battery LH and RH support brackets to the vehicle.

-

Install and hand-tighten the bolts (x4) that attach the center portion of the HV battery through the HV battery center rail ski cover.

- Open the LH rear door

- Remove the HV battery alignment rod from the LH rear inner bolt location.

-

Install and hand-tighten the LH rear inner HV battery bolts.

-

Lift the carpet flap, and then install and hand-tighten the LH middle inner HV battery bolt.

- Close the LH rear door.

- Open the LH front door.

-

Install and hand-tighten both LH front inner HV battery bolts.

- Repeat step 26 through step 32 step for the RH side of the vehicle.

- Fully lower the vehicle onto the HV battery.

-

Torque the LH and RH bolts (x16) that attach the HV battery to the vehicle.

35 Nm (25.8 lbs-ft)TIpUse of the following tool(s) is recommended:

35 Nm (25.8 lbs-ft)TIpUse of the following tool(s) is recommended:- 13 mm socket

- 3 in extension

-

Torque the bolts (x8) that attach the HV battery LH and RH support brackets to the vehicle.

110 Nm (81.1 lbs-ft)TIpUse of the following tool(s) is recommended:

110 Nm (81.1 lbs-ft)TIpUse of the following tool(s) is recommended:- 16 mm socket

- 3 in extension

-

Torque the bolts (x4) that attach the center portion of the HV battery through the center ski cover.

35 Nm (25.8 lbs-ft)TIpUse of the following tool(s) is recommended:

35 Nm (25.8 lbs-ft)TIpUse of the following tool(s) is recommended:- External Torx Plus EP14

- With an assistant, raise the vehicle, and then remove the battery table from underneath the vehicle.

- Set the vehicle to a comfortable working height, and then lower the vehicle into locks.

- Position the support stand to support the front portion of the rear subframe.

-

Remove the smaller bolts (x2) and the larger bolt that are used to attach the LH shear plate to the vehicle.

Figure 8. LH shown, RH similar -

Install the LH shear plate, and then install and hand-tighten the larger bolt that attaches the shear plate to the vehicle.

-

Install and hand-tighten the smaller bolts (x2) that attach the shear plate to the HV battery.

Figure 9. LH shown, RH similar -

Torque the large bolt that attaches the LH shear plate to the body.

130 Nm (95.9 lbs-ft)TIpUse of the following tool(s) is recommended:

130 Nm (95.9 lbs-ft)TIpUse of the following tool(s) is recommended:- 21 mm socket

- 6 in extension

-

Torque the small bolts that attach the LH shear plate to the body.

35 Nm (25.8 lbs-ft)NoteSome vehicles are equipped with self-tapping bolts from the factory. If the vehicle is equipped with a bolt with a hexagonal indentation on the bolt head (1637725-00-A), the torque value is 64 Nm.TIpUse of the following tool(s) is recommended:

35 Nm (25.8 lbs-ft)NoteSome vehicles are equipped with self-tapping bolts from the factory. If the vehicle is equipped with a bolt with a hexagonal indentation on the bolt head (1637725-00-A), the torque value is 64 Nm.TIpUse of the following tool(s) is recommended:- 13 mm socket

- 3 in extension

- Repeat step 41 through step 45 for the RH shear plate.

- Remove the support stand from underneath the rear subframe

-

Fasten the fir tree clips that attach the coolant hoses to the LH and RH shear plates.

Figure 10. LH shown, RH similar -

Fully raise the handle on the HV battery rear drive unit connector of the rear drive unit to HV battery harness.

-

Install the HV connector special tool onto the HV battery rear drive unit connector.

-

Use both hands to firmly connect the HV battery rear drive unit connector of the rear drive unit to HV battery harness to the HV battery header.

CAUTIONMake sure that the connector fits the header squarely and tightly, and that both retention pins enter the handle.

- Remove the HV connector special tool from the HV battery rear drive unit connector.

-

While pressing the HV battery rear drive unit connector onto the HV battery header, fully lower the handle.

CAUTIONMake sure that the handle does not bind as it is lowered.

