18/11/2024 04:11:46

Steering Rack (LHD RWD) (1st Generation) (Remove and Replace)

Correction Code 32010102

This procedure is for vehicles built

before April 10, 2016. For vehicles built after April 10, 2016: See

Steering Rack (LHD) (2nd Generation) (Remove and Replace)

Warning

If the vehicle has air

suspension, activate "Jack" mode on the touchscreen before raising and

supporting the vehicle.

- 2024-11-18: Updated firmware install step.

- 2023-07-13: Updated post-replacement routines.

Special tools required for this procedure:

| Part Number | Description |

| 1517282-00-A | Inner tie rod kit |

| 1517286-00-A | Anti rotation device |

| 1517285-00-A | Steering gear clamp |

| 1517283-00-A | 41mm straight crowfoot |

| 1517284-00-A | 38mm straight crowfoot |

Removal

- Center the steering wheel, and then hold the steering wheel in place with the steering holder.

- Remove the rear underhood apron. See .

- Remove the LH and RH underhood aprons. See .

- Remove the underhood storage carpet. See .

- Remove the underhood storage unit. See .

- Disconnect 12V power. See .

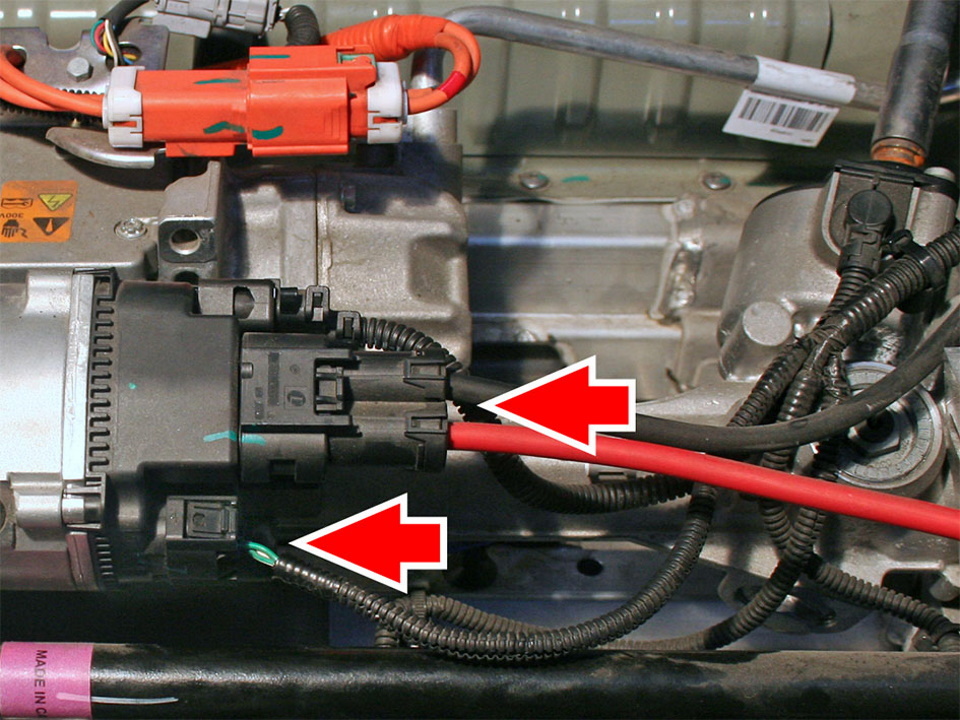

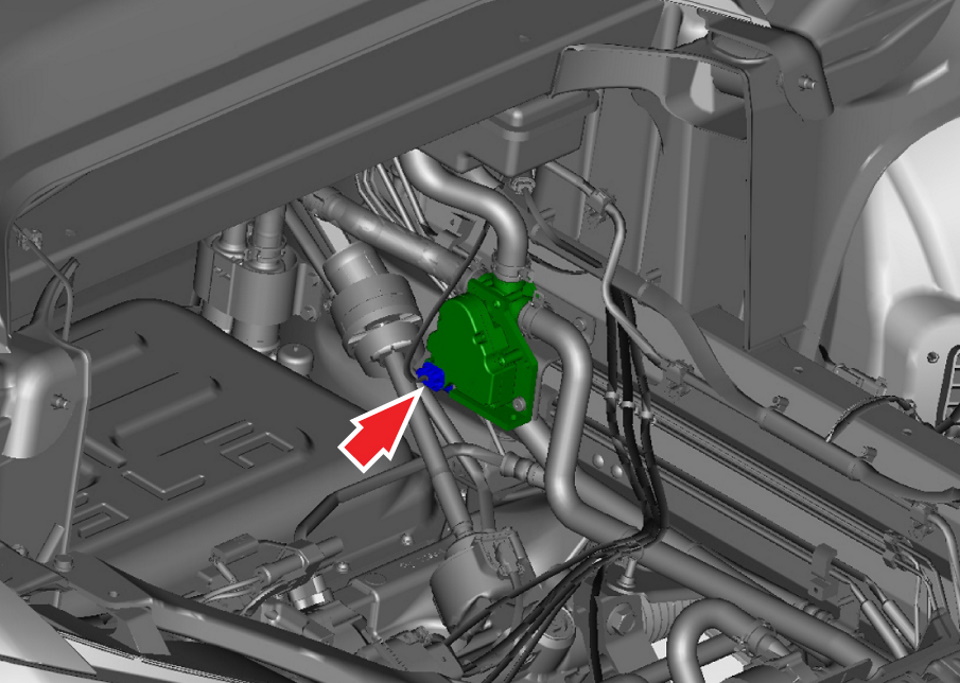

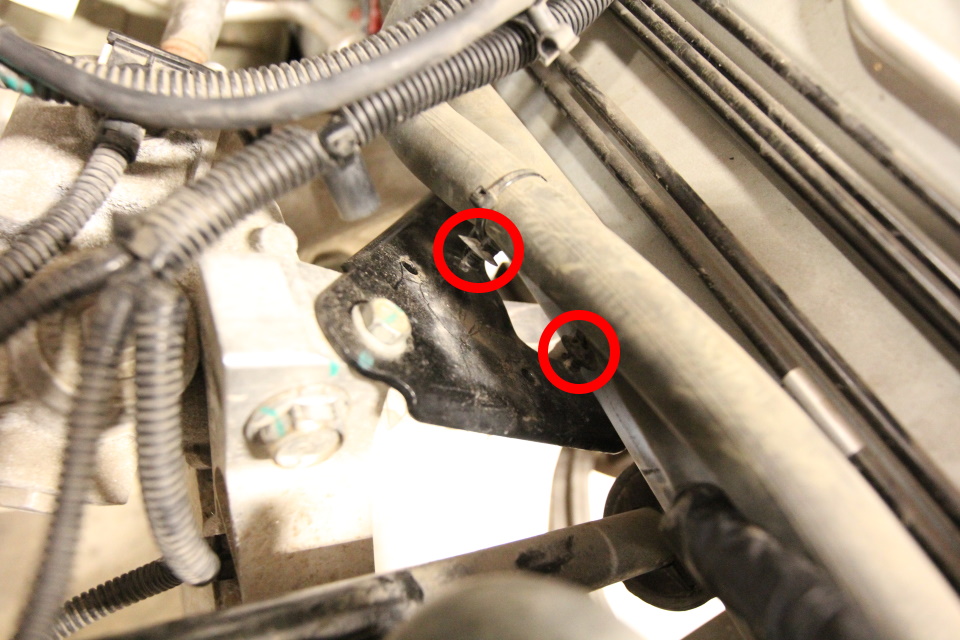

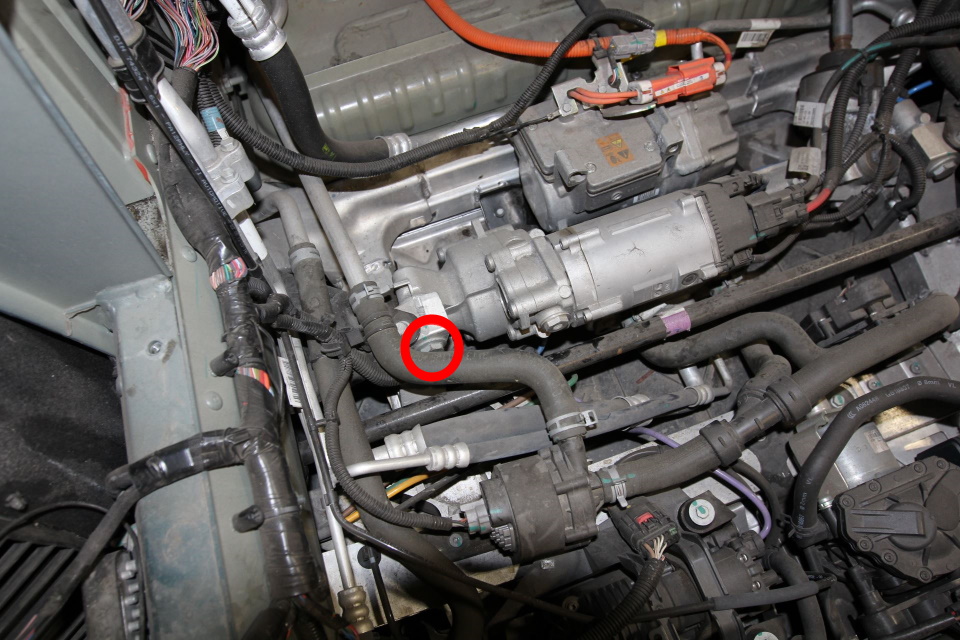

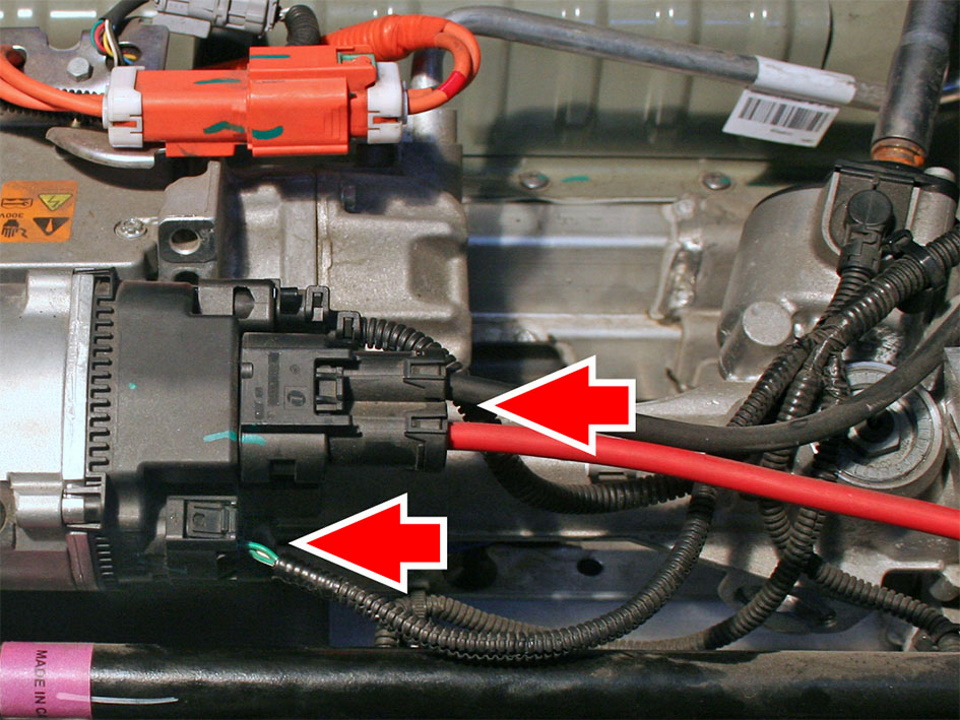

- Disconnect the steering rack electrical connector (x2).

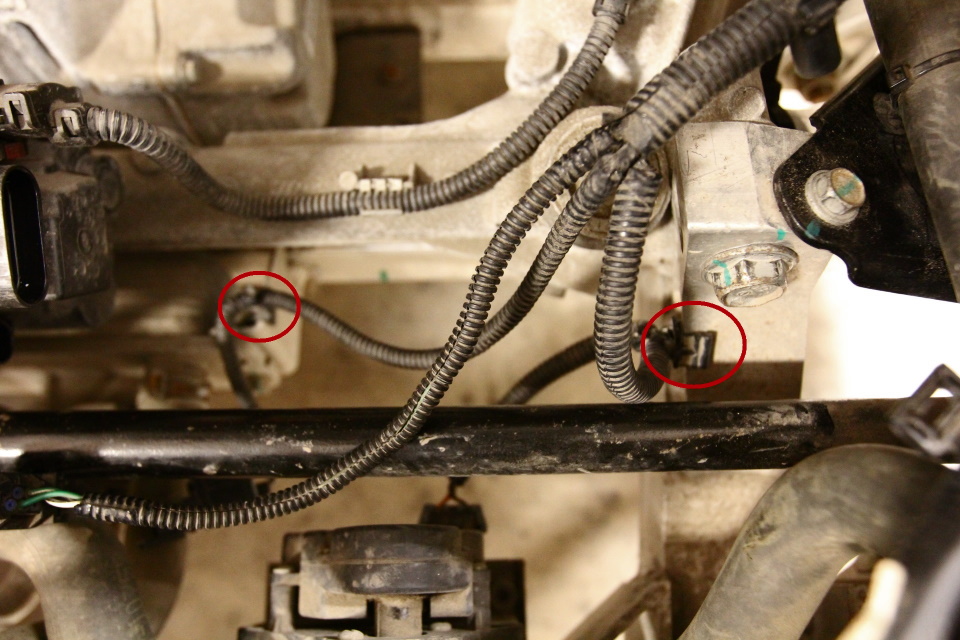

- Release the clips (x2) that attach the front harness to the vehicle, and move the front harness aside.

