Ground Strap - Rear Drive Unit (Remove and Replace)

Correction code

4001020012

FRT

1.68

NOTE: Unless

otherwise explicitly stated in the procedure, the above correction code and

FRT reflect all of the work required to perform this procedure, including

the linked procedures. Do

not stack correction codes unless explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how

they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection

to make sure wearing proper PPE when performing the below procedure.

NOTE: See Ergonomic Precautions for safe and

healthy working practices.

Correction code

4001020012

FRT

1.68

NOTE: Unless

otherwise explicitly stated in the procedure, the above correction code and

FRT reflect all of the work required to perform this procedure, including

the linked procedures. Do

not stack correction codes unless explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how

they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection

to make sure wearing proper PPE when performing the below procedure.

NOTE: See Ergonomic Precautions for safe and

healthy working practices.

- 2023-12-11: Updated last step with cross reference to Alignment Requirement Tables.

- 1129348-00-A XP-10 Power Supply, XP-10

- 1099645-00-B Fixture, Subframe, Model 3

- 1140311-00-A Lever Lock, HV Connector, Model 3

Only

technicians who have completed all required certification courses are permitted to

perform this procedure. Tesla recommends third party service provider technicians

undergo equivalent training before performing this procedure. For more information on

Tesla Technician requirements, or descriptions of the subject matter for third parties,

see HV Certification Requirements. Proper personal protective equipment (PPE) and insulating HV

gloves with a minimum rating of class 0 (1000V) must

be worn at all times a high voltage cable, busbar, or fitting is handled. Refer to Tech Note TN-15-92-003, High Voltage Awareness

Care Points

for additional safety

information.

Torque Specifications

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Nut that attaches the rear drive unit ground strap to the body |

10 Nm (7.4 lbs-ft) |

|

Reuse | |

| Bolts that attach the rear subframe to the body |

165 Nm (121.7 lbs-ft) |

|

Replace | |

| Bolt that attaches the ground strap to the rear drive unit |

6 Nm (4.4 lbs-ft) |

|

Reuse |

Remove

- Raise and support the vehicle. See Raise Vehicle - 2 Post Lift.

- Remove the rear underhood apron. See Underhood Apron - Rear (Remove and Replace).

- Disconnect the LV power. See LV Power (Disconnect and Connect).

- Remove the 2nd row lower seat cushion. See Seat Cushion - 2nd Row (Remove and Replace).

- Perform Vehicle HV Disablement Procedure. See Vehicle HV Disablement Procedure (Test/Adjust).

- Remove the LH and RH wheels. See Wheel Assembly (Remove and Install).

- Remove the rear aero shield panel. See Panel - Aero Shield - Rear (Remove and Replace).

- Remove the LH and RH rear suspension covers. See Cover - Rear Suspension - LH (Remove and Replace).

- Remove the rear fascia. See Fascia Assembly - Rear (Remove and Install).

-

Disconnect the RH subframe harness electrical connector.

-

Use a clip pry tool to

release the clip that attaches the RH subframe harness to the body.

-

Remove the nut that attaches the rear drive unit ground strap to the

body.

TIpUse of the following tool(s) is recommended:

- 10 mm 12-point deep socket

- Ratchet/torque wrench

- Remove the stabilizer bar. See Stabilizer Bar - Rear (Remove and Replace).

- Remove the rear HV battery skid plate. See Skid Plate - HV Battery - Rear (Remove and Replace).

- Remove the rear drive unit inlet hose. See Hose - Inlet - Rear Drive Unit Inverter (Remove and Replace).

- Remove the HV battery to the rear drive unit harness. See HV Harness - HV Battery to Rear Drive Unit (Remove and Replace).

- Position the rear subframe lifting tool beneath the rear subframe.

- Attach an air hose to the rear subframe lifting tool.

- With an assistant, raise the rear subframe lifting tool to support the rear subframe.

-

Loop the straps over the

rear subframe, hook the ends of the straps to the metal rings, and then pull

the straps tight to restrain the subframe to the rear subframe lifting

tool.

NoteLower the vehicle to give more slack to connect the straps to the rings, if necessary.

-

Mark the LH and RH rear subframe bolts for realignment during

installation.

