Torque Specifications - Battery System

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolt that attaches the FDU (Front Drive Unit) HV harness to the FDU |

10 Nm (7.4 lbs-ft) |

|

Reuse |

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolts that attach the power conversion system to the HV battery |

18 Nm (13.3 lbs-ft) |

|

Reuse | Upon installation, mark each bolt with a paint pen |

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolt that attaches the DC inlet positive busbar to the ancillary bay |

15 Nm (11.1 lbs-ft) -180 deg  5 Nm (3.7 lbs-ft) +60 deg |

|

Replace | |

| Bolt that attaches the DC inlet negative busbar to the ancillary bay |

15 Nm (11.1 lbs-ft) -180 deg  5 Nm (3.7 lbs-ft) +60 deg |

|

Replace | |

| Bolts (x2) that attach the FC positive outlet jumper to the ancillary bay |

15 Nm (11.1 lbs-ft) -180 deg  5 Nm (3.7 lbs-ft) +60 deg |

|

Replace | |

| Bolts (x2) that attach the FC negative outlet jumper to the ancillary bay |

15 Nm (11.1 lbs-ft) -180 deg  5 Nm (3.7 lbs-ft) +60 deg |

|

Replace | |

| Bolts (x3) that attach the HV battery fast charge contactor to the ancillary bay |

5.5 Nm (4.1 lbs-ft) |

|

Reuse |

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolt that attaches the AC filter harness to the negative DC inlet busbar |

15 Nm (11.1 lbs-ft) -180 deg  5 Nm (3.7 lbs-ft) +60 deg |

|

Replace | |

| Bolt that attaches the AC filter harness to the positive DC inlet busbar |

15 Nm (11.1 lbs-ft) -180 deg  5 Nm (3.7 lbs-ft) +60 deg |

|

Replace | |

| Bolts (x2) that attach the FC positive outlet jumper to the ancillary bay |

15 Nm (11.1 lbs-ft) -180 deg  5 Nm (3.7 lbs-ft) +60 deg |

|

Replace | |

| Bolts (x2) that attach the FC negative outlet jumper to the ancillary bay |

15 Nm (11.1 lbs-ft) -180 deg  5 Nm (3.7 lbs-ft) +60 deg |

|

Replace | |

| Bolts (x3) that attach the HV battery fast charge contactor to the ancillary bay |

5.5 Nm (4.1 lbs-ft) |

|

Reuse |

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolts that attach the HVC to the ancillary bay cover |

5 Nm (3.7 lbs-ft) +30 deg |

|

Replace | |

| Screws that attach the HVC tray to the ancillary bay |

2 Nm (1.5 lbs-ft) |

|

Reuse | Not necessary to remove these fasteners if only removing the HVC |

| Bolts that attach the HVC tray to the HVC |

2 Nm (1.5 lbs-ft) |

|

Reuse |

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| LH front inner HV battery bolt |