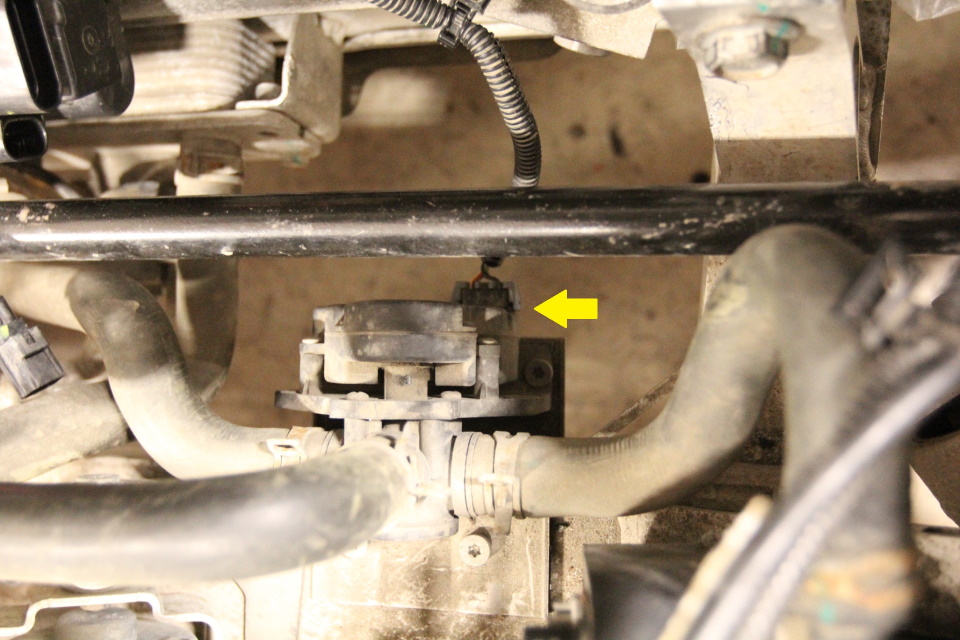

- Disconnect the chiller bypass 3-way coolant valve electrical connector, and then move the harness aside.

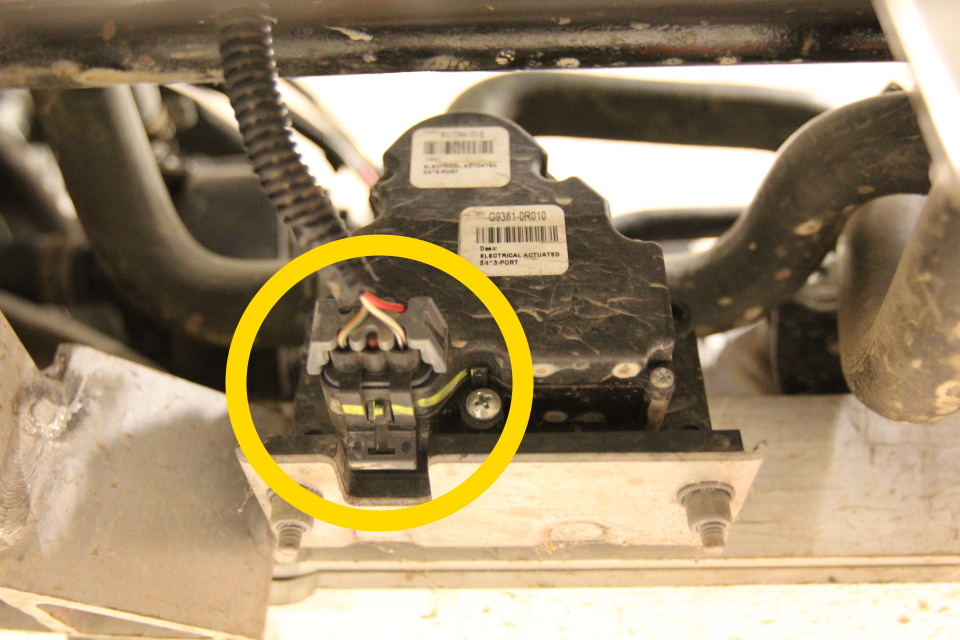

- Disconnect the 4 way coolant valve electrical connector.

