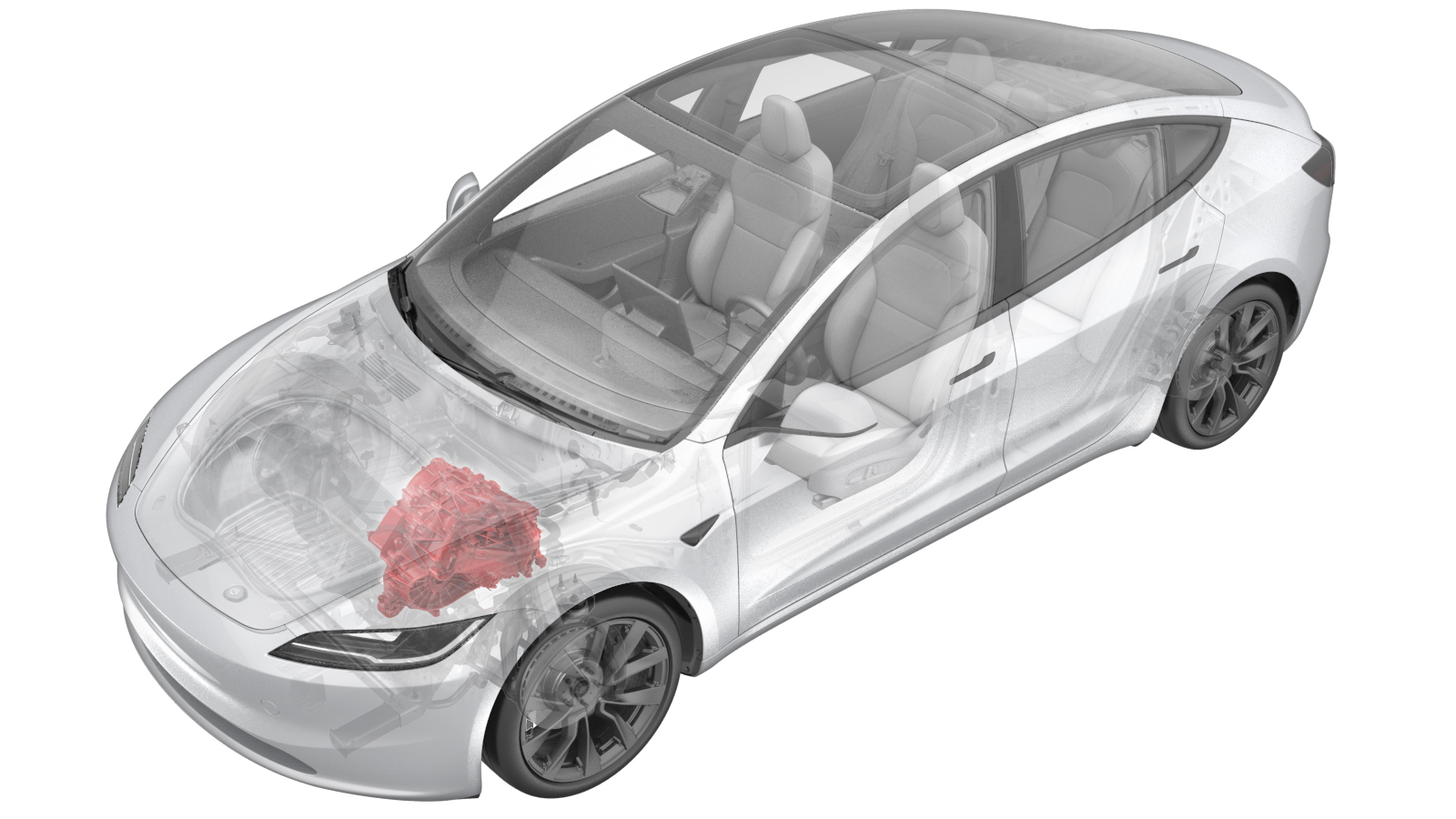

Drive Unit - Front (3DU) (Remove and Replace)

Correction code

3901010132

FRT

3.54

NOTE: Unless

otherwise explicitly stated in the procedure, the above correction code and

FRT reflect all of the work required to perform this procedure, including

the linked procedures. Do

not stack correction codes unless explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how

they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection

to make sure wearing proper PPE when performing the below procedure.

NOTE: See Ergonomic Precautions for safe and

healthy working practices.

