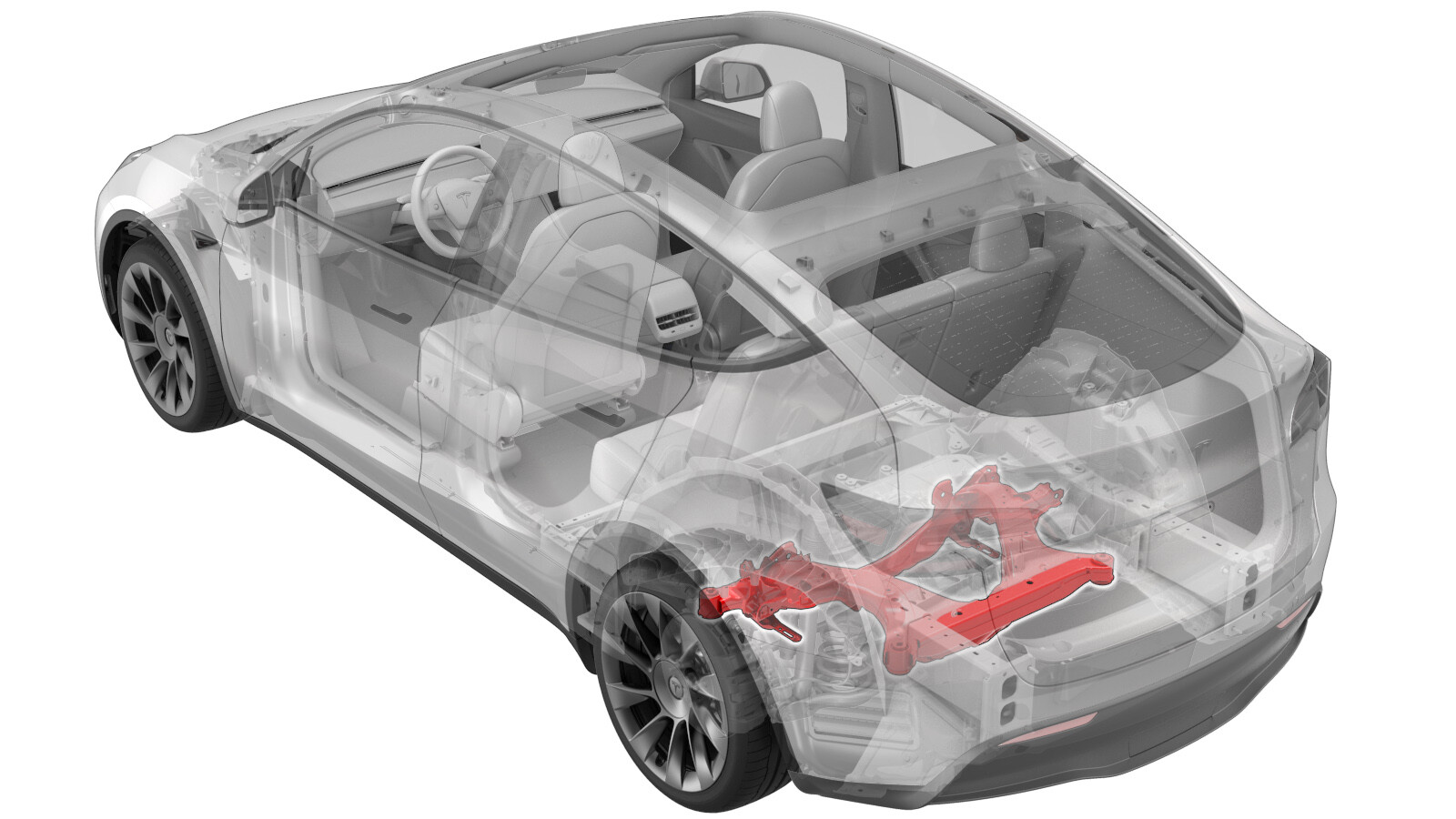

Subframe Assembly - Rear (Remove and Replace)

Correction code

30010202

4.08

NOTE: Unless otherwise explicitly

stated in the procedure, the above correction code and FRT reflect all of the work

required to perform this procedure, including the linked procedures. Do not stack correction codes unless

explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how they are created. To provide feedback on

FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when

performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

Correction code

30010202

4.08

NOTE: Unless otherwise explicitly

stated in the procedure, the above correction code and FRT reflect all of the work

required to perform this procedure, including the linked procedures. Do not stack correction codes unless

explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how they are created. To provide feedback on

FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when

performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

- 2026-02-13: Switched sequence of EPB Service Mode and Thermal Fill/Drain routines.

- 2023-10-25: Updated torque figure for rear upper fore link to knuckle and subframe from 76 Nm to 84 Nm.

- 2023-08-25: Updated EPB Service Mode reference.

- 2023-06-15: Added shear plate small bolts torque figure for Structural Pack vehicles.