136 Nm (100.3 lbs-ft) |

|

Reuse | |

| LH middle inner HV battery bolt |

66 Nm (48.7 lbs-ft) |

|

Reuse | |

| LH rear inner HV battery bolt |

66 Nm (48.7 lbs-ft) |

|

Reuse | |

| Bolt that secures the busbar cover access door |

9 Nm (6.6 lbs-ft) |

|

Reuse | |

| Bolts that attach the charge port busbar kit to the HV header |

9 Nm (6.6 lbs-ft) |

|

Reuse | |

| Nut that attaches the DCDC ground strap to the HV battery |

15 Nm (11.1 lbs-ft) |

|

Replace | PN - 1093060-00-A |

| Nut that attaches the positive 12V output to the PCS cable |

15 Nm (11.1 lbs-ft) |

|

Replace | PN - 1093060-00-A |

| Bolt that attaches the LH front wheel liner to the HV battery |

5 Nm (3.7 lbs-ft) |

|

Reuse | |

| Bolt that attaches the FDU HV harness to the FDU |

10 Nm (7.4 lbs-ft) |

|

Reuse | |

| Bolt that attaches the ground strap to the HV battery |

10 Nm (7.4 lbs-ft) |

|

Reuse | |

| Smaller bolts that attach the LH shear plate to the body |

35 Nm (25.8 lbs-ft) |

|

Reuse | |

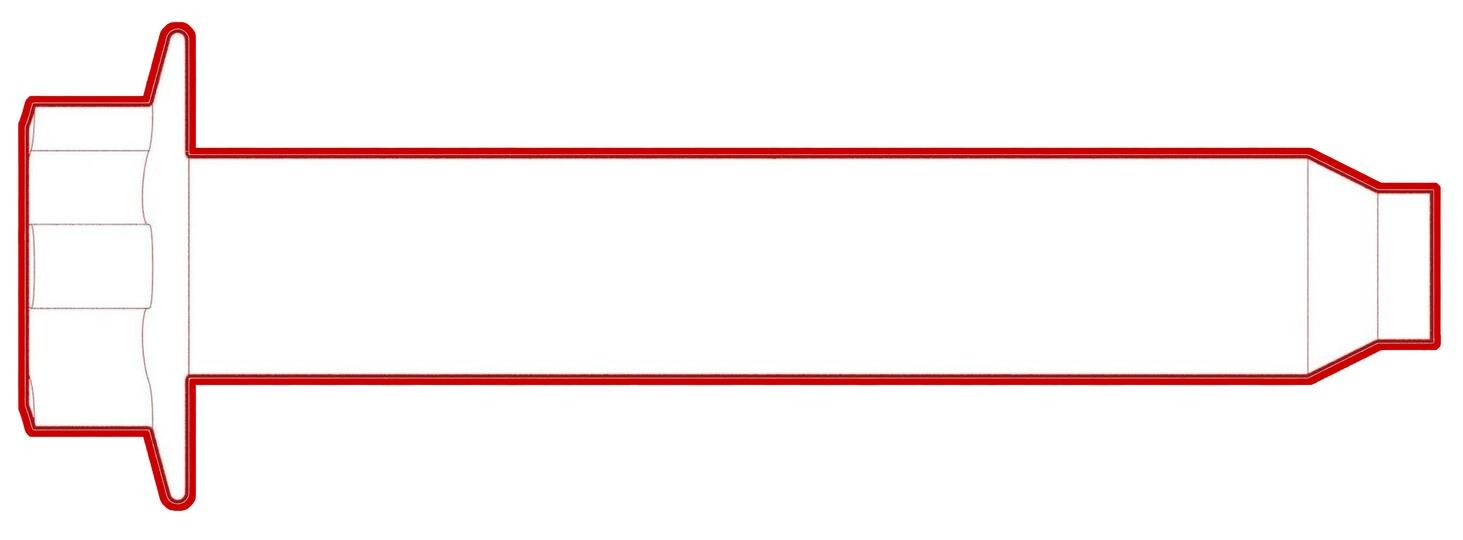

