2025-06-04

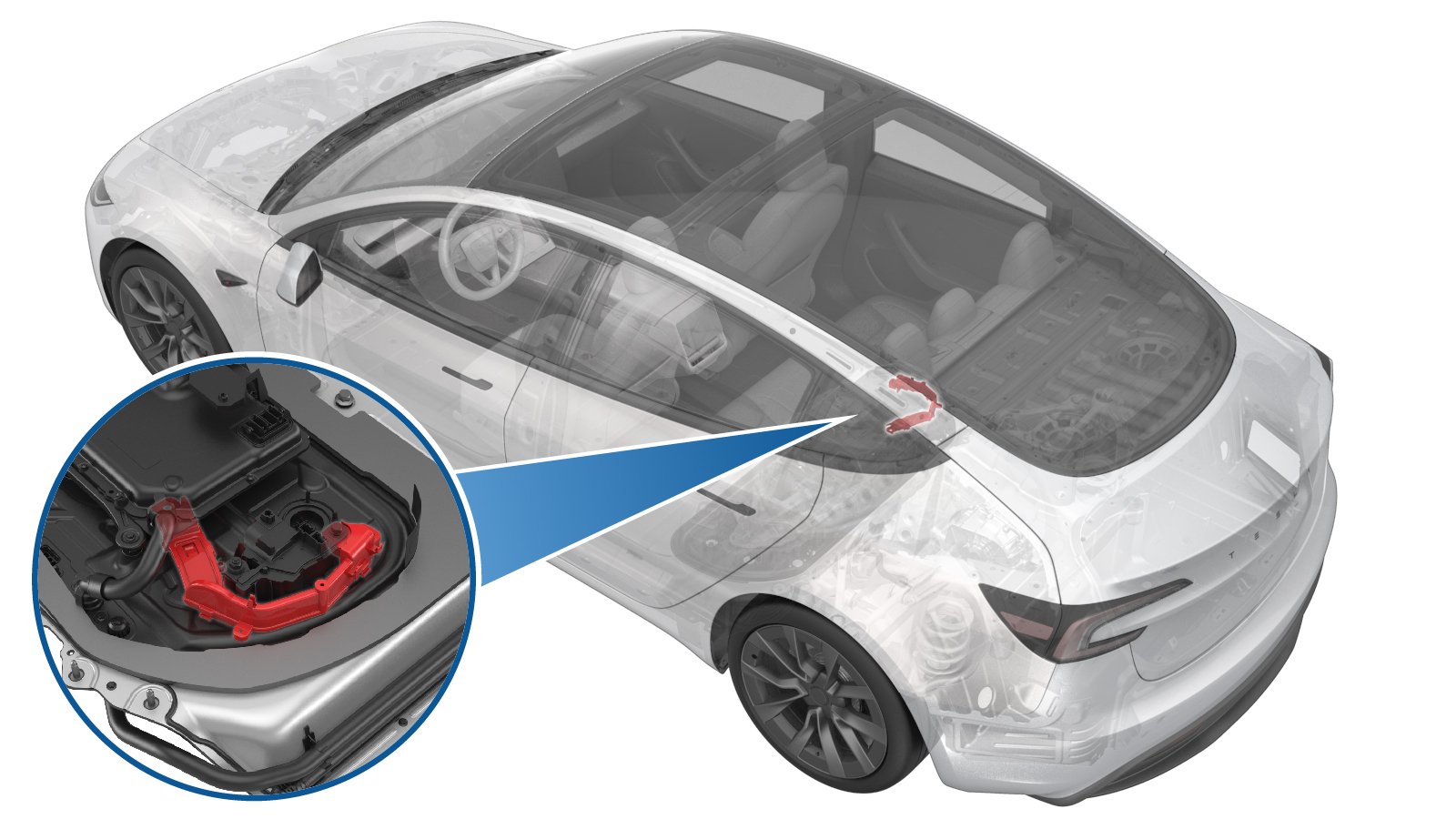

DC Link - Positive - Ancillary Bay (Remove and Replace)

Correction code

1630010152

2.40

NOTE: Unless otherwise explicitly stated in the procedure, the above correction code and FRT reflect all of the work required to perform this procedure, including the linked procedures. Do not stack correction codes unless explicitly told to do so.

