DC Input Assembly - HV Battery (Busbar Type) (Remove and Replace)

Correction code 16302402 1.56 NOTE: Unless otherwise explicitly stated in the procedure, the above correction code and FRT reflect all of the work required to perform this procedure, including the linked procedures. Do not stack correction codes unless explicitly told to do so. NOTE: See Flat Rate Times to learn more about FRTs and how they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com. NOTE: See Personal Protection to make sure wearing proper PPE when performing the below procedure. See Ergonomic Precautions for safe and healthy working practices.

- 2025-02-11: Split topic into Remove and Install sections and condensed procedure.

- 2023-06-21: Added a video at Step 2 in Removal part to illustrate how to correctly remove the charge port busbar connector from the busbar HV battery DC input assembly.

Remove

- Remove the pyrotechnic battery disconnect. See Pyrotechnic Battery Disconnect (Remove and Replace).

-

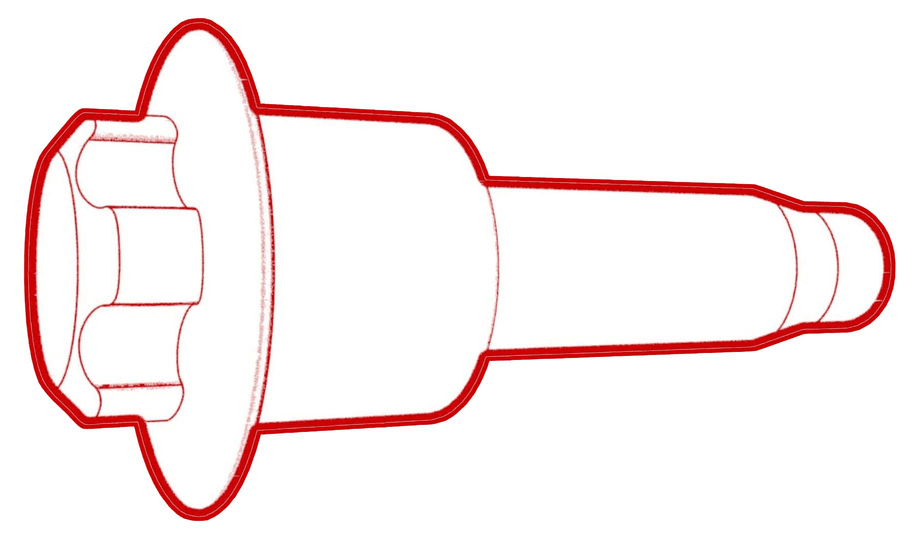

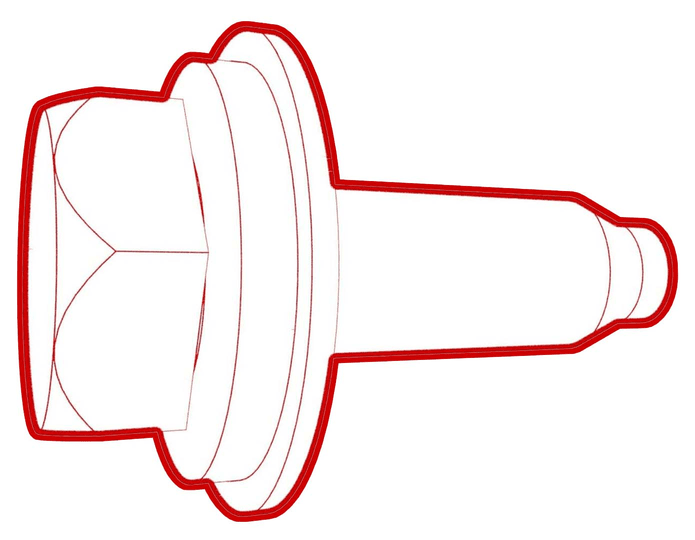

Remove the bolt that secures the

busbar access door on the busbar HV battery DC input assembly.

-

Remove the bolts (x2) that attach the

charge port busbar connector to the busbar HV battery DC input assembly.

-

Remove the charge port busbar

connector from the busbar HV battery DC input assembly.

-

Remove the insulator for the DC input

assembly.

-

Remove and discard the bolt that

attaches the negative DC input busbar to the negative fast charge contactor

busbar.

