Fuse - A/C Compressor - HV Battery (Remove and Replace)

Correction code

1630010302

FRT

0.90

NOTE: Unless

otherwise explicitly stated in the procedure, the above correction code and

FRT reflect all of the work required to perform this procedure, including

the linked procedures. Do

not stack correction codes unless explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how

they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection

to make sure wearing proper PPE when performing the below procedure.

NOTE: See Ergonomic Precautions for safe and

healthy working practices.

Correction code

1630010302

FRT

0.90

NOTE: Unless

otherwise explicitly stated in the procedure, the above correction code and

FRT reflect all of the work required to perform this procedure, including

the linked procedures. Do

not stack correction codes unless explicitly told to do so.

NOTE: See Flat Rate

Times to learn more about FRTs and how

they are created. To provide feedback on FRT values, email ServiceManualFeedback@tesla.com.

NOTE: See Personal Protection

to make sure wearing proper PPE when performing the below procedure.

NOTE: See Ergonomic Precautions for safe and

healthy working practices.

Equipment:

- 1057602-00-A Ratchet, 1/4" Sq Dr, HV Insulated

- 1057604-00-A Skt, 1/4" Sq Dr, 8mm, HV Insulated

- 1057606-00-A Skt, 1/4" Sq Dr, 13mm, HV Insulated

- 1131071-00-A Dummy Disconnect, Pyro, Safety

- 1108272-00-B Cap, Logic Conn, Inv, 3DU

- 1076927-00-A Resistance meter, microohm, Hioki RM 3548

- 1076927-00-A Resistance meter, microohm, Hioki RM 3548

Only

technicians who have completed all required certification courses are permitted to

perform this procedure. Tesla recommends third party service provider technicians

undergo equivalent training before performing this procedure. For more information on

Tesla Technician requirements, or descriptions of the subject matter for third parties,

see HV Certification Requirements. Proper personal protective equipment (PPE) and insulating HV

gloves with a minimum rating of class 0 (1000V) must

be worn at all times a high voltage cable, busbar, or fitting is handled. Refer to Tech Note TN-15-92-003, High Voltage Awareness

Care Points

for additional safety

information.

Torque Specifications

| Description | Torque Value | Recommended Tools | Reuse/Replace | Notes |

|---|---|---|---|---|

| Nuts (x2) that attach the A/C compressor fuse to the ancillary bay bus |

2.5 Nm (1.8 lbs-ft) |

|

Replace |

Remove

-

Remove the ancillary bay cover. See Ancillary Bay Cover (Remove and Replace).

WarningHV insulating gloves and leather glove protectors must be worn throughout the remainder of this procedure. Do not remove gloves or protectors until otherwise noted.