NOTE: See Flat Rate Times to learn more about FRTs and how they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when performing the below procedure.

NOTE: See Ergonomic Precautions for safe and healthy working practices.

Correction code

1630010152

2.40

NOTE: Unless otherwise explicitly stated in the procedure, the above correction code and FRT reflect all of the work required to perform this procedure, including the linked procedures. Do not stack correction codes unless explicitly told to do so.

NOTE: See Flat Rate Times to learn more about FRTs and how they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection to make sure wearing proper PPE when performing the below procedure.

NOTE: See Ergonomic Precautions for safe and healthy working practices.

- 2025-06-04: Added instruction to zero adjust the Hioki resistance meter prior to measurement.

Warning

This procedure is a DRAFT.

Although it has been validated, Warnings and Cautions might be missing. Follow safety

requirements and use extreme caution when working on or near High Voltage systems and

components.

Remove

-

Raise and support vehicle

NoteEnsure vehicle is not charging

-

Open all four doors

NoteIf vehicle is being powered down, Latch rear doors to prevent accidental closure

-

Lower all four windows

- Move LH front seat forward

-

Move RH front seat forward

- Open hood

-

Remove rear underhood apron

Note14x clips

-

Power off vehicle from center

display

NoteVia Controls > Safety > Power Off, Select Power Off button at warning dialogue box

-

Disconnect LV battery and First

Responder Loop

Note2x connectors, Release green locking tab, Press black tab then pull black connector lock outwards to release connection, Release red lock tab on FRL, Allow 2 minutes for all electrical circuits to fully discharge

-

Raise vehicle fully and lower lift

onto locks

NoteSet vehicle to comfortable working height, Make sure there's an audible click of the locks on both sides before lowering, otherwise vehicle may tilt to the side, Verify doors are clear of surrounding objects

-

Remove LH and RH clips securing rear

aero shield to wheel house liner

Note2x clips

-

Remove rear aero shield

Note11x bolts, 10mm, 5 Nm

-

Release LH side hose clip from rear

battery skid plate enclosure

Note1x fir tree clip

-

Release RH side hose clips from rear

battery skid plate enclosure

Note2x fir tree clips

-

Remove lower bolts securing HV battery

rear skid plate enclosure

Note2x bolts, EP10, 13 Nm, Older vins may be equipped with additional fastener count

-

Remove upper nut securing HV battery

rear skid plate enclosure

Note1x nut, 10mm, 13 Nm, Fastener count may vary on older built vehicles

-

Remove upper bolts securing HV battery

rear skid plate enclosure

Note4x bolts, 13mm, 35 Nm

-

Remove HV battery rear skid plate

enclosure

-

Position coolant drain container

underneath LH rear of HV battery

-

Disconnect LH coolant hose from rear

of HV battery

Note1x spring clip, 2x plugs, Plug both the coolant hose and passthrough

-

Remove fir tree clip securing coolant

hose to rear subframe shear plate

Note1x fir tree clip

-

Disconnect RDU inverter inlet tube

from LH rear of HV battery

Note1x spring clip, Plug hose connections as needed, Coolant loss greater than 1 L will require vacuum fill

-

Attach coolant drain hose adapter to

PCS outlet hose coupling

NoteUse adapter with 90 degree angle, Make sure locking tab is fully seated

-

Attach coolant drain hose adapter to

coolant hose extension

-

Attach coolant hose extension to

coolant drain hose

NoteUse caution as coolant may spill, Make sure to wear safety glasses

-

Position coolant drain container

underneath RH rear of vehicle

-

Disconnect rear PT supply hose from

rear of HV battery

Note1x spring clip, Plug hose connections as needed, Coolant loss greater than 1 L will require vacuum fill

-

Attach coolant pressure tester to PCS

inlet hose coupling

NoteThis adapter connected to regulated air line adapter, Make sure the locking tab is fully seated

