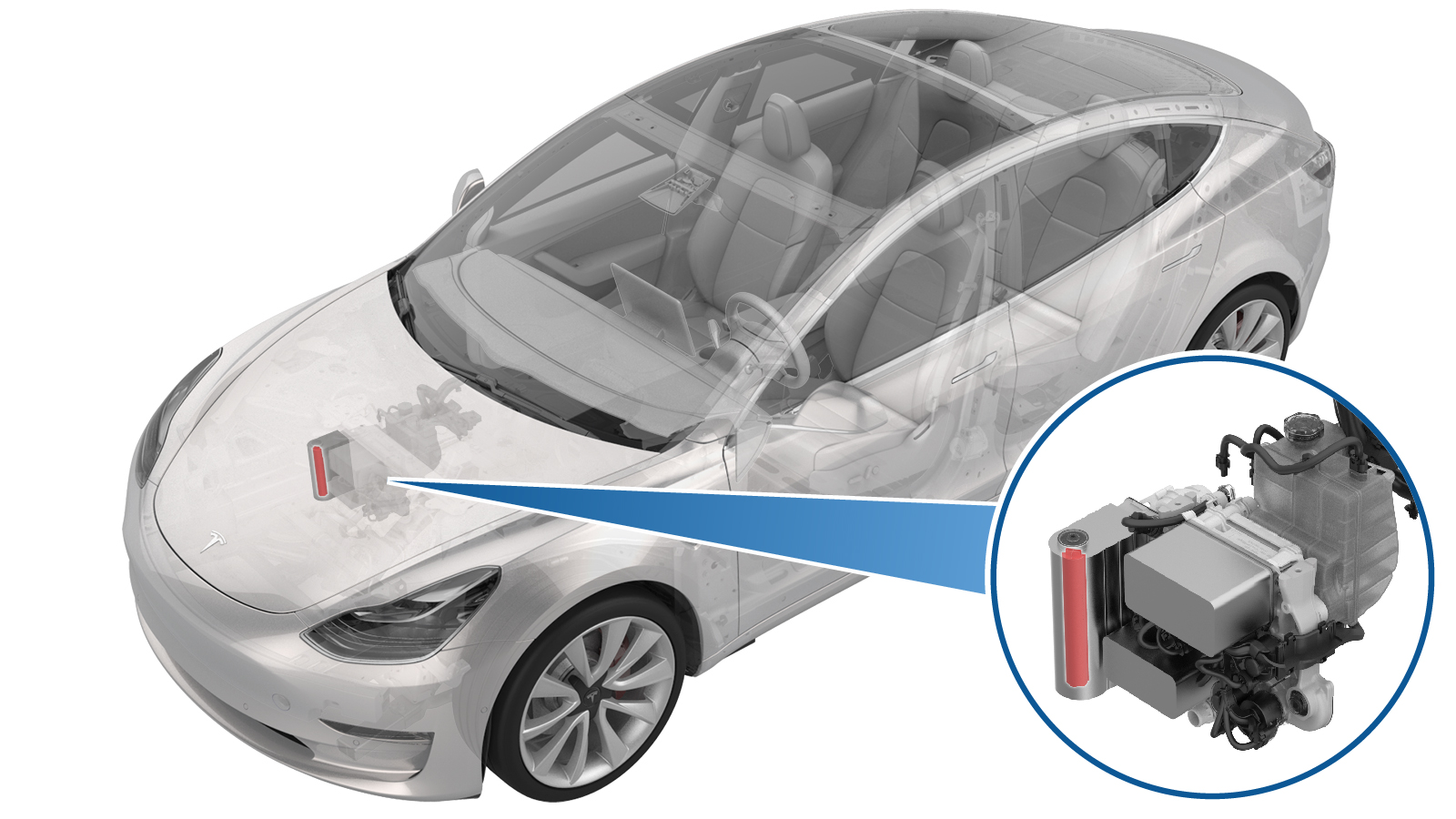

Desiccant (Heat Pump) (Remove and Replace)

Correction code

18202012

0.36

NOTE: Unless otherwise explicitly

stated in the procedure, the above correction code and FRT reflect all of the work

required to perform this procedure, including the linked procedures. Do not stack correction codes unless

explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how they are created. To provide feedback on

FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when

performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

Correction code

18202012

0.36

NOTE: Unless otherwise explicitly

stated in the procedure, the above correction code and FRT reflect all of the work

required to perform this procedure, including the linked procedures. Do not stack correction codes unless

explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how they are created. To provide feedback on

FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when

performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

-

2025-11-19:

Removed the

Test HVAC Performance

andTest Thermal Performance

routines. - 2025-05-08: Added additional step to check refrigerant system pressure on the touchscreen after refrigerant recovery.

- 2024-09-10: Added warnings to wear suitable protective clothing, consisting of face and eye protection, heat-proof gloves, rubber boots and apron or waterproof overalls must be worn when carrying out operations on the air conditioning system.

- 2024-08-28: Added note on adding correction code for refrigerant recovery/recharge 18200102 as a separate activity to the service visit, added special tools for accumulator cap removal.

