2024-11-17

PT Sensor - High Pressure (Remove and Replace)

Correction code

1840010132

FRT

0.30

NOTE: Unless otherwise explicitly stated in the procedure, the above correction code and FRT reflect all of the work required to perform this procedure, including the linked procedures. Do not stack correction codes unless explicitly told to do so.

NOTE: See Flat Rate Times to learn more about FRTs and how they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when performing the below procedure.

NOTE: See Ergonomic Precautions for safe and healthy working practices.

Correction code

1840010132

FRT

0.30

NOTE: Unless otherwise explicitly stated in the procedure, the above correction code and FRT reflect all of the work required to perform this procedure, including the linked procedures. Do not stack correction codes unless explicitly told to do so.

NOTE: See Flat Rate Times to learn more about FRTs and how they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when performing the below procedure.

NOTE: See Ergonomic Precautions for safe and healthy working practices.

- 2024-01-29: Updated steps to ensure consistency of thermal system related procedures.

- 1711245-00-A Snap On Ecotechnics Dual GAS AC Machine

- 1600833-00-A GEN 2 P/T SENSOR SOCKET, 24 MM

Warning

HFO-R1234yf and R134a are considered

hazardous and, if handled incorrectly, can cause serious injury. Suitable personal

protective equipment, consisting of face and eye protection, safety glasses, face

shield, heat-proof gloves, chemical resistant gloves, rubber boots and apron or

waterproof overall must be worn when carrying out operations on the air conditioning

system.

CAUTION

Thermal management components operate

under very tight specifications and can malfunction if Service procedures are not

carefully followed. DO NOT rely on

past experience with other thermal management systems; read through the Service Manual and

do not deviate from the instructions.

Note

This procedure requires the A/C

Refrigerant (Recovery and Recharge) procedure to be performed. If not already

automatically added to the Service Visit, add correction code 18200102 as a

separate activity to the Service Visit.

Torque Specifications

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolt that attaches the supermanifold-to-compressor A/C line to the supermanifold |

22 Nm (16.2 lbs-ft) |

|

Reuse | |

| High Pressure Pressure and Temperature Sensor |

9 Nm (6.6 lbs-ft) |

|

N/A |

|

Remove

- Remove the underhood storage unit. See Underhood Storage Unit (Remove and Replace).

- Unlock the vehicle gateway. See Gateway Unlock.

- On the touchscreen, touch and select Run to start the "Start Thermal Fill Drain (Refrigerant Only)" routine.

- Recover the A/C refrigerant (refrigerant only). See A/C Refrigerant (Recovery and Recharge) (Maintenance).

- Remove the AC hoses from the vehicle.

-

Remove the bolt that attaches the

supermanifold-to-compressor A/C line to the supermanifold.

TIpUse of the following tool(s) is recommended:

- 13 mm socket

- Flex head ratchet/flex head torque wrench

- 6 in extension

-

Remove the supermanifold-to-compressor

A/C line from the supermanifold, and move it aside.

NoteCarefully position the line so that oil does not drip out.