-

Attach coolant pressure tester to

pressure fitting adapter

-

Connect compressed air to coolant

pressure tester

-

Open regulator valve then slowly

adjust regulator to 50 psi

NoteUse caution as coolant may spill, Make sure to wear safety glasses

-

Open 2nd valve slowly

NoteUse caution as coolant may spill, Make sure to wear safety glasses

-

Set timer for 1 minutes and select

start

NoteOnce timer is complete, select Stop Reset

-

Close regulator valve

-

Set timer for 1 minutes and select

start

NoteOnce timer is complete, select Stop Reset

-

Open regulator valve slowly

-

Set timer for 1 minutes and select

start

NoteOnce timer is complete, select Stop Reset

-

Close regulator valve

-

Disconnect compressed air from coolant

pressure tester

-

Remove coolant pressure tester from

PCS inlet hose coupling

-

Position coolant drain container

underneath LH rear of HV battery

-

Remove coolant drain adapter with hose

from PCS outlet hose coupling

Note1x spring clip

-

Attach coolant pressure tester with

hose to PCS outlet hose coupling

Note1x spring clip, Make sure the locking tab is fully seated

-

Position coolant drain container

underneath RH rear of vehicle

-

Attach coolant drain adapter with hose

to PCS inlet hose coupling

Note1x spring clip, Make sure the locking tab is fully seated

-

Connect compressed air to coolant

pressure tester

-

Open regulator valve then slowly

adjust regulator to 50 psi

NoteUse caution as coolant may spill, Make sure to wear safety glasses

-

Open 2nd valve slowly

NoteUse caution as coolant may spill, Make sure to wear safety glasses

-

Set timer for 1 minutes and select

start

NoteOnce timer is complete, select Stop Reset

-

Close regulator valve

-

Set timer for 1 minutes and select

start

NoteOnce timer is complete, select Stop Reset

-

Open regulator valve slowly

-

Set timer for 1 minutes and select

start

NoteOnce timer is complete, select Stop Reset

-

Close regulator valve

-

Disconnect compressed air from coolant

pressure tester

-

Disconnect coolant hose extension from

coolant drain hose

-

Disconnect coolant drain hose adapter

from coolant hose extension

-

Remove coolant drain hose adapter from

PCS inlet hose coupling

Note1x spring clip, Install plug to inlet hose coupling

-

Position coolant drain container

underneath LH rear of HV battery

-

Remove pressure fitting adapter from

coolant pressure tester

-

Remove coolant pressure tester from

PCS outlet hose coupling

Note1x spring clip, Install plug to outlet hose coupling

- Remove coolant drain container from underneath vehicle

-

Lower vehicle fully

NoteRaise lift off locks, then hold lock release lever to keep locks free while vehicle is lowered

-

Release 2nd row seat cushion and

disconnect harness

Note2x clips, 2x connectors, Press tabs backward then pull front edge up

-

Verify operation of multimeter

NoteSet multimeter to DC voltage, Confirm multimeter is properly measuring voltage by testing the 16v battery

-

Remove all items from pockets and

ensure not wearing metal items

-

Inspect HV insulating gloves

NoteCheck gloves for damage prior to use, Refer to service document TN-15-92-003 R1, for information on inspecting HV gloves. https://service.teslamotors.com/protected-doc/ServiceBulletins/External/TN/TN-15-92-003_High_Voltage_Awareness_Care_Points_R4.pdf

-

Put on HV insulating gloves and

leather over gloves

NoteMake sure to wear Electrical Protective Gloves any time Hioki tester is used

-

Remove bolts securing ancillary bay

probe lid cover to ancillary bay cover

Note2x bolts, EP10 5-Lobe, 6 Nm, Discard after removal

-

Remove ancillary bay probe lid cover

from ancillary bay cover

-

Verify no high voltage

NoteMake sure to wear PPE (HV gloves, safety glasses) when working on high voltage component, If voltage is greater than 10V, Pack contactors are not open or welded, Stop work and reach out to Service Engineering

-

Inspect ancillary bay probe lid cover

gasket then position onto the ancillary bay cover

NoteConfirm no visual damage present,Wipe ancillary bay with IPA to clean surface,Allow to 1 minute dry time

