2025-03-27

Correction code

Correction code

Warning

This procedure is a DRAFT.

Although it has been validated, Warnings and Cautions might be missing. Follow safety

requirements and use extreme caution when working on or near High Voltage systems and

components.

Warning

Remove

all jewelry (watches, bracelets, rings, necklaces, earrings, ID tags, piercings, etc.)

from your person, and all objects (keys, coins, pens, pencils, tools, fasteners, etc.)

from your pockets before performing any procedure that exposes you to high

voltage.

Warning

If

corrective eyewear is necessary to safely perform any procedure, make sure that the

eyewear is securely restrained to the head and cannot fall

off.

Warning

Only

technicians who have completed all required certification courses are permitted to

perform this procedure. Tesla recommends third party service provider technicians

undergo equivalent training before performing this procedure. For more information on

Tesla Technician requirements, or descriptions of the subject matter for third parties,

see HV Certification Requirements. Proper personal protective equipment (PPE) and insulating HV

gloves with a minimum rating of class 0 (1000V) must

be worn at all times a high voltage cable, busbar, or fitting is handled. Refer to Tech Note TN-15-92-003,

High Voltage Awareness Care Pointsfor additional safety information.

- 2024-07-29: Added information on installing a recycling warning label with CE marking and manufacturer information, if this was present on the ancillary bay cover being replaced.

- 2023-11-08: Added/updated HV insulating glove steps.

- 2023-05-22: Added caution for correct positive DC cable connection.

- 1108781-BB-F: LABEL - RECYCLING WARNING - EU or

- 1108781-SH-F: LABEL - RECYCLING WARNING - EU

Remove

Warning

When servicing the ancillary bay cover and components in or around the ancillary bay, there is a possibility of encountering metal flashing on the inner edge of the vehicle single-piece rear casting. These sharp protrusions are a cut hazard, and proper PPE should be worn if there is a chance of contacting the flashing unprotected. If not already wearing leather over gloves, then at least wear cut-resistant gloves when the flashing is present.

- Open all four doors

- Lower all four windows

- Move LH front seat forward

-

Partially remove LH rear door seal

-

Remove LH 7s Lower C-Pillar Trim

Note8x clips, Rear edge is mated with groove in trunk side trim, Release clips at the front of LH rear sill trim working your way back towards rear of sill trim

-

Fold 60 seat into down position

-

Disconnect logic connector at LH seat frame

Note1x connector

-

Move 60 seat forward using towel bar

NoteWith one hand on towel bar pull up and slide the seat forward with your other hand

-

Remove 60 seat rear outboard track fastener

Note1x patch bolt, 11mm, 37 Nm, Discard after removal

-

Remove 60 seat rear inboard track fasteners

Note2x patch bolts, 11mm, 37 Nm, Discard after removal

-

Move 60 seat fully rearward using towel bar

NoteWith one hand on towel bar pull up and slide the seat forward with your other hand

-

Remove 60 seat outboard track cover

Note1x clip, Slide covers forward to release from 60 seat tracks

-

Remove center track cover from 2nd row seats

Note2x clips, Slide covers forward to release from 2nd row seat tracks

-

Release cabin carpet from 60 seat

NotePull cabin carpet towards front of vehicle

-

Remove 60 seat front inboard track fasteners

Note1x bolts, 11mm, 37 Nm, Discard after removal

-

Remove 60 seat front outboard track fasteners

Note1x bolts, 11mm, 37 Nm, Discard after removal

-

Remove 2nd row 60 seat assembly from vehicle

NoteRecommend assistance

- Move RH front seat forward

-

Partially remove RH rear door seal

NotePillar and sill trim have tabs seated underneath seal

-

Remove RH rear sill trim

Note8x clips, Rear edge is mated with groove in trunk side trim, Release clips at the front of LH rear sill trim working your way back towards rear of sill trim

-

Remove 40 seat outboard track cover

Note1x clip, Slide cover forward to release from 40 seat track

-

Release cabin carpet from 40 seat

NotePull cabin carpet towards front of vehicle

-

Remove bolts securing 40 seat podium to vehicle

Note2x patch bolts, 11mm, 37 Nm, Discard bolts after removal

-

Fold 40 seat into down position

-

Disconnect 40 frame connector

Note1x connector

-

Move 40 seat forward using towel bar

NoteWith one hand on towel bar pull up and slide the seat forward with your other hand