-

Slide the release to lock the HV battery rear drive unit connector handle in the secured position.

-

Verify that the HV battery rear drive unit connector is fully seated, and compare both sides of the connector that it is properly secured in place.

NoteAn improperly seated connector might lead to connector damage and rear drive unit problems later on.

-

Install the nut that attaches the rear drive unit HV electrical harness bracket to the HV battery.

10 Nm (7.4 lbs-ft)TIpUse of the following tool(s) is recommended:

10 Nm (7.4 lbs-ft)TIpUse of the following tool(s) is recommended:- 10 mm socket

- 4 in extension

- Position the coolant drain beneath the RH rear of the HV battery.

-

Remove the hose plugs, and then connect coolant outlet hose to rear power train return hose.

CAUTIONPerform a push-pull test to verify that the hose is fully seated.

- Position the coolant drain underneath the LH rear of the HV battery.

-

Remove the hose plugs, and then connect rear drive unit inverter inlet hose to the rear of HV battery.

CAUTIONPerform a push-pull test to verify that the hose is fully seated.

- Remove the coolant drain from underneath the vehicle.

- Install the rear HV battery skid plate, but only hand-tighten the fasteners. See Skid Plate - HV Battery - Rear (Remove and Replace).

-

Torque the fasteners that attach the rear skid plate to the vehicle. See Skid Plate - HV Battery - Rear (Remove and Replace).

NoteSome vehicles are equipped with self-tapping bolts from the factory. If the vehicle is equipped with a bolt with a hexagonal indentation on the bolt head (1637725-00-A), the torque value is 64 Nm.

- Install the mid aero shield panel. See Panel - Aero Shield - Rear (Remove and Replace).

- Position the coolant drain under the front LH side of the HV battery.

-

Fasten the clips that attach the HV battery front manifold hose to the body.

-

Remove the plugs from the chiller to HV battery hose and the manifold at the LH side of the vehicle, immediately connect the male and female fittings, and then fasten the clip.

NotePerform a push-pull-push test on the fittings to make sure that they are secure.

-

Remove the plugs from the HV battery return hose at the LH side of the vehicle, immediately connect the male and female fittings, and then fasten the clip.

NotePerform a push-pull-push test on the fittings to make sure that they are secure.

- Position the coolant drain under the front RH side of the HV battery.

-

Remove the plugs from the rear powertrain supply hose at the RH side of the vehicle, immediately connect the male and female fittings, and then fasten the clip.

NotePerform a push-pull-push test on the fittings to make sure that they are secure.

-

Remove the plugs from the powertrain return hose at the RH side of the vehicle, immediately connect the male and female fittings, and then fasten the clip.

NotePerform a push-pull-push test on the fittings to make sure that they are secure.

- Remove the coolant drain from underneath the vehicle.

- Remove the plastic bracket that attaches the HV connectors to the HV battery.

-

If not present, apply abrasion tape to the A/C compressor HV connector harness.

-

Connect the A/C compressor HV connector, and then engage the connector lock.

-

Install the A/C compressor electrical harness bracket to the front of the HV battery, and then fasten the clips that attach the bracket to the HV battery.

-

Install the bolt that attaches the ground strap to the HV battery

10 Nm (7.4 lbs-ft)TIpUse of the following tool(s) is recommended:

10 Nm (7.4 lbs-ft)TIpUse of the following tool(s) is recommended:- 10mm ratcheting combination flex head wrench

-

Fully raise the handle on the front drive unit HV connector of the front drive unit to HV battery harness.

-

Install the HV connector special tool onto the front drive unit HV connector.

-

Use both hands to firmly connect the front drive unit HV connector of the front drive unit to HV battery harness to the front drive unit HV header.

CAUTIONMake sure that the connector fits the header squarely and tightly, and that both retention pins enter the handle.

- Remove the HV connector special tool from the front drive unit HV connector.

-

While pressing the front drive unit HV connector onto the front drive unit HV header, fully lower the handle.

CAUTIONMake sure that the handle does not bind as it is lowered.

-

Slide the release to lock the front drive unit HV connector handle in the secured position.

