Damper Assembly - Front - Pair (Remove and Replace)

Correction code

31151302

0.78

NOTE: Unless otherwise explicitly

stated in the procedure, the above correction code and FRT reflect all of the work

required to perform this procedure, including the linked procedures. Do not stack correction codes unless

explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how they are created. To provide feedback on

FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when

performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

Correction code

31151302

0.78

NOTE: Unless otherwise explicitly

stated in the procedure, the above correction code and FRT reflect all of the work

required to perform this procedure, including the linked procedures. Do not stack correction codes unless

explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how they are created. To provide feedback on

FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when

performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

Torque Specifications

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Nuts that attach the front upper control arm mount to the front spring and damper |

23 Nm (17.0 lbs-ft) |

|

Reuse | |

| Bolt that attaches the front wheel speed sensor to the knuckle |

5 Nm (3.7 lbs-ft) |

|

Reuse | |

| Nut that attaches the front jounce bracket to the stud on the body |

6 Nm (4.4 lbs-ft) |

|

Reuse | |

| Bolt and nyloc nut that attach the front upper control arm to the knuckle |

56 Nm (41.3 lbs-ft) |

|

Replace nut (1111145-00-A), reuse bolt | |

| Nyloc nut that attaches the front stabar link to the front strut |

98 Nm (72.3 lbs-ft) |

|

Replace (1111543-00-A or later) | Hold the joint in place with the T40 |

| Bolt and nut that attach the strut to the lower control arm |

106 Nm (78.2 lbs-ft) |

|

Reuse |

Remove

- Place the vehicle on a lift but do not raise it at this time.

- Remove the fresh air intake duct. See Duct - Fresh Intake (Remove and Replace).

- Remove the windshield washer reservoir filler neck. See Filler Neck - Reservoir - Windshield Washer (LHD) (Remove and Replace).