- 2024-03-19: Added A/C compressor oil density note.

- 2023-04-04: Updated A/C oil type to be used with reference to Fluids and Capacities for A/C oil specifications.

- 2023-08-23: Added reminding of wearing PPEs.

- 2024-03-01: Updated the way of performing the routines from using Toolbox to using the touchscreen.

- 2024-04-02: Added reminding of checking the pressure of A/C system before opening the accumulator.

Equipment:

- 1081547-00-B SMALL SLIDE HAMMER

- 1985068-00-A FEMALE TO FEMALE THREADED ADAPTER

Torque Specifications

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Accumulator dust cap | Hand-tight |

|

Replace |

Remove

- Remove the underhood storage unit. See Underhood Storage Unit (Remove and Replace).

- Place the vehicle in Service Mode by using the touchscreen. See Service Mode.

- Unlock the vehicle gateway. See Gateway (Unlock).

- On the touchscreen, tap the Service Mode "wrench" (at the bottom of the touchscreen UI), and then tap , click Run, and allow the routine to complete.

- Disconnect 12V/LV power. See 12V/LV Power (Disconnect and Connect).

-

Recover the A/C refrigerant.

See Recovery (Heat Pump Model 3).

WarningMake sure there is no overpressure in the A/C system before performing the following steps. Failure to do so may result in damage to components and/or personal injury.

-

On the touchscreen, make sure that the refrigerant system pressure is at atmospheric level (approx. 1 bar).

NoteOn the touchscreen, touch .

- Remove the A/C hoses from vehicle.

-

Carefully depress the Schrader valves (x2) to level out any pressure difference between the A/C system pressure and the actual ambient atmospheric pressure.

CAUTIONMake sure to depress both Schrader valves. Failure to do so may result in injury.

-

If present, remove and

discard the dust cap from the accumulator.

NoteUse of the following tool(s) is recommended:

- Torx T30 socket

-

Use snap ring pliers to

remove and discard the accumulator cap snap ring.

WarningWear the Face Shield throughout the entire process to protect against foreign objects flying out under pressure.

-

Thread the female to female threaded

adapter onto the slide hammer, thread adapter onto the accumulator cap, and then use the

slide hammer to remove the accumulator cap.

NoteDiscard the accumulator cap after removal.

-

Use needle nose pliers to

remove the desiccant bag from the accumulator.

- Weigh the desiccant bag. This is considered the "wet weight."

- Determine the "dry weight" of the desiccant bag: Inspect the bag for a label that contains the Part Number (P), Serial Number (S), and Dry Weight (W). If the label is missing, or if the dry weight is not visible, assume the dry weight is 90.4 grams.

- Subtract the dry weight from the wet weight. This is the amount of oil that must be added to the system in addition to the oil that was removed during refrigerant recovery. Note this amount for later.

Install

-

Install the desiccant bag in the accumulator.

NoteMake sure the tab on the desiccant bag faces upward.

-

Lubricate the new

accumulator cap O-rings with the appropriate A/C oil. See Fluids and Capacities for A/C oil

specifications. Then install the cap on the accumulator.

-

Use the snap ring pliers to

install the new accumulator cap snap ring.

WarningWear the Face Shield throughout the entire process to protect against foreign objects flying out under pressure.NoteMake sure the snap ring is fully seated in the groove on the inside of the accumulator bore.

-

Hand-tighten the new dust cap to the

accumulator.

NoteScrew the dust cap until it bottoms out on the accumulator.NoteUse of the following tool(s) is recommended:

- Torx T30 socket

- Install A/C hoses to the vehicle.

- Initiate and complete the vacuum leak test, then return to this procedure. See Vacuum Leak Test and Oil Injection (Heat Pump Model 3).

- Remove the low side A/C hose from the supermanifold to HVAC A/C line assembly.

-

Inject the amount of oil

that was lost to:

- Removal of the old desiccant bag. See step 16.

- Refrigerant recovery. See Vacuum Leak Test and Oil Injection (Heat Pump Model 3).

CAUTIONDO NOT forget to inject the amount of oil that was lost to removal of the old desiccant bag. Failure to do so might cause catastrophic damage to the thermal system.NoteFor calculations, both ND-11 and RB100EV compressor oils have a density of 0.98 grams/ml at 15°C.- Given a value in grams, divide by 0.98 to find the value in ml (milliliters or cc).

- Given a value in ml (milliliters or cc), multiply by 0.98 to find the value in grams.

- Install the low side A/C hose to the supermanifold to HVAC A/C line assembly.

-

Recharge the A/C

refrigerant. See Recharge (Heat Pump Model 3).

NoteDo not disconnect the laptop from the vehicle yet.

- Connect the 12V/LV power. See 12V/LV Power (Disconnect and Connect).

- Unlock the vehicle gateway. See Gateway (Unlock).

- On the touchscreen, select , click Run, and allow the routine to complete.

- Disable Service Mode. See Service Mode.

- Install the underhood storage unit. See Underhood Storage Unit (Remove and Replace).