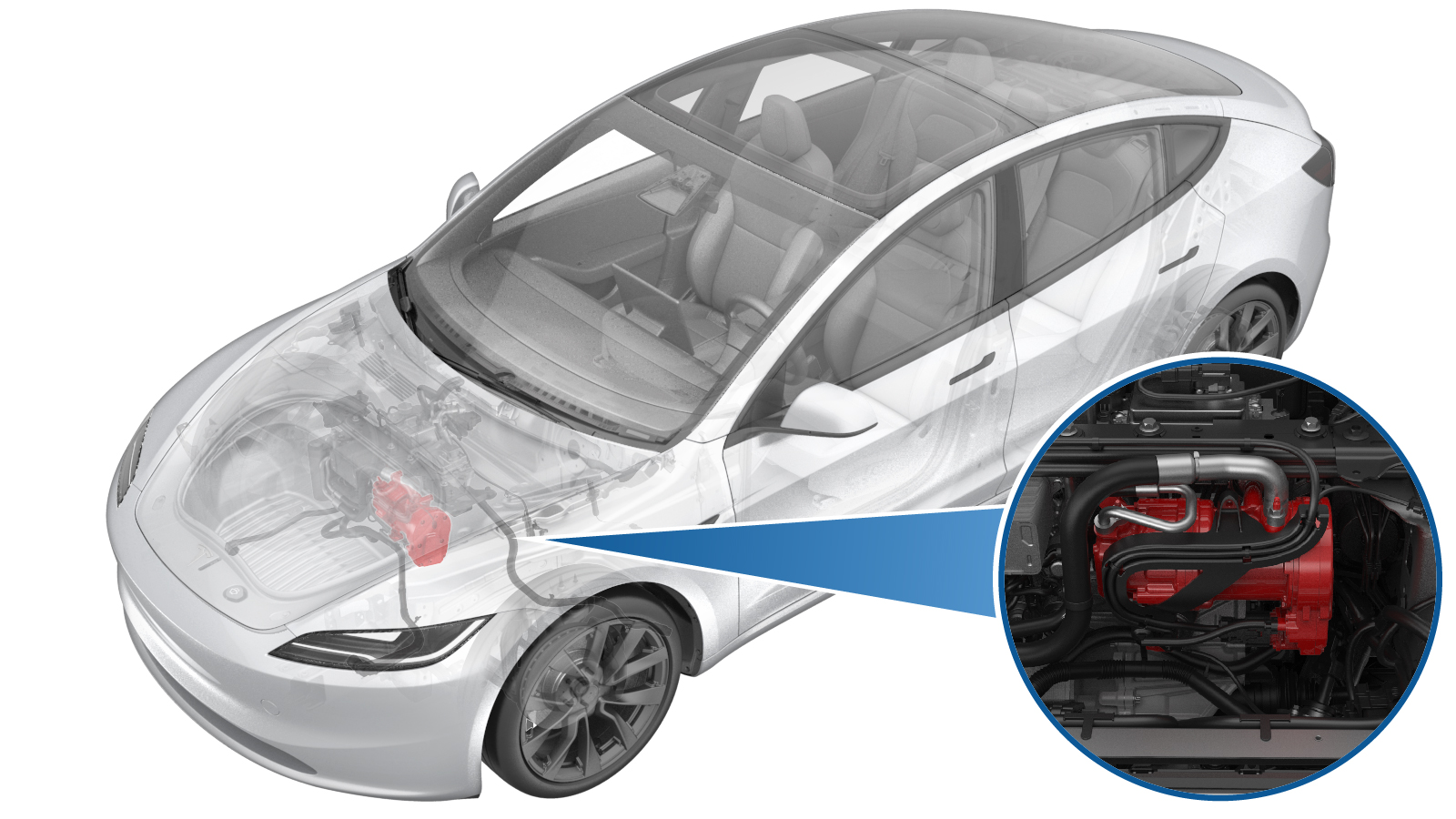

A/C Compressor (Remove and Replace)

Correction code

1820020012

FRT

1.02

NOTE: Unless

otherwise explicitly stated in the procedure, the correction code and FRT

listed above reflect all of the work required to perform this procedure,

including the linked procedures. Do not stack correction

codes unless explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how

they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection

to make sure you are wearing proper PPE when performing the procedure

below.