-

Install bolts securing ancillary bay

probe lid cover to ancillary bay cover

Note2x bolts, E10 5-Lobe, 6 Nm, Install new fasteners

-

Remove HV insulating gloves

-

Disconnect HVC logic connector and

install logic cap

Note1x connector, 1x cap, Release locking tab then push the handle downward to release connector

-

Remove bolts securing ancillary bay

cover to HVC

Note3x bolts, E10, 5 Nm + 30 degrees

-

Remove bolts securing ancillary bay

cover to HV battery

Note18x bolts, E10 5-Lobe, 8 Nm, Use E10 5-Lobe socket without magnet, The fasteners are captive and will stay attached to the ancillary bay cover

-

Inspect HV insulating gloves

NoteCheck gloves for damage prior to use, Refer to service document TN-15-92-003 R1, for information on inspecting HV gloves. https://service.teslamotors.com/protected-doc/ServiceBulletins/External/TN/TN-15-92-003_High_Voltage_Awareness_Care_Points_R4.pdf

-

Put on HV insulating gloves and

leather over gloves

NoteMake sure to wear Electrical Protective Gloves any time Hioki tester is used

-

Remove ancillary bay cover from HV

battery

-

Inspect ancillary bay for any missing

insulators

NoteInstall service insulator kit before continuing to next step, The number of bolts on newer vehicles may vary

-

Remove bolts securing pyro disconnect

to ancillary bay

Note1x insulator, patch bolts, 13mm, 9 Nm, Discard after removal

-

Remove pyro disconnect from ancillary

bay

Note1x connector from the bottom, Lift pyro disconnect straight up and out of the ancillary bay

-

Install pyro disconnect dummy

-

Use bungee to secure HVC in an upwards

position

NoteWrap bungee around RH headrest

-

Position absorbent sheets below and

around PCS coolant inlet hose to avoid excess coolant dripping

-

Disconnect PCS coolant inlet hose from

PCS

Note2x clips, 2x plugs, Insert the special tool away from the PCS, between the ancillary bay housing and the hose, There is not sufficient room to install the special tool on the PCS side, May cause damage to the tool or the hose retainers, Install plugs to PCS and hose

-

Disconnect PCS coolant outlet hose

from PCS

Note2x clips, 2x plugs, Use the special tool to release clips, Place absorbent sheet under hose to catch excess coolant, Visually inspect area for any coolant residue, Clean with shop towel if necessary, Install plugs to PCS and hose

-

Disconnect PCS to DC bus HV

connector

Note1x connector, Release the locking tab by pulling upward, May need plastic trim tool to help lift the connector upward

-

Disconnect PCS logic connector from

PCS

Note1x connector

-

Disconnect PCS LV connector from

PCS

Note1x connector, Release the locking tab by pulling upward, May need plastic trim tool to help lift the connector upward

-

Disconnect PCS to AC harness

connector

Note1x connector, Release the locking tab by pulling upward, May need plastic trim tool to help lift the connector upward

-

Remove bolts securing PCS to HV

battery

Note5x bolts, 8mm, 18 Nm, Ensure onlythe 8mm fasteners are removed, Do not remove the T30 fasteners

-

Secure suction cups to PCS

NoteContinue pressing plunger until red line is no longer visible

-

Lift PCS up and out of ancillary bay

area and remove from vehicle

NoteSlightly tilt rear of PCS upward then lift out to remove, Inspect any missing insulators under PCS, Install any missing insulators before continuing to next step, Visually inspect area for any coolant residue, Clean with shop towel if necessary

-

Install HV joint insulator for

positive busbar module 2 to pyro disconnect

Note1x insulator

-

Install HV joint insulator for

negative busbar module 3 to shunt

Note1x insulator

-

Install HV joint insulator for

positive DC link to module 4

Note1x insulator

-

Disconnect ancillary bay harness

connectors from positive pack contactor

Note2x connectors

-

Remove ancillary bay harness clip from

positive pack contactor

Note1x clip

-

Remove HV joint insulators from

positive HV switch

Note2x insulators

-

Remove bolt securing positive pack

contactor to positive busbar

Note1x patch bolt, 13mm, 9 Nm, Discard after removal

-

Remove nut securing positive pack

contactor to module 4 rear terminal

Note1x patch nut, 13mm, 9 Nm, Discard after removal

-

Remove nuts securing positive pack

contactor to ancillary bay

Note3x nuts, 10mm, 8 Nm, Use insulated magnet to retrieve the nuts after removal, The number of nuts on newer vehicles may vary