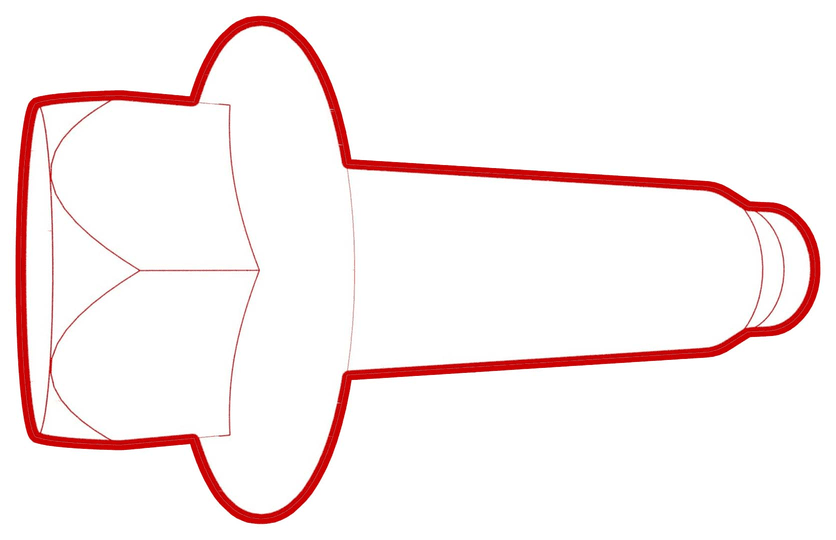

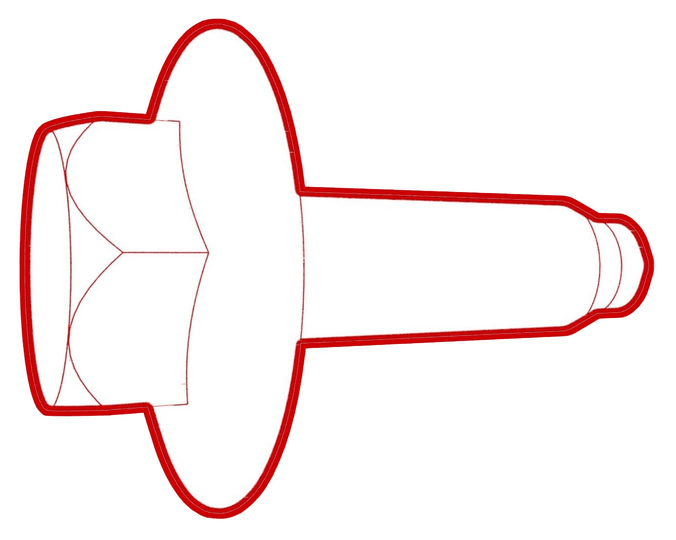

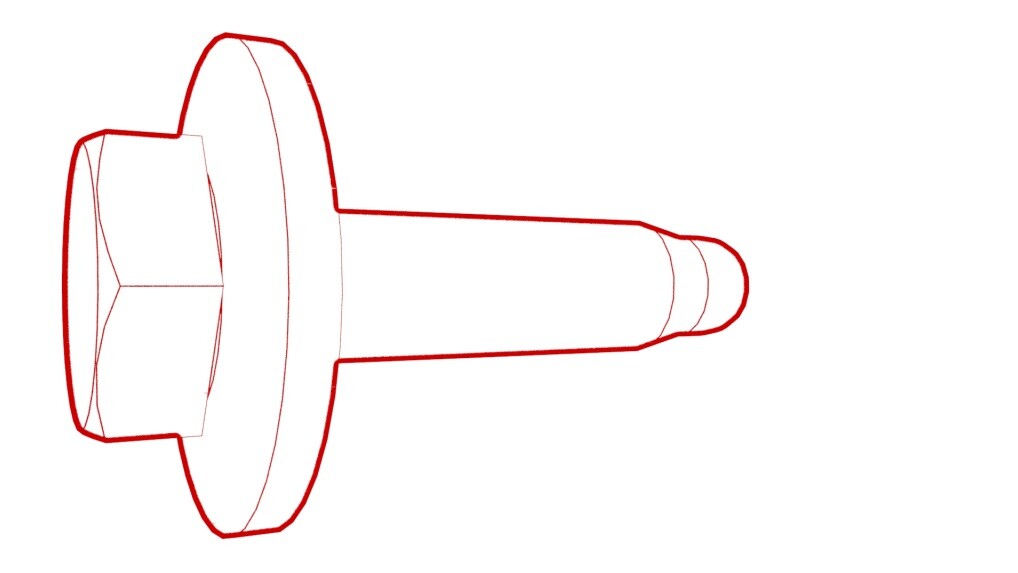

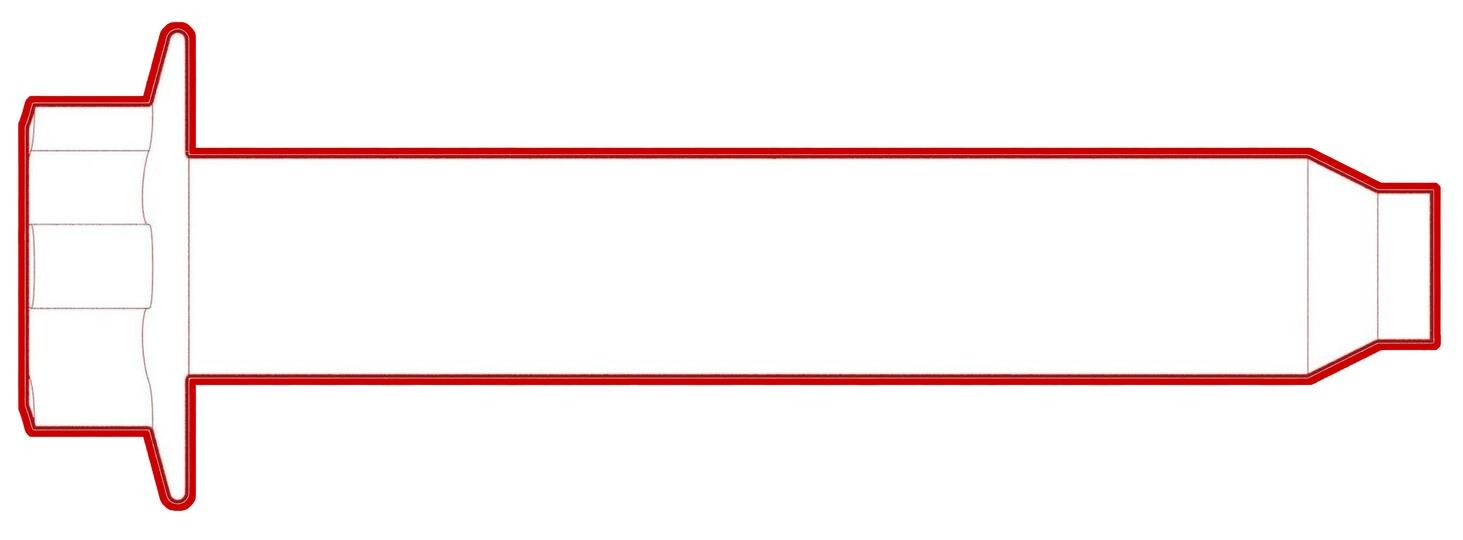

| Larger bolt that attaches the LH shear plate to the body |

130 Nm (95.9 lbs-ft) |

|

Replace | PN - 1461657-00-A |

| Nut that attaches the RDU HV electrical harness bracket to the HV battery |

10 Nm (7.4 lbs-ft) |

|

Reuse | |

| Center bolts (x4) that attach the HV battery through the HV battery center rail ski cover |