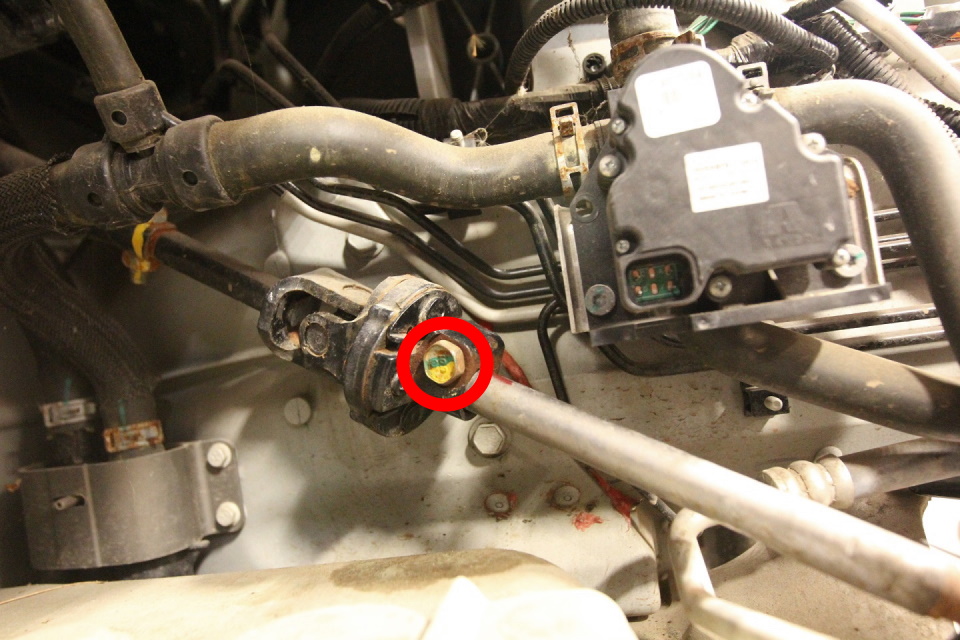

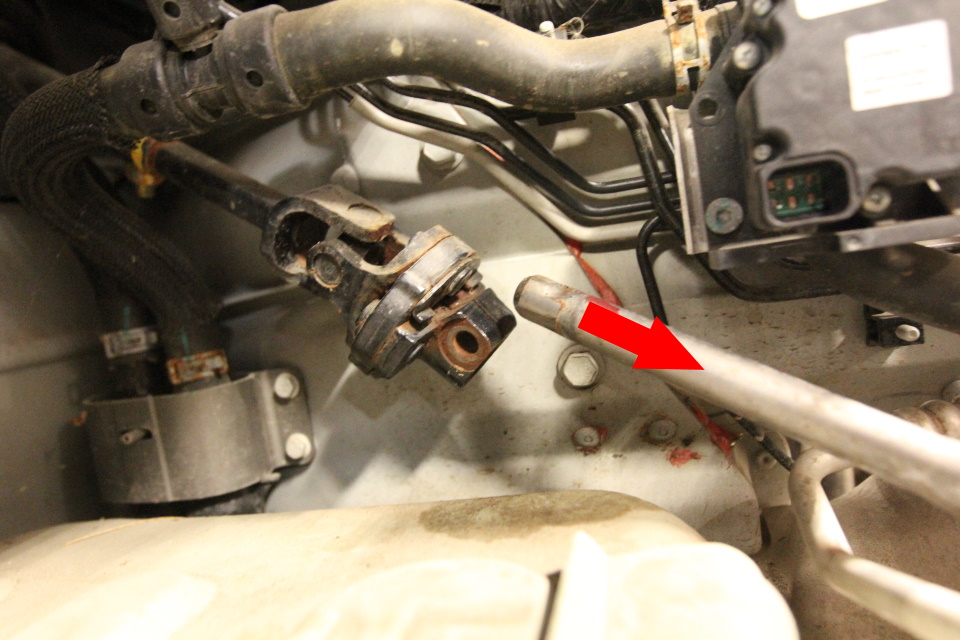

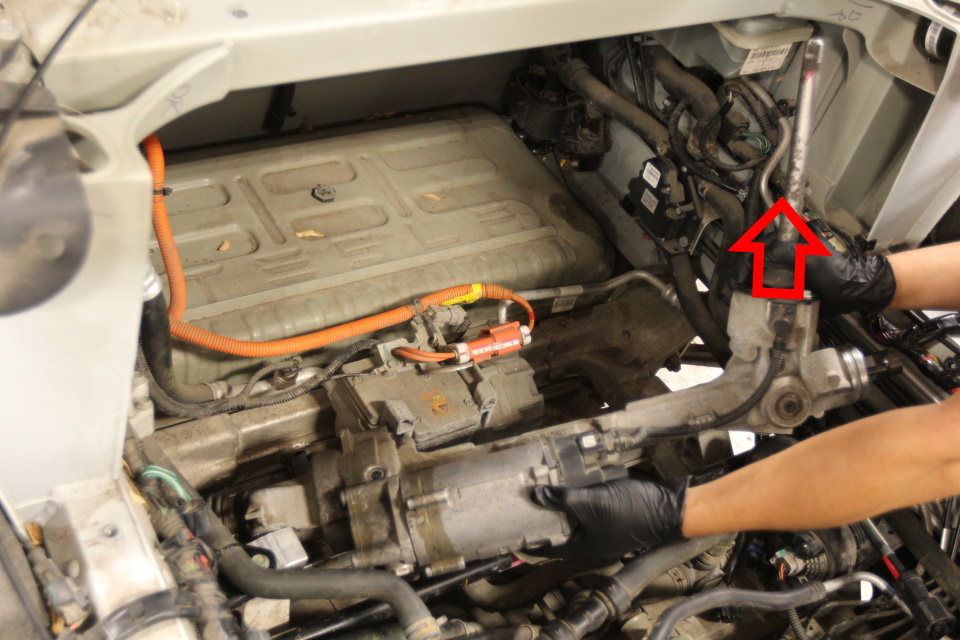

- Remove and discard the bolt that attaches lower steering column intermediate shaft