Inverter Coolant Leak Test (Inspection)

Correction code

40202010

FRT

2.76

NOTE: Unless

otherwise explicitly stated in the procedure, the above correction code and

FRT reflect all of the work required to perform this procedure, including

the linked procedures. Do

not stack correction codes unless explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how

they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection

to make sure wearing proper PPE when performing the below procedure.

NOTE: See Ergonomic Precautions for safe and

healthy working practices.

Correction code

40202010

FRT

2.76

NOTE: Unless

otherwise explicitly stated in the procedure, the above correction code and

FRT reflect all of the work required to perform this procedure, including

the linked procedures. Do

not stack correction codes unless explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how

they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection

to make sure wearing proper PPE when performing the below procedure.

NOTE: See Ergonomic Precautions for safe and

healthy working practices.

- 1133843-00-A Kit, Coolant Drain & Fill Adapters, M3

- 1133843-00-B M3 Coolant Drain and Fill Adapters

- 1132185-00-D Coolant Leak Test Adapter Kit

- 1053600-00-D Pressure Test Fixture

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| LH mount bolt that attaches the drive unit to the subframe |

80 Nm (59.0 lbs-ft) |

|

Reuse | |

| Bolts (x3) that secure the rear drive unit LH mount assembly |

35 Nm (25.8 lbs-ft) + 55 degrees |

|

Reuse |

Procedure

- Lower the rear drive unit and subframe assembly, and support the center of the rear drive unit with protective block. See Drive Unit - Rear (3DU) (Remove and Replace).

-

Release the rear drive unit ground

strap clip from the subframe.

-

Release the inverter to cooler hose

clip.

-

Release the rear drive unit inverter

to oil cooler hose.