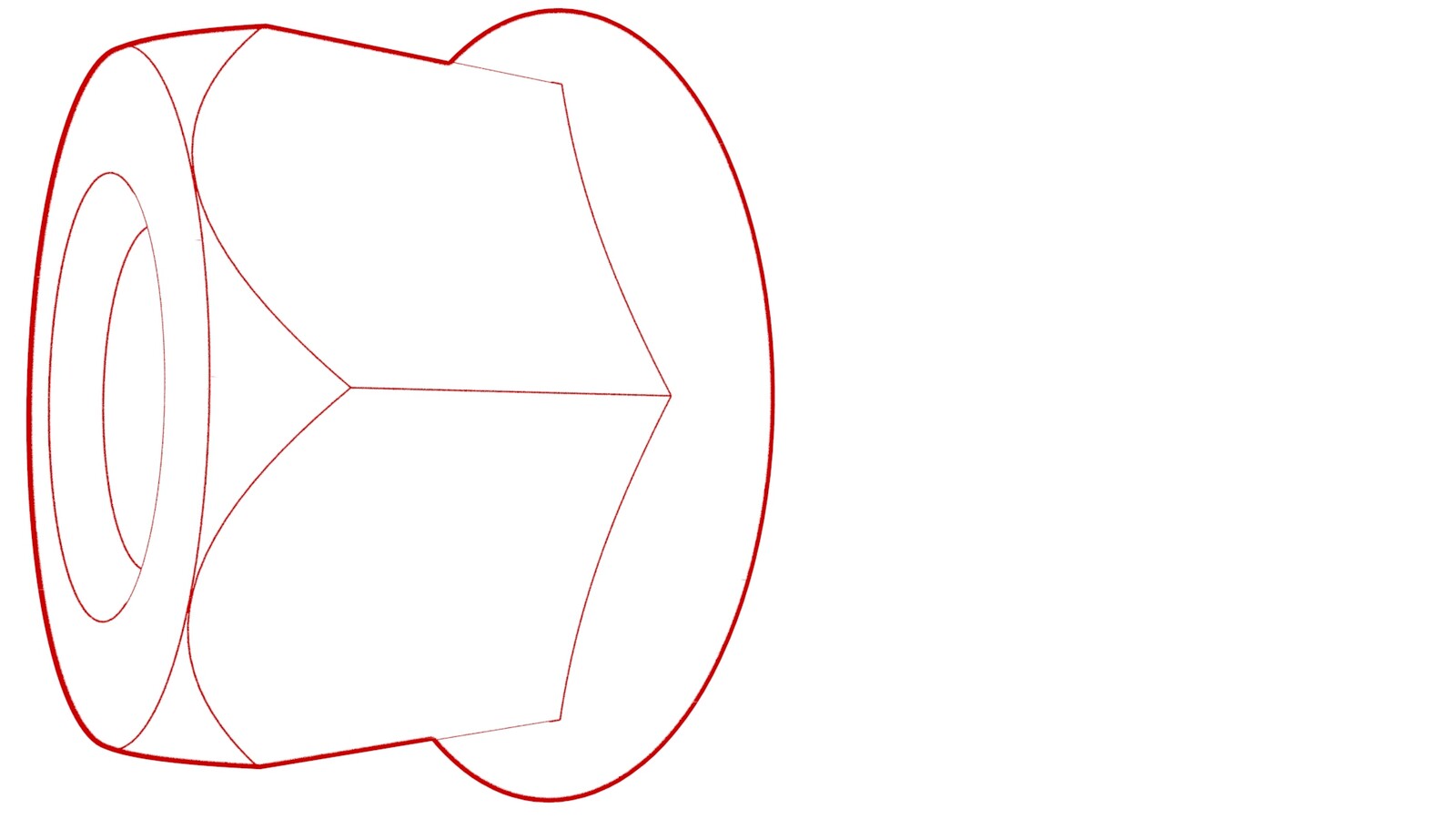

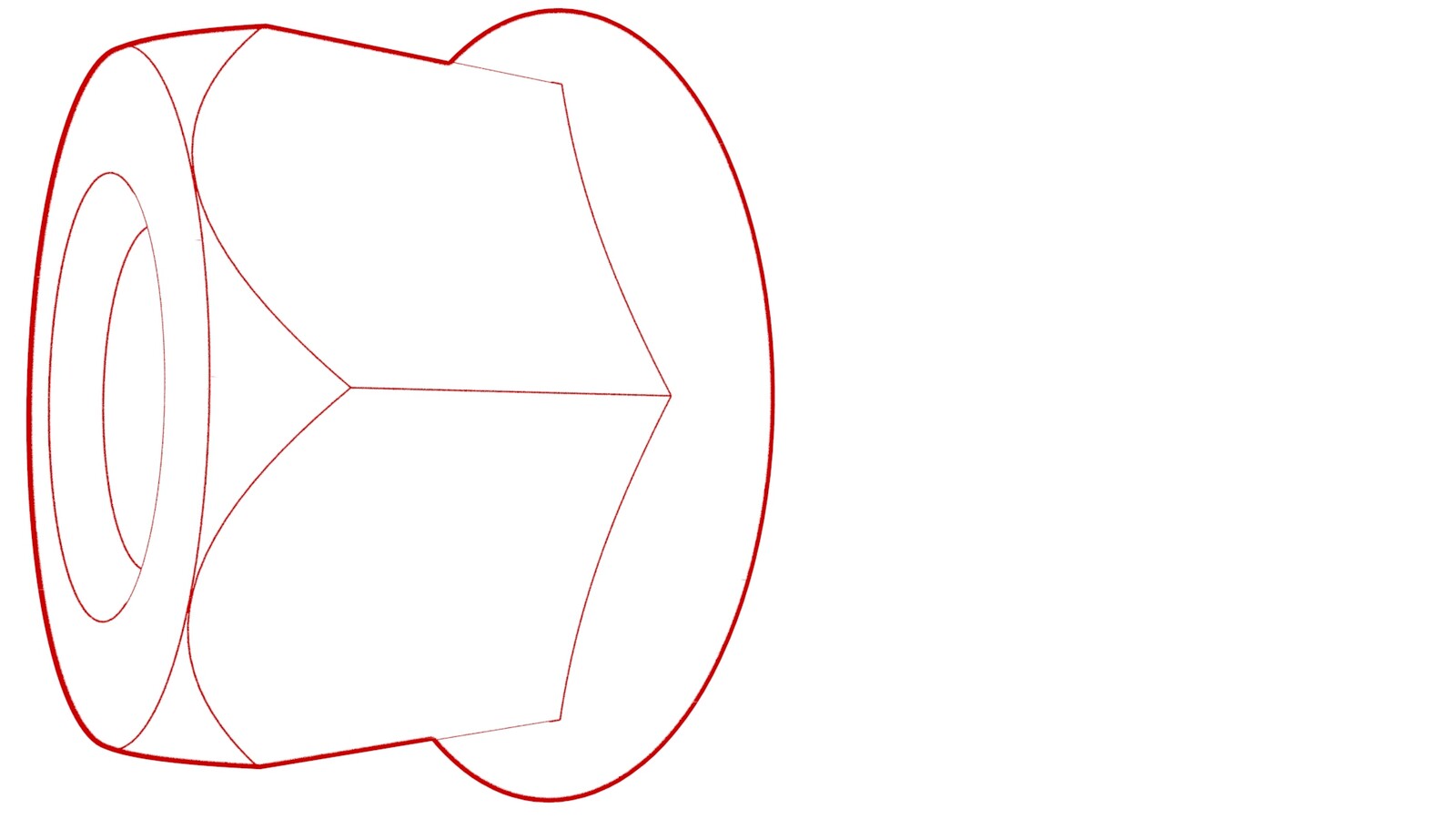

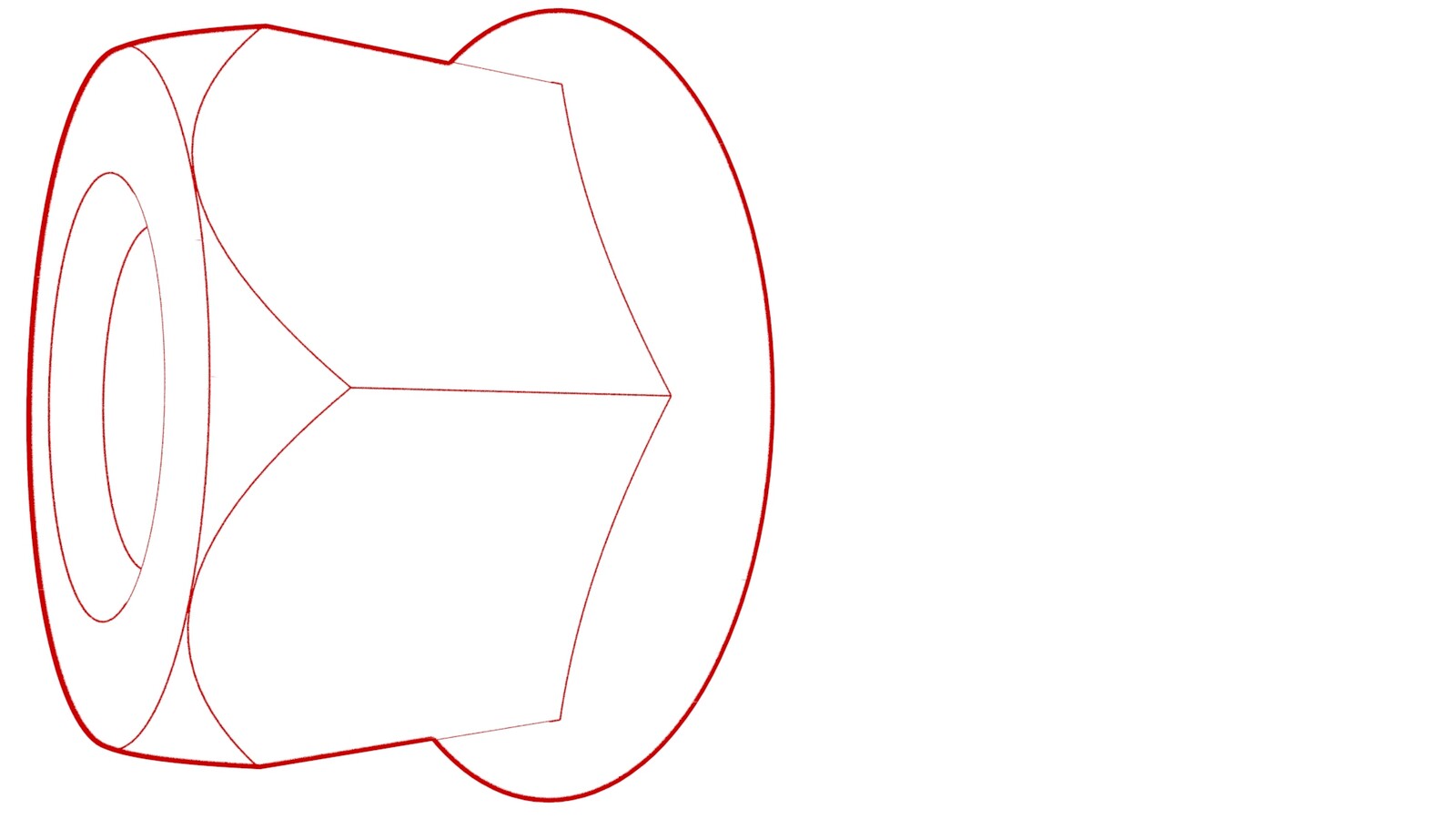

-

