Inverter - Rear Drive Unit (3DU) (Remove and Replace)

Correction code

40200602

2.88

NOTE: Unless otherwise explicitly

stated in the procedure, the above correction code and FRT reflect all of the work

required to perform this procedure, including the linked procedures. Do not stack correction codes unless

explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how they are created. To provide feedback on

FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when

performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

Correction code

40200602

2.88

NOTE: Unless otherwise explicitly

stated in the procedure, the above correction code and FRT reflect all of the work

required to perform this procedure, including the linked procedures. Do not stack correction codes unless

explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how they are created. To provide feedback on

FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when

performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

- 2025-06-12: Updated the mount bolts and inverter bolts from "reuse" to "replace".

- 2024-12-04: Updated inverter fastener torque sequence.

- 2024-04-05: Updated gearbox fluid information with link.

- 2024-02-27: Updated gearbox fluid to KAF 1.

- 2023-10-10: Added note to make sure that correct ground strap is available.

- 2023-07-25: Removed resolver error learn substeps.

- 2023-07-17: Removed photos showing bare hands.

Equipment:

- 1130479-00-A Skt, 3/8in Dr, 10EP Torx Plus External

- 1140311-00-A Lever Lock, HV Connector, Model 3

- 1450875-00-A Kit, Inverter Leak Test Adapter, M3

- 1026636-00-A Pack Enclosure Leak Tester, HV Battery

- 1140311-00-A Lever Lock, HV Connector, Model 3

Remove

- While performing the courtesy inspection, note any abnormal tire wear that could indicate the need for an alignment.

- Move the vehicle to a 2 post lift. See Raise Vehicle - 2 Post Lift.

-

Place stanchions around the

rear of the vehicle to setup a safety perimeter.

- Verify that the vehicle firmware is version 2022.20.6 or later. Update the vehicle firmware if this is not the case. See Software Update.

- Connect a laptop with Toolbox 3 to the vehicle. See Toolbox (Connect and Disconnect).

-

In Toolbox 3, click the

Dashboards tab, and type ‘Rear Drive Inverter Replacement'

into the search field, and click [Model 3/Y] REAR Drive

INVERTER - Replacement.

-

From the BEFORE INVERTER

SWAP Action List, click Store Drive Inverter

Bootloader Data before Replacement, click Run, and

allow the routine to complete.

- From the BEFORE INVERTER SWAP Action List, click Store Drive Inverter Application Data before Replacement, click Run, and allow the routine to complete.

- From the BEFORE INVERTER SWAP Action List, click Start Thermal Fluid Fill/Drain (Coolant only), click Run, and allow the routine to complete.

-

Disconnect the laptop with

Toolbox 3 from the vehicle. See Toolbox (Connect and Disconnect).

NoteDo not close this instance of Toolbox 3 as it is needed later on in the procedure.

- Remove the rear underhood apron. See Underhood Apron - Rear (Remove and Replace).

- Remove the cabin intake duct. See Duct - Upper - Cabin Intake (Remove and Replace).

- Remove the outer HVAC plenum duct. See Plenum - Inlet - HVAC (Remove and Replace).

- Disconnect LV power. See 12V/LV Power (Disconnect and Connect).

- Perform Vehicle HV Disablement Procedure. See Vehicle HV Disablement Procedure.

- Remove the LH and RH rear wheels. See Wheel (Remove and Replace).

- Remove the LH and RH rear suspension covers. See Cover - Rear Suspension - LH (Remove and Replace).

- Remove the mid aero shield panel. See Panel - Aero Shield - Rear (Remove and Replace).

- Remove the rear diffuser. See Diffuser - Rear Fascia (Remove and Replace).

-

Disconnect the electrical harness

from the rear subframe harness RH connector.

-

Release the clip that

attaches the rear subframe harness to the body on the RH side.

-

Disconnect the electrical harness

from the rear subframe harness LH connector.

-

Release the clip that

attaches the rear subframe harness to the body on the LH side.

-

Remove the nut that attaches

the rear drive unit ground strap to the body in the LH rear wheel arch, and

then remove the ground strap from the body.

-

Remove and discard the nut

that attaches the LH rear stabilizer bar end link to the rear stabilizer

bar.