-

Remove positive pack contactor from

ancillary bay

Note2x guide pins

-

Release positive LV output cover from

PCS cable

Note1x cover

-

Remove bolt securing DCDC ground

busbar to body

Note1x bolt, 12mm, 20 Nm

-

Remove nut securing DCDC ground busbar

to HV battery

Note1x nyloc nut, 13mm, 9 Nm, Discard nut after removal

-

Remove DCDC ground busbar

-

Remove nut securing positive LV output

from PCS cable and move cable aside

Note1x nut, 13mm, 15 Nm, Discard after removal

-

Remove bolts securing DCDC pass

through to ancillary bay

Note2x bolts, E10 5-Lobe, 10 Nm

-

Remove DCDC pass through from

ancillary bay

NoteElectrical Protective Gloves

-

Remove HV joint insulator for positive

DC link to module 4

Note1x insulator

-

Remove nut securing DC link to module

4

Note1x patch nut, 13mm, 9 Nm, Discard after removal

-

Move positive DC link out to allow

access to ancillary bay harness clips

-

Remove ancillary bay harness clips

from positive DC link

Note3x clips

-

Remove positive DC link from ancillary

bay

Note2x guide pins

Install

-

Position the positive DC link for

installation

Note2x guide pins

-

Install ancillary bay harness clips to

positive DC link

Note3x clips

-

Install nut securing joint DC link to

module 4

Note1x patch nut, 13mm, 9 Nm, Install new patch bolt, Mark after torque

-

Use the Hioki meter to measure

resistance on DC link to module 4 and busbar

NotePerform zero adjust to Hioki meter prior to testing. See Resistance Meter (Zero Adjust).Note1x HV joint, 60 μΩ or less

-

Install HV joint insulator for

positive DC link to module 4

Note1x insulator

-

Position DCDC pass through to

ancillary bay for installation

NoteElectrical Protective Gloves

-

Install bolts securing DCDC pass

through to ancillary bay

Note2x bolts, E10 5-Lobe, 10 Nm, Mark the bolts after torque

-

Install positive LV output

Note1x nut, 13mm, 9 Nm, Make sure rubber boot is not pinched between cable terminal and pass through

-

Install positive LV output cover to

PCS cable

Note1x cover

-

Install DCDC ground busbar

NoteSlotted hole goes to body side

-

Install bolt securing DCDC ground

busbar to body

Note1x bolt, 12mm, 20 Nm

-

Install nut securing DCDC ground

busbar to HV battery

Note1x nyloc nut, 13mm, 9 Nm, Install new nyloc nut

-

Position positive pack contactor to

ancillary bay for installation

Note2x guide pins

-

Install nuts securing positive pack

contactor to ancillary bay

Note3x nuts, 10mm, 8 Nm, Use insulated magnet as needed to position nuts onto studs, The number of nuts on newer vehicles may vary

-

Install bolt securing positive pack

contactor to positive busbar

Note1x patch bolt, 13mm. 9 Nm, Install new patch bolt, Mark after torque

-

Install nut securing positive pack

contactor to HV battery tall terminal to module 4 rear terminal

Note1x patch nut, 13mm, 9 Nm, Install new patch nut, Mark after torque

-

Use the Hioki meter to measure

resistance from HV joint between HV battery positive contactor and the center of HV

battery positive terminal

Note1x HV joint, 110 μΩ or less

-

Perform Hioki impedance test at HV

joint of positive pack contactor to DC link busbar

Note1x HV joint, The acceptable resistance is between 0.020 mΩ (20 μΩ) and 0.060 mΩ (60 μΩ), If the resistance is greater than 0.060 mΩ (60 μΩ), there is too much resistance in the High Voltage joint. Remove the fastener, clean areas with isopropyl alcohol, install fastener back and test again. If the resistance is less than 0.020 mΩ (20 μΩ), reposition the probes and measure again.