Correction code

3901010132

FRT

3.54

NOTE: Unless

otherwise explicitly stated in the procedure, the above correction code and

FRT reflect all of the work required to perform this procedure, including

the linked procedures. Do

not stack correction codes unless explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how

they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection

to make sure wearing proper PPE when performing the below procedure.

NOTE: See Ergonomic Precautions for safe and

healthy working practices.

- 2024-01-24: Added a note to install a new motor ID label in hood/trunk for China, Japan and Korea.

- 1137855-00-A TOOL, REAR RIDE HEIGHT TORQUE, MODEL 3

- 1705887-00-A ½" Dr. Electric Impact

- 1498673-00-A KIT, CABLE AXLE REMOVER, MS/MX/M3

- 1130279-00-A Lifting Sling, Drive Unit, Model 3 (NA, APAC)

- 1080270-00-A 12V Maintainer Charger

- 1773092-00-A Adapter, Diagnostic Harness, All models

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Bolts (x4) that attach the front end carrier to the LH and RH front subframe crash can assemblies |

16 Nm (11.8 lbs-ft) |

|

Reuse | |

| Bolts (x2) that attach the LH and RH motor mounts to the LH and RH motor mount brackets |

105 Nm (77.4 lbs-ft) |

|

Reuse | |

| Bolt that attaches the front drive unit mount to the front subframe |

80 Nm (59.0 lbs-ft) |

|

Reuse | |

| Bolts that attach the front drive unit to the crate |

|

Reuse |

Remove

- Verify there is no abnormal tire wear that could indicate the need for an alignment per Courtesy Inspection.

- Put the vehicle on a 2-post lift.

- Open all doors and lower all windows.

- Move the LH and RH front seats forward.

- Place the vehicle in Service Mode by using the touchscreen. See Service Mode.

- Unlock the vehicle gateway. See Gateway Unlock.

-

On the touchscreen, tap the Service Mode "wrench" (at the bottom of the touchscreen

UI), and then tap , click Run, and allow the routine to

complete.

NoteThermal Fill/Drain routine has a 5-hour time limit.

- Perform Vehicle HV Disablement Procedure. See Vehicle HV Disablement Procedure (Test/Adjust).

-

Remove the front subframe

assembly. See Subframe Assembly -Front (Remove and Replace).

NotePause after tightening the straps on the subframe.

-

Remove the bolts (x4) that attach the front end carrier to the LH and RH front

subframe crash can assemblies.

TIpUse of the following tool(s) is recommended:

- Cordless Ratchet/Impact Driver

- 13 mm socket

- Ratchet/torque wrench

- 2 in extension

-

Remove the bolts (x2) that attach the LH and RH motor mounts to the LH and RH motor

mount brackets.

TIpUse of the following tool(s) is recommended:

- External Torx E18

- Flex head ratchet/flex head torque wrench

- 3/8 in to ½ in adapter

- Cordless Ratchet/Impact Driver

- ¼ in to 3/8 in adapter

- 6 in extension

- Ratchet/torque wrench

-

Continue to remove the front subframe assembly. See Subframe Assembly -Front (Remove and Replace).

NoteTerminate after removing the subframe lifting tool from under the vehicle.

-

Position a fluid catcher under the

subframe and fixture assembly to catch all coolant loss.

NoteIf necessary, use a fordable funnel (1463565-00-A) as required for the following steps.

-

Release the clips (x3) that

secure the hose which attaches the front drive unit inverter to the oil

cooler from the heat exchanger, the inverter fluid coupling, and the front

drive unit, and then remove the hose from the front drive unit.

-

Release the spring clip that

attaches the front drive unit inverter inlet hose to the 90 degrees fluid

coupling.

-

Release the clips (x2) that

secure the front drive unit inverter inlet hose to the vehicle, and then

remove the hose from the vehicle.

-

Release the locking tab, and

then push the handle downward to disconnect the front drive unit inverter

logic connector.

-

Release the front drive unit

harness clips (x2) from the inverter housing.

-

Release the red locking tab

to disconnect the front drive unit resolver connector.

-

Release the front drive unit

harness clip from the resolver housing.

-

Pull the red locking tab to

disconnect the oil pump connector.

- Use the cable removal kit (1498673-00-A) to separate the LH and the RH half shafts from the front drive unit.