to the steering rack input shaft, and then slid off the steering rack input shaft.

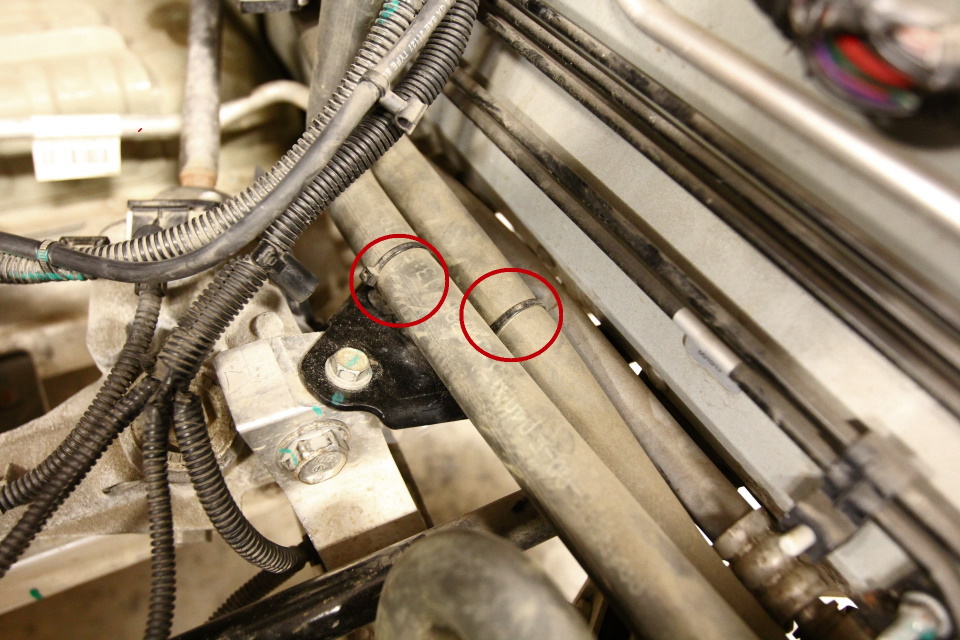

- Release the clips (x2) that attach the coolant hoses to the LH front subframe brace.

