Power Conversion System (Remove and Install)

Correction code

16301001

2.28

NOTE: Unless otherwise explicitly

stated in the procedure, the above correction code and FRT reflect all of the work

required to perform this procedure, including the linked procedures. Do not stack correction codes unless

explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how they are created. To provide feedback on

FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when

performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

Correction code

16301001

2.28

NOTE: Unless otherwise explicitly

stated in the procedure, the above correction code and FRT reflect all of the work

required to perform this procedure, including the linked procedures. Do not stack correction codes unless

explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how they are created. To provide feedback on

FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when

performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

- 1111868-00-B Connector Removal, Coolant, PCS, M3

- 1135762-00-A Kit, Svc Plug, Cooling Hose, Model 3

- 1114917-00-A Tool, Vacuum Cup, 3" x 6" (Qty 2)

- 1076927-00-A Resistance meter, micro ohm, Hioki RM 3548

Only

technicians who have completed all required certification courses are permitted to

perform this procedure. Tesla recommends third party service provider technicians

undergo equivalent training before performing this procedure. For more information on

Tesla Technician requirements, or descriptions of the subject matter for third parties,

see HV Certification Requirements. Proper personal protective equipment (PPE) and insulating HV

gloves with a minimum rating of class 0 (1000V) must

be worn at all times a high voltage cable, busbar, or fitting is handled. Refer to Tech Note TN-15-92-003, High Voltage Awareness

Care Points

for additional safety

information.

Torque Specifications

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Nuts that attach the positive/negative terminal of the DCDC harness to the positive/negative DCDC passthrough busbar |

4.5 Nm (3.3 lbs-ft) |

|

Reuse | |

| Bolts that attach the power conversion system to the HV battery |

6 Bolt Power Conversion System:  6 Nm (4.4 lbs-ft) 5 Bolt Power Conversion System:  18 Nm (13.3 lbs-ft) |

|

Reuse | Upon installation, mark each bolt with a paint pen |

Remove

-

Place the vehicle on the 2-post

lift.

TIpEnsure the vehicle is not charging.

- Open all doors and lower all windows.

- Remove the cabin intake duct. See Duct - Upper - Cabin Intake (Remove and Replace).

- Perform Vehicle HV Disablement Procedure. See Vehicle HV Disablement Procedure.

- Remove the ancillary bay cover. See Cover - Ancillary Bay (Remove and Replace).

-

Inspect the ancillary bay for any

missing insulators. Install the missing insulators before continuing.

NoteThe number of bolts on newer vehicles may vary.

-

Reinstall the logic connector cap onto

the high voltage controller (HVC) connector.

-

Raise the high voltage controller

vertically, and then restrain the controller with a bungee strap.

- Remove the HV insulating gloves.

- Drain the coolant from the power conversion system. See Ancillary Bay Coolant (Drain and Refill).

- Lower the vehicle fully.

- Inspect the HV insulating gloves, then put on the HV insulating gloves and leather over gloves.

- Remove the pyrotechnic battery disconnect. See Pyrotechnic Battery Disconnect (Remove and Replace).

- Position absorbent sheets below and around the power conversion system (PCS) coolant inlet and outlet hoses to avoid excess coolant dripping.

-

Use the coolant connector removal tool

to release the clips that attach the coolant input tube to the power conversion system,

and remove the tube from the power conversion system. See Tube - Input - Coolant - Power Conversion System (Remove and Replace).

NoteThis video demonstrates how to disconnect the coolant hose from the power conversion system and plug the fittings.

- Install plugs into the coolant input port of the power conversion system and the open end of the coolant input tube.

-

Use the coolant connector removal tool

to release the clips that attach the coolant output tube to the power conversion system,

and remove the tube from the power conversion system. See Tube - Output - Coolant - Power Conversion System (Remove and Replace).

NoteRefer to the video in the previous step.

- Install plugs into the coolant output port of the power conversion system and the open end of the coolant output tube.

-

Wipe around the power conversion

system coolant ports, wipe the ends of the coolant tubes, and wipe up any spilled

coolant.

CAUTIONSpilled coolant can create an electrical path.

- If the DCDC passthrough is a cable type, skip to step 23, otherwise, continue to the next step.

