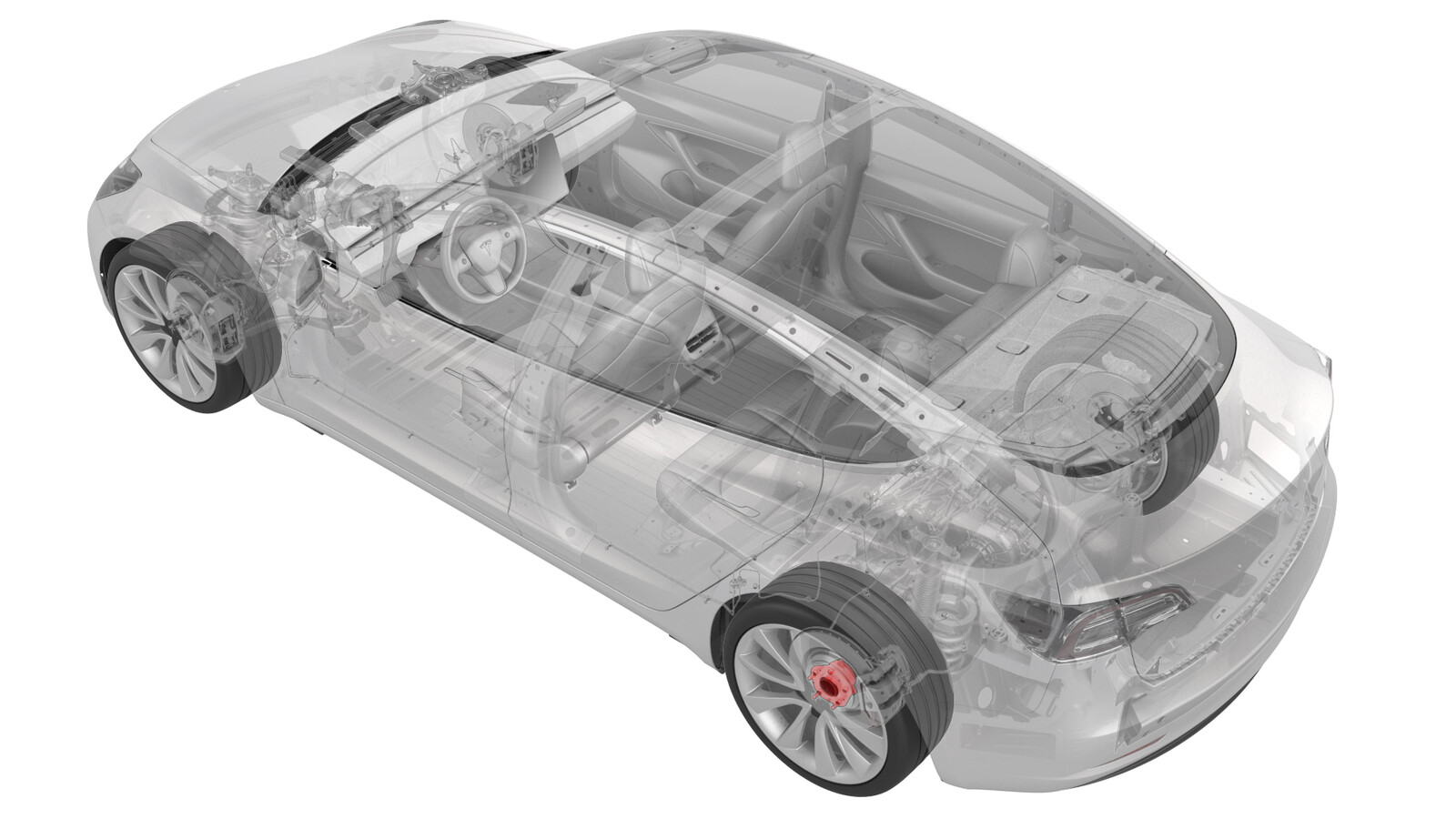

Hub - Rear - LH (Remove and Replace)

Correction code

31030702

0.48

NOTE: Unless otherwise explicitly

stated in the procedure, the above correction code and FRT reflect all of the work

required to perform this procedure, including the linked procedures. Do not stack correction codes unless

explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how they are created. To provide feedback on

FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when

performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

Correction code

31030702

0.48

NOTE: Unless otherwise explicitly

stated in the procedure, the above correction code and FRT reflect all of the work

required to perform this procedure, including the linked procedures. Do not stack correction codes unless

explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how they are created. To provide feedback on

FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when

performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

- 2025-11-25: Added note to remove knuckle if hub is seized to knuckle.