NoteUse a 5mm allen wrench to prevent the ball joint stud from turning and damaging the ball joint.

-

Remove LH rear stabilizer

bar end link from the rear stabilizer bar.

NoteMove the stabilizer bar up and down to ease removal of the end link.

-

Remove and discard the nut

that attaches the RH rear stabilizer bar end link to the rear stabilizer

bar.

NoteUse a 5mm allen wrench to prevent the ball joint stud from turning and damaging the ball joint.

-

Remove RH rear stabilizer

bar end link from the rear stabilizer bar.

NoteMove the stabilizer bar up and down to ease removal of the end link.

-

Remove and discard the bolts

(x4) that attach the rear stabilizer bar to the rear subframe, and then

remove the stabilizer bar from the subframe.

-

Release the clips (x2) that

attach the coolant hoses to LH shear plate.

-

Release the clips (x4) that

secure coolant hoses to the rear skid plate.

NoteClip quantity varies with older vehicles.

-

Release the clips (x2) that

attach the coolant hoses to RH shear plate.

- Remove the HV battery rear skid plate. See Skid Plate - HV Battery - Rear (Remove and Replace).

-

Position a coolant drain

collector underneath the LH rear of the HV battery.

-

Release the clip, disconnect

the rear drive unit inverter inlet hose from the HV battery, and then

immediately plug both fittings.

-

Release the clip, disconnect

the rear drive unit inverter inlet hose from the rear drive unit inverter,

and then immediately plug both fittings.

-

Release the clip that

attaches the rear drive unit inverter inlet tube from rear drive unit HV

harness.

-

Remove the rear drive unit

inverter inlet tube down and out from between the rear subframe and the HV

battery.

-

Remove the coolant drain

collector from under the vehicle.

-

Release the locking tab,

push the handle downward, and then disconnect the rear subframe electrical

harness from the rear drive unit inverter logic connector.

CAUTIONOnce disconnected, make sure that coolant does not get into the connectors.

-

Release the clip that

attaches the rear subframe electrical harness to the rear drive unit

inverter.

- Put on HV gloves and leather overgloves.

-

Remove the bolt that

attaches the rear drive unit HV harness bracket to the rear drive unit

inverter.

-

Slide the red locking tab,

raise the black handle, disconnect the rear drive unit HV harness from the

rear drive unit inverter HV header,and then set the HV harness aside.

-

Remove the nut(s) that

attach(es) the rear drive unit HV harness bracket to the HV

battery.

-

Slide the red locking tab,

raise the black handle, and then disconnect the rear drive unit HV harness

from the HV battery header.

-

Remove the rear drive unit

HV harness down and out from between the rear subframe and the HV

battery.

NoteRotate the harness as it is removed to allow access for the bracket.

- Remove HV gloves and leather overgloves.

-

Position the subframe

lifting tool under, and up against the rear subframe.

-

With the help of an

assistant, fully secure the straps (x3) that attach the rear subframe to the

subframe lifting tool.

-

Use a paint pen to trace

around the LH and RH rear subframe mounting bolts, so that the bolts can be

realigned later during the subframe installation.

-

Use a paint pen to apply a

witness mark where the rear subframe contacts the body at the LH and RH rear

subframe mounting bolts, so that the subframe can be realigned to the body

later during subframe installation.

-

Remove the small bolts (x2)

that attach the LH shear plate to the HV battery.

-

Remove the large bolt that

attaches the LH shear plate and rear subframe to the body, and then remove

shear plate.

-

Remove the small bolts (x2)

that attach the RH shear plate to the HV battery.

-

Remove the large bolt that

attaches the RH shear plate and rear subframe to the body, and then remove

shear plate.

-

Remove and discard the LH

rear subframe bolt that attaches the subframe to the body.

-

Remove and discard the RH

rear subframe bolt that attaches the subframe to the body.

-

Carefully lower the subframe

and rear drive unit assembly approximately 8.25 cm (3.25 in) from the

vehicle.

WarningDo not lower the subframe any more than 8.25 cm (3.25 in) as suspension and brake components are still attached to both the subframe and the body.

-

Tilt the subframe fixture

forward in order to access motor mount fasteners.