Equipment:

- 1099645-00-B Fixture, Subframe, Model 3

- 1130279-00-A Lifting Sling, Drive Unit, Model 3 (NA, APAC)

- 1130481-00-A Adapter, Subframe, Body Shop, Model 3

- 1096075-00-A Tool, Hub Puller, Hydraulic

- 1498673-00-A KIT, CABLE AXLE REMOVER, MS/MX/M3

- 1140311-00-A Lever Lock, HV Connector, Model 3

Torque Specifications

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Rear halfshaft nuts |

245 Nm (180.7 lbs-ft) |

|

Replace | 1115558-00-A |

| Bolts (x4) that attach the LH/RH rear brake caliper brackets to the knuckles |

83 Nm (61.2 lbs-ft) |

|

Replace | 1088969-00-B |

| Bolt that attaches the rear LH/RH ABS wheel speed sensor to the knuckle |

5 Nm (3.7 lbs-ft) |

|

Reuse | |

| Bolts that attach the LH/RH rear damper at the top mount |

41 Nm (30.2 lbs-ft) |

|

Reuse | |

|

Bolt and nut that attach the LH rear damper assembly to the LH rear lower aft link Bolt and nut that attaches the LH rear lower aft link to the knuckle Bolt and nut that attach the LH rear lower aft link to the subframe |

115 Nm (84.8 lbs-ft) |

|

Reuse | |

| Bolts that attach the LH/RH rear rotor to the LH/RH rear hub |

5 Nm (3.7 lbs-ft) |

|

Reuse | |

| Nut that attaches the end link to the stabilizer bar |

55 Nm (40.6 lbs-ft) |

|

Replace | 1111542-00-A |

|

Bolt and nut that attach the LH rear lower fore link to the knuckle Bolt and nut that attach the LH/RH rear lower fore link to the subframe |

76 Nm (56.0 lbs-ft) |

|

Reuse | |

|

Bolt and nut that attach the LH rear upper aft link to the knuckle Bolt and nut that attaches the LH/RH rear upper aft link to the subframe |

134 Nm (98.8 lbs-ft) |

|

Reuse |

Note The bolt and nut

will be tightened to specification during the Four Wheel Alignment

(Check and Adjust) at the end of the Front Subframe Assembly (Remove

and Install) procedure. |

|

Bolt and nut that attach the LH rear upper fore link to the knuckle Bolt and nut that attaches the LH rear upper fore link to the subframe |

84 Nm (61.9 lbs-ft) |

|

Reuse | |

| Bolt and nut that attach the LH rear toe link to the knuckle |

76 Nm (56.0 lbs-ft) |

|

Reuse |

Note The bolt and nut

will be tightened to specification during the Four Wheel Alignment

(Check and Adjust) at the end of the Front Subframe Assembly (Remove

and Install) procedure. |

| Nut that attaches the rear drive unit ground strap to the body |

10 Nm (7.4 lbs-ft) |

|

Reuse | |

| Nut that attaches the HV battery to rear drive unit harness bracket to the HV battery |

10 Nm (7.4 lbs-ft) |

|

Reuse | |

| Smaller bolts that attach the LH and RH shear plates to the vehicle (non-Structural Pack vehicles) |

35 Nm (25.8 lbs-ft) |

|

Reuse | |

| Smaller bolts that attach the LH shear plate to the HV battery (Structural Pack vehicles) |

62 Nm (45.7 lbs-ft) |

|

Reuse | |

| Larger bolts that attach the LH and RH shear plates to the vehicle |

130 Nm (95.9 lbs-ft) |

|

Replace | 1461657-00-A |

| Bolts that attach the LH and RH of the rear subframe to the body |

165 Nm (121.7 lbs-ft) |

|

Replace | 1461657-00-A |

| Bolt that attaches the rear drive unit HV harness bracket to the rear drive unit |

6 Nm (4.4 lbs-ft) |

|

Reuse | |

|

Bolt that attaches the LH/RH mount of the rear drive unit to the rear subframe Bolt that attaches the rear of the rear drive unit to the rear subframe |

80 Nm (59.0 lbs-ft) |

|

Reuse | |

| Bolt and nut that attaches the LH/RH rear toe link to the subframe |

85 Nm (62.7 lbs-ft) |

|

Reuse |

Remove

- Raise and support the vehicle. See Raise Vehicle - 2 Post Lift.

- Open all doors and fully lower all windows.

- Perform the following routine using Service Mode or Toolbox (see 0005 - Service Modes): PROC_VCFRONT_X_START-THERMAL-FILL-DRAIN-COOLANTvia Toolbox: (link)

- Enable EPB Service Mode. See Parking Brake - Caliper - Rear - LH (Release)

- Perform the vehicle electrical isolation procedure. See Vehicle HV Disablement Procedure.

- If equipped, remove the LH and RH rear wheel center caps. See Cap - Wheel (Remove and Replace).

-

Loosen the LH and RH rear

drive unit halfshaft nut.

TIpUse of the following tool(s) is recommended:

- 32 mm deep impact socket

-

Loosen the LH and RH rear

wheel lug nuts.

CAUTIONUse only hand tools to remove or install the fasteners. Do not use impact or power tools.CAUTIONUse a 6 point socket. Do not use a 12 point socket or a specialty socket.

- Close all doors.

- Remove the rear fascia diffuser. See Diffuser - Rear Fascia (Remove and Replace).