-

Install HV joint insulators onto

positive pack contactor

Note2x insulators

-

Install ancillary bay harness clip to

positive pack contactor

Note1x clip

-

Connect ancillary bay harness

connectors to positive pack contactor

Note2x connectors

-

Position the PCS into ancillary

bay

NoteEnsure all busbar insulators beneath PCS are present, Slightly tilt rear of PCS upward and lower into position, Align datum into PCS holes, Inspect for any coolant residue inside ancillary bay and clean with absorbent sheets if necessary

-

Remove suction cups from PCS

-

Install bolts securing PCS to HV

battery

Note5x bolts, 8mm, 18 Nm

-

Connect PCS to fastcharge contactor HV

harness connector

Note1x connector, Push connector downward then push the locking tab downward to install connector, Make sure the connector is fully seated

-

Connect PCS LV connector to PCS

Note1x connector, Push connector downward then push the locking tab downward to install connector, Make sure the connector is fully seated

-

Connect PCS logic connector to

PCS

Note1x connector

-

Connect PCS to DC bus HV

connector

Note1x connector, Push connector downward then push the locking tab downward to install connector, Make sure the connector is fully seated

-

Replace o-ring on PCS side inlet

hose

Note1x o-ring, Apply light amount of Krytox 203

-

Connect PCS coolant inlet hose to

PCS

Note2x clips, 1xplug, Remove plug from PCS, Place absorbent sheet under hose to catch excess coolant, Caution when installing this hose, it's difficult to align hose to coupling, Use caution not to damage the o-rings, Perform push-pull-push test to make sure coolant hose is fully latched, Then visually verify clip is fully seated

-

Replace o-ring on PCS side outlet

hose

Note1x o-ring, Apply light amount of Krytox 203

-

Connect PCS coolant outlet hose to

PCS

Note2x clips, 1x plug, Remove plug from PCS, Place absorbent sheet under hose to catch excess coolant, Caution not to damage the o-rings, Perform push-pull-push test to make sure coolant hose is fully latched, Then visually verify clip is fully seated, Visually inspect area for any coolant residue, Clean with shop towel if necessary

-

Lay HVC in original position

NoteRelease bungee from back of headrest

-

Remove pyro disconnect dummy

-

Clean mating surfaces

NoteAllow to 1 minute dry time,Use an IPA wipe to clean the HV mating surfaces of the shunt, busbar, and the pyrotechnic battery disconnect

-

Set multimeter to "LoZ" (low

impedance) mode

-

Measure voltage between busbar and

shunt

NoteWhile still measuring the voltage, have an assistant position the pyrotechnic battery disconnect into the HV battery for installation. Make sure to align the pins of the connector with the new pyrotechnic battery disconnect, and then press the pyrotechnic battery disconnect down onto the busbars

-

Position pyro disconnect to ancillary

bay for installation

Note1x connector, Make sure to align the 2 pins with pyro disconnect, The pyro disconnect can only be installed one way

-

Install bolts securing pyro disconnect

to ancillary bay

Note2x patch bolts, 13mm, 9 Nm

-

Use the Hioki meter to measure

resistance from module 2 busbar to pyro disconnect

Note1x HV joint, 48 μΩ or less.

-

Use the Hioki meter to measure

resistance from pyro disconnect to shunt

Note1x HV joint, 33 μΩ or less.

-

Remove service insulator kit

-

Inspect ancillary bay walls for

damage

NoteAny dent or depression in the seal that causes it to not be flat will result in a leak, and cannot be reused, Any paint that comes off the ancillary bay wall, whether or not it sticks to the seal, will require enclosure leak test when reassembled, It can still be reused

-

Inspect ancillary bay cover seal to

confirm it has no visual damage

NoteImage up close for clarity, Delaminated and torn seals cannot be reused

-

Position ancillary bay cover to HV

battery for installation

NoteEnsure all accessible insulators are present, wearing Electrical Protective Gloves is not necessary once all HV components are covered.