- Position the front subframe assembly under the gantry.

-

Connect the shackles (x3) to

secure the drive unit sling (1130279-00-A) onto the front drive unit, and

then connect the sling to the gantry.

Note

Follow the instruction and the layout on the tool.

The sling is color-coded.

Make sure that the sling is fully and properly secured.

WarningThe video(s) included in this procedure are meant as an overview for supplemental purposes only. Follow all of the steps listed in the procedure to avoid damage to components and/or personal injury. - Raise the sling until there is slight tension on the cables.

-

Remove the bolt that

attaches the front drive unit mount to the front subframe.

TIpUse of the following tool(s) is recommended:

- Flex head ratchet/flex head torque wrench

- 18 mm socket

- Cordless 3/8in Dr Impact

- Raise the gantry, and then carefully lift the front drive unit out of the front subframe. As the front drive unit is lifted, maneuver the half shafts out of the way.

- Lower the front drive unit onto an appropriate surface, and then release the drive unit sling from the front drive unit, but leave its attachment to the gantry hook.

Install

-

Position a new front drive

unit and its crate underneath the gantry.

- Release the protective covers (x10) from the new front drive unit and transfer them onto the old drive unit.

-

Connect the shackles (x3) to

secure the drive unit sling onto the new front drive unit, and then connect

the sling to the gantry.

Note

Follow the instruction and the layout on the tool.

The sling is color-coded.

Make sure that the sling is fully and properly secured.

- Raise the sling until there is slight tension on the cables.

-

Remove the bolts (x3) that

attach the new front drive unit to the crate.

TIpUse of the following tool(s) is recommended:

- 19 mm socket

- Ratchet/torque wrench

- Prybar Med

- Carefully lower the new front drive unit into the front subframe. As the front drive unit is lowered, maneuver the axles into the front drive unit for later installation. Line up the front drive unit with the support stands.

-

Install the bolt that

attaches the new front drive unit mount to the front subframe.

80 Nm (59.0 lbs-ft)TIpUse of the following tool(s) is recommended:

80 Nm (59.0 lbs-ft)TIpUse of the following tool(s) is recommended:- Flex head ratchet/flex head torque wrench

- 18 mm socket

- Cordless 3/8in Dr Impact

- Lower the sling to relieve the tension on the cables, and then disconnect the shackles (x3) to release the drive unit sling from the new front drive unit.

- Connect the shackles (x3) to the old front drive unit, lift the old front drive unit, and carefully lower it into the crate.

-

Install and hand-tighten the

bolts (x3) that attach the old front drive unit to the crate.

NoteRaise and lower the front drive unit as needed to align the bolts. Use a prybar as required.TIpUse of the following tool(s) is recommended:

- 19 mm socket

- Ratchet/torque wrench

- Prybar Med

- Lower the sling to relieve the tension on the cables, and then disconnect the shackles (x3) to release the drive unit sling from the old front drive unit.

- Remove the drive unit sling from the gantry hook, and then move the old front drive unit away and prepare for the material review board (MRB).

- Move the front subframe away from under the gantry.

-

Position and align the RH and the LH half shaft axle splines, and install

them into the front drive unit, and then install the LH and the RH front

half shafts into the front drive unit.

Note

- Straighten out the knuckles and the half shafts, and apply a shifting force to seat the half shafts into the front drive unit.

- Do not overexert the splines or the half shafts to avoid damage.

- Verify that the half shafts are fully seated. If not, make sure that the splines are properly aligned, and the half shafts are leveled straight when being seated.

-

Connect the oil pump connector.

-

Connect the front drive unit resolver connector.

-

Secure the front drive unit harness clip to the resolver housing.

-

Secure the front drive unit harness clips (x2) onto the inverter

housing.

-

Connect the front drive unit inverter logic connector.

-

Secure the clips (x2) that

attach the front drive unit inverter inlet hose to the vehicle to install

the hose.

-

Secure the spring clip that

attaches the front drive unit inverter inlet hose to the 90 degrees fluid

coupling.

NotePerform a push-pull-push test to make sure that the hose is fully secured.

-

Install the clips (x3) that

secure the hose which attaches the front drive unit inverter to the oil

cooler to the front drive unit, the inverter fluid coupling, and the heat

exchanger.

- Position the lifting tool and the subframe under the vehicle for installation.

- Connect air supply to the subframe lifting tool.