- Remove the LH and RH rear suspension covers. See Cover - Rear Suspension - LH (Remove and Replace).

- Lower and lock the vehicle at a comfortable working height.

- Remove the LH and RH rear wheels. See Wheel Assembly (Remove and Install).

-

Remove and discard the bolts (x2) that

attach the LH rear brake caliper bracket to the knuckle, and then hang the caliper

bracket on the body with an S-hook. Repeat this step on the RH rear brake caliper.

TIpUse of the following tool(s) is recommended:

- External Torx E18

-

Remove the bolt that attaches the rear

LH ABS wheel speed sensor to the knuckle.

TIpUse of the following tool(s) is recommended:

- 10 mm socket

-

Release the clip and remove

the grommet that attach the rear LH ABS wheel speed sensor cable to the rear

knuckle and bracket.

-

Install a spring compressor

onto the LH rear coil spring.

TIpUse of the following tool(s) is recommended:

- Gedore Spring Compressor

-

Remove the bolts that attach

the LH rear damper at the top mount.

TIpUse of the following tool(s) is recommended:

- 15 mm socket

- Position a 3/4 ton support stand underneath the LH rear lower aft link and knuckle.

-

Loosen the bolt and nut that

attach the LH rear damper to the LH lower aft link.

TIpUse of the following tool(s) is recommended:

- 21 mm socket

- 21 mm combination wrench

- Flex head ratchet/flex head torque wrench

-

Remove the bolt and nut that attach

the LH rear lower aft link to the LH rear suspension knuckle.

TIpUse of the following tool(s) is recommended:

- 21 mm socket

-

Remove the bolt and nut that attach

the LH rear lower aft link to the subframe, and then with assistance, remove the lower

aft link assembly.

TIpUse of the following tool(s) is recommended:

- 21 mm socket

-

Remove and discard the LH

rear halfshaft nut and washer.

TIpUse of the following tool(s) is recommended:

- 32 mm deep impact socket

-

Remove the bolt that attach

the LH rear brake rotor to the hub, but do not remove the rotor from the

assembly.

TIpUse of the following tool(s) is recommended:

- 10 mm socket

-

Position the hub puller onto

the LH rear hub assembly, and then secure the puller with the wheel lug nuts

(x2) and hub puller washers (x2).

TIpUse of the following tool(s) is recommended:

- 21 mm socket

- Flex head ratchet/flex head torque wrench

- 6 in extension

-

Rotate the hub puller

counterclockwise to free the LH rear halfshaft from the LH rear hub

splines.

TIpUse of the following tool(s) is recommended:

- 17 mm deep socket

- Remove the hub puller tool from the LH rear hub assembly.

-

Install the bolt that attaches the LH

rear brake rotor to the hub.

5 Nm (3.7 lbs-ft)TIpUse of the following tool(s) is recommended:

5 Nm (3.7 lbs-ft)TIpUse of the following tool(s) is recommended:- 10 mm socket

- Position a 3/4 ton support stand underneath the LH rear knuckle.

-

Remove and discard the nut that

attaches the LH rear stabilizer bar end link to the stabilizer bar, and then remove the

bar from the end link.

TIpUse of the following tool(s) is recommended:

- 15 mm socket

- 5 mm hex socket

- 15 mm flex head combination ratcheting wrench

NoteMove the stabilizer up and down as needed to achieve the correct angle for removal. If necessary, use a pry bar for assistance. -

Remove the bolt and nut that attach

the LH rear lower fore link to the knuckle.

TIpUse of the following tool(s) is recommended:

- 18 mm socket

-

Remove the bolt and nut that

attach the LH rear upper aft link to the LH rear suspension knuckle.

TIpUse of the following tool(s) is recommended:

- 21 mm socket

-

Remove the bolt and nut that

attach the LH rear upper fore link to the LH rear suspension knuckle.

TIpUse of the following tool(s) is recommended:

- 18 mm socket

-

Remove the bolt and nut that

attach the LH rear toe link to the LH rear suspension knuckle.

TIpUse of the following tool(s) is recommended:

- 18 mm socket

-

With assistance, remove the

LH rear knuckle, hub and rotor assembly from the vehicle.

-

Position the axle remover

cable around the inner joint of the LH rear drive unit halfshaft, and then

use a cable tie to hold the axle remover cable in position.

Figure 1. Axle removed from drive unit for demonstration purposes - Hook the axle remover slide hammer on the 2 axle remover cable loops, and then use the slide hammer to release the halfshaft from the drive unit.

- With assistance, remove the LH rear drive unit halfshaft from the rear drive unit, and then install a halfshaft plug into the opening of the gearbox.

- Repeat step 14 through step 38 for the RH side of the vehicle.

- Fully raise and lock the vehicle.

- Remove the LH and RH rear wheel arch liners. See Wheel Arch Liner - Rear - LH (Non-Structural Pack) (Remove and Replace).

-

Release the connector lock,

and then disconnect the RH 12V subframe harness connector.

-

Release the clip that

attaches the subframe electrical harness to the body.

-

Release the connector lock,

and then disconnect the LH 12V subframe harness connectors.