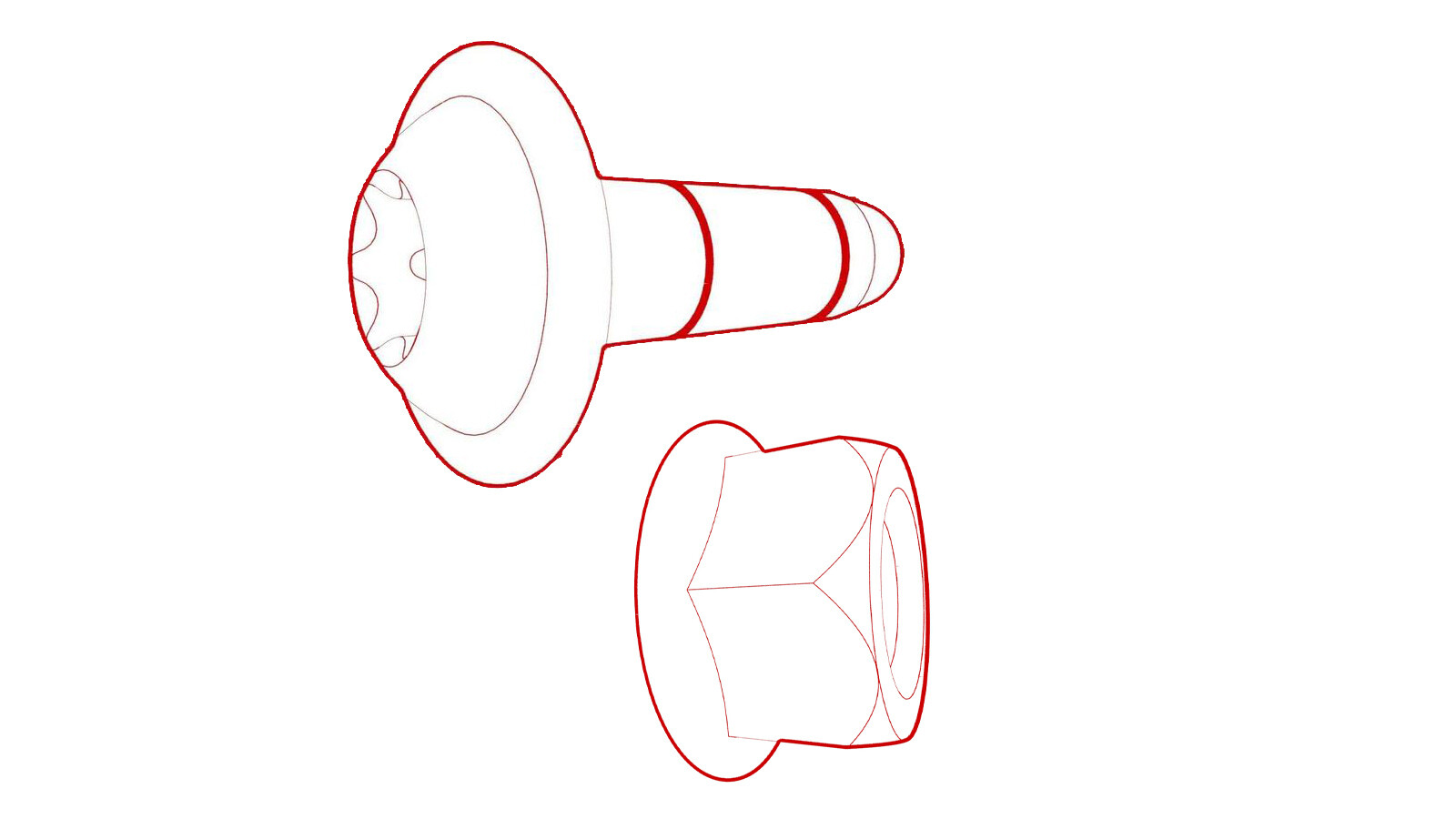

Remove the nuts (x3) that

attach the front upper control arm mount to the LH and RH front spring and

damper assembly.