-

Install the front subframe

assembly. See Subframe Assembly -Front (Remove and Replace).

NoteStart after connecting the air hose to the front subframe lifting tool, and pause after torquing the bolts (x2) that attach the LH and RH mid mounts to the body.

-

Install the bolts (x4) that attach the front end carrier to the LH and RH front

subframe crash can assemblies.

16 Nm (11.8 lbs-ft)TIpUse of the following tool(s) is recommended:

16 Nm (11.8 lbs-ft)TIpUse of the following tool(s) is recommended:- Cordless Ratchet/Impact Driver

- 13 mm socket

- Ratchet/torque wrench

- 2 in extension

-

Install the bolts (x2) that attach the LH and RH motor mounts to the LH and RH motor

mount brackets.

105 Nm (77.4 lbs-ft)TIpUse of the following tool(s) is recommended:

105 Nm (77.4 lbs-ft)TIpUse of the following tool(s) is recommended:- External Torx E18

- Flex head ratchet/flex head torque wrench

- 3/8 in to ½ in adapter

- Cordless Ratchet/Impact Driver

- ¼ in to 3/8 in adapter

- 6 in extension

- Ratchet/torque wrench

- Release the fixture straps from the front subframe.

- Lower the front subframe lifting tool from the vehicle.

- Disconnect the air hose from the front subframe lifting tool.

- Remove the front subframe lifting tool from under the vehicle.

-

Continue to install the front subframe assembly. See Subframe Assembly -Front (Remove and Replace).

NoteStart from hand-tightening the nut and bolt that attach the LH strut to the LH front lower lateral link.

- Install the front fascia. See Fascia - Front (Remove and Replace).

- Install the underhood storage unit. See Underhood Storage Unit (Remove and Replace).

-

Perform a cooling system vacuum

refill. See Cooling System - Vacuum Refill (Test/Adjust).

NoteTerminate after removing both coolant containers from the vehicle.

- Connect the 2nd row seat harness and secure the cushion.

- Connect the first responder loop and leave LV battery disconnected, then connect the LV battery maintenance-charger.

- Remove the steering wheel holder and the steering wheel level from the vehicle.

- Move the LH and RH front sear to original position.

- On the touchscreen, tap the Service Mode "wrench" (at the bottom of the touchscreen UI), and then tap , and allow the routine to complete.

- Locally connect a laptop with Toolbox 3 to the vehicle. See Toolbox (Connect and Disconnect).

-

On the laptop, select Actions tab and search for "Redeploy",

select via Toolbox: (link),

click run, and allow the routine to complete.

NoteThe routine will state pass, but the update will continue to run in the background. UI will indicate the status of update.

-

Once the firmware redeploy is complete, verify on center display that the release

notes are present.

NoteIf the redeploy fails, an error message will display on the UI.

- Disconnect the LV battery maintenance-charger and connect the LV battery.

-

On the touchscreen, select , tap Run, and allow the routine to complete.

Note

- The routine will last for a while after the stop message displays. The coolant pumps are audible.

- The test lasts for approximately 10 mins. Do not start another routine during this time.

- Make sure that the vehicle is not in Drive. Putting the vehicle into Drive will stop this routine.

- The speed in the test varies from 3500-6500 RPM (idle speed = ~1500 RPM) and the actuated valve varies between SERIES and PARALLEL.

- If the speed hovers at 7000 RPM, it indicates the pumps are air locked. Perform the vacuum fill again. Continue to add the coolant and purge until the coolant level reaches between the NOM and MAX Lines on the bottle.

-

Inspect the coolant level, top off as

necessary, and then install the coolant bottle cap.

NoteEnsure that the coolant level is at the "Max" line.

- On the touchscreen, tap , then click the START button next to Test Thermal Performance, click Run, and allow the routine to complete.

- Disconnect the laptop.

- Install the rear underhood apron. See Underhood Apron - Rear (Remove and Replace).

- Disable Service Mode. See Service Mode.

- Raise all windows and close all doors.

- Remove the lift arms from below the vehicle.

- For China, Japan and Korea only: Carefully remove the old motor label from the hood, and install a new motor label to match the new motor information.

- Refer to the Alignment Requirement tables to determine whether an EPAS alignment check (EC) or four wheel alignment check (AC) is necessary. If performed, add the alignment check/adjust as a separate activity. See Alignment Requirement - Suspension.