-

Release the clip that

attaches the LH subframe electrical harness to the body.

-

Remove the nut that attaches

the rear drive unit ground strap to the body.

TIpUse of the following tool(s) is recommended:

- 10 mm 12-point deep socket

- Remove the rear stabilizer bar. See Stabilizer Bar - Rear (Remove and Replace).

- Remove the rear HV battery skid plate. See Skid Plate - HV Battery - Rear (Remove and Replace).

- Position the coolant drain beneath the LH rear of the HV battery.

-

Disconnect the rear drive

unit inverter inlet hose from the rear of the HV battery, and then plug the

male and female fittings.

- Position the coolant drain container beneath the LH rear drive unit area.

-

Disconnect the coolant inlet

hose from the rear drive unit, and then plug the hose.

- Position the coolant drain container beneath the RH rear of the HV battery.

-

Release the clip and

disconnect the coolant outlet hose to rear powertrain return coupling, and

immediately plug the male and female fittings.

- Remove the coolant drain container from underneath the vehicle.

-

Remove the nut that attaches the HV

battery to rear drive unit harness bracket to the HV battery.

TIpUse of the following tool(s) is recommended:

- 10 mm socket

-

Slide the release to unlock

the HV battery rear drive unit connector handle of the rear drive unit to HV

battery harness from the secured position.

-

Fully raise the handle on

the HV battery rear drive unit connector.

- Remove the HV battery rear drive unit connector from the HV battery header.

- Position the rear subframe lifting tool beneath the rear subframe.

- Attach an air hose to the rear subframe lifting tool.

- With an assistant, raise the rear subframe lifting tool to support the rear subframe.

-

Loop the straps over the

rear subframe, hook the ends of the straps to the metal rings, and then pull

the straps tight to restrain the subframe to the rear subframe lifting

tool.

NoteLower the vehicle to give more slack to connect the straps to the rings, if necessary.

-

Release the fir tree clips

that attach the coolant hoses to the LH shear plate.

-

Remove the smaller bolts

that attach the LH shear plate to the HV battery.

TIpUse of the following tool(s) is recommended:

- 13 mm socket

- 3 in extension

-

Remove and discard the

larger bolt that attaches the LH shear plate and rear subframe to the body,

and then remove the LH shear plate.

TIpUse of the following tool(s) is recommended:

- 21 mm socket

-

Hand-tighten the smaller

bolts that attach the LH shear plate to the body.

NoteDo not install the shear plate at this time.

- Repeat step 64 through step 67 for the RH shear plate.

-

Remove and discard the bolts

(x2) that attach the rear subframe to the body.

TIpUse of the following tool(s) is recommended:

- 21 mm socket

-

With an assistant, slowly

lower the rear subframe lifting tool to remove the rear subframe from the

vehicle.

CAUTIONAssist with the routing of HV harnesses and coolant hoses through components so that they do not "catch".

- Disconnect the air supply from the rear subframe lifting tool.

- Move the rear subframe and rear subframe lifting tool away from the vehicle.

-

Release the clip that

attaches the rear drive unit inlet hose to the HV harness bracket, and then

remove the hose from the rear subframe assembly.

-

Remove the bolt that attaches the rear

drive unit HV harness bracket to the rear drive unit.

TIpUse of the following tool(s) is recommended:

- 10 mm socket

-

Slide the release to unlock

the rear drive unit HV connector handle of the rear drive unit to HV battery

harness from the secured position.

-

Fully raise the handle on

the rear drive unit HV connector.

- Remove the rear drive unit HV cable from the subframe assembly.

-

Disconnect the electrical

harness from the inverter low voltage connector.

-

Release the clip that

attaches the low voltage electrical harness to the inverter.

-

Release the clips that

attach the resolver electrical harness to the rear drive unit, and then

disconnect the electrical connector.

-

Disconnect the oil pump

connector from the rear drive unit assembly.

- Position the drive unit stand underneath the gantry.

- Attach the drive unit sling tool to the rear drive unit.

- Attach the drive unit sling tool to the gantry.

- Raise the sling tool so that there is a slight tension on the cables.

-

Remove the bolts (x2) that attach the

LH and RH mounts of the rear drive unit to the rear subframe.

TIpUse of the following tool(s) is recommended:

- 18 mm socket

-

Remove the bolt that

attaches rear of the rear drive unit to the rear subframe.

TIpUse of the following tool(s) is recommended:

- 18 mm socket

- With assistance, raise the drive unit sling tool to lift the rear drive unit out of the rear subframe.

- Move the subframe and lifting tool from underneath the drive unit.

-

Remove the bolt and nut that attach

the LH rear upper aft link to the subframe.

TIpUse of the following tool(s) is recommended:

- 21 mm socket

-

Remove the bolt and nut that attach

the LH rear upper fore link to the subframe.

TIpUse of the following tool(s) is recommended:

- 18 mm socket

-

Remove the bolt and nut that attach

the LH rear toe link to the subframe.

TIpUse of the following tool(s) is recommended:

- 18 mm 12-point deep socket

NoteRotate the eccentric bolt to find the correct position for removal. -

Remove the bolt and nut that attach

the LH rear lower fore link to the subframe.