-

Insert a rubber or wood

block between the rear drive unit and the subframe fixture so as to support

the rear drive unit while the LH mount is removed.

-

Remove the LH mount bolt

that attaches the rear drive unit LH mount to the rear

subframe.

NoteUse a pry bar between the block and rear drive unit to unload the bolt so that it can be removed.

-

Release the clip that

attaches the rear drive unit ground strap to the rear subframe.

-

Release the clip, disconnect

the rear drive unit inverter to heat exchanger hose from the rear drive unit

inverter outlet, and then immediately plug both fittings.

-

Release the clip that

attaches the rear drive unit inverter to heat exchanger hose to the rear

drive unit LH mount.

-

Remove and discard the bolts

(x3) that attach the rear drive unit LH mount to the rear drive

unit.

-

Remove the rear drive unit

LH mount up, over, and out between the rear subframe and the body.

-

Put on the ESD wrist strap

and attach it to the rear drive unit inverter housing.

-

Remove and discard the rear

drive unit phase out cover label to access the bolts behind.

-

Remove the bolts (x2) that

attach the phase out cover to the rear drive unit gearbox, and then use a

plastic trim tool to remove the cover from the gearbox.

-

Inspect the condition of the

phase out cover and O-rings. If the cover has less than 6 O-rings, or if the

O-rings or cover are damaged, discard the cover and use a new cover, part

1096984-00-C or newer revision, for installation.

-

Remove the bolts (x3) that

attach the rear drive unit motor 3-phase terminals to the rear drive unit LH

inverter 3-phase terminals.

-

Remove and discard the bolts

(x12) that attach the rear drive unit inverter to the rear drive unit

gearbox.

-

Carefully remove the rear

drive unit inverter from the rear drive unit gearbox, and move the inverter

down and out between the rear subframe and drive unit.

CAUTIONTake care not to damage the inverter circuit board when removing the inverter.

- Remove the plugs from the inverter and drain the coolant.

-

Set the rear drive unit

inverter onto an ESD mat, and then remove the ESD wrist strap clip from the

inverter housing.

-

Inspect the rear drive unit

gearbox housing to make sure that there is no gap pad stuck there. If there

is, remove the gap pad, clean the area with an alcohol wipe, and allow at

least one minute to dry.

NoteAlso inspect the gearbox housing and remove any dropped fasteners or loose debris.