NOTE: See Ergonomic Precautions for safe and

healthy working practices.

Correction code

1820020012

FRT

1.02

NOTE: Unless

otherwise explicitly stated in the procedure, the correction code and FRT

listed above reflect all of the work required to perform this procedure,

including the linked procedures. Do not stack correction

codes unless explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how

they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection

to make sure you are wearing proper PPE when performing the procedure

below.

NOTE: See Ergonomic Precautions for safe and

healthy working practices.

- 2026-01-13: Revised procedure to flush the system and eliminate oil weighing and correction steps.

- 2024-02-06: Remove the Flush steps and updated the routines and the amount of oil in the replacement compressor.

Only

technicians who have completed all required certification courses are permitted to

perform this procedure. Tesla recommends third party service provider technicians

undergo equivalent training before performing this procedure. For more information on

Tesla Technician requirements, or descriptions of the subject matter for third parties,

see HV Certification Requirements. Proper personal protective equipment (PPE) and insulating HV

gloves with a minimum rating of class 0 (1000V) must

be worn at all times a high voltage cable, busbar, or fitting is handled. Refer to Tech Note TN-15-92-003, High Voltage Awareness

Care Points

for additional safety

information.

Torque Specifications

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolt that attaches the A/C compressor HV harness bracket to the A/C compressor |

9 Nm (6.6 lbs-ft) |

|

Reuse | |

| Bolt that attaches the ground strap to the A/C compressor |

7 Nm (5.2 lbs-ft) |

|

Reuse | |

| Nut that attaches the low pressure fitting to the A/C compressor |

22 Nm (16.2 lbs-ft) |

|

Reuse | |

| Nut that attaches the high pressure fitting to the A/C compressor |

22 Nm (16.2 lbs-ft) |

|

Reuse | |

| Bolts (x2) that attach the A/C compressor assembly to the strut tower brace |

31 Nm (22.9 lbs-ft) |

|

Reuse | |

| Bolts (x3) that attach the A/C compressor bracket to the A/C compressor |

9 Nm (6.6 lbs-ft) |

|

Reuse |

Remove

- Set up the A/C machine.

- Unlock the vehicle gateway. See Gateway Unlock.

- On the touchscreen, tap the Service Mode "wrench" (at the bottom of the touchscreen UI), and then tap , and allow the routine to complete.

- Disconnect the LV battery. See LV Power (Disconnect and Connect).

- Remove the underhood storage unit. See Underhood Storage Unit (Remove and Replace).

-

Recover the A/C refrigerant.

See A/C Refrigerant (Recovery and Recharge) (Restore).

NoteRecover the refrigerant while continuing this procedure.

- Remove the 2nd row lower seat cushion. See Seat Cushion - 2nd Row (Remove and Replace).

- Perform Vehicle HV Disablement Procedure. See Vehicle HV Disablement Procedure (Test/Adjust).

- Remove the LV battery. See LV Battery (Remove and Replace).

-

Release the connector

locking tab, then disconnect the A/C logic electrical connector from the A/C

compressor.

NoteDO NOT push down on the red locking tab. Pull the tab away from the connector until the connector is unlocked, and then continue pulling to release the connector.TIpUse of the following tool(s) is recommended:

- Pick Miniature Soft Grip, 90 degree tip, 6 in

-

Use a clip pry tool to

release the retaining clip that attaches the A/C compressor logic harness to

the A/C compressor HV harness bracket.

-

Disconnect the HV harness electrical connector from the A/C

compressor.