TIpUse of the following tool(s) is recommended:

- 18 mm socket

- Repeat step 90 through step 93 for the RH side of the subframe assembly.

-

Release the clips that

attach the subframe harness to the bottom of the rear subframe.

-

Release the clips (x9) that

attach the subframe harness to the top of the rear subframe, and then remove

the harness from the subframe.

-

With assistance, release the

straps that secures the subframe to lifting tool, and then remove the

subframe from the lifting tool.

Install

- With assistance, install a new subframe into the lifting tool, and then secure the straps.

-

Install the clips (x9) that

attach the subframe harness to the top of the rear subframe.

-

Install the clips that

attach the subframe harness to the bottom of the rear subframe.

- Move the subframe and lifting tool beneath the drive unit.

- With assistance, lower the sling to install the rear drive unit into the subframe.

-

Install and hand-tighten the

bolt that attaches rear of the rear drive unit to the rear subframe.

TIpUse of the following tool(s) is recommended:

- 18 mm socket

-

Install and hand-tighten the bolts

(x2) that attach the LH and RH mounts of the rear drive unit to the rear subframe.

TIpUse of the following tool(s) is recommended:

- 18 mm socket

- Lower the drive unit sling to release tension in the cable.

- Remove the drive unit sling from the gantry.

- Remove the hooks (x3) that attaches the drive unit sling tool to the rear drive unit.

-

Torque the LH, RH and rear motor mount

bolts.

80 Nm (59.0 lbs-ft)TIpUse of the following tool(s) is recommended:

80 Nm (59.0 lbs-ft)TIpUse of the following tool(s) is recommended:- 18 mm socket

-

Install the clips that

attach the resolver electrical harness to the rear drive unit, and then

connect the electrical connector.

-

Connect the oil pump

connector from the rear drive unit assembly.

-

Install the clip that

attaches the low voltage electrical harness to the inverter.

-

Connect the electrical

harness from the inverter low voltage connector.

-

Install and hand-tighten the bolt and

nut that attach the RH rear upper aft link to the subframe.

TIpUse of the following tool(s) is recommended:

- 21 mm socket

-

Install and hand-tighten the bolt and

nut that attach the RH rear upper fore link to the subframe.

TIpUse of the following tool(s) is recommended:

- 18 mm socket

-

Install and hand-tighten the bolt and

nut that attach the RH rear toe link to the subframe.

TIpUse of the following tool(s) is recommended:

- 18 mm 12-point deep socket

NoteRotate the eccentric bolt to find the correct position for removal. -

Install and hand-tighten the bolt and

nut that attach the RH rear lower fore link to the subframe.

TIpUse of the following tool(s) is recommended:

- 18 mm socket

- Repeat step 16 through step 19 for the LH side of the subframe assembly.

- Position the rear drive unit HV cable on the rear subframe.

-

Fully raise the handle on

the rear drive unit HV connector.

-

Install the HV connector

special tool onto the rear drive unit HV connector.

-

Use both hands to firmly

connect the rear drive unit HV connector to the rear drive unit.

CAUTIONMake sure that the connector fits the header squarely and tightly, and that both retention pins enter the handle.

- Remove the HV connector special tool from the rear drive unit HV connector.

-

While pressing the rear

drive unit HV connector onto the rear drive unit HV header, fully lower the

handle.

CAUTIONMake sure that the handle does not bind as it is lowered.

-

Slide the release to lock

the rear drive unit HV connector handle in the secured position.

-

Verify that the rear drive

unit HV connector is fully seated, and compare both sides of the connector

that it is properly secured in place.

NoteAn improperly seated connector might lead to connector damage and rear drive unit problems later on.

-

Install the bolt that attaches the HV

harness bracket to the inverter.

6 Nm (4.4 lbs-ft)TIpUse of the following tool(s) is recommended:

6 Nm (4.4 lbs-ft)TIpUse of the following tool(s) is recommended:- 10 mm socket

-

Connect the rear drive unit

inlet hose to the inverter coolant coupling, and then fasten the spring

clip.

CAUTIONPerform a push-pull test to verify that the hose is fully seated.

-

Install the clip that

attaches the rear drive unit inlet hose to the HV harness bracket.

- Position the subframe lifting tool and rear subframe underneath the vehicle.

- Connect the air line to the subframe lifting tool.

-

With an assistant, slowly

raise the rear drive unit and subframe into position.

CAUTIONAssist with the routing of HV harnesses and coolant hoses through components so that they are not pinched or broken.

-

Hand-tighten the new bolts

(x2) that attach the rear subframe to the body.

NoteThe tightening of the bolts will be performed later in this procedure.

-

Install the LH and RH shear plates to

the rear subframe and HV battery, and then hand-tighten new larger bolts to attach the

shear plates to the subframe.

NoteThe tightening of the bolt will be performed later in this procedure.

-

Hand-tighten the smaller bolts that

attach the LH and RH shear plates to the HV battery.

NoteThe tightening of the bolts will be performed later in this procedure.

-

Torque the smaller bolts

that attach the LH and RH shear plates to the vehicle.