NoteUse of the following tool(s) is recommended:

- 13 mm deep socket

- 3 in extension

Figure 1. LH side shown, RH side similar - Remove the front LH and RH wheels. See Wheel Assembly (Remove and Install).

-

Remove the bolt that

attaches the front wheel speed sensor to the knuckle.

NoteUse of the following tool(s) is recommended:

- 10 mm deep socket

- 4 in extension

Figure 2. LH side shown, RH side similar -

Release the clips (x2) that

attach the front wheel speed sensor harness to the knuckle, and then move

the wheel speed sensor harness out of the way.

Figure 3. LH side shown, RH side similar -

Remove the nut that attaches

the front jounce bracket to the stud on the body, and then release the

jounce bracket.

NoteUse of the following tool(s) is recommended:

- 10 mm deep socket

- 4 in extension

Figure 4. LH side shown, RH side similar -

Remove the bolt and nyloc

nut (discard the nut) that attach the front upper control arm to the

knuckle.

TIpCompress the joint to allow the bolt to be fully removed.NoteNote the direction of the bolt and nut before removal.NoteUse of the following tool(s) is recommended:

- T47 socket

- 15 mm wrench

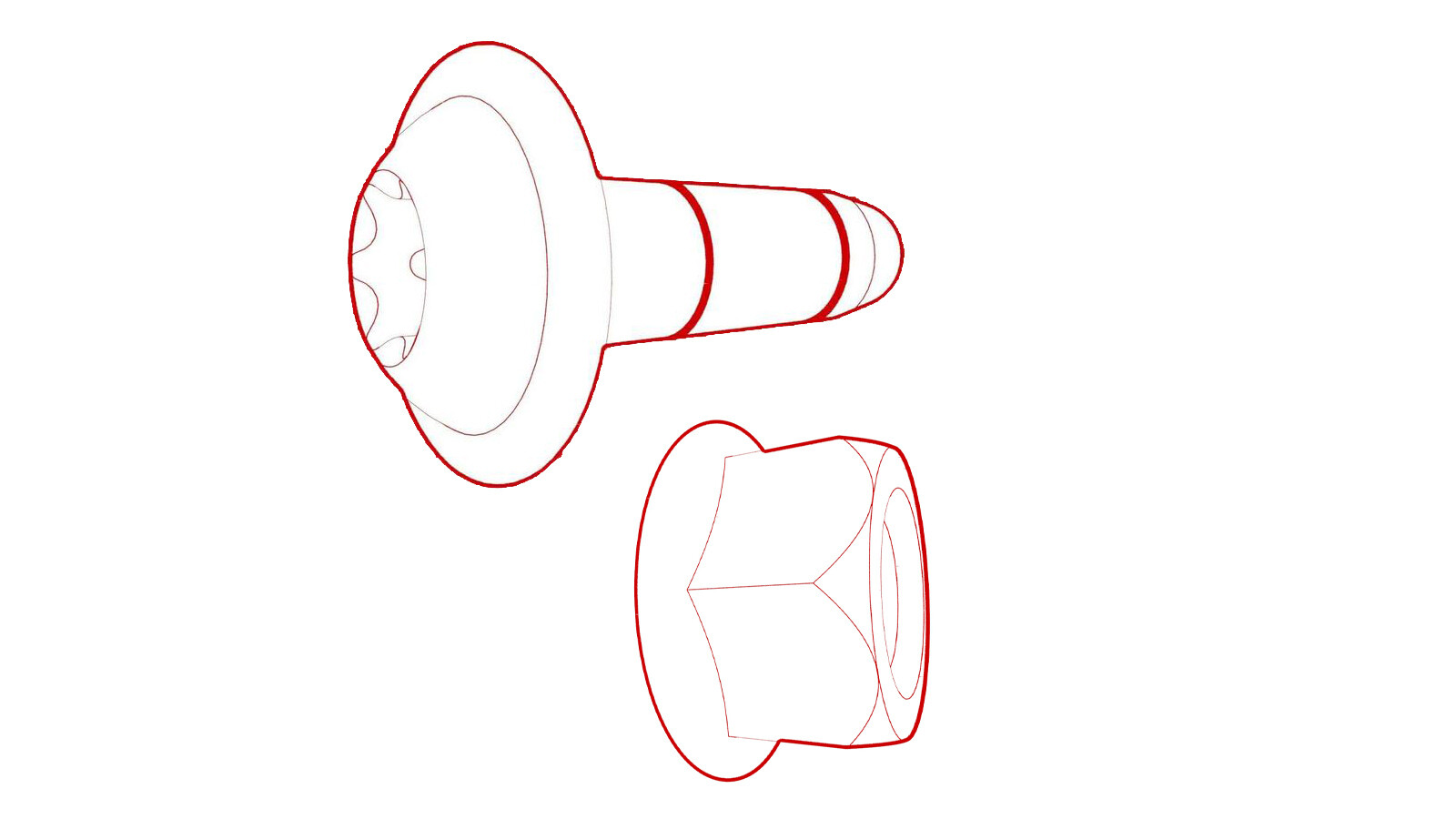

Figure 5. LH side shown, RH side similar -

While holding the joint in

place, remove and discard the nyloc nut that attaches the front stabar link

to the front strut.

NoteUse of the following tool(s) is recommended:

- 18 mm wrench

- 18 mm socket (torque)

- T40 socket

- 6 in extension

Figure 6. LH side shown, RH side similar -

Move the front stabar link

assembly away from the working area.

TIpMove the stabar up and/or down to get the correct angle needed to remove the link.