TIpUse of the following tool(s) is recommended:

- Pick Miniature Soft Grip, 90 degree tip, 6 in

-

Remove the bolt that attaches the A/C compressor HV harness bracket to the

A/C compressor.

TIpUse of the following tool(s) is recommended:

- 13 mm 12-point deep socket

- Cordless Ratchet/Impact Driver

- Ratchet/torque wrench (for installation only)

- Remove the A/C compressor HV harness from the A/C compressor and move it aside.

-

Remove the bolt that

attaches the ground strap to the A/C compressor, and then move the ground

strap aside.

TIpUse of the following tool(s) is recommended:

- Torx T25 socket

- Cordless Ratchet/Impact Driver

- Ratchet/torque wrench

-

Use a clip pry tool to

release the clip that attaches the coolant hose to the A/C compressor

bracket.

-

Use a clip pry tool to

release the clips (x2) that attach the coolant hose to the A/C compressor

bracket.

- After refrigerant recovery is complete, carefully depress the Schrader valves (x2) to level out any pressure difference between the A/C system pressure and the actual ambient atmospheric pressure.

-

Remove the nut that attaches the low

pressure fitting to the A/C compressor.

TIpUse of the following tool(s) is recommended:

- 13 mm socket

- 3 in extension

- Ratchet/torque wrench (for installation only)

-

Remove the nut that attaches

the high pressure fitting to the A/C compressor, and then set the hose

assembly aside.

TIpUse of the following tool(s) is recommended:

- 13 mm socket

- 3 in extension

- Ratchet/torque wrench (for installation only)

-

With an assistant, remove

the bolts (x2) that attach the A/C compressor assembly to the strut tower

brace, and then carefully maneuver the assembly towards the front of the

vehicle, under the strut tower support brace. Rest the A/C compressor

assembly on the front underhood storage unit reinforcement beam.

CAUTIONDo not rest the A/C compressor on the HV connector.TIpUse of the following tool(s) is recommended:

- 15 mm socket

- Cordless Ratchet/Impact Driver

- Ratchet/torque wrench

-

With an assistant, remove

the bolts (x3) that attach the A/C compressor bracket to the A/C compressor,

and then remove the bracket from the compressor.

TIpUse of the following tool(s) is recommended:

- 10 mm deep socket

- Cordless Ratchet/Impact Driver

- Ratchet/torque wrench

- Remove the HV harness cover from the A/C compressor.

- Remove the desiccant, see Desiccant (Remove and Replace).

- Install the new cap into the accumulator, and then install the new snap ring into the accumulator.

-

Install A/C flush adapters onto the

A/C manifold to compressor line.

-

Connect A/C machine hoses to A/C flush

adapters.

-

On the A/C machine touchscreen, select

, and enter 25 mins vacuum time. Follow the machine guide to start the

flush, and then allow the process to complete.

NoteSystem flush procedure runs for approximately 90 minutes.

- Note the part numbers and serial numbers of the old and new A/C compressors.

Install

-

Install the NVH acoustic cover onto

the new compressor.

- Install the HV harness cover to the A/C compressor.

-

Position the A/C compressor bracket on

the A/C compressor, and then install the bolts (x3) that attach the bracket to the

compressor.

9 Nm (6.6 lbs-ft)TIpUse of the following tool(s) is recommended:

9 Nm (6.6 lbs-ft)TIpUse of the following tool(s) is recommended:- 10 mm deep socket

- Cordless Ratchet/Impact Driver

- Ratchet/torque wrench

-

With an assistant supporting the A/C

compressor assembly under the strut tower brace, hand-start the bolts (x2) that attach

the A/C compressor assembly to the brace, and then torque the bolts.

31 Nm (22.9 lbs-ft)TIpUse of the following tool(s) is recommended:

31 Nm (22.9 lbs-ft)TIpUse of the following tool(s) is recommended:- 15 mm socket

- Cordless Ratchet/Impact Driver

- Ratchet/torque wrench

-

Replace the O-rings on the high

pressure and low pressure supermanifold to A/C compressor hose fittings.