For non-Structural Pack vehicles:

35 Nm (25.8 lbs-ft)For Structural Pack vehicles:

35 Nm (25.8 lbs-ft)For Structural Pack vehicles: 62 Nm (45.7 lbs-ft)TIpUse of the following tool(s) is recommended:

62 Nm (45.7 lbs-ft)TIpUse of the following tool(s) is recommended:- 13 mm socket

- 3 in extension

-

Torque the large bolts that attach the

LH and RH shear plates to the vehicle, and then mark them with a paint pen after

torquing.

130 Nm (95.9 lbs-ft)TIpUse of the following tool(s) is recommended:

130 Nm (95.9 lbs-ft)TIpUse of the following tool(s) is recommended:- 21 mm socket

-

Torque the bolts that attach the LH

and RH rear subframe to the body, and then mark them with a paint pen after

torquing.

165 Nm (121.7 lbs-ft)TIpUse of the following tool(s) is recommended:

165 Nm (121.7 lbs-ft)TIpUse of the following tool(s) is recommended:- 21 mm socket

-

Fasten the fir tree clips

that attach the coolant hoses to the LH and RH shear plates.

Figure 2. LH shear plate shown, RH shear plate similar - Release the straps and lower the subframe lifting tool from the vehicle.

- Disconnect the air line from the subframe lifting tool, and then remove the tool from underneath the vehicle.

-

Fully raise the handle on

the HV battery rear drive unit harness connector.

-

Install the HV connector

special tool onto the HV battery rear drive unit connector.

-

Use both hands to firmly

connect the HV battery rear drive unit connector of the rear drive unit to

HV battery harness to the HV battery header.

CAUTIONMake sure that the connector fits the header squarely and tightly, and that both retention pins enter the handle.

- Remove the HV connector special tool from the HV battery rear drive unit connector.

-

While pressing the HV

battery rear drive unit connector onto the HV battery header, fully lower

the handle.

CAUTIONMake sure that the handle does not bind as it is lowered.

-

Slide the release to lock

the HV battery rear drive unit connector handle in the secured

position.

-

Verify that the HV battery

rear drive unit connector is fully seated, and compare both sides of the

connector that it is properly secured in place.

NoteAn improperly seated connector might lead to connector damage and rear drive unit problems later on.

-

Install the nut that attaches the rear

drive unit HV electrical harness bracket to the HV battery.

10 Nm (7.4 lbs-ft)TIpUse of the following tool(s) is recommended:

10 Nm (7.4 lbs-ft)TIpUse of the following tool(s) is recommended:- 10 mm socket

- Position the coolant drain beneath the RH rear of the HV battery.

-

Remove the hose plugs, and

then connect coolant outlet hose to rear power train return hose.

CAUTIONPerform a push-pull test to verify that the hose is fully seated.

- Position the coolant drain underneath the LH rear of the HV battery.

-

Remove the hose plugs, and

then connect rear drive unit inverter inlet hose to the rear of HV

battery.

CAUTIONPerform a push-pull test to verify that the hose is fully seated.

- Remove the coolant drain from underneath the vehicle.

- Install the rear HV battery skid plate. See Skid Plate - HV Battery - Rear (Remove and Replace).

- Install the rear stabilizer bar. See Stabilizer Bar - Rear (Remove and Replace).

-

Install the bolt that attaches the

rear drive unit ground strap to the body.

10 Nm (7.4 lbs-ft)NoteReinstall the washer if the vehicle had this washer during removal.TIpUse of the following tool(s) is recommended:

10 Nm (7.4 lbs-ft)NoteReinstall the washer if the vehicle had this washer during removal.TIpUse of the following tool(s) is recommended:- 10 mm 12-point deep socket

-

Fasten the LH subframe

electrical harness barrel clip to the body.

-

Connect the electrical

connector for the LH side 12V subframe harness.

Figure 3. LH side shown, RH similar - Repeat steps 60 and 61 for the RH side of the vehicle.

- Partially lower and lock the vehicle to a comfortable working height.

-

Remove the halfshaft plugs

from the gearbox, and then with assistance, install the LH and RH front

drive unit halfshafts into the front drive unit.

CAUTIONTake care not to damage or displace the oil seal.CAUTIONMake sure that the opening of the snap ring is facing towards the bottom of the drive unit.NoteMove the front knuckle assembly aside to provide enough clearance to safely install the front drive unit halfshaft.NoteNew front drive units come pre-filled with gearbox fluid. Clean up any leaks during installation and top off the gearbox fluid as necessary. For more information, search for 1446276-00-B in the Service Tooling Catalog.

-

Verify that the halfshafts

are fully seated:

- Carefully push the halfshaft into the drive unit until there is an audible "click" from the halfshaft stub contacting the pinion shaft.

- There will be a slight pulling sensation on the halfshaft as the halfshaft circlip locks into place.

- Pull on the inner halfshaft cup to confirm that the circlip is locked into place. If the halfshaft detaches from the drive unit then reinstall the halfshaft and then test that it is fully seated.

-

Apply approximately 1 gram

of Molykote M-77 Lubricant Paste only to the hub

mating face on the outboard side of the LH rear drive unit halfshaft.