35 Nm (25.8 lbs-ft) |

|

Reuse | |

| Bolts that attach the HV battery LH and RH support brackets to the vehicle |

110 Nm (81.1 lbs-ft) |

|

Reuse | |

| Bolts (x16) that attach the HV battery to the vehicle |

35 Nm (25.8 lbs-ft) |

|

Reuse |

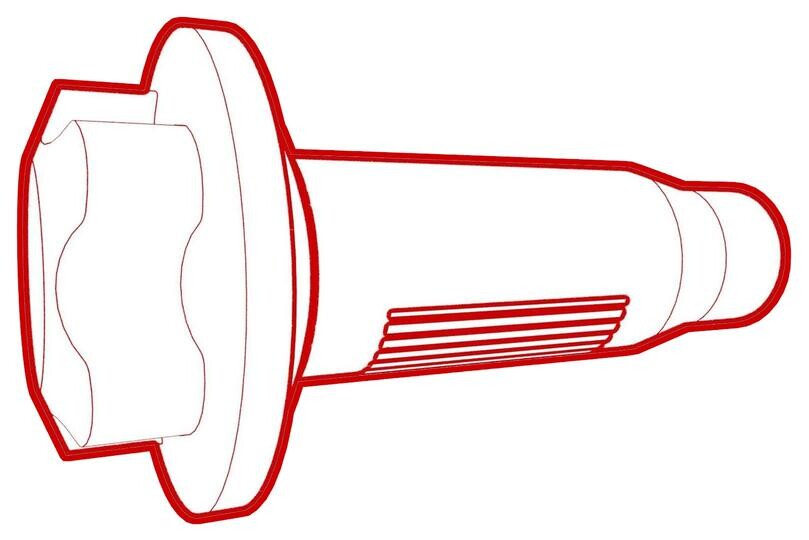

Note Some vehicles are

equipped with self-tapping bolts in bolt position #8-15 from the

factory. If the vehicle is equipped with a bolt with a hexagonal

indentation on the bolt head (1637725-00-A), the torque value is 64 Nm. |

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| LH front inner HV battery bolt |

136 Nm (100.3 lbs-ft) |

|

Reuse | |

| LH middle inner HV battery bolt |

66 Nm (48.7 lbs-ft) |

|

Reuse | |

| LH rear inner HV battery bolt |

66 Nm (48.7 lbs-ft) |

|

Reuse | |

| Bolt that secures the busbar cover access door |

9 Nm (6.6 lbs-ft) |

|

Reuse | |

| Bolts that attach the charge port busbar kit to the HV header |

9 Nm (6.6 lbs-ft) |

|

Reuse | |

| Nut that attaches the DCDC ground strap to the HV battery |

15 Nm (11.1 lbs-ft) |

|

Replace | 1523698-00-A |

| Nut that attaches the positive 12V output to the PCS cable |

15 Nm (11.1 lbs-ft) |

|

Replace | 1523698-00-A |

| Bolt that attaches the LH front wheel liner to the HV battery |

5 Nm (3.7 lbs-ft) |

|

Reuse | |

| Smaller bolts that attach the LH shear plate to the body |

35 Nm (25.8 lbs-ft) |

|

Reuse | |

| Larger bolt that attaches the LH shear plate to the body |

130 Nm (95.9 lbs-ft) |

|

Replace | 1461657-00-A |

| Nut that attaches the RDU HV electrical harness bracket to the HV battery |

10 Nm (7.4 lbs-ft) |

|

Reuse | |

| Center bolts (x4) that attach the HV battery through the HV battery center rail ski cover |

35 Nm (25.8 lbs-ft) |

|

Reuse | |

| Outer bolts (x2) that attach the center rail ski cover to the HV battery |

32 Nm (23.6 lbs-ft) |

|

Reuse | |

| Bolts that attach the HV battery LH and RH support brackets to the vehicle |

110 Nm (81.1 lbs-ft) |

|

Reuse | |

| Bolts (x16) that attach the HV battery to the vehicle |

35 Nm (25.8 lbs-ft) |

|

Reuse |

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| LH front inner HV battery bolt |

136 Nm (100.3 lbs-ft) |

|

Reuse | |

| LH middle inner HV battery bolt |

66 Nm (48.7 lbs-ft) |

|

Reuse | |

| LH rear inner HV battery bolt |

66 Nm (48.7 lbs-ft) |

|

Reuse | |

| Bolt that secures the busbar cover access door |

9 Nm (6.6 lbs-ft) |

|

Reuse | |

| Bolts that attach the charge port busbar kit to the HV header |

9 Nm (6.6 lbs-ft) |

|

Reuse | |

| Nut that attaches the DCDC ground strap to the HV battery |

15 Nm (11.1 lbs-ft) |

|

Replace | 1523698-00-A |

| Nut that attaches the positive 12V output to the PCS cable |

15 Nm (11.1 lbs-ft) |

|

Replace | 1523698-00-A |

| Bolt that attaches the LH front wheel liner to the HV battery |

5 Nm (3.7 lbs-ft) |

|

Reuse | |

| Smaller bolts that attach the LH shear plate to the body |

35 Nm (25.8 lbs-ft) |

|

Reuse | |

| Larger bolt that attaches the LH shear plate to the body |

130 Nm (95.9 lbs-ft) |

|

Replace | 1461657-00-A |

| Nut that attaches the RDU HV electrical harness bracket to the HV battery |

10 Nm (7.4 lbs-ft) |

|

Reuse | |

| Center bolts (x4) that attach the HV battery through the HV battery center rail ski cover |