-

Verify that the front drive unit HV connector is fully seated, and compare both sides of the connector that it is properly secured in place.

NoteAn improperly seated connector might lead to connector damage and front drive unit problems later on.

-

Install the bolt that attaches the front drive unit HV harness to the front drive unit.

10 Nm (7.4 lbs-ft)TIp

10 Nm (7.4 lbs-ft)TIp- External Torx Plus EP10

- Install the front HV battery skid plate. See Skid Plate - HV Battery - Front (Remove and Replace).

- Remove the bungee straps from the LH and RH wheel arch liners.

-

Install the bolt and clips that attach the LH front wheel liner to the HV battery and lower wheel well area. Repeat this step for the RH side of the vehicle.

5 Nm (3.7 lbs-ft)TIpUse of the following tool(s) is recommended:

5 Nm (3.7 lbs-ft)TIpUse of the following tool(s) is recommended:- 10 mm socket

- 4 in extension

- Install the front aero shield panel. See Panel - Aero Shield - Front (Non-Structural Pack) (Remove and Replace).

- Lower the vehicle fully, and chock a wheel.

-

Remove the chock, and with an assistant, push the vehicle away from the lift to a stall, and then re-chock the wheel.

CAUTIONPush the vehicle for a very short distance and at less than 1 MPH.

-

Install the nut that attaches the positive 12V output to the PCS cable, and then close the cover.

15 Nm (11.1 lbs-ft)CAUTIONEnsure the rubber boot is not pinched between the cable terminal and passthrough.CAUTIONMake sure the positive output cable is positioned properly and in the right direction against the plastic anti-rotation edge on the DCDC passthrough.TIpUse of the following tool(s) is recommended:

15 Nm (11.1 lbs-ft)CAUTIONEnsure the rubber boot is not pinched between the cable terminal and passthrough.CAUTIONMake sure the positive output cable is positioned properly and in the right direction against the plastic anti-rotation edge on the DCDC passthrough.TIpUse of the following tool(s) is recommended:- 13 mm socket

- 3 in extension

-

Install a new nut that attaches the DCDC ground strap to the HV battery.

15 Nm (11.1 lbs-ft)TIpUse of the following tool(s) is recommended:

15 Nm (11.1 lbs-ft)TIpUse of the following tool(s) is recommended:- 13 mm 12-point deep socket

- 4 in extension

-

Remove the logic cap, and then connect the HVC logic connector.

- Apply a small amount of Penetrox onto the HV connector joints.

- Position the busbar kit connector and lower onto the HV header.

-

Install the bolts that attach the charge port busbar kit to the HV header.

9 Nm (6.6 lbs-ft)TIpUse of the following tool(s) is recommended:

9 Nm (6.6 lbs-ft)TIpUse of the following tool(s) is recommended:- 10 mm deep socket

- Perform a zero adjust of the Hioki resistance meter in preparation to measure resistances. See Resistance Meter (Zero Adjust).

- Put on the HV insulating gloves and leather over gloves.

-

Use the Hioki resistance meter to measure the resistance between the charge port busbar connector lead and the DC input HV header bolt head.

NoteThe acceptable resistance is between 0.050 mΩ (50 μΩ) and 0.195 mΩ (195 μΩ). If the measured resistance is above 0.195 mΩ (195 μΩ), there is too much resistance in the High Voltage joint. Remove the fastener, clean areas with isopropyl alcohol, install fastener back and test again.NoteIf the resistance is lower than 0.050 mΩ (50 μΩ), reposition the probes and measure again. If after 4 attempts the resistance is consistently lower than 0.050 mΩ (50 μΩ), the test has passed; continue to the next step.

- Repeat step the previous step for the other charge port busbar connector lead and DC input HV header bolt head.

- Remove the HV insulating gloves and leather over gloves.

-

Install the bolt that secures the busbar cover access door.

9 Nm (6.6 lbs-ft)TIpUse of the following tool(s) is recommended:

9 Nm (6.6 lbs-ft)TIpUse of the following tool(s) is recommended:- 10 mm deep socket

-

If there is a 3-phase (AC) connection

between the charge port and HV battery, connect it:

-

Install the clip that attaches the logic electrical harness to the LH seat frame.