CAUTIONDo not apply any lubricant to the halfshaft splines. If lubricant is mistakenly applied, wipe the splines clean with a shop towel.

Figure 4. Lubricate the area highlighted red - Position a support stand underneath the RH rear suspension.

-

With assistance, install the

RH rear halfshaft into the RH knuckle, hub and rotor assembly, and then

position the knuckle assembly onto the support stand.

-

Install and hand-tighten the

bolt and nut that attach the RH rear upper aft link to the RH rear

suspension knuckle.

Figure 5. LH side shown, RH similar -

Install and hand-tighten the bolt and nut that attach the RH rear upper fore link to

the RH rear suspension knuckle.

Figure 6. LH side shown, RH similar -

Install and hand-tighten the

bolt and nut that attach the RH toe link to the RH rear suspension

knuckle.

Figure 7. LH side shown, RH similar -

Install and hand-tighten the

bolt and nut that attach the RH rear lower fore link to the RH rear

suspension knuckle.

Figure 8. LH side shown, RH similar -

With assistance, position the RH rear

lower aft link assembly to the subframe, and then install and hand-tighten the bolt and

nut that attach the assembly to the subframe.

TIpUse of the following tool(s) is recommended:

- 21 mm socket

-

Install and hand-tighten the

bolt and nut that attach the RH rear aft lower link to the RH rear

suspension knuckle.

Figure 9. LH side shown, RH similar -

Install the bolts that attach the RH

rear damper at the top mount.

41 Nm (30.2 lbs-ft)TIpUse of the following tool(s) is recommended:

41 Nm (30.2 lbs-ft)TIpUse of the following tool(s) is recommended:- 15 mm socket

Figure 10. LH shown; RH similar -

Position the RH rear end link into the

stabilizer bar, and then install a new nut that attaches the end link to the stabilizer

bar.

55 Nm (40.6 lbs-ft)NoteMove the stabilizer up and down as needed to achieve the correct angle for installation.TIpUse of the following tool(s) is recommended:

55 Nm (40.6 lbs-ft)NoteMove the stabilizer up and down as needed to achieve the correct angle for installation.TIpUse of the following tool(s) is recommended:- 15 mm socket

-

Install a new nut and washer that

attach the RH rear halfshaft to the LH rear hub assembly.

NoteNut will be torqued at a later step.TIpUse of the following tool(s) is recommended:

- 32 mm deep impact socket

- Remove the support stand from beneath the RH rear suspension.

-

Position the RH rear brake caliper

onto the RH rear knuckle, and then install new bolts that attach the caliper to the

knuckle.

83 Nm (61.2 lbs-ft)TIpUse of the following tool(s) is recommended:

83 Nm (61.2 lbs-ft)TIpUse of the following tool(s) is recommended:- External Torx E18

-

Install the grommet that

attaches the rear RH ABS wheel speed sensor cable to the rear RH

knuckle.

CAUTIONPerform a push-pull check on the grommet to make sure it is securely fastened to the knuckle.

Figure 11. LH shown, RH similar -

Install the rear RH ABS wheel speed

sensor to the knuckle, and then install the bolt to attach the sensor to the

knuckle.

5 Nm (3.7 lbs-ft)TIpUse of the following tool(s) is recommended:

5 Nm (3.7 lbs-ft)TIpUse of the following tool(s) is recommended:- 10 mm socket

Figure 12. LH shown, RH similar - Repeat step 64 through step 81 for the LH side of the vehicle.

-

Remove the bolt that

attaches the RH rear brake rotor to the hub, but do not remove the rotor

from the assembly.

TIpUse of the following tool(s) is recommended:

- 10 mm socket

- Hand-tighten the nuts that attach the rear hub jack adapter to the LH rear hub.

-

Position a support stand

underneath the LH lower rear control arm, and then raise the support stand

to simulate vehicle at ride height.

-

Use the rear ride height

torque gauge to verify that the suspension is set within ride height

specification.

NoteMight need to adjust the support stand or spring compressor tool slightly.

-

Measure the distance between

the bottom of the quarter panel to the center of the rear axle to make sure

that the rear suspension is set to ride height: The distance should measure

427 mm.

-

Tighten the bolt and nut that attach

the RH rear upper aft link to the subframe.

134 Nm (98.8 lbs-ft)TIpUse of the following tool(s) is recommended:

134 Nm (98.8 lbs-ft)TIpUse of the following tool(s) is recommended:- 21 mm socket

Figure 13. LH shown, RH similar -

Torque the bolt and nut that attach

the RH rear upper fore link to the subframe.

84 Nm (61.9 lbs-ft)TIpUse of the following tool(s) is recommended:

84 Nm (61.9 lbs-ft)TIpUse of the following tool(s) is recommended:- 18 mm socket

Figure 14. LH shown, RH similar -

Torque the bolt and nut that attach

the RH rear toe link to the subframe.

85 Nm (62.7 lbs-ft)TIpUse of the following tool(s) is recommended:

85 Nm (62.7 lbs-ft)TIpUse of the following tool(s) is recommended:- 18 mm 12-point deep socket

Figure 15. LH shown, RH similar -

Tighten the bolt and nut that attach

the RH rear lower fore link to the subframe.