- 2024-01-19: Updated EPB Service Mode reference.

- 2023-11-30: Updated torque figure for rear halfshaft nut from 245 Nm to 300 Nm.

- 2023-04-20: Revised the procedures.

- 2023-05-25: Added the whole procedure video as an overview for supplemental purposes only.

- 2023-09-11: Update the bolts that attach the LH rear hub to the knuckle from discard to reuse.

- 2023-11-13: Changed the step order of removing the brake rotor bolt due to the hub puller tool is updated.

Remove

-

Inspect the tires for

abnormal wear.

NoteNote any abnormal tire wear that could indicate the need for an alignment.

- Open the LH front door and lower the LH front window.

- Raise and support the vehicle. See Raise Vehicle - 2 Post Lift.

- Enable the EPB Service Mode. See Parking Brake - Caliper - Rear - LH (Release).

- If equipped, remove the LH rear wheel center cap. See Cap - Wheel (Remove and Replace).

- Loosen the LH rear wheel lug nuts, but do not remove the wheel at this time. See Wheel Assembly (Remove and Install).

-

Loosen the LH rear halfshaft

nut.

- Remove the LH rear wheel. See Wheel Assembly (Remove and Install).

-

Disconnect the electrical

wiring harness connector from the parking brake.

-

Remove and discard the bolts

(x2) that attach the LH rear caliper to the LH rear knuckle, remove the

caliper from the knuckle, and allow the caliper to hang from an S-hook.

83 Nm (61.2 lbs-ft)NoteHand-tighten the lug nut to secure the rotor on early production vehicles.TIpUse of the following tool(s) is recommended:

83 Nm (61.2 lbs-ft)NoteHand-tighten the lug nut to secure the rotor on early production vehicles.TIpUse of the following tool(s) is recommended:- External Torx E18

- Ratchet/torque wrench

-

Remove and discard the nut,

and remove the washer that attach the LH halfshaft to the hub

assembly.

- Install the hub puller onto the LH rear rotor, and then install and hand-tighten the puller washers (x2) and the lug nuts (x2) onto the rotor studs.

- Use the hub puller to free the halfshaft from the hub splines.

- Remove the lug nuts (x2) and the puller washers (x2) from the LH rear rotor studs, and then remove the hub puller from the rotor.

-

Remove the bolt that attaches the

brake rotor to the hub.

NoteEarly production vehicles may not be equipped with a bolt securing the rotor.

-

Remove the LH rear brake

rotor from the vehicle.

CAUTIONPlace the rotor face down to prevent damage to the rotor face.

-

Remove the bolts (x3) that attach the

LH rear hub to the knuckle, and remove the hub from the vehicle.

85 Nm (62.7 lbs-ft)CAUTIONIf the hub is seized to the knuckle and cannot be removed without damaging the half-shaft boot, remove the knuckle, then remove the hub screws.

85 Nm (62.7 lbs-ft)CAUTIONIf the hub is seized to the knuckle and cannot be removed without damaging the half-shaft boot, remove the knuckle, then remove the hub screws.

Install

-

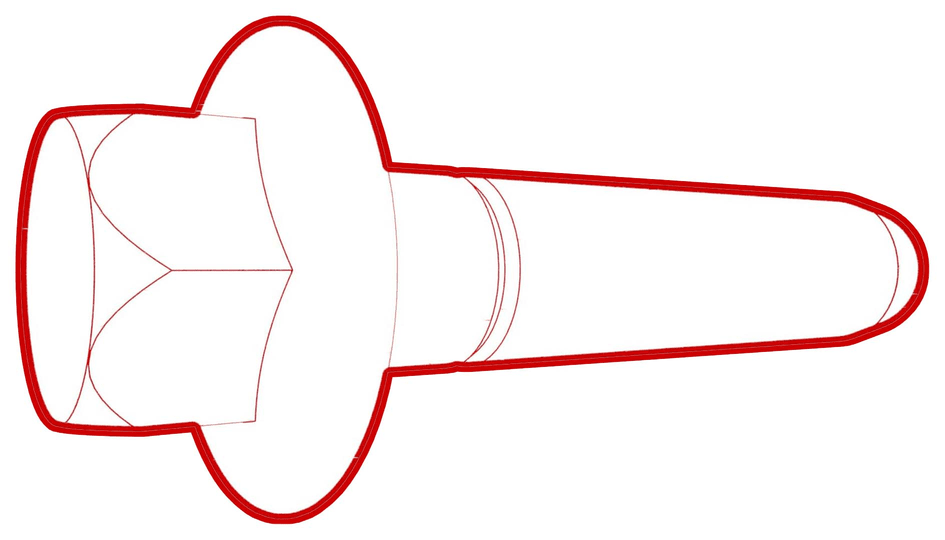

Inspect the tone ring on the

LH rear hub prior to installation.