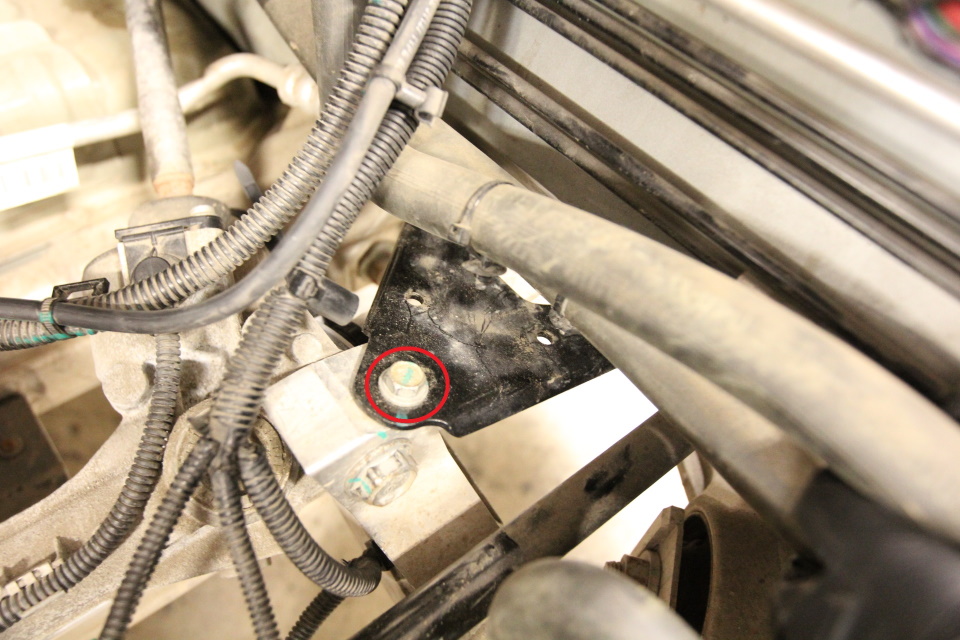

- Remove the upper bolt from the LH front subframe brace.

- Remove the LH and RH front wheels. See .

- Fully raise the vehicle. See .

- Remove the front aero shield panel. See .

-

Remove the bolts (x2) attach the LH subframe brace to the body, and then remove

the brace from the vehicle.

NoteSlide the LH subframe brace out from in between the front subframe.

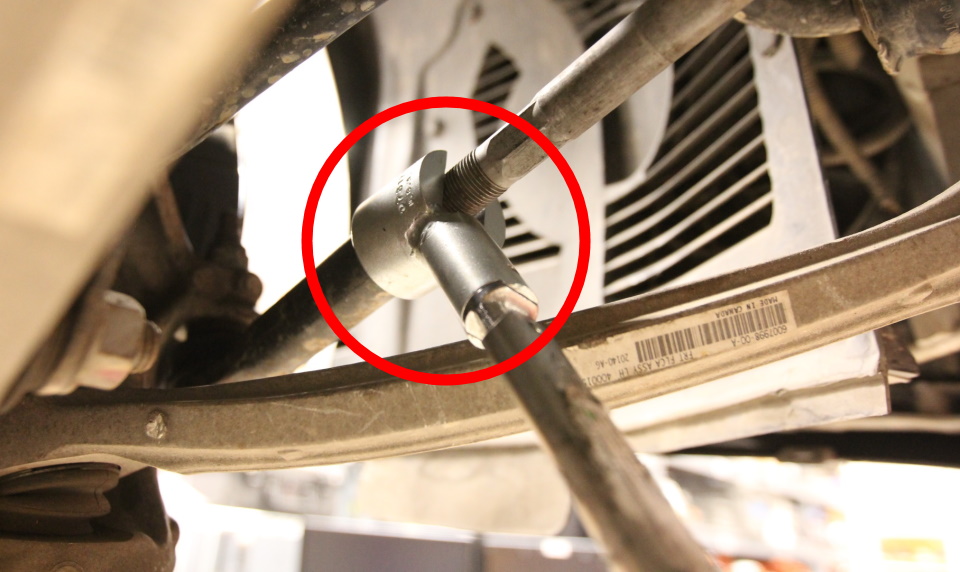

- Loosen the jam nut that attaches the LH tie rod.

- Partially lower the vehicle.