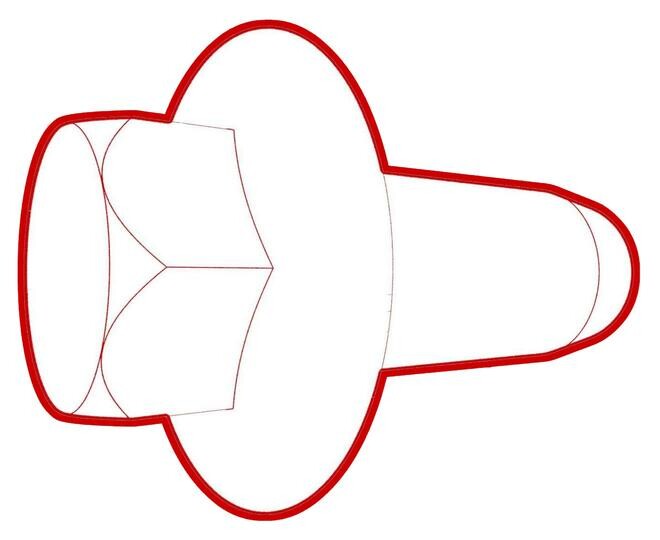

-

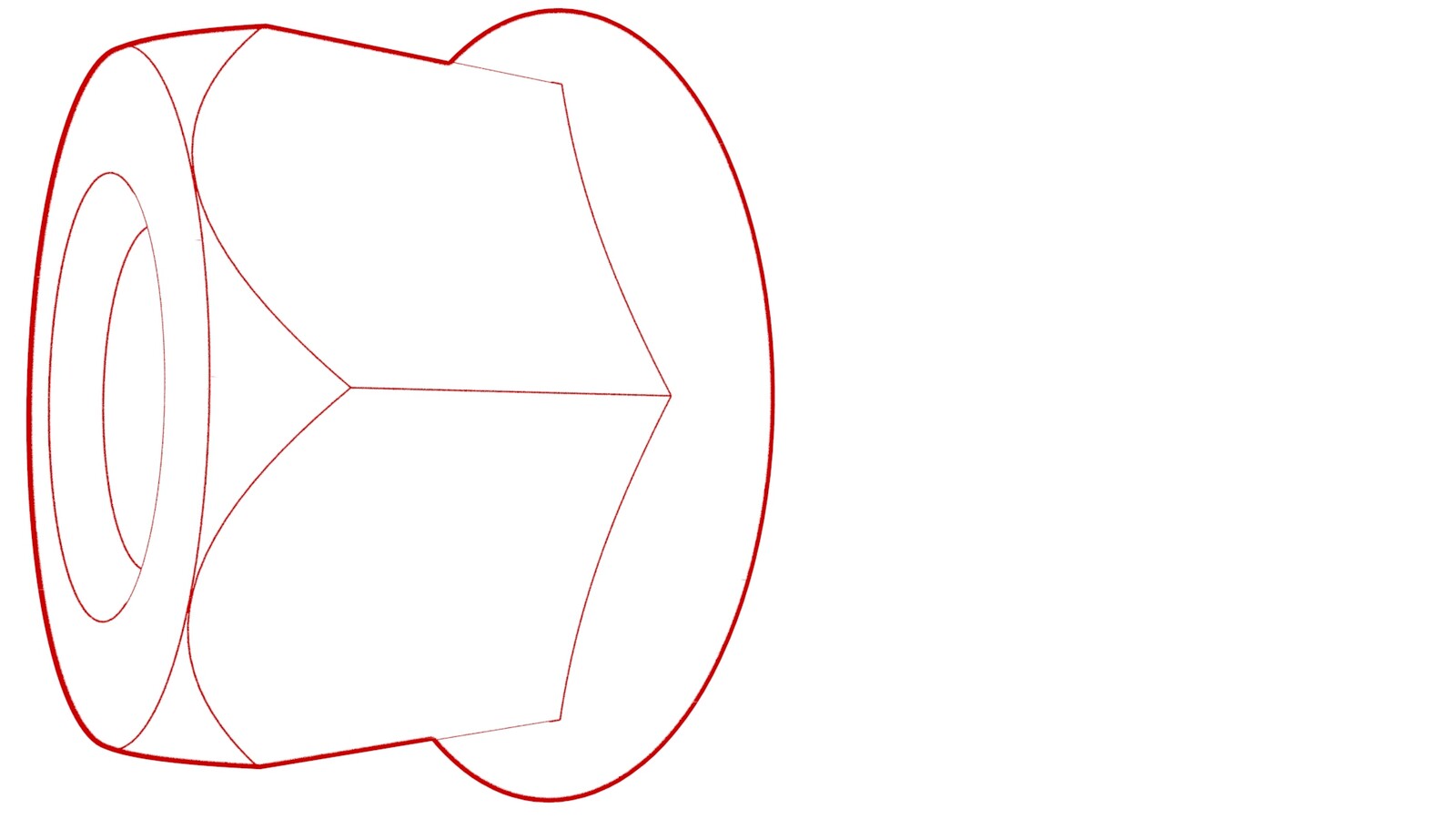

Remove the bolt and nut that

attach the strut to the lower control arm.

NoteNote the direction of the bolt and nut before removal.NoteUse of the following tool(s) is recommended:

- 21 mm socket

- 21 mm wrench

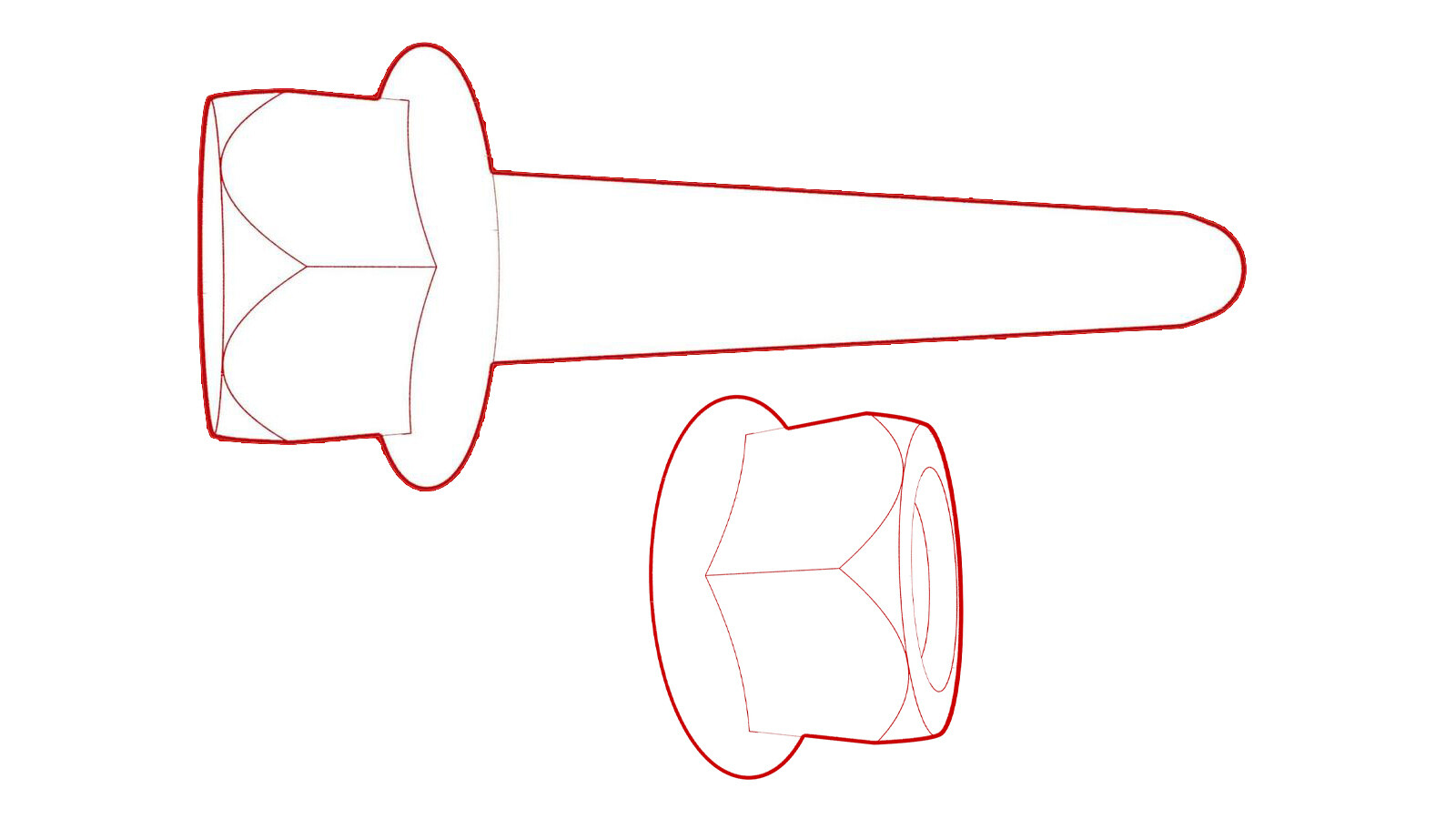

Figure 7. LH side shown, RH side similar -

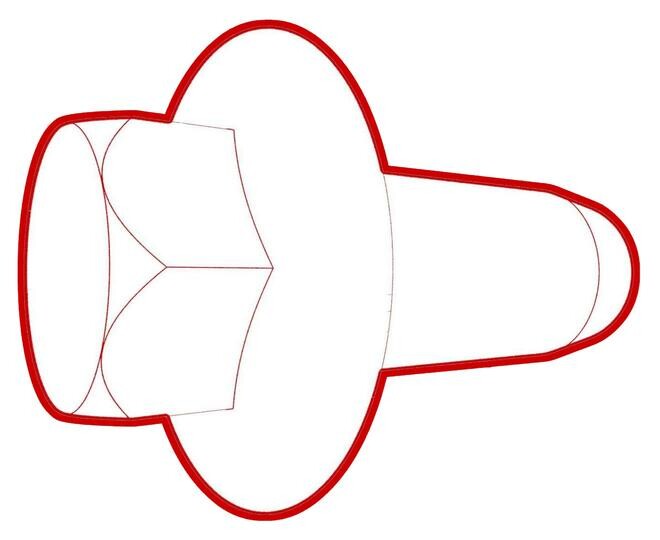

Remove the coil spring and

damper assembly from the vehicle.

TIpLift the upper control arm to create clearance for removal.

Figure 8. LH side shown, RH side similar - Repeat steps 6 through 13 on the RH side of the vehicle.

Install

-

Maneuver the LH coil spring

and damper assembly into place.

TIpLift the upper control arm to create clearance for installation.

Figure 9. LH side shown, RH side similar -

Hand tighten the bolt and

nut that attach the LH strut to the lower control arm.

NoteThe fasteners are torqued later in the procedure.

Figure 10. LH side shown, RH side similar - Repeat steps 1 and 2 on the RH side of the vehicle.

- Lower the vehicle to a comfortable working height and support onto locks. If the lift cannot be locked in that position, set the lift to its lowest lockable position and use a step stool to gain access to the shock tower.