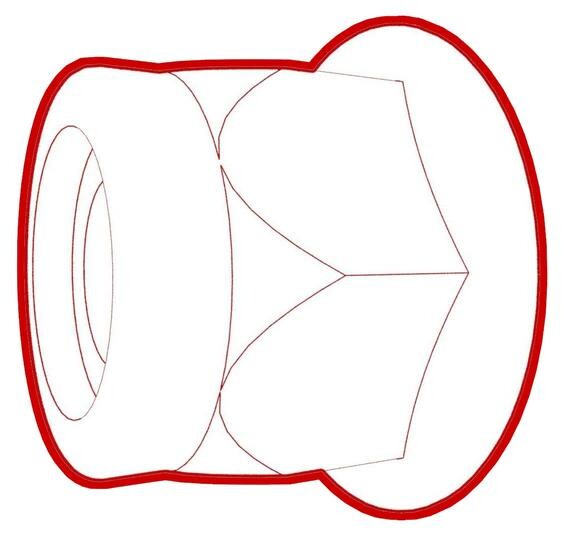

-

Remove the nut that attaches the

positive terminal of the DCDC harness to the positive DCDC passthrough busbar.

TIpUse of the following tool(s) is recommended:

- 8 mm socket

- 4 in extension

- Ratchet/torque wrench

-

Remove the nut that attaches the

negative terminal of the DCDC harness to the negative DCDC passthrough busbar.

TIpUse of the following tool(s) is recommended:

- 8 mm socket

- 4 in extension

- Ratchet/torque wrench

-

Raise the locking tab on the DCDC

passthrough connector, and then remove the connector from the power conversion

system.

TIpUse a plastic trim tool to help disconnect the DCDC passthrough connector.

Figure 1. Busbar Type DCDC Passthrough Figure 2. Cable Type DCDC Passthrough -

Disconnect the LV connector, the DC

bus HV connector, and the HV battery AC inlet harness connector from the power

conversion system.

-

Release the clips that attach the HV

battery AC inlet harness to the power conversion system, and move the harness

aside.

-

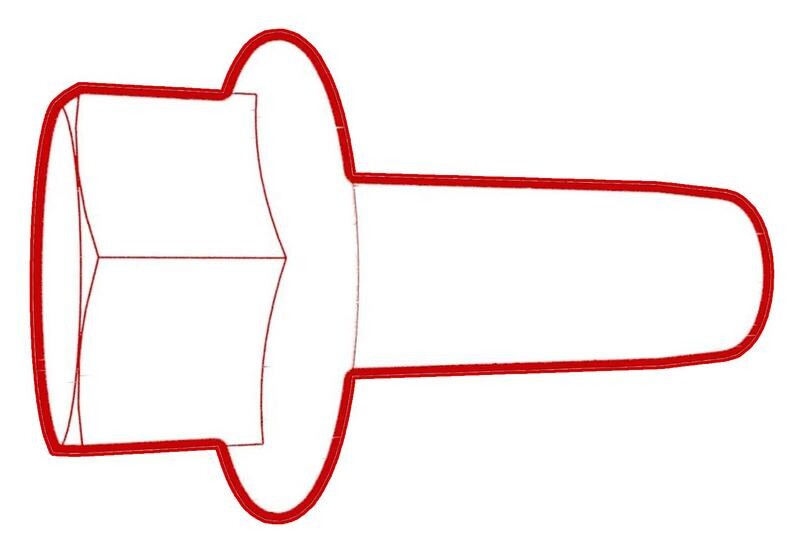

Remove the hex head bolts that attach

the power conversion system to the HV battery.

CAUTIONOnly remove the 8 mm hex bolts. DO NOT remove the Torx T30 bolts.NoteFasteners count may vary depending on production date.NoteSome 5-bolt power conversion system mountings have only 4 bolts. Upon installation of the power conversion system, install the fifth bolt.TIpUse of the following tool(s) is recommended:

- Insulated tools:

- 8 mm socket

- 10 in extension

- Ratchet/torque wrench

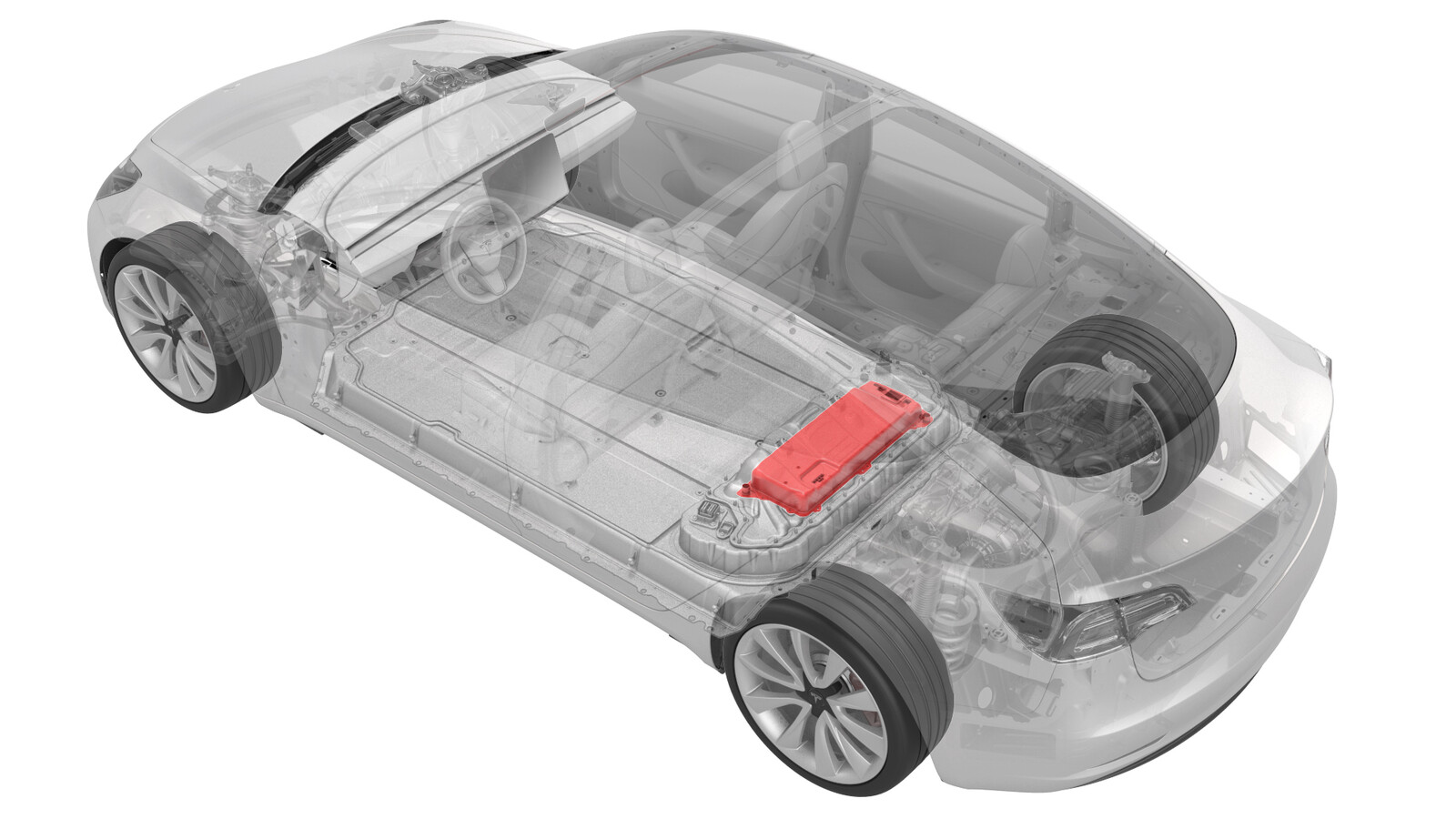

Figure 3. Vehicles Made Before 9/11/18 - 6-Bolts Figure 4. Vehicles Made On 9/11/18 And Thereafter - 5-Bolts - Insulated tools:

-

Install 2 suction cups on the power conversion system.

CAUTIONDo not install the suction cups on top of any labels, as this will reduce suction.NoteContinue pushing the suction button until the red line indicator is no longer visible.

-

With assistance, use suction cups to

lift the power conversion system out of the ancillary bay.

NoteWhen removing the PCS from the vehicle, one technician should be in the vehicle, lifting the PCS from the ancillary bay and handing it over to the assisting technician that stands outside the vehicle.CAUTIONKeep the power conversion system level as you lift it, to prevent spilling coolant.

- Inspect the area for coolant residue and wipe with a clean towel.

- Remove the plugs from the power conversion system, drain the coolant into a coolant drain, and then replace the plugs.

- Remove the absorbent pads from around the power conversion system coolant ports.

- Remove the suction cups from the power conversion system.

Install

- Perform a zero adjust of the Hioki resistance meter in preparation to measure resistances later in this procedure. See Resistance Meter (Zero Adjust).

- Wipe the power conversion system dry.

-

Inspect the area of the ancillary bay

where the power conversion system will be installed, and wipe up any spilled

coolant.

CAUTIONSpilled coolant can create an electrical path.

- Ensure all busbar insulators beneath the PCS are present.

-

With assistance, use suction cups to

lift the power conversion system into the ancillary bay with the datums are aligned into

the PCS holes, and then remove the suction cups.