-

Remove HV insulating gloves

-

Install bolts securing ancillary bay

cover to HV battery

Note18x bolts, E10 5-Lobe, 8 Nm, Use E10 5-Lobe socket without magnet, Fasteners are captive, Follow torque sequence per image

-

Install bolts securing ancillary bay

cover to HVC

Note3x bolts, E10, 5 Nm + 30 degrees

-

Remove logic cap and connect HVC logic

connector

Note1x connector, 1x cap, Align connector then pull the handle to locking position get connector fully seated

-

Connect 2nd row seat harness and

secure cushion

Note2x clips, 2x connectors, Insert buckles through holes, Slide rear inward then align front clips, Perform push-pull-push test

-

Raise vehicle fully and lower lift

onto locks

NoteSet vehicle to comfortable working height, Make sure there's an audible click of locks on both sides before lowering, otherwise vehicle may tilt to side

-

Position coolant drain container

underneath RH rear of vehicle

-

Install coolant pressure test plug

adapter to PCS inlet hose coupling

Note1x spring clip, 1x plug, Remove plug from inlet hose coupling, Make sure the locking tab is fully seated

-

Position coolant drain container

underneath LH rear of HV battery

-

Install coolant pressure tester to PCS

outlet hose coupling

Note1x spring clip, 1x plug, Remove plug from outlet hose coupling, Make sure the locking tab is fully seated

-

Install pressure fitting adapter to

coolant pressure tester

-

Connect compressed air to coolant

pressure tester

-

Open regulator valve then slowly

adjust regulator to 50 psi

-

Slowly open valve on pressure

regulator and allow pressure to reach specification

-

Close the valve and let pressure

settle

NoteWait 2 minutes for pressure to settle, Record the reading

-

Perform the coolant pressure leak

test

NoteWait for another 4 minutes and record the reading. Max delta 0.35 psi. Check coolant hose to see if it is fully seated or not if pressure test fails

-

Remove pressure fitting adapter from

coolant pressure tester

-

Remove coolant pressure tester from

PCS outlet hose coupling

Note1x spring clip

-

Remove plug from HV battery and

connect RDU inverter inlet tube

Note1x spring clip, 1x plug, Perform push-pull-push test to make sure hose is fully engaged

-

Connect LH coolant hose to rear of HV

battery

Note1x spring clip, 2x plugs, Remove plugs, Perform push-pull-push test to make sure hose is fully seated.Vacuum fill required if > 1L lost during repair

-

Position coolant drain container

underneath RH rear of vehicle

-

Remove coolant pressure test plug

adapter from PCS inlet hose coupling

Note1x spring clip

-

Connect rear PT supply hose to rear of

HV battery and plug hose

Note1x spring clip, 1x plugs, Remove plugs, Perform push-pull-push test to make sure hose is fully seated.Vacuum fill required if > 1L lost during repair

- Remove coolant drain container from underneath vehicle

-

Position HV battery rear skid plate

enclosure onto HV battery for installation

NoteRecommend assistance if needed

-

Install upper bolts securing HV

battery rear skid plate enclosure hand tight

Note4x bolts, 13mm, 35 Nm, Torque at later step

-

Install upper nut securing HV battery

rear skid plate enclosure hand tight

Note1x nut, 10mm, 13 Nm, Torque at later step

-

Install lower bolts securing HV

battery rear skid plate enclosure

Note2x bolts, EP10, 13 Nm, Earlier vins may be equipped with additional bolts

-

Torque bolts securing HV battery rear

skid plate enclosure to vehicle

Note4x bolts, 13mm, 35 Nm

-

Torque upper nut securing HV battery

rear skid plate enclosure

Note1x nut, 10mm, 13 Nm

-

Install RH side hose clips to HV

battery rear skid plate enclosure

Note2x fir tree clips

-

Install LH side hose clip to HV

battery rear skid plate enclosure

Note1x clip

-

lnstall rear aero shield

Note11x bolts, 10mm, 5 Nm, Apply Loctite 222 onto rear aero shield bolts

-

Install LH and RH clips securing rear

aero shield to wheel house liner

Note2x clips

-

Lower vehicle fully

NoteRaise lift off locks, then hold lock release lever to keep locks free while vehicle is lowered

