Fender Alignment

Correction code

10000004

Adjustable FRT

NOTE: This procedure uses an adjustable correction code. Use the correction code listed above and manually enter the actual amount of time spent performing this procedure. Do not stack correction codes unless explicitly told to do so.

NOTE: See Flat Rate Times to learn more about FRTs and how they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when performing the below procedure.

NOTE: See Ergonomic Precautions for safe and healthy working practices.

Correction code

10000004

Adjustable FRT

NOTE: This procedure uses an adjustable correction code. Use the correction code listed above and manually enter the actual amount of time spent performing this procedure. Do not stack correction codes unless explicitly told to do so.

NOTE: See Flat Rate Times to learn more about FRTs and how they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when performing the below procedure.

NOTE: See Ergonomic Precautions for safe and healthy working practices.

- 2023-12-20: Updated the original nonadjustable correction code to the new adjustable one.

Procedure

-

Identify any adjacent panels that may also need adjustment to successfully align the fender to within specification.

NoteIf multiple panels require adjustment, the best practice is to start with a panel that is adjacent to a fixed panel on the vehicle (e.g. quarter panel or roof rail).NoteThe optimal adjustment order is the following:

- Trunk/liftgate

- Rear doors

- Front doors

- Fenders

- Hood

- Identify what directions the fender needs to be adjusted to bring it within specification.