-

Remove bolts securing 40 seat inner and outer tracks to vehicle

Note2x patch bolts, 11mm, 37 Nm, Discard bolts after removal

-

Move 40 seat fully rearward using towel bar

NoteWith one hand on towel bar pull up and slide the seat rearward with your other hand

-

Remove 40 seat from vehicle

NoteRecommend assistance, Do not support 40 seat by cushion pan, Support 40 seat by podium

-

Remove 3rd row seat cushion and disconnect harness

Note1x connector, Pull LH and RH release lever under 3rd row seat cushion to release seat cushion

-

Remove 3rd row RH seat cushion bolster

Note1x bolt, 13mm, 37 Nm, Slide RH cushion bolster towards front of vehicle to remove

-

Remove 3rd row LH seat cushion bolster

Note1x bolt, 13mm, 37 Nm, Slide LH seat cushion bolster towards front of vehicle to remove

-

Release clip securing 3rd row carpet to LH support bracket

Note1x clip

-

Make a slit in 3rd row carpet around LH seat belt

NoteCut a thin straight line on 3rd row carpet from seat belt opening to edge of carpet

-

Remove 3rd row carpet from under LH trunk side trim

-

Release clip securing RH body harness to body

-

Make a slit in 3rd row carpet around RH seat belt

NoteCut a thin straight line on 3rd row carpet from seat belt opening to edge of carpet

-

Remove 3rd row carpet from under RH trunk side trim

-

Remove 3rd row carpet from vehicle

- Open the hood.

-

Remove the rear apron.

- Disconnect 12V/LV power. See 12V/LV Power (Disconnect and Connect).

-

Disconnect the HVC logic connector and install logic cap

Note1x connector, 1x cap, Release locking tab then push the handle downward to release connector

-

Remove 3rd row NVH insulator

- Empty all pockets and remove all metal objects such as watches and jewelery.

-

Inspect the HV insulating gloves for any damage.

-

Put on the HV insulating gloves and leather over gloves.

-

Remove bolts securing ancillary bay probe lid cover to ancillary bay cover

Note2x bolts, EP10 5-Lobe, 6 Nm, Discard after removal

-

Remove ancillary bay probe lid cover from ancillary bay cover

-

Verify no high voltage

NoteMake sure to wear PPE (HV gloves, safety glasses) when working on high voltage component, Measure B+ to Ground, B- to Ground, B+ to B-, If voltage is greater than 10V, Pack contactors are not open or welded, Stop work and reach out to Service Engineering

-

Inspect ancillary bay probe lid cover gasket then position onto the ancillary bay cover

NoteConfirm no visual damage present, Replace gasket if damage is found

-

Install the bolts securing ancillary bay probe lid cover to ancillary bay cover

Note2x bolts, EP10 5-Lobe, 6 Nm, Install new fasteners

- Remove HV insulating gloves

-

Release positive 12V output cover from PCS cable

Note1x cover

-

Remove nut securing positive 12V output from PCS cable and move cable aside

Note1x nut, 13mm, 15 Nm, Discard after removal

-

Remove fasteners securing ancillary bay cover to high voltage controller (HVC)

Note4x bolts, E10, 5 Nm + 30 degrees, Discard after removal, Newer vehicles may be equipped with 3x bolts

-

Put on HV insulating gloves and leather over gloves.

WarningContinue to wear the gloves until instructed to remove them.

-

Remove bolts securing ancillary bay cover to HV battery

Note18x bolts, E10 5-Lobe, 8 Nm, Use E10 5-Lobe socket without magnet, The fasteners are captive and will stay attached to the ancillary bay cover

-

Remove HVC logic cap

Note1x cap

-

Remove ancillary bay cover from HV battery

NoteInspect the ancillary bay for any missing insulators, Install any missing insulators that are accessible before continuing to next step

Install

-

For Europe only: Check the ancillary bay cover that is being replaced for the presence of a recycling warning label that includes a CE marking and manufacturer information.