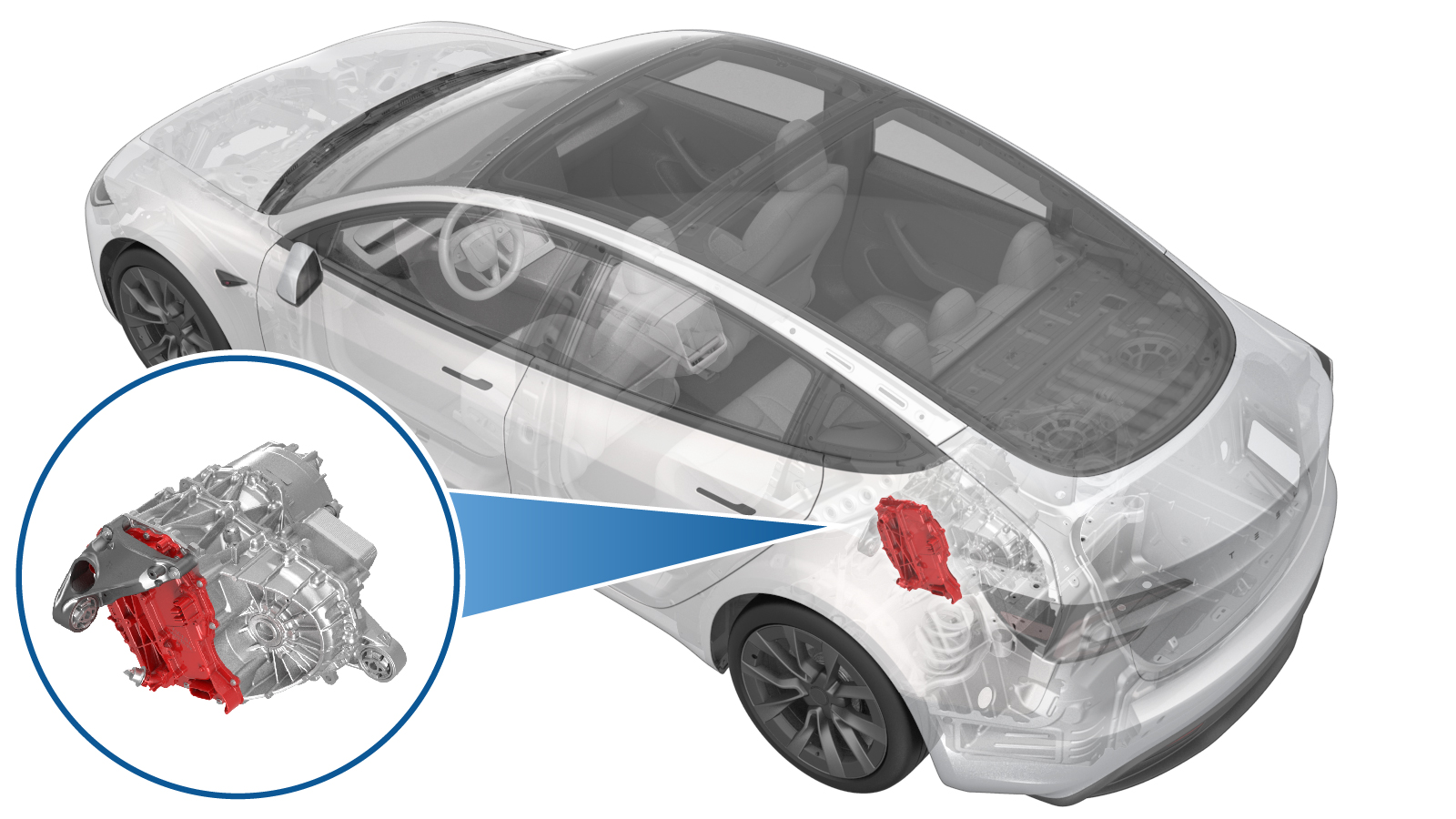

NoteImage zoomed in for clarity.

-

Remove the LH mount bolt that attaches

the drive unit to the subframe.

NoteUse a pry to aid as needed. Do not damage the drive unit casting.TIpUse of the following tool(s) is recommended:

- Ratchet/torque wrench

- 18 mm socket

- Prybar Med

- 18 mm deep socket

- Cordless Ratchet/Impact Driver

- Flex head ratchet/flex head torque wrench

-

Remove and discard the bolts (x3) that

secure the rear drive unit LH mount assembly, and then maneuver upwards to remove the LH

mount assembly from between the rear drive unit and the subframe.

TIpUse of the following tool(s) is recommended:

- Ratchet/torque wrench

- 3 in extension

- External Torx E14

- Cordless Ratchet/Impact Driver

- Torque wrench with angle measurement

-

Attach the coolant drain and fill

adapters to the coolant inlet hose at the bottom of the inverter.

NoteUse the adapter with 90 degree angle. Make sure the locking tab is fully seated.

-

Attach the coolant hose extension to

the coolant drain and fill adapters.

WarningMake sure to wear safety glasses.NoteBe careful as the coolant may spill.

-

Attach the coolant hose extension to

the coolant drain hose.

WarningMake sure to wear safety glasses.NoteBe careful as the coolant may spill.

-

Connect the coolant pressure test

adapter to the outlet hose at the top of inverter.

NoteConnect this adapter to the regulated air line adapter. Make sure the locking tab is fully seated.

-

Connect drive unit pressure test

fixture to the coolant leak test adapter.

WarningMake sure to wear safety glasses.NoteBe careful as the coolant may spill.

-

Connect the compressed air to the

coolant pressure tester.

-

Open regulator valve P1, and then

slowly adjust the regulator to 26 psi.

-

Open regulator valve P2 to speed

drain.

WarningMake sure to wear safety glasses.NoteBe careful as the coolant may spill.

-

Close regulator valve P2.

-

Disconnect the coolant drain and fill

adapter from coolant inlet hose at bottom of the inverter.

WarningMake sure to wear safety glasses.NoteBe careful as the coolant may spill.

-

Connect coolant pressure test adapter

to the coolant inlet hose.

WarningMake sure to wear safety glasses.NoteBe careful as the coolant may spill.