-

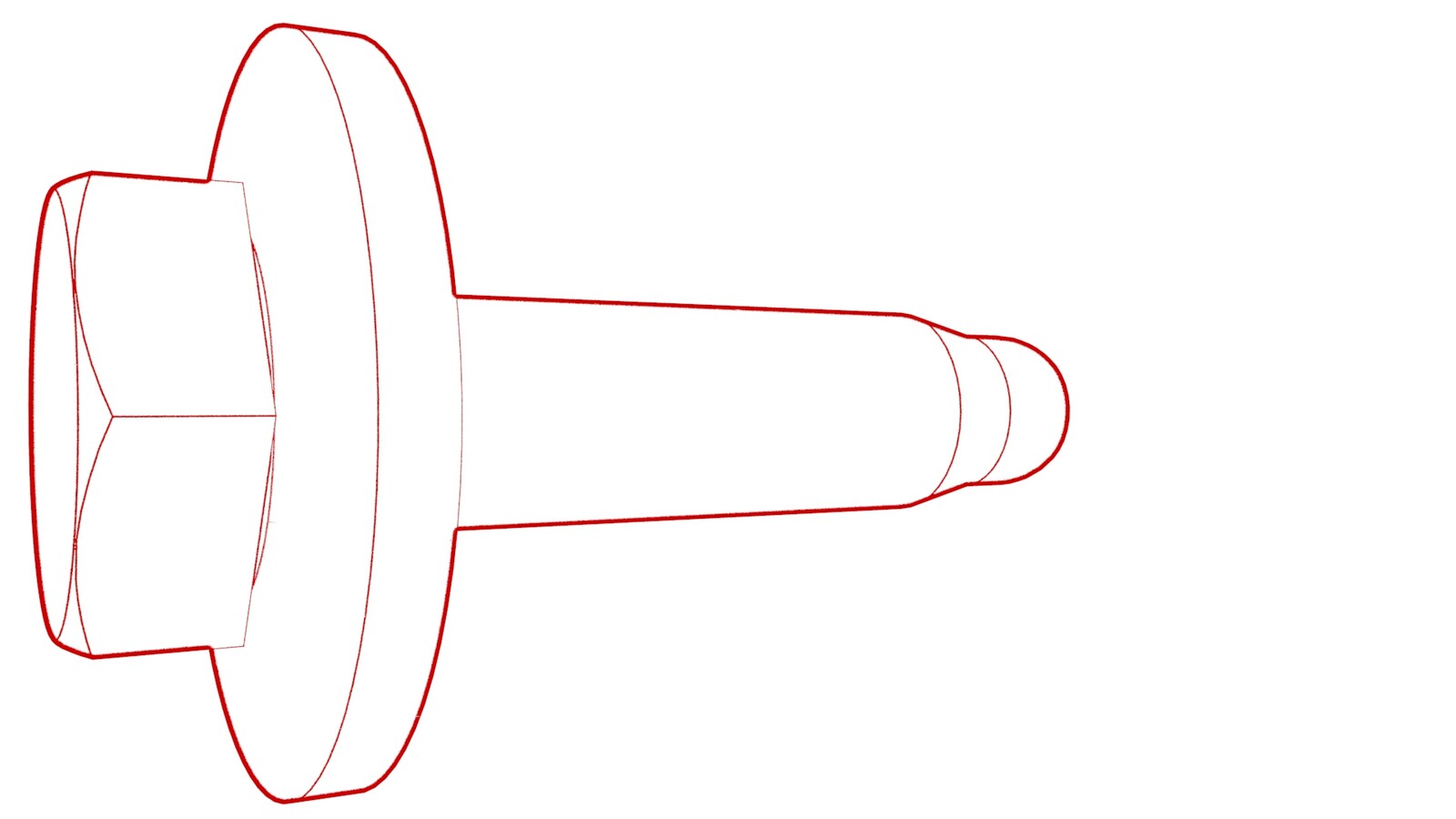

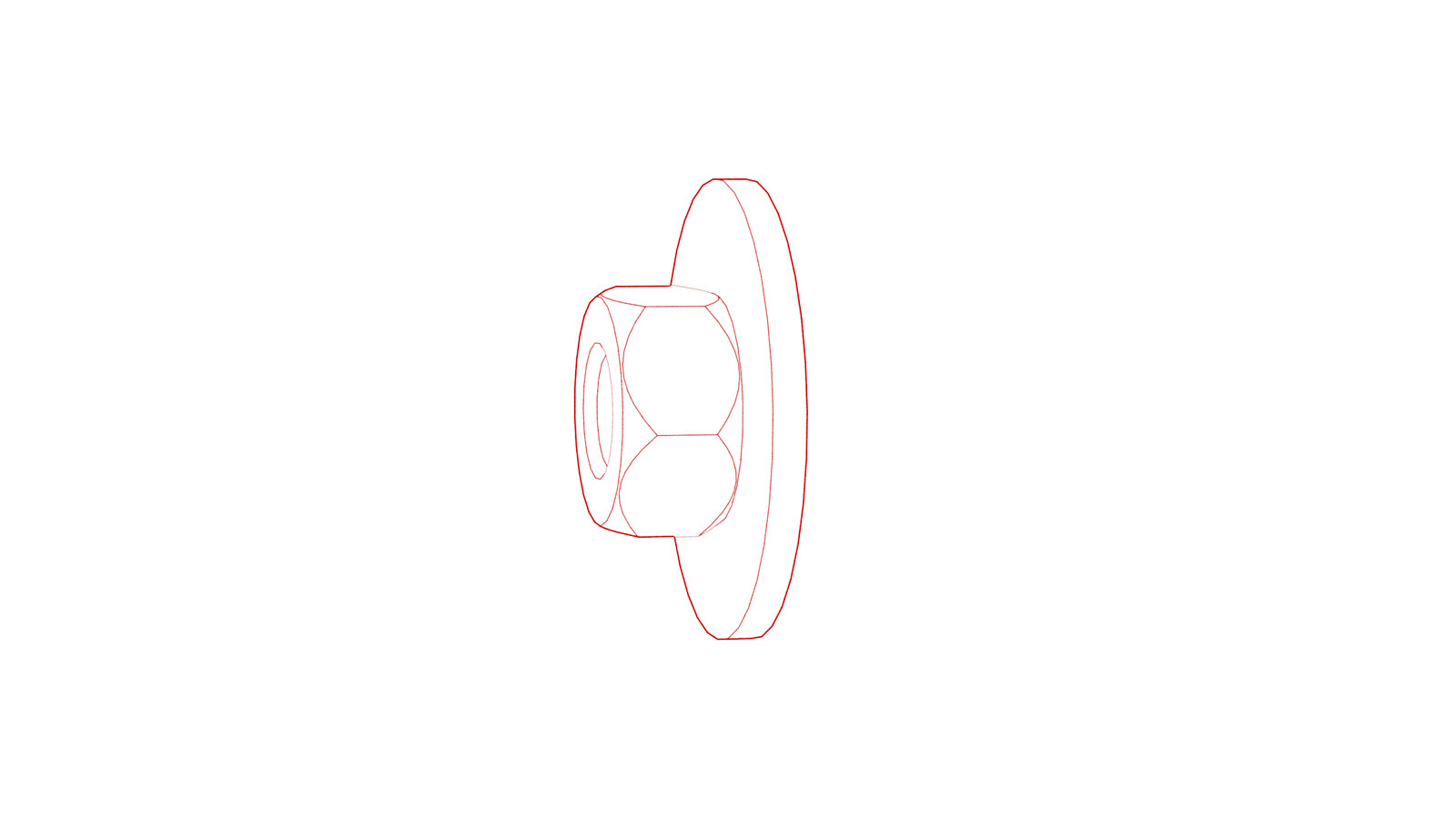

Use the images to identify the hardware that needs to be loosened to adjust the fender position in the necessary directions.

NoteModel 3 images shown; Model Y similar.

- Loosen the necessary bolts just enough to enable adjusting the fender with a light application of force.

- Retighten them.

-

Check to see if the fit has improved.

CAUTIONAdjust the fender in only one direction at a time to reduce risk of damage from panels contacting each other during the adjustment process.

- Repeat the process until the fender fit is within gap and flushness specifications.

- Re-torque all hardware that was loosened back to factory values.

Torque Specifications

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolts that attach the top of the front fascia to the vehicle |

4 Nm (2.9 lbs-ft) |

|

Reuse | |

| Bolt that attaches the LH front wheel liner to the HV battery |

5 Nm (3.7 lbs-ft) |

|

Reuse | |

| Bolt that attaches the LH corner of the front fascia to the fender |

4 Nm (2.9 lbs-ft) |

|

Reuse Replace | |

| Bolt that attaches the RH corner of the front fascia to the fender |

4 Nm (2.9 lbs-ft) |

|

Reuse | |

| Bolts that attach the upper LH front fender bracket to the body |

9.8 Nm (7.2 lbs-ft) |

|

Reuse | |

| Bolt that attaches the LH front fender bracket to the body |

9.8 Nm (7.2 lbs-ft) |

|

Reuse | |

| Bolt that attaches the rear LH front fender bracket to the body |

9.8 Nm (7.2 lbs-ft) |

|

Reuse | |

| Nuts that attach the lower LH front fender bracket to the body |

9.8 Nm (7.2 lbs-ft) |

|

Reuse |