NoteWhen installing the PCS to the ancillary bay, the assisting technician should be standing outside the vehicle, handing over the PCS to the technician that is inside the vehicle.

-

Install the hex head bolts that attach

the power conversion system to the HV battery, and then mark the bolts with a paint pen

after they are torqued.

NoteFasteners count may vary depending on production date.NoteIf the 5-bolt power conversion system mounting had only 4 bolts, install the fifth bolt.TIpUse of the following tool(s) is recommended:

- Insulated tools:

- 8 mm socket

- 10 in extension

- Ratchet/torque wrench

- 6 Bolt Power Conversion System - Torque to 6 Nm (4.4 ft-lbs)

- 5 Bolt Power Conversion System - Torque to 18 Nm (13.3 ft-lbs)

Figure 5. Vehicles Made Before 9/11/18 - 6-Bolts Figure 6. Vehicles Made On 9/11/18 And Thereafter - 5-Bolts - Insulated tools:

-

Fasten the clips that attach the HV

battery AC inlet harness to the power conversion system.

-

Connect the logic connector, DC bus HV

connector, and HV battery AC inlet harness connector to the power conversion

system.

NoteMake sure the connectors are fully seated, and then engage the locking tabs.TIpTo lock the DC bus HV and HV battery AC inlet connectors, push down on the locking tab.

-

Firmly connect the DCDC passthrough

connector to the power conversion system, and then lower the locking tab.

Figure 7. Busbar Type DCDC Passthrough Figure 8. Cable Type DCDC Passthrough - If the DCDC passthrough is a cable type, skip to step 15, otherwise, continue to the next step.

-

Install the nut that attaches the

negative terminal of the DCDC harness to the negative DCDC passthrough busbar, and then

mark the nut with a paint pen after it is torqued.

4.5 Nm (3.3 lbs-ft)TIpUse of the following tool(s) is recommended:

4.5 Nm (3.3 lbs-ft)TIpUse of the following tool(s) is recommended:- 8 mm socket

- 4 in extension

- Ratchet/torque wrench

-

Install the nut that attaches the

positive terminal of the DCDC harness to the positive DCDC passthrough busbar, and then

mark the nut with a paint pen after it is torqued.

4.5 Nm (3.3 lbs-ft)TIpUse of the following tool(s) is recommended:

4.5 Nm (3.3 lbs-ft)TIpUse of the following tool(s) is recommended:- 8 mm socket

- 4 in extension

- Ratchet/torque wrench

-

Use the Hioki resistance meter to

measure the resistance between the positive joint of the DCDC harness and the positive

terminal of the 12V DCDC passthrough.

NoteThe maximum acceptable resistance is 0.100 mΩ (100 μΩ). There is too much resistance in the High Voltage joint. Remove the fastener, clean areas with isopropyl alcohol, install fastener back and test again

Figure 9. Generic Measurement - Actual busbars and fasteners might appear different -

Use the Hioki resistance meter to

measure the resistance between the negative joint of the DCDC harness and the negative

terminal of the 12V DCDC passthrough.

NoteThe maximum acceptable resistance is 0.100 mΩ (100 μΩ). There is too much resistance in the High Voltage joint. Remove the fastener, clean areas with isopropyl alcohol, install fastener back and test again

Figure 10. Generic Measurement - Actual busbars and fasteners might appear different - Cut a slit halfway through 2 absorbent pads and surround each power conversion system coolant tube coupling with a pad.

- Remove the plugs from the coolant output tube and coolant output coupling.

- Replace the coolant output tube O-rings (2x), and then lubricate the O-rings with Krytox 203.

-

Connect the coolant output tube to the

power conversion system. See Tube - Output - Coolant - Power Conversion System (Remove and Replace).

CAUTIONMake sure the hose is fully aligned with the coupling and that the o-rings are correctly seated before attempting to install the hose.CAUTIONMake sure that the coolant output tube is securely connected by firmly pressing down on it, verify that both clips have fully engaged the barb on the power conversion system, and then pull up on the fitting to check retention.

-

Wipe up any spilled coolant.

CAUTIONSpilled coolant can create an electrical path.

- Remove the plugs from the coolant input tube and coolant input coupling.

- Replace the coolant input tube O-rings (2x), and then lubricate the O-rings with Krytox 203.

-

Connect the coolant input tube to the

power conversion system. See Tube - Input - Coolant - Power Conversion System (Remove and Replace).