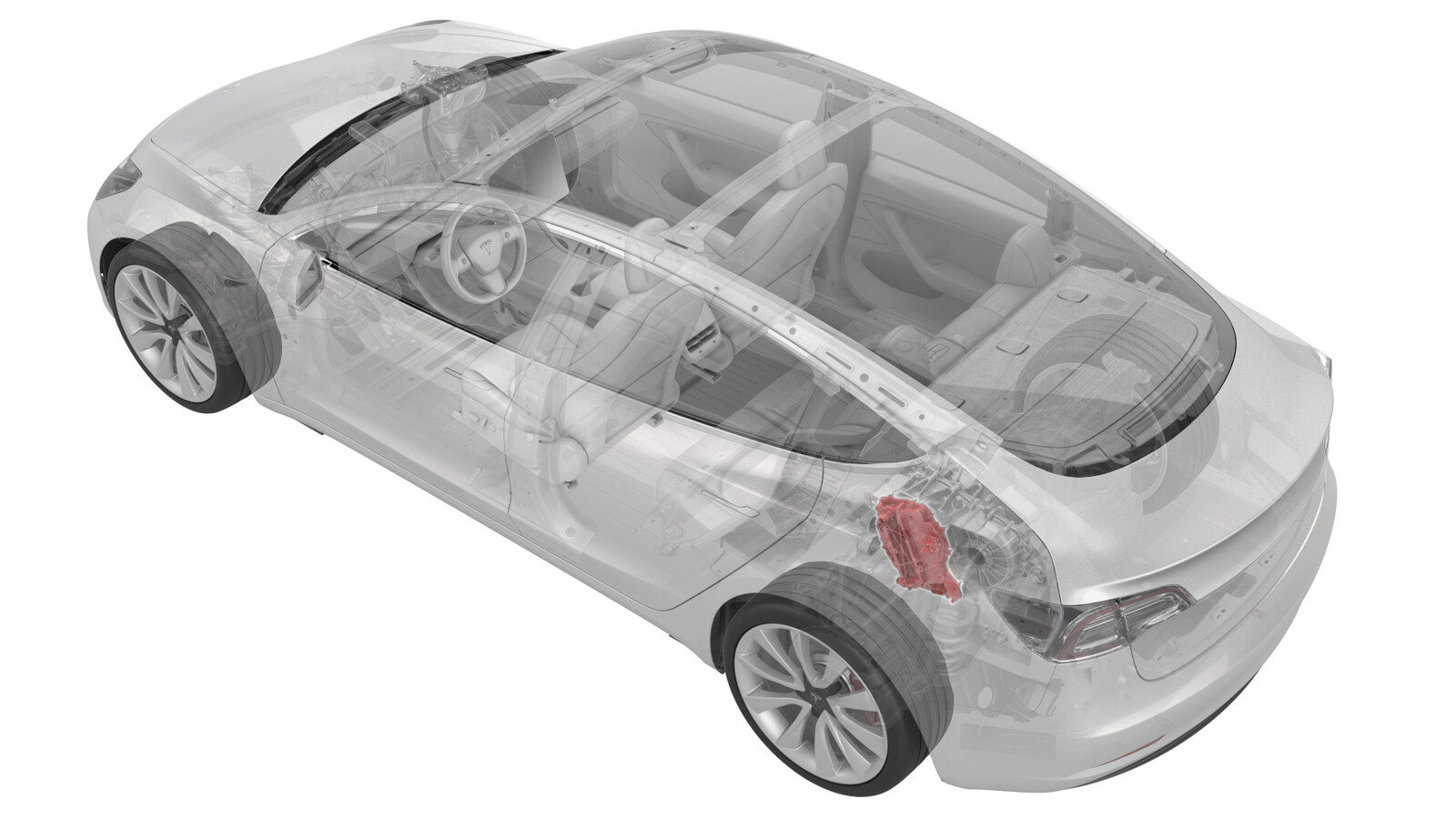

Figure 1. Gap pad installed on the rear drive unit inverter PCB

Install

-

Prepare the new rear drive unit inverter and attach the ESD strap to the

new inverter housing

-

Use an IPA wipe to clean the phase terminals of the rear drive unit motor

and the new rear drive unit inverter, and allow at least one minute to

dry.

-

Inspect the condition of the gap pad on the new rear drive unit inverter

PCB. Replace the gap pad if it does not fulfill these criteria:

- New and undamaged condition.

- Fully covers the discharge resistor array and no resistors are visible.

- Clean and free of debris.

- Evenly adhered to the inverter PCB.

-

Make sure that a new gasket

is installed onto the new rear drive unit inverter.

-

Carefully install the new rear drive unit inverter in and up between the

rear subframe and rear drive unit. Align the inverter to the 2 pins in the

rear drive unit gearbox, and then install the inverter to the gearbox.

CAUTIONTake care not to damage the inverter circuit board when installing the inverter.NoteMake sure that the phase terminals align during installation.

-

Install and hand-tighten new

bolts (x12) that attach the new rear drive unit inverter to the rear drive

unit LH gearbox.

-

Tighten the 2 bolts nearest

the alignment dowels first, and then tighten the remaining bolts (x10) that

attach the new rear drive unit inverter to the rear drive unit

gearbox.

12.5 Nm (9.2 lbs-ft)

12.5 Nm (9.2 lbs-ft) -

Install and hand-tighten the bolts (x3) that attach the rear drive unit

motor 3-phase terminals to the new rear drive unit inverter 3-phase

terminals.

-

Tighten the bolts (x3) that attach the rear drive unit motor 3-phase

terminals to the new rear drive unit inverter 3-phase

terminals.

11.5 Nm (8.5 lbs-ft)CAUTIONIf any bolts are dropped into the gearbox housing, they must be retrieved.NoteIf installing a new bolt, tighten to 12.5 Nm, back off 180 degrees, then torque to 5 Nm +40 degrees.