-

Remove and discard the bolt that

attaches the positive DC input busbar to the positive fast charge contactor

busbar.

-

Disconnect the electrical harness from

the busbar HV battery DC input assembly connector.

-

Remove and discard the bolts (x4) that

attach the busbar HV battery DC input assembly to the ancillary bay, and then remove the

input assembly from the ancillary bay.

Install

- Perform a zero adjust of the Hioki resistance meter in preparation to measure resistances later in this procedure. See Resistance Meter (Zero Adjust).

-

Install the busbar HV battery DC input

assembly into the ancillary bay.

NoteEnsure seal is not damaged and seated properly

-

Install new bolts (x4) to attach the

busbar HV battery DC input assembly to the ancillary bay, and then mark the bolts with a

paint pen after tightening.

10 Nm (7.4 lbs-ft)

10 Nm (7.4 lbs-ft) -

Install a new bolt to attach the

negative DC input busbar to the negative fast charge contactor busbar, precondition the

bolt by torquing to 15 Nm, then back off one half turn, retorque to 5 Nm +60 deg, and

then mark the bolt with a paint pen.

15 Nm (11.1 lbs-ft) -180 deg

15 Nm (11.1 lbs-ft) -180 deg 5 Nm (3.7 lbs-ft) +60 deg

5 Nm (3.7 lbs-ft) +60 deg -

Install a new bolt to attach the

positive DC input busbar to the positive fast charge contactor busbar, precondition the

bolt by torquing to 15 Nm, then back off one half turn, retorque to 5 Nm +60 deg, and

then mark the bolt with a paint pen.

15 Nm (11.1 lbs-ft) -180 deg

15 Nm (11.1 lbs-ft) -180 deg 5 Nm (3.7 lbs-ft) +60 deg

5 Nm (3.7 lbs-ft) +60 deg -

Use the Hioki resistance meter to

measure the resistance at the HV joint between the negative DC input busbar and the

negative fast charge contactor busbar.

NoteThe maximum acceptable resistance is 0.060 mΩ (60 μΩ). If the resistance is above this value, escalate to Service Engineering.

-

Use the Hioki resistance meter to

measure the resistance at the HV joint between the positive DC input busbar and the

positive fast charge contactor busbar.

NoteThe maximum acceptable resistance is 0.060 mΩ (60 μΩ). If the resistance is above this value, escalate to Service Engineering.

-

Install the insulator for the DC input

assembly.

-

Connect the electrical harness to the

DC input assembly connector.

-

Use an alcohol wipe to clean residual

Penetrox from the charge port busbar connector contact surface, and allow 1 minute to

dry.

-

Use an alcohol wipe to clean the

contact surface of the busbar HV battery DC input assembly header, and allow 1 minute to

dry.

-

Apply 2 drops of Penetrox A-13 to each

contact surface of the busbar HV battery DC input assembly header, one on each

side.

-

Spread the Penetrox evenly so that the contact surface is completely covered.

-

Install the charge port busbar

connector onto the busbar HV battery DC input assembly.

-

Install the bolts (x2) that attach the

charge port busbar connector to the busbar HV battery DC input assembly.

9 Nm (6.6 lbs-ft)

9 Nm (6.6 lbs-ft) -

Use the Hioki resistance meter to

measure the resistance at the HV joint between each charge port busbar lead and its

respective bolt.

NoteThe acceptable resistance is between 50 𝜇Ω and 195 𝜇Ω. If the resistance is greater than 195 𝜇Ω, escalate to Service Engineering. If the resistance is lower than 50 𝜇Ω, reposition the probes and measure again. If the resistance is repeatedly between 0 𝜇Ω and 50 𝜇Ω, proceed to the next step.

-

Close the busbar access door on the

busbar HV battery DC input assembly and then install the bolt that secures the door

closed.

9 Nm (6.6 lbs-ft)

9 Nm (6.6 lbs-ft) - Measure the voltage across the pyrotechnic battery disconnect mount points, and then install the pyrotechnic battery disconnect. See Pyrotechnic Battery Disconnect (Remove and Replace).

-

Install the ancillary bay cover. See Cover - Ancillary Bay (Remove and Replace).

NotePerform an ancillary bay air leak test when instructed to do so.

- Connect 12V power. See 12V/LV Power (Disconnect and Connect).