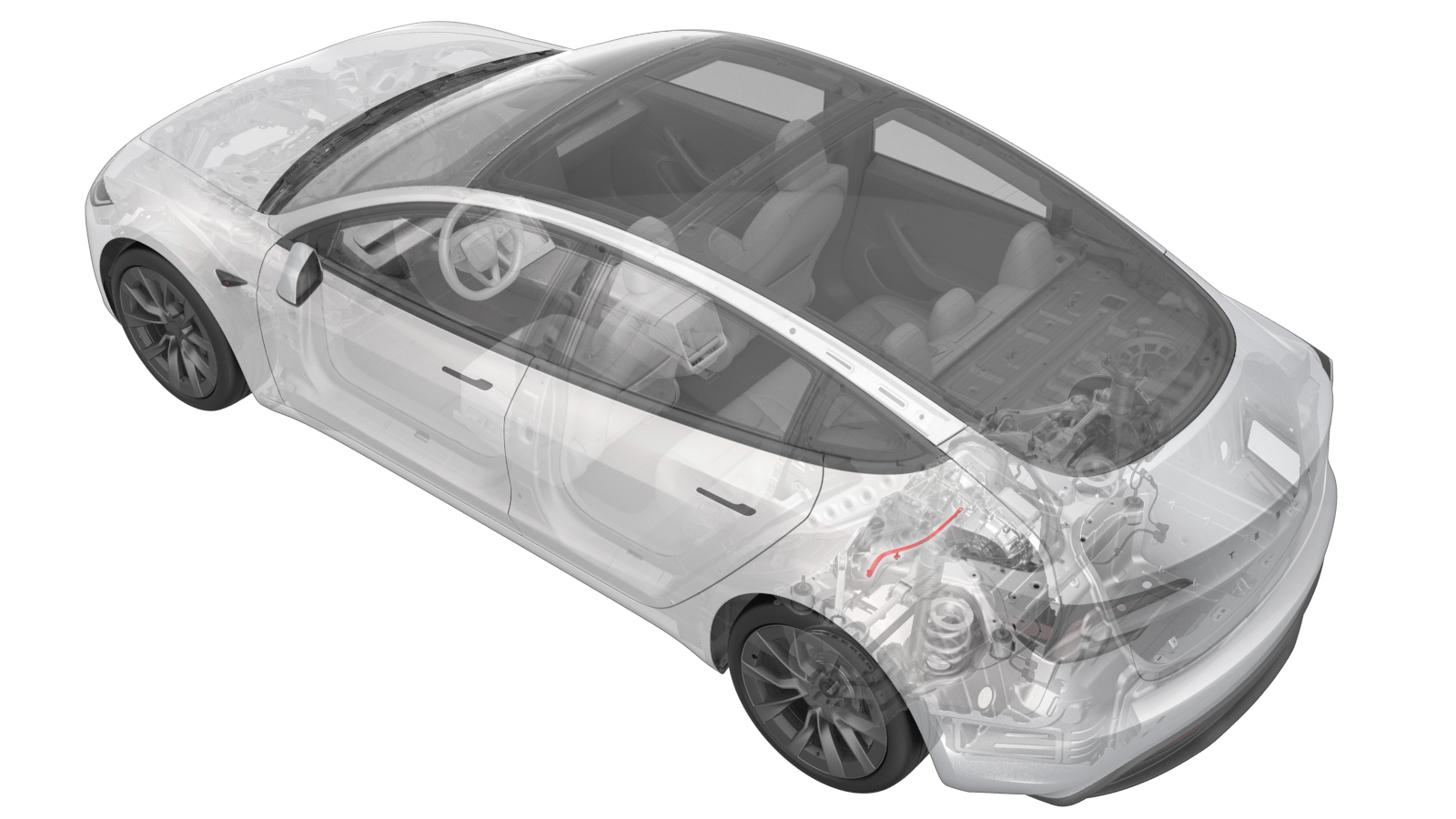

Figure 1. LH shown; RH similar - Remove the LH and RH rear subframe front shear plates. See Shear Plate - Rear Subframe - LH (Remove and Replace).