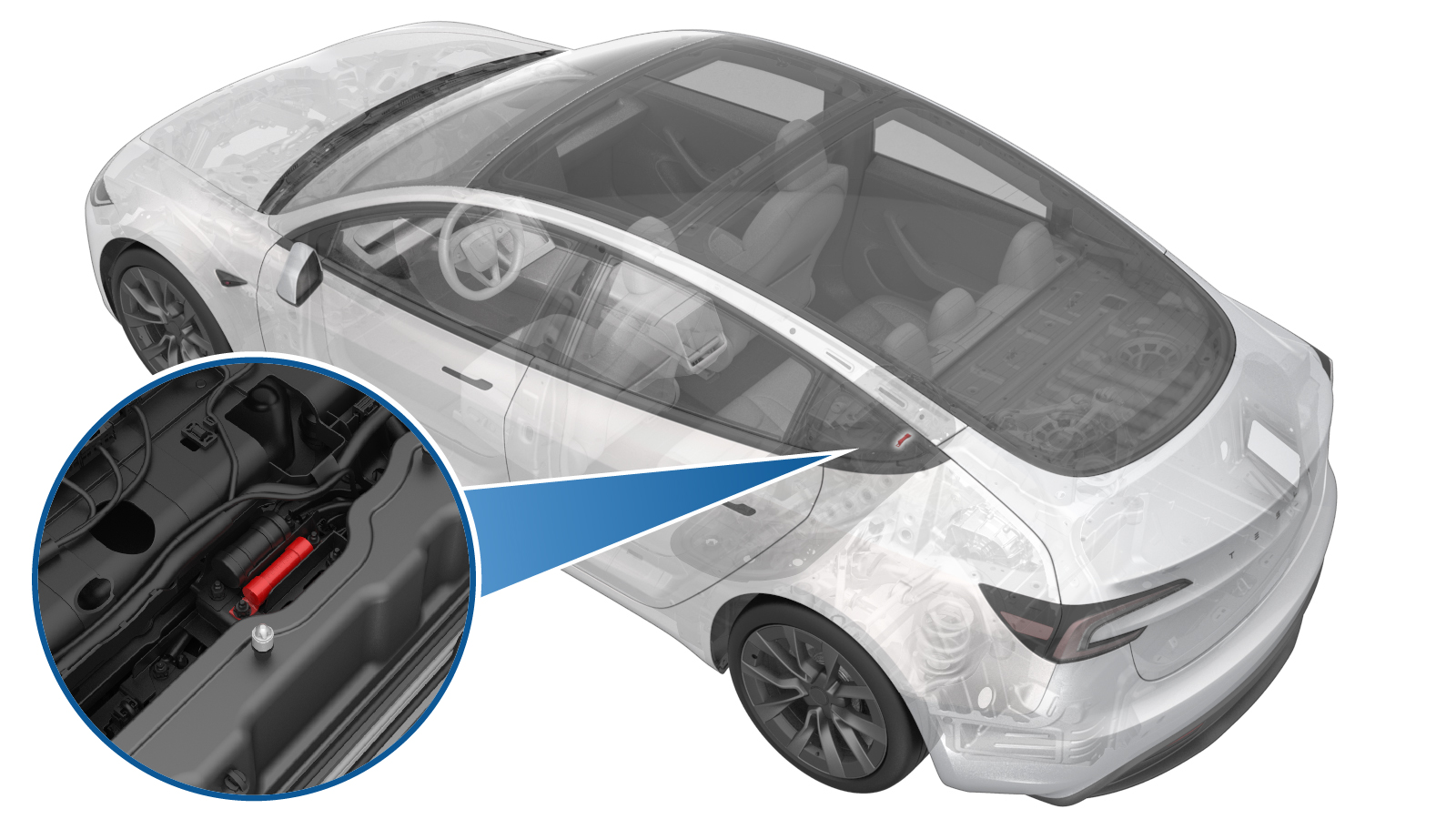

- Remove the pyrotechnic battery disconnect. See Pyro Disconnect - HV Battery (Remove and Replace).

-

Remove and discard the nuts

(x2) that attach the A/C compressor fuse to the ancillary bay bus, and then

remove the fuse.

TIpUse of the following tool(s) is recommended:

- Insulated

tools:

- 8 mm socket

- Ratchet/torque wrench

WarningThe video(s) included in this procedure are meant as an overview for supplemental purposes only. Follow all of the steps listed in the procedure to avoid damage to components and/or personal injury. - Insulated

tools:

Install

-

Perform a zero adjust of the

Hioki resistance meter in preparation to measure resistances later in this

procedure.

WarningHV insulating gloves and leather glove protectors must be worn throughout the remainder of this procedure. Do not remove gloves or protectors until otherwise noted.

-

Install the A/C compressor

fuse to the ancillary bay bus, and then install new nuts (x2) to attach the fuse

to the bus.

2.5 Nm (1.8 lbs-ft)TIpUse of the following tool(s) is recommended:

2.5 Nm (1.8 lbs-ft)TIpUse of the following tool(s) is recommended:- Insulated

tools:

- 8 mm socket

- Ratchet/torque wrench

- Insulated

tools:

-

Use the Hioki resistance

meter to measure the resistance at the HV joint of the A/C compressor fuse

and the positive DC busbar.

CAUTIONDo not short the side of the probe tip to the edge of the fuse lug.NoteThe maximum acceptable resistance is 0.145 mΩ (145 μΩ). There is too much resistance in the High Voltage joint. Remove the fastener, clean areas with isopropyl alcohol, install fastener back and test again

-

Use the Hioki resistance

meter to measure the resistance at the HV joint of the A/C compressor fuse

and the electrical harness terminal.

CAUTIONDo not short the side of the probe tip to the edge of the nut's captive washer.NoteThe maximum acceptable resistance is 0.105 mΩ (105 μΩ). There is too much resistance in the High Voltage joint. Remove the fastener, clean areas with isopropyl alcohol, install fastener back and test again

- Measure the voltage across the pyrotechninc battery disconnect mount points, and then install the pyrotechnic battery disconnect. See Pyro Disconnect - HV Battery (Remove and Replace).

-

Install the ancillary bay cover. See Ancillary Bay Cover (Remove and Replace).

NoteBefore installing the ancillary bay cover, inspect the ancillary bay cover seal and confirm there is no visual damage. If the seal is torn and/or delaminated, replace the ancillary bay cover.