-

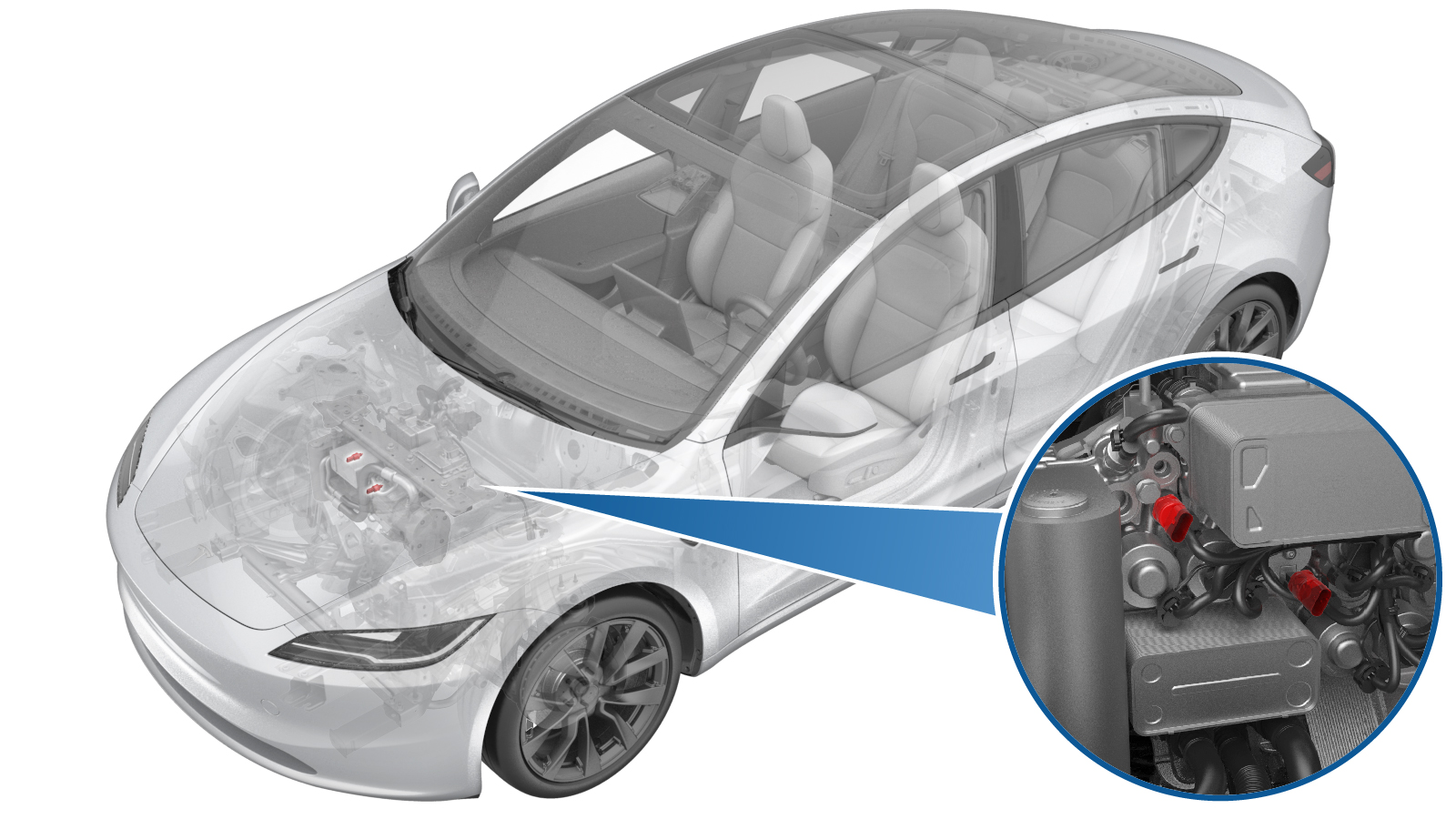

Release the locking tab, and then

disconnect the electrical connector from the high pressure and temperature sensor.

CAUTIONDO NOT push down on the red locking tab. Pull the tab away from the connector until the connector is unlocked, and then continue pulling the main body of the connector to fully disconnect it.WarningThe video(s) included in this procedure are meant as an overview for supplemental purposes only. Follow all of the steps listed in the procedure to avoid damage to components and/or personal injury.

-

Use the P/T sensor socket to remove

the high pressure temperature sensor from the supermanifold.

CAUTIONUse only hand tools to remove the PT sensor. Impact or power tools will break the threads.CAUTIONUse only the P/T sensor socket to remove the sensor. Using other tools can damage the connector housing.TIpUse of the following tool(s) is recommended:

- GEN 2 P/T SENSOR SOCKET, 24 MM

- Flex head ratchet/flex head torque wrench

- 6 in extension

- Record the part numbers and serial numbers of the old and new sensors in the repair order.

Install

- Lubricate the new high pressure temperature sensor threads and O-ring with the appropriate A/C oil. See Fluids and Capacities for A/C oil specifications.

-

Install and hand-tighten the high

pressure temperature sensor until the sensor O-ring just makes contact with the

Supermanifold.

NoteUse an inspection mirror to visualize this and subsequent steps.WarningThe video(s) included in this procedure are meant as an overview for supplemental purposes only. Follow all of the steps listed in the procedure to avoid damage to components and/or personal injury.

- Manually back off and tighten the high pressure temperature sensor in an incremental manner so that the sensor O-ring properly slides into the chamfer in the Supermanifold.

- If the high pressure temperature sensor O-ring appears to pinch, or no longer slides into the chamfer, stop and reverse thread the sensor until the O-ring no longer appears to be pinched.

-

Continue to back off and tighten the

high pressure temperature sensor until the O-ring slides completely into the chamfer and

is no longer visible.

NoteThere should be no gap, and the sensor body should be bottomed out against the Supermanifold.

-

Use the P/T sensor socket to tighten

the high pressure temperature sensor to the specified torque value.

9 Nm (6.6 lbs-ft)CAUTIONUse only hand tools to install the PT sensor. Impact or power tools will break the threads.CAUTIONUse only the P/T sensor socket to install the sensor. Using other tools can damage the sensor.TIpUse of the following tool(s) is recommended:

9 Nm (6.6 lbs-ft)CAUTIONUse only hand tools to install the PT sensor. Impact or power tools will break the threads.CAUTIONUse only the P/T sensor socket to install the sensor. Using other tools can damage the sensor.TIpUse of the following tool(s) is recommended:- GEN 2 P/T SENSOR SOCKET, 24 MM

- Flex head ratchet/flex head torque wrench

- 6 in extension

-

Connect the electrical connector on

the high pressure and temperature sensor.

CAUTIONPush the red locking tab towards the connector to engage the locking mechanism. DO NOT push down or pull up on the red locking tab.

-

Install new seal washers on the

supermanifold side of the supermanifold-to-compressor A/C line, and then lubricate the

washers with a small amount of the appropriate A/C oil. See Fluids and Capacities for A/C oil specifications.

-

Position the

supermanifold-to-compressor A/C line on the supermanifold, and then hand tighten the

bolt that attaches the A/C line to the supermanifold.

-

Tighten the bolt that attaches the A/C

line to the supermanifold.

22 Nm (16.2 lbs-ft)TIpUse of the following tool(s) is recommended:

22 Nm (16.2 lbs-ft)TIpUse of the following tool(s) is recommended:- 13 mm socket

- Flex head ratchet/flex head torque wrench

- 6 in extension

- Install the AC hoses to the vehicle.

- Perform the vacuum leak test and oil injection. See Vacuum Leak Test and Oil Injection.

-

Recharge the A/C refrigerant. See

A/C Refrigerant (Recovery and Recharge) (Maintenance).

NoteDo not disconnect the laptop from the vehicle yet.

- Remove the AC hoses from the vehicle.

- Install caps onto the AC ports.

- If a refrigerant leak detector is available, make sure that there is no leak at the high pressure temperature sensor.

- On the touchscreen, tap the Service Mode "wrench" (at the bottom of the touchscreen UI), and then tap , click Run, and allow the routine to complete.

- Select , select the START next to Test Thermal Performance, click Run, and allow the routine to complete.

- Select , select the START next to Test HVAC Performance, click Run, and allow the routine to complete.

- Exit Service Mode through UI. See Service Mode.

- Install the underhood storage unit. See Underhood Storage Unit (Remove and Replace).