11.5 Nm (8.5 lbs-ft)CAUTIONIf any bolts are dropped into the gearbox housing, they must be retrieved.NoteIf installing a new bolt, tighten to 12.5 Nm, back off 180 degrees, then torque to 5 Nm +40 degrees. -

Lightly lubricate the rear

drive unit gearbox phase out cover bores with clean gearbox fluid, and if a

new phase out cover is to be installed, lightly lubricate the O-rings of the

cover.

NoteRefer to Fluids and Capacities to determine which gearbox fluid is applicable.

-

Install the phase out cover into the rear drive unit gearbox, and then

install the bolts (x2) that attach the cover to the gearbox.

14 Nm (10.3 lbs-ft)

14 Nm (10.3 lbs-ft) -

Install a new phase out cover label.

-

Remove the ESD wrist strap from the new inverter, attach it to the old

inverter, and prepare the old inverter for shipment to MRB.

- Perform an inverter air leak test. See Inverter Air Leak Test.

-

Install the rear drive unit LH mount in, over, and down between the rear

subframe and the body.

-

Install the rear drive unit

LH mount to the rear drive unit, and then install and hand-tighten new bolts

(x3) that attach the mount to the drive unit.

NoteMount Bolt PN: 1111864-00-B

-

Tighten the bolts (x3) that attach the rear drive unit LH mount to the rear

drive unit in the sequence shown.

35 Nm (25.8 lbs-ft) +55 deg

35 Nm (25.8 lbs-ft) +55 deg -

Install the LH mount bolt that attaches the rear drive unit LH mount to the

rear subframe.

80 Nm (59.0 lbs-ft)NoteUse a pry bar between the block and rear drive unit to position the mount so that the bolt can be installed.

80 Nm (59.0 lbs-ft)NoteUse a pry bar between the block and rear drive unit to position the mount so that the bolt can be installed. -

Remove the block from between the rear drive unit and the subframe

fixture.

-

Remove the plugs from the fittings, immediately connect the rear drive unit

inverter to heat exchanger hose to the rear drive unit inverter outlet,

fasten the clip, and then perform a Push-Pull-Push check of the

fitting.

-

Fasten the clip that attaches the rear drive unit inverter to heat

exchanger hose to the rear drive unit LH mount.

-

Fasten the clip that

attaches the rear drive unit ground strap to the rear subframe.

-

Tilt the subframe fixture backward to its original position.

-

Carefully raise the subframe and rear drive unit assembly until they are up

against the body.

CAUTIONBe mindful of the suspension and brake components that are still attached to both the subframe and the body.

-

Install and hand-tighten a new RH rear subframe bolt to attach the rear

subframe to the body.

-

Install and hand-tighten a new LH rear subframe bolt to attach the rear

subframe to the body.

-

Install the RH shear plate to the rear subframe, and then install a new

large bolt to attach the RH shear plate and rear subframe to the

body.

-

Install and hand-tighten the small bolts (x2) that attach the RH shear

plate to the HV battery.

-

Install the LH shear plate to the rear subframe, and then install a new

large bolt to attach the LH shear plate and rear subframe to the

body.

-

Install and hand-tighten the small bolts (x2) that attach the LH shear

plate to the HV battery.

-

Use a pry bar to shimmy the

rear subframe with respect to the body, so that the subframe mounting bolts

are centered in the tracings, and the witness marks align where the subframe

contacts the body.

-

Tighten the RH rear subframe

bolt that attaches the rear subframe to the body, and then mark the bolt

after tightening.

165 Nm (121.7 lbs-ft)

165 Nm (121.7 lbs-ft) -

Tighten the LH rear subframe

bolt that attaches the rear subframe to the body, and then mark the bolt

after tightening.

165 Nm (121.7 lbs-ft)

165 Nm (121.7 lbs-ft) -

Tighten large bolt that

attaches the LH shear plate and rear subframe to the body, and then mark the

bolt after tightening.

130 Nm (95.9 lbs-ft)

130 Nm (95.9 lbs-ft) -

Tighten large bolt that

attaches the RH shear plate and rear subframe to the body, and then mark the

bolt after tightening.

130 Nm (95.9 lbs-ft)

130 Nm (95.9 lbs-ft) -

Tighten the small bolts (x2) that attach the RH shear plate to the HV

battery.