-

Connect the logic connector at the LH seat frame.

-

Torque the LH and RH rear inner HV battery bolts.

66 Nm (48.7 lbs-ft)TIpUse of the following tool(s) is recommended:

66 Nm (48.7 lbs-ft)TIpUse of the following tool(s) is recommended:- 16 mm socket

- 6 in extension

- Remove the folded shop towel from underneath the rear cabin carpet.

-

Install the clips (x3) that attach the rear carpet to the vehicle.

-

Install the clip securing the LH lower B-pillar to body.

- Install the LH lower C-pillar trim. See Trim - C-Pillar - Lower - LH (Remove and Replace).

- Repeat steps 110 and 111 for the RH side of the vehicle.

- Install the 2nd row seat assembly.

-

Torque the LH middle inner HV battery bolt, and then fold the carpet to its original position. Repeat this step on the RH side of the vehicle.

66 Nm (48.7 lbs-ft)TIpUse of the following tool(s) is recommended:

66 Nm (48.7 lbs-ft)TIpUse of the following tool(s) is recommended:- 16 mm socket

- Install the 2nd row floor mat into the vehicle.

-

Torque both RH front inner HV battery bolts, and then install the foam plugs.

136 Nm (100.3 lbs-ft)TIpUse of the following tool(s) is recommended:

136 Nm (100.3 lbs-ft)TIpUse of the following tool(s) is recommended:- Torx Plus EP20 socket

- 6 in extension

-

Fold the RH front main cabin carpet forward to its original position, and then install the clip that attaches the LH carpet to the vehicle.

- Install the RH lower A-pillar trim. See Trim - A-Pillar - Lower - LH (Remove and Replace).

- Install the RH middle A-pillar trim. See Trim - A-Pillar - Middle - LH (Remove and Replace).

- Install the RH instrument panel end cap. See End Cap - Instrument Panel - LH (Remove and Replace).

- Install the RH center console side panel carpet. See Side Panel - Center Console - LH (Remove and Replace).

- Install the RH front floor mat.

- Install the front passenger footwell cover. See Cover - Footwell - Driver (Remove and Replace).

- Repeat step 116 through step 123 for the LH side of the vehicle.

- Connect 12V power. See 12V/LV Power (Disconnect and Connect).

-

Connect an LV maintainer to the vehicle, but do not disconnect the LV battery. See LV Maintainer (Connect and Disconnect).

NoteOn 12V lead acid batteries, connect the 12V maintainer to the lead acid battery terminals.

- Shift into Park to release the Electronic Parking Brake service mode, and then remove the wheel chock.

- Connect a laptop with Toolbox 3 to the vehicle. See Toolbox (Connect and Disconnect).

- Enable Service Mode Plus. See Service Mode Plus.

- Perform a cooling system vacuum refill. See Cooling System (Vacuum Refill).

-

On the vehicle touchscreen, touch .

-

Under High-Voltage-Battery, touch High Voltage Battery Replacement.

-

Under After High Voltage Battery Replacement, touch CAN ECU Redeploy, and then in the window that opens, touch Run.

-

Under After High Voltage Battery Replacement, touch High Voltage Battery Replacement Routine, and then in the window that opens, touch Run.

- Disable Service Mode Plus. See Service Mode Plus.

- Disconnect the laptop with Toolbox 3 from the vehicle. See Toolbox (Connect and Disconnect).

- Disconnect the 12V/LV battery maintainer.

- Install the rear underhood apron. See Underhood Apron - Rear (Remove and Replace).

- Raise all windows and close all doors.

-

Remove lift pads from the LH rocker.

-

Install the butyl patch that covers the LH rocker access holes.

- Install the LH rocker panel carrier. See Carrier - Rocker Panel - LH (Remove and Replace).

- Install the LH lower rocker panel cover. See Cover - Rocker Panel - Lower - LH (Remove and Replace).

- Repeat step 140 though step 143 for the RH side of the vehicle.