35 Nm (25.8 lbs-ft) |

|

Reuse | |

| Outer bolts (x2) that attach the center rail ski cover to the HV battery |

32 Nm (23.6 lbs-ft) |

|

Reuse | |

| Bolts that attach the HV battery LH and RH support brackets to the vehicle |

110 Nm (81.1 lbs-ft) |

|

Reuse | |

| Bolts (x16) that attach the HV battery to the vehicle |

35 Nm (25.8 lbs-ft) |

|

Reuse |

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolt that attaches the pyrotechnic battery disconnect to the HV battery |

9 Nm (6.6 lbs-ft) |

|

Replace |

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolt that attaches the rear skid plate to the lower HV battery |

13 Nm (9.6 lbs-ft) |

|

Reuse | |

| Nut that attaches the rear skid plate to the upper HV battery |

13 Nm (9.6 lbs-ft) |

|

Reuse | |

| Upper bolts that attach the rear skid plate to the HV battery |

35 Nm (25.8 lbs-ft) |

|

Reuse |

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Nut that attaches the positive 12V output cable to the DCDC passthrough |

15 Nm (11.1 lbs-ft) |

|

Replace |

Note

Mark the fastener with a

paint pen after torquing.

|

| Bolt that attaches the ancillary bay cover to the high voltage controller |

5 Nm (3.7 lbs-ft) +30 deg |

|

Reuse | |

| Bolt attaches the ancillary bay cover to the HV battery |

8 Nm (5.9 lbs-ft) |

|

Reuse |

CAUTION Use an External Torx E10 5-Lobe socket that is not magnetized. Sockets with magnets will not fully grip and can possibly strip the bolt head. Note Torque these fasteners in the sequence specified in the installation step. Note These bolts are attached to the ancillary bay cover. |

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolts (EPL10 or EPR10) that attach the ancillary bay cover to the HV battery |

5 Nm (3.7 lbs-ft) |

|

Reuse Replace |

Note Torque these fasteners in the sequence

specified in the installation step. Note These bolts are attached to the ancillary

bay cover. |

| Bolts (EPL10 or EPR10) that attach the charge port header to the ancillary bay cover |

10 Nm (7.4 lbs-ft) |

|

Reuse | |

| Bolts (EPL10) that attach the 3-phase header to the ancillary bay |

6 Nm (4.4 lbs-ft) |

|

Reuse | |

| Bolts (E10 or EPL14) that attach the ancillary bay cover to the HV controller |

10 Nm (7.4 lbs-ft) |

|

||

| Bolts (T20) that attach the PCS LVDC header to the ancillary bay cover |

2.5 Nm (1.8 lbs-ft) |

|

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolt that attaches the HV probe cover to the ancillary bay cover |

6 Nm (4.4 lbs-ft) |

|

Replace |

Note

Mark the fastener with a

paint pen after torquing.

|

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolt that attach the lower rear edge of the LH wheel arch liner to the body |

5 Nm (3.7 lbs-ft) |

|

Reuse |

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

|

Bolt that attaches the positive pack contactor to the positive busbar Nut that attaches the positive pack contactor to the module 4 rear terminal |

9 Nm (6.6 lbs-ft) |

|

Replace |

Bolt: 1104475-00-F Nut: 1104654-00-B |

| Nuts that attach the positive pack contactor to the ancillary bay |

8 Nm (5.9 lbs-ft) |

|

Reuse | |

|

Bolt that attaches the negative pack contactor to the DC link busbar joint Nut that attaches the negative pack contactor to HV battery tall silicon terminal |

9 Nm (6.6 lbs-ft) |

|

Replace |

Bolt: 1104475-00-F Nut: 1104654-00-B |

| Nuts that attach the negative pack contactor to the ancillary bay |

8 Nm (5.9 lbs-ft) |

|

Reuse |

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolt that attaches the shunt assembly to the ancillary bay |

9 Nm (6.6 lbs-ft) |

|

Replace |