-

Remove coolant bottle cap

-

Place empty coolant container into

front storage area

-

Fill container with at least 15L of

coolant

-

Place filled coolant container into

front storage area

-

Install refill tool cap onto coolant

bottle assembly

-

Setup vacuum refill tool

NoteVerify all valves on refill tool are in the closed position, See image for clarity

-

Install vacuum refill hose into refill

cap on coolant bottle

NotePerform push-pull-push test to verify hose is fully engaged

-

Position overflow hose into empty

container

-

Place refill hose inside filled

coolant container

NoteMake sure hose end is fully submerged into coolant

-

Connect shop air supply to coolant

refill tool

NoteIf not already done, Verify refill valve is set to off

-

Open air inlet valve to draw a vacuum,

Once gauge stabilizes, Fully close valve

NoteGauge stabilizes roughly (60-70 cmHg), Vacuum should not drop after the valves are closed

-

Slowly open coolant refill valve to

allow coolant to be drawn into coolant refill hose, Close valve when hose is full of

coolant

NoteThis purges trapped air from the hose

- Monitor gauge for 30 seconds to verify a vacuum is maintained in cooling system

- Reopen the air inlet valve for 3 minutes to continue evacuating cooling system, then close valve

-

Slowly open refill valve to allow

coolant to be drawn into system

NoteMake sure hose end of refill hose is fully submerged during entire process

-

Once gauge reads zero, close refill

valve

-

Disconnect shop air supply from

coolant refill tool

-

Remove coolant refill hose from

coolant container

-

Remove coolant overflow hose from

coolant container

-

Remove vacuum refill hose from refill

cap on coolant bottle

-

Remove coolant refill tool from

vehicle

-

Remove both coolant containers from

inside underhood area

-

Connect First Responder Loop and LV

battery

Note2x connectors, Secure FRL first, Seat LV battery connection and push black connector lock inwards to secure, Engage green locking tab when fully seated

-

Place vehicle in service mode through

UI

NoteSelect vehicle's badge icon in Controls > Software for four seconds and then type "service" into dialog box

-

Unlock vehicle gateway

NoteAfter vehicle has been put into "Service Mode", place keycard on center console to turn on drive rails, hold down the brake pedal, while keep pressing right hand signal button simultaneously for at least 10 seconds, "GTW UNLOCKING" should pop up on the UI right next to the VIN during these 10 seconds, once gateway is unlocked "GTW UNLOCKED 5400" will be displayed on the UI next to the VIN, the gateway will remain unlocked for 90 minutes, follow steps on Toolbox article #5582900 for any additional information

-

Access Thermal System routines using

the UI

NoteSelect Service mode > Thermal

-

Select "Start Coolant Air Purge" using

the UI

NoteWait until coolant pumps stop running (audible noise), Routine Passed will appear, but pumps will run for 10 minutes, If you start next another routine during this time, it will fail, Make sure vehicle is not in "Drive", Routine is still running despite the completed message, Idle speed = ~1500 RPM, Test will vary speeds from 3500-6500 RPM and actuate valves between SERIES and PARALLEL, Putting vehicle into "Drive" will stop this routine, If speeds hover at 7000 RPM, this indicates the pumps are air locked, perform a vacuum fill, Continue to add coolant and purge until the coolant level reaches between the NOM and MAX Lines on the bottle.

-

Inspect coolant level and top off as

necessary

NoteEnsure that fluid level is at Max line

-

Install coolant bottle cap

-

Install rear underhood apron

Note14x clips, Hold rear wall of frunk to keep from flexing while engaging front clips

- Close hood

-

Move RH front seat to original

position

- Move LH front seat to original position

-

Exit Service Mode through UI

NoteExit Service Mode: Controls > Service Mode > Exit Service Mode, Press and hold to exit

-

Raise all windows

-

Close all four doors

-

Remove lift arms from below

vehicle

NoteLower rack arms fully and remove them from under vehicle