35 Nm (25.8 lbs-ft)

35 Nm (25.8 lbs-ft) -

Tighten the small bolts (x2) that attach the LH shear plate to the HV

battery.

35 Nm (25.8 lbs-ft)

35 Nm (25.8 lbs-ft) -

Release the straps (x3) that attach the rear subframe to the subframe

lifting tool.

-

Lower the subframe lifting

tool, and move it out from under the vehicle.

- Put on HV gloves and leather overgloves.

-

Install the rear drive unit HV harness in and up between the rear subframe

and the HV battery.

NoteRotate the harness as it is installed to allow access for the bracket.

-

Verify that the black release lever of the rear drive unit HV harness

connector is in the open position, install the connector flat and square to

the HV battery header, secure the release lever to the closed position, and

then slide the red connector locking tab.

-

Install the nut(s) that

attach(es) the rear drive unit HV harness bracket to the HV

battery.

10 Nm (7.4 lbs-ft)

10 Nm (7.4 lbs-ft) -

Verify that the black release lever of the rear drive unit HV harness

connector is in the open position, install the connector flat and square to

the rear drive unit inverter HV header, secure the release lever to the

closed position, and then slide the red connector locking tab.

-

Install the bolt that attaches the rear drive unit HV harness bracket to

the rear drive unit inverter.

6 Nm (4.4 lbs-ft)

6 Nm (4.4 lbs-ft) - Remove the HV gloves and leather overgloves.

- Inspect the rear subframe electrical harness logic connector and the rear drive unit inverter logic connector for coolant, and use shop air and a clean dry shop towel to remove any coolant from the connectors.

-

Connect the rear subframe

electrical harness to the rear drive unit inverter logic connector, raise

the handle upward, and fasten the locking tab.

-

Fasten the clip that attaches the rear subframe electrical harness to the

rear drive unit inverter.

-

Position a coolant drain collector underneath the LH rear of the HV

battery.

-

Install the rear drive unit inverter inlet tube in and up between the rear

subframe and the HV battery.

-

Fasten the clip that attaches the rear drive unit inverter inlet tube to

rear drive unit HV harness.

-

Remove the plugs from the fittings, immediately connect the rear drive unit

inverter inlet hose to the HV battery, fasten the clip, and then perform a

Push-Pull-Push check of the fitting.

-

Remove the plugs from the

fittings, immediately connect the rear drive unit inverter inlet hose to the

rear drive unit inverter, fasten the clip, and then perform a Push-Pull-Push

check of the fitting.

-

Remove the coolant drain collector from under the vehicle.

-

Fasten the barrel clip that attaches the rear drive unit inverter inlet

hose to the HV battery.

- Install the HV battery rear skid plate. See Skid Plate - HV Battery - Rear (Remove and Replace).

-

Fasten the clips (x2) that attach the coolant hoses to RH shear

plate.

-

Fasten the clips (x4) that secure coolant hoses to the rear skid

plate.

NoteClip quantity varies with older vehicles.

-

Fasten the clips (x2) that attach the coolant hoses to LH shear

plate.

-

Install the rear stabilizer bar to the rear subframe, and then install new

bolts (x4) to attach the stabilizer bar to the subframe.

30 Nm (22.1 lbs-ft)

30 Nm (22.1 lbs-ft) -

Install the LH rear stabilizer bar end link into the rear stabilizer

bar.

NoteMove the stabilizer bar up and down to ease installation of the end link.

-

Install a new nut to attach the LH rear stabilizer bar end link to the rear

stabilizer bar.

55 Nm (40.6 lbs-ft)NoteUse a 5mm allen wrench to prevent the ball joint stud from turning and damaging the ball joint.

55 Nm (40.6 lbs-ft)NoteUse a 5mm allen wrench to prevent the ball joint stud from turning and damaging the ball joint. -

Install the RH rear stabilizer bar end link into the rear stabilizer

bar.

NoteMove the stabilizer bar up and down to ease installation of the end link.

-

Install a new nut to attach the RH rear stabilizer bar end link to the rear

stabilizer bar.