CAUTIONReplace the hub if tone ring shows signs of damage.

Figure 1. Bad tone ring Figure 2. Good tone ring -

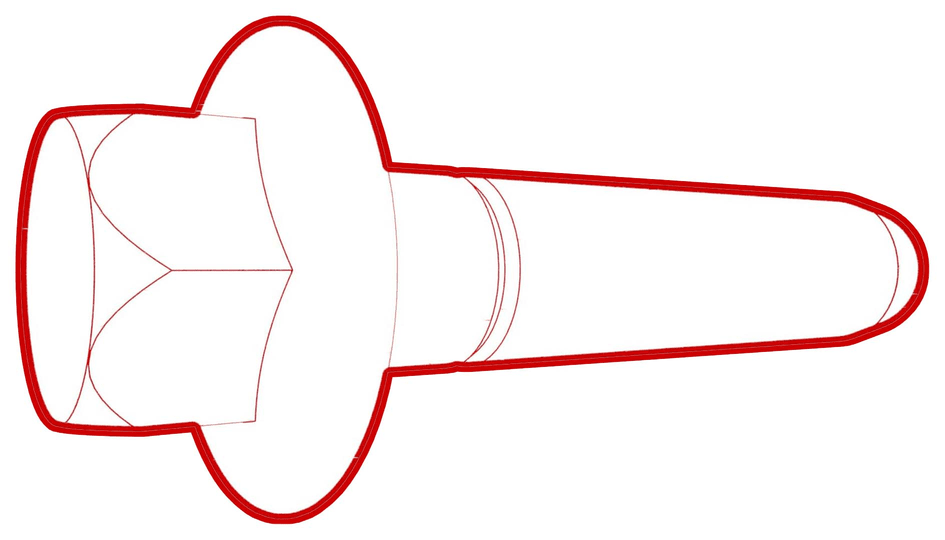

Apply approximately 1 gram

of Molykote M-77 Lubricant Paste only to the hub

mating face on the outboard side of the LH rear drive unit halfshaft.

CAUTIONDo not apply any lubricant to the halfshaft splines. If lubricant is mistakenly applied, wipe the splines clean with a shop towel.

Figure 3. Lubricate the area highlighted red -

Position the LH rear hub

into the knuckle, and then install the bolts (x3) that attach the hub to the

vehicle.

85 Nm (62.7 lbs-ft)

85 Nm (62.7 lbs-ft) -

Install a new nut and washer

that attach the LH rear halfshaft to the LH rear hub assembly.

NoteNut will be torqued at a later step.TIpUse of the following tool(s) is recommended:

- 32 mm deep impact socket

- 6 in extension

-

Position the LH rear brake

rotor onto the LH rear hub, and then install the bolt that attaches the

rotor to the hub.

5 Nm (3.7 lbs-ft)TIpUse of the following tool(s) is recommended:

5 Nm (3.7 lbs-ft)TIpUse of the following tool(s) is recommended:- 10 mm socket

- 2 in extension

- Ratchet/torque wrench

-

Install new bolts (x2) that

attach the LH rear caliper bracket to the knuckle.

83 Nm (61.2 lbs-ft)TIpUse of the following tool(s) is recommended:

83 Nm (61.2 lbs-ft)TIpUse of the following tool(s) is recommended:- External Torx E18

- Ratchet/torque wrench

-

Connect the electrical

harness to the LH rear brake caliper connector.

- Install the LH rear wheel. See Wheel Assembly (Remove and Install).

-

Install the LH rear halfshaft

nut.

300 Nm (221.2 lbs-ft)TIpUse of the following tool(s) is recommended:

300 Nm (221.2 lbs-ft)TIpUse of the following tool(s) is recommended:- Flex head ratchet/flex head torque wrench

- 6 in extension

- 32 mm deep impact socket

- Ratchet/torque wrench

- If equipped, install the LH rear wheel center cap. See Cap - Wheel (Remove and Replace).

- On the vehicle touchscreen, press and hold the park button to release EPB service mode.

- Close the LH front door and raise the LH front window.

- Remove the vehicle from the lift.

- Refer to the Alignment Requirement tables to determine whether an EPAS alignment check (EC) or four wheel alignment check (AC) is necessary. If performed, add the alignment check/adjust correction code as a separate activity to the SV. See Alignment Requirement - Suspension.