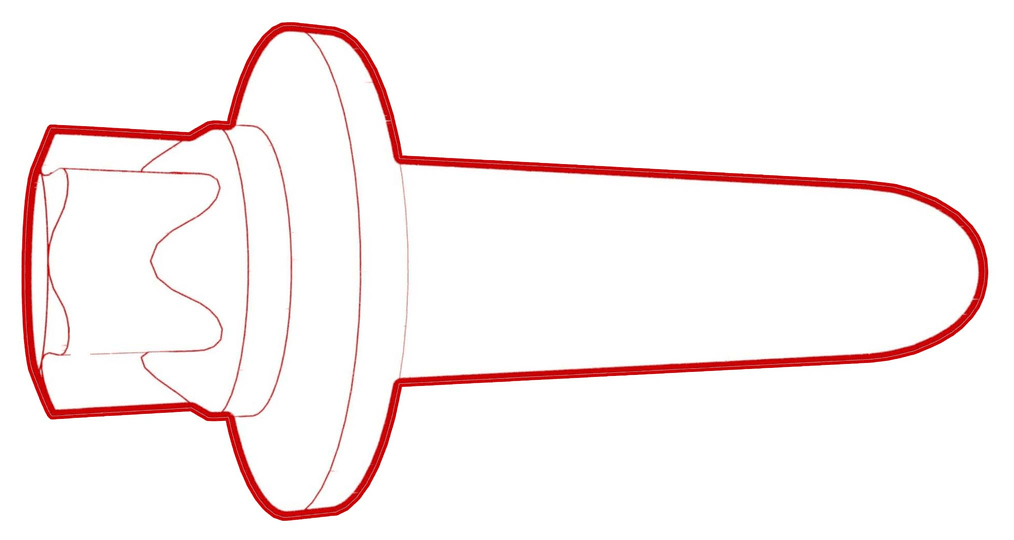

Figure 1. 1108781-BB-F shown, 1108781-SH-F similar - If the recycling warning label with CE marking and manufacturer information is not present on the ancillary bay cover being replaced, continue to the next step.

- If the recycling warning label with CE marking and manufacturer information is present on the ancillary bay cover being replaced:

- Note the area where the recycling warning label is affixed on the ancillary bay cover being replaced.

- Clean the corresponding area on the new ancillary bay cover with an IPA wipe and allow 1 minute dry time.

- Install a new recycling label with CE marking and Manufacturing Information (part number 1108781-BB-F or 1108781-SH-F) on the new ancillary bay cover.NoteFor the correct part number, refer to the part number printed on the label that is attached to the ancillary bay cover being replaced.

-

If the old ancillary bay cover has

volcano brackets, and the replacement ancillary bay cover does not have the same brackets,

rework the High Voltage Controller (HVC) as required to achieve proper fitment between the

replacement cover and HVC. If the replacement cover has volcano brackets, skip to the next

step in this procedure.

Figure 2. Replacement ancillary bay cover without volcano brackets Figure 3. Ancillary bay cover rework area; Cover shown installed for clarity Figure 4. HVC standoff to be removed; Ancillary bay cover shown removed for clarity -

Inspect ancillary bay walls for damage

NoteAny dent or depression in the seal that causes it to not be flat will result in a leak, and cannot be reused, Any paint that comes off the ancillary bay wall, whether or not it sticks to the seal, will require enclosure leak test when reassembled, It can still be reused

-

Inspect ancillary bay cover seal to confirm it has no visual damage

NoteImage up close for clarity, Delaminated and torn seals cannot be reused

-

If the aluminum tape retrofit patch is missing or damaged, remove the patch (if present), clean the area with an IPA wipe, apply another patch of aluminum tape, and wet out the patch with a silicone roller to set the adhesive.

TIpUse of the following tool(s) is recommended:

- 3M 425 Aluminum Foil Tape - 0601363

Figure 6. 5-Bolt to 4-Bolt Patch 50mm x 50mm Figure 7. 4-Bolt to 3-Bolt Patch 30mm x 30mm -

Position the ancillary bay cover to HV battery for installation

NoteEnsure all accessible insulators are present, wearing Electrical Protective Gloves is not necessary once all HV components are covered.