-

Open regulator valve P2 again.

NoteClose the right side regulator valve when the pressure reaches 26 psi and stabilizes. Fill time is 60 seconds.

- Wait 60 seconds to test pressure, and record the value of starting pressure.

-

Wait another 4 minutes for pressure to

settle, and then record the value of end pressure. Subtract the ending pressure from the

starting pressure:

- If the difference is greater than 0.200psi, check the hose, adapter, plug fittings, and check the regulator pressure, and then retest. If the difference is still greater than 0.200 psi, escalate a Toolbox session.

- If the difference is 0.200 psi or less, continue the procedure.

-

Disconnect the compressed air from the

coolant pressure tester.

-

Disconnect drive unit pressure test

fixture from the coolant leak test adapter.

WarningMake sure to wear safety glasses.NoteBe careful as the coolant may spill.

-

Disconnect the coolant pressure test

adapter from the outlet hose.

-

Disconnect the coolant pressure test

adapter from the coolant inlet hose.

-

Position the LH mount assembly in

between the rear drive unit and the subframe.

-

Install and torque new bolts (x3) that

secure the rear drive unit LH mount assembly.

35 Nm (25.8 lbs-ft) + 55 degreesTIpUse of the following tool(s) is recommended:

35 Nm (25.8 lbs-ft) + 55 degreesTIpUse of the following tool(s) is recommended:- Ratchet/torque wrench

- 3 in extension

- External Torx E14

- Cordless Ratchet/Impact Driver

- Torque wrench with angle measurement

-

Install the LH mount bolt that

attaches the drive unit to the subframe.

80 Nm (59.0 lbs-ft)TIpUse of the following tool(s) is recommended:

80 Nm (59.0 lbs-ft)TIpUse of the following tool(s) is recommended:- Ratchet/torque wrench

- 18 mm socket

- Prybar Med

- 18 mm deep socket

- Cordless Ratchet/Impact Driver

- Flex head ratchet/flex head torque wrench

- Remove the center support from beneath the rear drive unit.

-

Secure the inverter to cooler hose to

the inverter.

NotePerform a push-pull-push test to make sure the hose is fully engaged.

-

Secure the inverter to cooler hose

clip.

-

Secure the rear drive unit ground

strap clip onto the subframe.

-

Install the rear drive unit and

subframe assembly. See Drive Unit - Rear (3DU) (Remove and Replace).

NoteTerminate after disabling the EPB Service Mode.

- On the touchscreen, touch , and allow the routine to complete.

-

Select , click Run, and allow the routine to complete.

Note

- The routine will last for a while after the stop message displays. The coolant pumps are audible.

- The test lasts for approximately 10 mins. Do not start another routine during this time.

- Make sure that the vehicle is not in Drive. Putting the vehicle into Drive will stop this routine.

- The speed in the test varies from 3500-6500 RPM (idle speed = ~1500 RPM) and the actuated valve varies between SERIES and PARALLEL.

- If the speed hovers at 7000 RPM, it indicates the pumps are air locked. Perform the vacuum fill again. Continue to add the coolant and purge until the coolant level reaches between the NOM and MAX Lines on the bottle.

-

Inspect the coolant level, top off as

necessary, and then install the coolant bottle cap.

NoteEnsure that the coolant level is at the "Max" line.

- On the touchscreen, touch , touch the START button next to Test Thermal Performance, click Run, and allow the routine to complete.

- Touch the START button next to Test HVAC Performance, click Run, and allow the routine to complete.

- Disable Service Mode. See Service Mode.

-

Install the clips (x3) that secure the

fresh air gutter assembly.

- Install the rear underhood apron. See Underhood Apron - Rear (Remove and Replace).

- Raise all windows and close all doors.

- Remove the lift arms from below the vehicle.

- Refer to the Alignment Requirement tables to determine whether an EPAS alignment check (EC) or four wheel alignment check (AC) is necessary. If performed, add the alignment check/adjust as a separate activity. See Alignment Requirement - Suspension.