-

Remove and discard the LH and RH bolts that attach the rear subframe to the

body.

TIpUse of the following tool(s) is recommended:

- 21 mm socket

- 6 in extension

- Ratchet/torque wrench

Figure 2. LH shown; RH similar - With an assistant, slowly lower the rear subframe and rear drive unit about 3.25 in (8.25 cm) from the vehicle.

- Tilt the subframe fixture forward to access the ground strap.

-

Use a clip pry tool to

release the clip that attaches the rear drive unit ground strap to the rear

subframe.

-

Remove the bolt that attaches the ground strap to the rear drive

unit.

TIpUse of the following tool(s) is recommended:

- 10 mm socket

- 4 in extension

- Ratchet/torque wrench

Install

-

Install the bolt that

attaches the ground strap to the rear drive unit.

6 Nm (4.4 lbs-ft)TIpUse of the following tool(s) is recommended:

6 Nm (4.4 lbs-ft)TIpUse of the following tool(s) is recommended:- 10 mm socket

- 4 in extension

- Ratchet/torque wrench

-

Fasten the clip that attaches the rear drive unit ground strap to the rear

subframe.

- Return the subframe fixture forward to its original position.

- Raise the rear subframe and rear drive unit.

-

Hand-tighten the LH and RH bolts that attach the rear subframe to the

body.

Figure 3. LH shown; RH similar - Install the LH and RH rear subframe front shear plates. See Shear Plate - Rear Subframe - LH (Remove and Replace).

- Position the subframe to the locations as marked during removal.

-

Torque the LH and RH bolts

that attach the rear subframe to the body, and then mark them with a paint

pen after torquing.

165 Nm (121.7 lbs-ft)TIpUse of the following tool(s) is recommended:

165 Nm (121.7 lbs-ft)TIpUse of the following tool(s) is recommended:- 21 mm socket

- 6 in extension

- Ratchet/torque wrench

Figure 4. LH shown; RH similar - Lower the rear subframe lifting tool from the vehicle.

- Disconnect the air hose from the rear subframe lifting tool.

- Remove the subframe lifting tool from the vehicle.

- Install the HV battery to the rear drive unit harness. See HV Harness - HV Battery to Rear Drive Unit (Remove and Replace).

- Install the rear drive unit inlet hose. See Hose - Inlet - Rear Drive Unit Inverter (Remove and Replace).

- Install the rear HV battery skid plate. See Skid Plate - HV Battery - Rear (Remove and Replace).

- Install the stabilizer bar. See Stabilizer Bar - Rear (Remove and Replace).

-

Install the nut that

attaches the rear drive unit ground strap to the body.

10 Nm (7.4 lbs-ft)TIpUse of the following tool(s) is recommended:

10 Nm (7.4 lbs-ft)TIpUse of the following tool(s) is recommended:- 10 mm 12-point deep socket

- Ratchet/torque wrench

-

Fasten the clip that attaches the RH subframe harness to the body.

-

Connect the RH subframe harness electrical connector.

- Install the rear fascia. See Fascia Assembly - Rear (Remove and Install).

- Install the LH and RH rear suspension covers. See Cover - Rear Suspension - LH (Remove and Replace).

- Install the rear aero shield panel. See Panel - Aero Shield - Rear (Remove and Replace).

- Perform the vacuum refill procedure. See Cooling System - Vacuum Refill (Test/Adjust).

- Install the LH and RH wheels. See Wheel Assembly (Remove and Install).

- Install the 2nd row lower seat cushion. See Seat Cushion - 2nd Row (Remove and Replace).

- Connect the LV power. See LV Power (Disconnect and Connect).

- Install the rear underhood apron. See Underhood Apron - Rear (Remove and Replace).

- Install the LH and RH rear wheels. See Wheel Assembly (Remove and Install).

- Remove the vehicle from the 2 post lift. See Raise Vehicle - 2 Post Lift.

- In this procedure, the front or rear subframe was removed and reinstalled. Therefore, refer to the Alignment Requirement tables to determine whether an EPAS alignment check (EC) or four wheel alignment check (AC) is necessary. If performed, add the alignment check/adjust as a separate activity. See Alignment Requirement - Suspension.