-

Install HVC logic cap

Note1x cap

-

Install bolts securing ancillary bay cover to HV battery

Note18x bolts, E10 5-Lobe, 8 Nm, Use E10 5-Lobe socket without magnet, Fasteners are captive, Follow torque sequence per image

- Remove HV insulating gloves.

-

Install fasteners securing ancillary bay cover to high voltage controller (HVC)

Note4x bolts, E10, 5 Nm + 30 degrees, Install new bolts, Newer vehicles may be equipped with 3x bolts

-

Install positive 12V output from PCS cable and torque nut securing it

CAUTIONMake sure the positive output cable is positioned properly and in the right direction against the plastic anti-rotation edge on the DCDC passthrough.Note1x nut, 13mm, 9 Nm, Install new nut, Mark the nut after torque, Make sure rubber boot is not pinched between cable terminal and pass through

-

Install positive 12V output cover to PCS cable

Note1x cover

-

Install 3rd row NVH insulator

-

Remove logic cap and connect the HVC logic connector

Note1x connector, 1x cap, Align connector then pull the handle to locking position get connector fully seated

-

Install 3rd row carpet into vehicle

-

Install 3rd row carpet under RH trunk side trim

-

Install clip securing RH body harness to body

Note1x clip

-

Install 3rd carpet under LH trunk side trim

-

Install clip securing 3rd row carpet to LH support bracket

Note1x clip

- Connect 12V/LV power. See 12V/LV Power (Disconnect and Connect).

-

Install 3rd row LH seat cushion bolster

Note1x bolt, 13mm, 37 Nm, Slide LH seat cushion bolster into seat frame assembly

-

Install 3rd row RH seat cushion bolster

Note1x bolt, 13mm, 37 Nm, Slide RH seat cushion bolster into seat frame assembly

-

Install 3rd row seat cushion and connect harness

Note1x connector, Secure 3rd row seat cushion into RH and LH latches

-

Install 40 seat into vehicle

NoteRecommend assistance, Do not support 40 seat by cushion pan, Support 40 seat by podium

-

Connect 40 seat frame connector to body harness

Note1x connector

-

Install bolts securing 40 seat podium to vehicle hand tight

Note2x patch bolts, 11mm, 37 Nm, Install new bolts, Torque at later step

-

Move 40 seat forward using towel bar

NoteWith one hand on towel bar pull up and slide the seat forward with your other hand

-

Install bolts securing 40 seat inner and outer tracks to vehicle

Note2x patch bolts, 11mm, 37 Nm, Install new bolts

-

Move 40 seat to original position

-

Torque bolts securing 40 seat podium to vehicle

Note2x patch bolts, 11mm, 37 Nm

-

Install cabin carpet to 40 seat

-

Install 40 seat outboard track cover

Note1x clip

-

Install RH rear sill trim

Note8x clips, Rear edge is mated with groove in trunk side trim, Install rear edge of RH rear sill trim into trunk side trim and work your way forward securing clips

-

Reseat RH rear door seal

NoteSeat pillar and sill trim tabs underneath seal

- Move the RH front seat to its original position.

-

Install 2nd row 60 seat assembly

NoteRecommend assistance

-

Connect logic connector at LH 60 seat frame

Note1x connector

-

Install fasteners securing 60 seat frame to body

Note5x patch bolts, 11mm, 37 Nm, Install new patch bolts, Bottom seat bolts located behind main carpet, Torque in sequence; Outboard front -> Both inboard rear -> Outboard rear -> Inboard front

-

Secure cabin carpet to 60 seat

NoteStrap velcro on

-

Move 60 seat to original position

-

Install 60 seat outboard track cover

Note1x clip

-

Install center track cover to 2nd row seats

Note2x clip, Slide cover straight on to clip to 2nd row seat tracks

-

Install LH 7s Lower C-Pillar Trim

Note8x clips, Rear edge is mated with groove in trunk side trim, Release clips at the front of LH rear sill trim working your way back towards rear of sill trim

-

Reseat LH rear door seal

NoteSeat pillar and sill trim tabs underneath seal

- Move LH front seat to original position

- Raise all four windows

-

Close all four doors

NoteIf 12V is powered up, Unlatch rear doors before closing