CAUTIONMake sure the hose is fully aligned with the coupling and that the o-rings are correctly seated before attempting to install the hose.CAUTIONMake sure that the coolant input tube is securely connected by firmly pressing down on it, verify that both clips have fully engaged the barb on the power conversion system, and then pull up on the fitting to check retention.

-

Wipe up any spilled coolant.

CAUTIONSpilled coolant can create an electrical path.

- Remove the leather over gloves and the HV insulating gloves.

- On the drive unit pressure test fixture, close P2 (outlet valve), and open P1(inlet valve).

- Connect the coolant pressure test adapter to the HV battery.

- Connect the drive unit pressure test fixture to the coolant pressure test adapter.

- Perform an ancillary bay coolant leak test. See Ancillary Bay Coolant Leak Test.

-

Connect the 12V auxiliary battery

negative terminal only.

6 Nm (4.4 lbs-ft)WarningDO NOT reconnect the first responder loop at this time.CAUTIONDo not follow the procedure to connect 12V power at this time.

6 Nm (4.4 lbs-ft)WarningDO NOT reconnect the first responder loop at this time.CAUTIONDo not follow the procedure to connect 12V power at this time.Figure 11. Model 3/Model Y with lead acid 12V battery Figure 12. Model 3 with Li-ion LV battery -

Depending on the type of auxiliary

battery fitted to the vehicle, choose on of the following:

- If the vehicle is equipped with a lead-acid 12V auxiliary battery, connect a 12V charger to the 12V auxiliary battery terminals.

- If the vehicle is equipped with a Li-ion LV auxiliary battery, connect a LV maintainer to the vehicle. See LV Maintainer (Connect and Disconnect).

- With an assistant checking the power conversion system for leaks, top off the superbottle.

-

Perform the following

routine using Service Mode or Toolbox (see 0005 - Service Modes):

TEST_VCFRONT_X_THERMAL-COOLANT-AIR-PURGEvia Toolbox: (link)via Service Mode:

- Thermal ➜ Actions ➜ Coolant Purge Stop or Coolant Purge Start

- Thermal ➜ Coolant System ➜ Coolant Purge Start

- Drive Inverter ➜ Front Drive Inverter Replacement ➜ Coolant Air Purge

- Drive Inverter ➜ Rear Drive Inverter Replacement ➜ Coolant Air Purge

- Drive Inverter ➜ Rear Left Drive Inverter Replacement ➜ Coolant Air Purge

- Drive Inverter ➜ Rear Right Drive Inverter Replacement ➜ Coolant Air Purge

- Drive Unit ➜ Front Drive Unit Replacement ➜ Coolant Air Purge

- Drive Unit ➜ Rear Drive Unit Replacement ➜ Coolant Air Purge

NoteMake sure the vehicle is not in Drive.NoteThe test will last for approximately 10 minutes. Monitor and keep the superbottle topped off while the test is running. Coolant pump speeds can be monitored in Service Mode + (see Service Mode Plus), in the CAN Viewer submenu. If pump speeds stay above 6900 rpm, there is still air entrapped in the system; run a cooling system vacuum refill. - When the air purge is complete, top off the superbottle, and then install the superbottle cap.

- Power off the vehicle from the touchscreen.

- Remove the 12V charger from the 12V auxiliary battery terminals or disconnect the LV maintainer from the vehicle. See LV Maintainer (Connect and Disconnect).

-

Depending on the vehicle

configuration, choose one of the following:

- If the vehicle is equipped with a lead-acid 12V auxiliary battery, disconnect the 12V auxiliary battery negative terminal.

- If the vehicle is equipped with a Li-ion LV auxiliary battery, disconnect the LV battery connector from the LV battery.

- Inspect and put on PPE including the HV insulating gloves and leather over gloves.

- Release the bungee strap from the high voltage controller and rear RH seat headrest, and then lower the controller into the ancillary bay.

- Measure the voltage across the pyrotechnic battery disconnect mount points, and then install the pyrotechnic battery disconnect. See Pyrotechnic Battery Disconnect (Remove and Replace).

- Install the ancillary bay cover. See Cover - Ancillary Bay (Remove and Replace).

- Remove the leather over gloves and the HV insulating gloves.

- Install the 2nd row lower seat cushion. See Seat Cushion - Lower - 2nd Row (Remove and Replace).

- Connect 12V/LV power. See 12V/LV Power (Disconnect and Connect).

- Install the cabin intake duct. See Duct - Upper - Cabin Intake (Remove and Replace).

- Install the rear apron. See Underhood Apron - Rear (Remove and Replace).

- Raise all windows and close all doors.

- Remove the vehicle from the 2 post lift. See Raise Vehicle - 2 Post Lift.