NoteO-ring for high pressure line: 1111737-00-A WASHER, 3/8,STL ZN, SEAL.NoteO-ring for low pressure line: 1111740-00-A WASHER, 3/4,STL ZN, SEAL.NoteLubricate O-rings with ND-11 oil prior to installation.

Figure 1. Low pressure fitting shown; high pressure fitting similar -

Remove the transport plugs from the

new compressor.

TIpUse of the following tool(s) is recommended:

- 13 mm socket

-

Position the supermanifold to A/C

compressor high pressure fitting on the A/C compressor, and then install the nut that

attaches the fitting to the A/C compressor.

22 Nm (16.2 lbs-ft)TIpUse of the following tool(s) is recommended:

22 Nm (16.2 lbs-ft)TIpUse of the following tool(s) is recommended:- 13 mm deep socket

-

Position the supermanifold to A/C

compressor low pressure fitting on the A/C compressor, and then install the nut that

attaches the fitting to the A/C compressor.

22 Nm (16.2 lbs-ft)TIpUse of the following tool(s) is recommended:

22 Nm (16.2 lbs-ft)TIpUse of the following tool(s) is recommended:- 13 mm deep socket

-

Install a new desiccant. See Desiccant (Remove and Replace).

NoteReuse the accumulator cap and the snap ring used during flushing.

- Perform the vacuum leak test and refill A/C refrigerant. See A/C Refrigerant (Recovery and Recharge) (Restore).

-

Install the clips (x2) that attach the

coolant hose to the A/C compressor bracket.

-

Install the clip that attaches the

coolant hose to the A/C compressor bracket.

-

Position the ground strap on the A/C

compressor, and then install the bolt that attaches the ground strap to the A/C

compressor.

7 Nm (5.2 lbs-ft)TIpUse of the following tool(s) is recommended:

7 Nm (5.2 lbs-ft)TIpUse of the following tool(s) is recommended:- Torx T25 socket

- Cordless Ratchet/Impact Driver

- Ratchet/torque wrench

- Position the A/C compressor HV harness to the A/C compressor.

-

Install the bolt that attaches the A/C

compressor HV harness bracket to the A/C compressor.

9 Nm (6.6 lbs-ft)TIpUse of the following tool(s) is recommended:

9 Nm (6.6 lbs-ft)TIpUse of the following tool(s) is recommended:- 13 mm 12-point deep socket

- Cordless Ratchet/Impact Driver

- Ratchet/torque wrench (for installation only)

-

Connect the HV harness electrical

connector to the A/C compressor.

-

Install the retaining clip that

attaches the A/C compressor logic harness to the A/C compressor HV harness

bracket.

-

Connect the A/C compressor logic

electrical connector to the A/C compressor, and then engage the locking tab.

NotePush the red locking tab into the connector to engage the locking mechanism. DO NOT push down or pull up on the red locking tab.

- Install the LV battery. See LV Battery (Remove and Replace).

- Install the 2nd row lower seat cushion. See Seat Cushion - 2nd Row (Remove and Replace).

- Connect a LV maintainer. See LV Maintainer (Connect and Disconnect) (Maintenance).

- Enable Service Mode. See Service Mode.

- Unlock the vehicle gateway. See Gateway Unlock.

-

On the touchscreen, touch , and select and save the correct type.

NoteRefer to Toolbox article 5696900 for details on compressor configuration.NoteCheck the compressorType and make sure it shows as intended.

- Reinstall the software. See Software Reinstall - Touchscreen.

-

On the touchscreen, perform the

following steps:

- Disable Service Mode. See Service Mode.

- Disconnect LV maintainer. See LV Maintainer (Connect and Disconnect) (Maintenance).

- Connect LV power. See LV Power (Disconnect and Connect).

- Install the underhood storage unit. See Underhood Storage Unit (Remove and Replace).

- Raise all windows and close the doors.