55 Nm (40.6 lbs-ft)NoteUse a 5mm allen wrench to prevent the ball joint stud from turning and damaging the ball joint.

55 Nm (40.6 lbs-ft)NoteUse a 5mm allen wrench to prevent the ball joint stud from turning and damaging the ball joint. -

Install the rear drive unit ground strap to the body in the LH rear wheel

arch, and then install the nut that attaches the ground strap to the

body.

10 Nm (7.4 lbs-ft)

10 Nm (7.4 lbs-ft) -

Fasten the clip that attaches the rear subframe harness to the body on the

LH side.

-

Connect electrical harness to the rear subframe harness LH connector.

-

Fasten the clip that attaches the rear subframe harness to the body on the

RH side.

-

Connect electrical harness to the rear subframe harness RH connector.

- Install the rear diffuser. See Diffuser - Rear Fascia (Remove and Replace).

- Install the mid aero shield panel. See Panel - Aero Shield - Rear (Remove and Replace).

- Install the LH and RH rear suspension covers. See Cover - Rear Suspension - LH (Remove and Replace).

- Perform a cooling system vacuum refill. See Cooling System (Vacuum Refill).

- Connect LV power. See 12V/LV Power (Disconnect and Connect).

- Connect an LV maintainer to the vehicle, and then disconnect the LV battery. See LV Maintainer (Connect and Disconnect).

- Reconnect the laptop with Toolbox 3 to the vehicle.

-

In Toolbox 3, click the

Dashboards tab, and type ‘Rear Drive Inverter Replacement'

into the search field, and click [Model 3/Y] REAR Drive

INVERTER - Replacement.

-

From the AFTER INVERTER SWAP

Action List, click Stop Thermal Fluid Fill/Drain, click Run, and

allow the routine to complete.

- From the AFTER INVERTER SWAP Action List, click Restore REAR Drive INVERTER Bootloader Data after Replacement and Usage ID Configuration, click Run, and allow the routine to complete.

- From the AFTER INVERTER SWAP Action List, click Service CAN Redeploy, click Run, and allow the update to finish.

- Reconnect the LV battery, and then disconnect the LV maintainer. See LV Maintainer (Connect and Disconnect).

- From the AFTER INVERTER SWAP Action List, click Restore Drive Inverter Application Data after Replacement, click Run, and allow the routine to complete.

- From the AFTER INVERTER SWAP Action List, click Secure pairing (immobilizer pairing) between the Security Controller and Drive Inverter and Vehicle Odometer Pairing to UI, click Run, and allow the routine to complete.

- From the AFTER INVERTER SWAP Action List, click Coolant Air Purge, click Run, and allow the routine to complete.

- From the AFTER INVERTER SWAP Action List, click Thermal System Performance Test, click Run, and allow the routine to complete.

-

Add coolant to the reservoir as necessary, and install the reservoir

cap.

-

Manually engage the hood latch.

NoteIf the hood is open, or if the hood latch is not manually engaged, the vehicle speed will be limited and the resolver learn routine will fail.

- Touch the brake pedal to ensure the drive rails are on.

-

From the RESOLVER LEARN Action List, click Rear Drive Unit Resolver Error Learning, click Run, and follow the displayed instructions.

- Disconnect the laptop with Toolbox 3 from the vehicle.

- Install the LH and RH rear wheels. See Wheel (Remove and Replace).

-

Remove the stanchions from the rear of the vehicle.

- On the vehicle touchscreen, open the hood to disengage the hood latch.

- Install the outer HVAC plenum duct. See Plenum - Inlet - HVAC (Remove and Replace).

- Install the cabin intake duct. See Duct - Upper - Cabin Intake (Remove and Replace).

- Install the rear underhood apron. See Underhood Apron - Rear (Remove and Replace).

- Remove the vehicle from the 2 post lift. See Raise Vehicle - 2 Post Lift.

-

Perform a validation test drive at road and highway speeds to determine if an alignment check is necessary.

- If the test drive shows the vehicle to track poorly or pull to the side, or if steering is sloppy or off center, then perform a four wheel alignment check. See Four Wheel Alignment Check, and add this service to the SV.

- If the test drive shows the vehicle to steer and handle as expected, then an alignment check is not necessary.