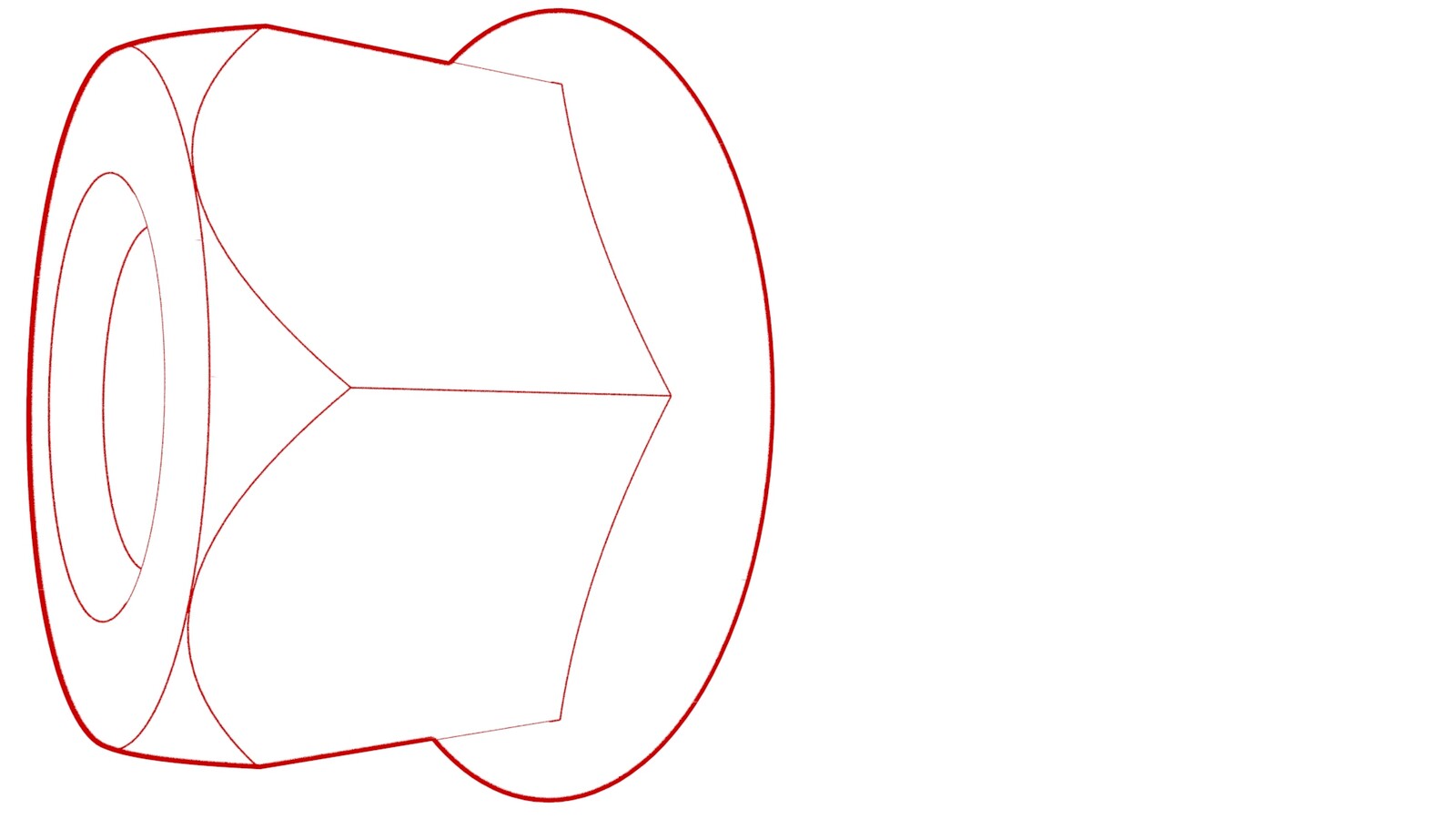

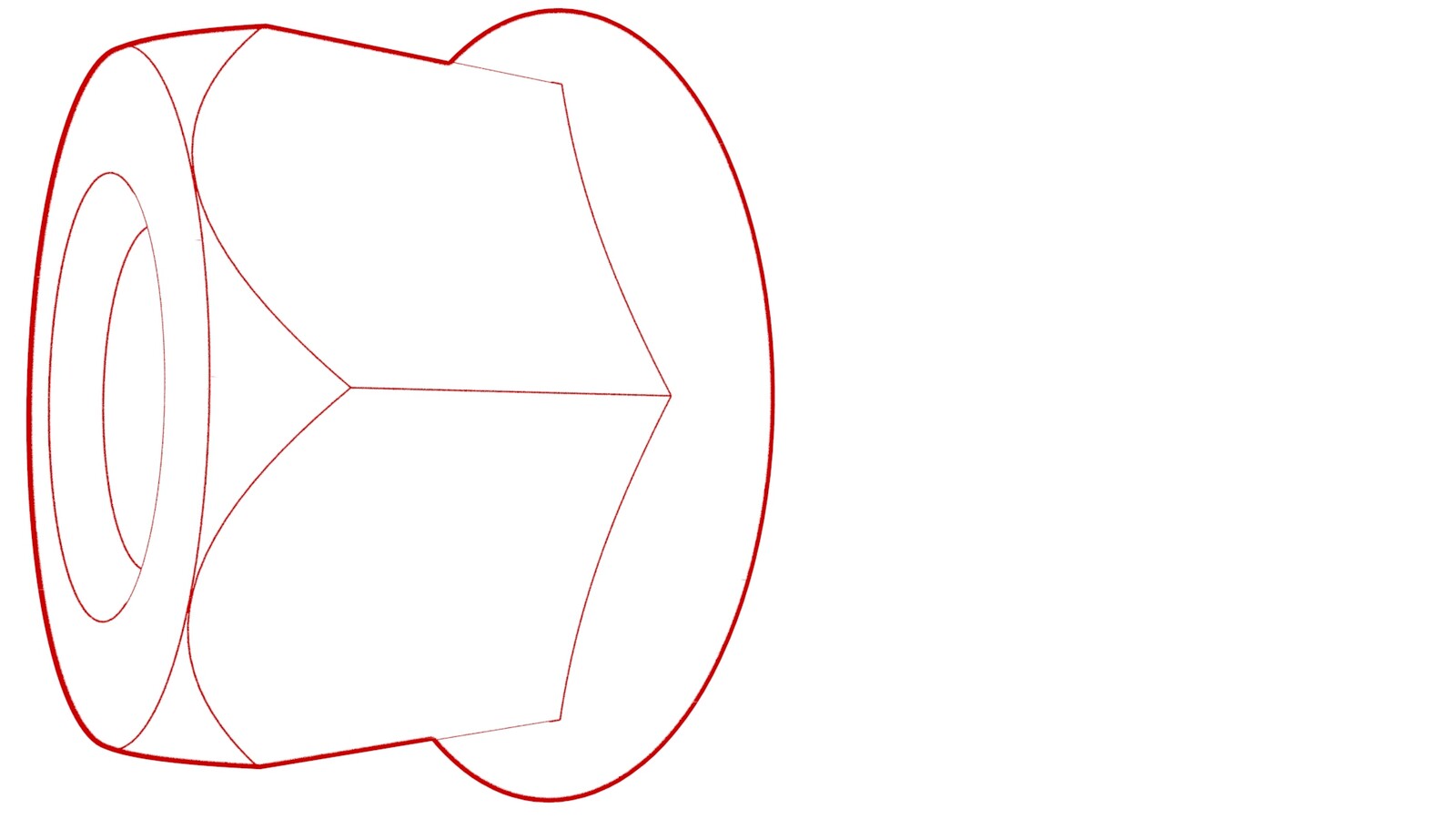

-

Install the nuts (x3) that

attach the front upper control arm mount to the LH and RH front spring and

damper assembly.

23 Nm (17.0 lbs-ft)NoteUse of the following tool(s) is recommended:

23 Nm (17.0 lbs-ft)NoteUse of the following tool(s) is recommended:- 13 mm deep socket

- 3 in extension

Figure 11. LH side shown, RH side similar - Raise the vehicle to a comfortable working height and support onto locks.

-

Maneuver the front stabar

link assembly for installing to the LH front strut.

TIpMove the stabilizer bar up and/or down to get the correct angle for installation.

-

Install a new nyloc nut that

attaches the front stabar link to the front strut.

98 Nm (72.3 lbs-ft)NoteCounter hold ball joint while installing the nut.NoteUse of the following tool(s) is recommended:

98 Nm (72.3 lbs-ft)NoteCounter hold ball joint while installing the nut.NoteUse of the following tool(s) is recommended:- 18 mm wrench

- 18 mm socket (torque)

- T40 socket

- 6 in extension

Figure 12. LH side shown, RH side similar -

Install the bolt and a new

nyloc nut that attach the LH front upper control arm to the knuckle.

56 Nm (41.3 lbs-ft)TIpCompress the joint to allow the bolt to be installed.NoteUse of the following tool(s) is recommended:

56 Nm (41.3 lbs-ft)TIpCompress the joint to allow the bolt to be installed.NoteUse of the following tool(s) is recommended:- T47 socket

- 15 mm wrench

Figure 13. LH side shown, RH side similar -

Install the nut that

attaches the front jounce bracket to the stud on the body.

6 Nm (4.4 lbs-ft)NoteThe bracket has an alignment tab to aid installation.NoteUse of the following tool(s) is recommended:

6 Nm (4.4 lbs-ft)NoteThe bracket has an alignment tab to aid installation.NoteUse of the following tool(s) is recommended:- 10 mm deep socket

- 4 in extension

Figure 14. LH side shown, RH side similar -

Install the clips (x2) that

attach the front wheel speed sensor harness to the knuckle.

Figure 15. LH side shown, RH side similar -

Install the bolt that

attaches the front wheel speed sensor to the knuckle.

5 Nm (3.7 lbs-ft)NoteUse of the following tool(s) is recommended:

5 Nm (3.7 lbs-ft)NoteUse of the following tool(s) is recommended:- 10 mm deep socket

- 4 in extension

Figure 16. LH side shown, RH side similar -

Remove the bolt that

attaches the LH front brake rotor to the hub.

Figure 17. LH side shown, RH side similar -

Install the hub jack adapter

onto the LH front hub and hand-tighten the lug nuts.

Figure 18. LH side shown, RH side similar -

Use an underhoist stand to

support the hub jack adapter.

Figure 19. LH side shown, RH side similar -

Measure the distance between

the bottom of the fender panel and the center of the front axle and adjust

the underhoist stand so that the front suspension is set to ride

height.

NoteFor proper ride height, the distance should be 461 mm.

Figure 20. Illustration for indication purpose only -

Torque the bolt and nut that

attach the strut to the lower control arm.

106 Nm (78.2 lbs-ft)TIpUse of the following tool(s) is recommended:

106 Nm (78.2 lbs-ft)TIpUse of the following tool(s) is recommended:- 21 mm socket

- 21 mm wrench

Figure 21. LH side shown, RH side similar -

Remove the underhoist stand

from underneath the LH front suspension.

Figure 22. LH side shown, RH side similar -

Remove the lug nuts that

attach the hub jack adapter, and then remove the hub jack adapter from the

vehicle.

Figure 23. LH side shown, RH side similar -

Install the bolt that

attaches the LH front brake rotor to the hub.

5 Nm (3.7 lbs-ft)

5 Nm (3.7 lbs-ft)Figure 24. LH side shown, RH side similar - Repeat steps 13 through 20 on the RH side of the vehicle.

- Install the front LH and RH front wheels. See Wheel Assembly (Remove and Install).

- Install the windshield washer reservoir filler neck. See Filler Neck - Reservoir - Windshield Washer (LHD) (Remove and Replace).

- Install the fresh air intake duct. See Duct - Fresh Intake (Remove and Replace).

- Install the rear underhood apron. See Underhood Apron - Rear (Remove and Replace).

- Refer to the Alignment Requirement tables to determine whether an EPAS alignment check (EC) or four wheel alignment check (AC) is necessary. If performed, add the alignment check/adjust correction code as a separate activity to the SV. See Alignment Requirement - Suspension.