76 Nm (56.0 lbs-ft)TIpUse of the following tool(s) is recommended:

76 Nm (56.0 lbs-ft)TIpUse of the following tool(s) is recommended:- 18 mm socket

Figure 16. LH shown, RH similar -

Tighten the bolt and nut that attach

the RH rear lower aft link to the subframe.

115 Nm (84.8 lbs-ft)TIpUse of the following tool(s) is recommended:

115 Nm (84.8 lbs-ft)TIpUse of the following tool(s) is recommended:- 21 mm socket

Figure 17. LH shown, RH similar -

Tighten the bolt and nut that attach

the RH rear damper assembly to the RH rear lower aft link.

115 Nm (84.8 lbs-ft)TIpUse of the following tool(s) is recommended:

115 Nm (84.8 lbs-ft)TIpUse of the following tool(s) is recommended:- 21 mm socket

Figure 18. LH shown, RH similar -

Tighten the bolt and nut that attach

the RH rear lower aft link to the RH rear suspension knuckle. Mark the bolt with a paint

pen.

115 Nm (84.8 lbs-ft)TIpUse of the following tool(s) is recommended:

115 Nm (84.8 lbs-ft)TIpUse of the following tool(s) is recommended:- 21 mm socket

Figure 19. LH shown, RH similar -

Tighten the bolt and nut that attach

the RH rear upper aft link to the RH rear suspension knuckle. Mark the bolt with a paint

pen.

134 Nm (98.8 lbs-ft)TIpUse of the following tool(s) is recommended:

134 Nm (98.8 lbs-ft)TIpUse of the following tool(s) is recommended:- 21 mm socket

Figure 20. LH shown, RH similar -

Tighten the bolt and nut that attach

the RH rear upper fore link to the RH rear suspension knuckle. Mark the bolt with a

paint pen.

84 Nm (61.9 lbs-ft)TIpUse of the following tool(s) is recommended:

84 Nm (61.9 lbs-ft)TIpUse of the following tool(s) is recommended:- 18 mm socket

Figure 21. LH shown, RH similar -

Tighten the bolt and nut that attach

the RH toe link to the RH rear suspension knuckle. Mark the bolt with a paint pen.

76 Nm (56.0 lbs-ft)TIpUse of the following tool(s) is recommended:

76 Nm (56.0 lbs-ft)TIpUse of the following tool(s) is recommended:- 18 mm socket

Figure 22. LH shown, RH similar -

Tighten the bolt and nut that attach

the RH rear lower fore link to the RH rear suspension knuckle. Mark the bolt with a

paint pen.

76 Nm (56.0 lbs-ft)TIpUse of the following tool(s) is recommended:

76 Nm (56.0 lbs-ft)TIpUse of the following tool(s) is recommended:- 18 mm socket

Figure 23. LH shown, RH similar -

Tighten the nut that attaches the end

link to the stabilizer bar. Mark the nut with a paint pen.

55 Nm (40.6 lbs-ft)TIpUse of the following tool(s) is recommended:

55 Nm (40.6 lbs-ft)TIpUse of the following tool(s) is recommended:- 15 mm socket

- Remove the support stand front underneath the RH suspension.

- Remove the hub jack adapter from the RH rear hub.

-

Install the bolt that attaches the RH

rear brake rotor to the RH rear hub.

5 Nm (3.7 lbs-ft)TIpUse of the following tool(s) is recommended:

5 Nm (3.7 lbs-ft)TIpUse of the following tool(s) is recommended:- 10 mm socket

Figure 24. LH shown, RH similar - Remove the spring compressor from the RH rear coil spring.

- Repeat step 83 through step 103 for the LH side of the vehicle.

- Install the LH and RH rear suspension covers. See Cover - Rear Suspension - LH (Remove and Replace).

- Install the mid aero shield panel. See Panel - Aero Shield - Rear (Remove and Replace).

- Install the rear wheels. See Wheel Assembly (Remove and Install).

-

Torque the LH and RH rear halfshaft

nuts.

245 Nm (180.7 lbs-ft)TIpUse of the following tool(s) is recommended:

245 Nm (180.7 lbs-ft)TIpUse of the following tool(s) is recommended:- 32 mm deep impact socket

- If equipped, install the LH and RH front wheel center caps. See Cap - Wheel (Remove and Replace).

- Perform a vacuum refill of the cooling system. See Cooling System (Vacuum Refill).

-

Press and hold the park button to release the EPB service mode.

NoteRemove the wheel chocks if necessary.

- Install the rear underhood apron. See Underhood Apron - Rear (Remove and Replace).

- Install the 2nd row lower seat cushion. See Seat Cushion - Lower - 2nd Row (Remove and Replace).

- Refer to the Alignment Requirement tables to determine whether an EPAS alignment check (EC) or four wheel alignment check (AC) is necessary. If performed, add the alignment check/adjust correction code as a separate activity to the SV. See Alignment Requirement - Suspension.

- Restore the driver and front passenger seats back to their original positions.