-

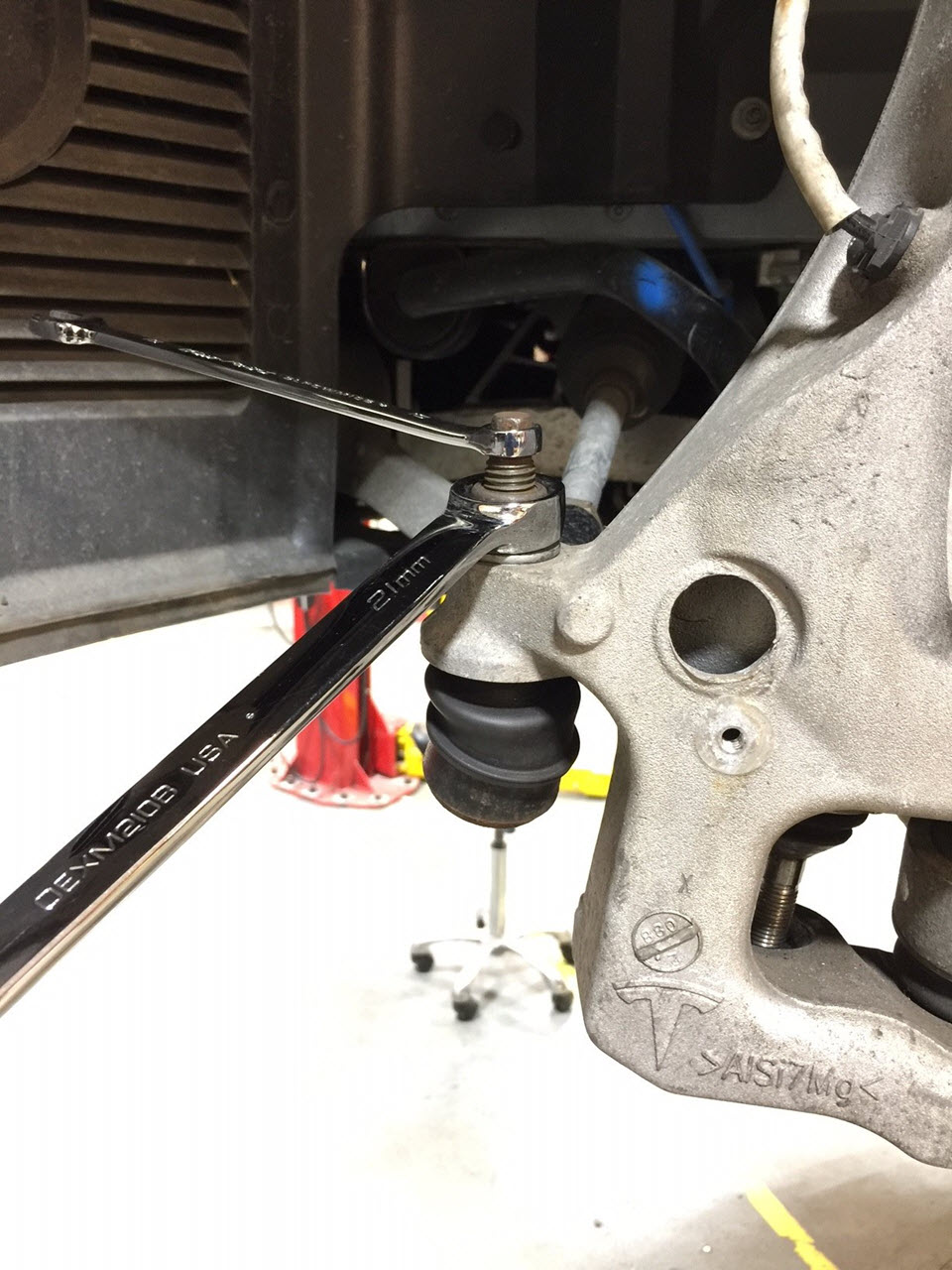

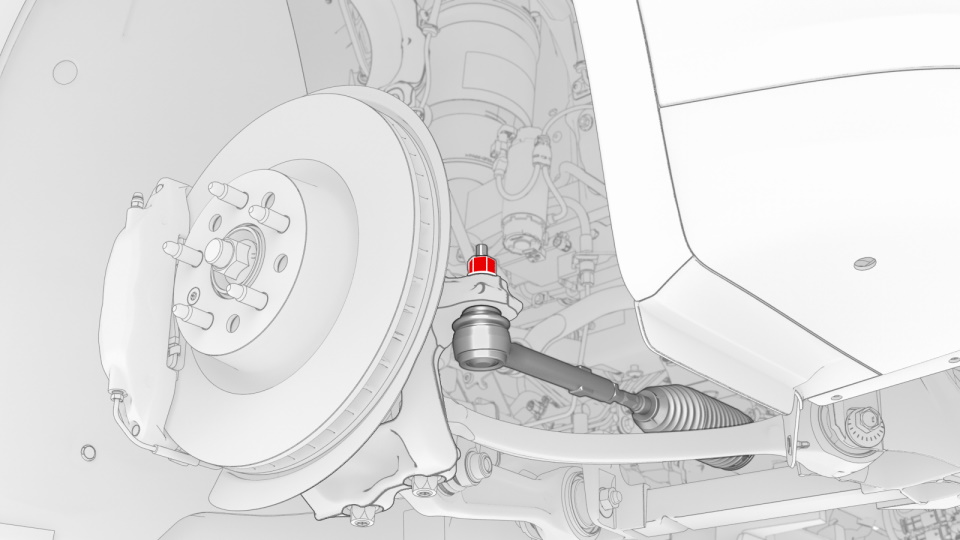

Remove and discard the nut that

attaches the tie rod end to the LH front knuckle.

CAUTIONPrevent ball joint damage by holding the ball joint pin with another wrench to counterforce the tie rod end nut.

-

Loosen the LH outer tie rod, and

then remove the outer tie rod from the steering rack.

NoteRecord the number of turns it takes to remove the outer tie rod end from the steering rack to ease reinstallation.

- Remove the LH jam nut from the steering rack.

-

Remove the clamp that attaches

the outer side of the bellows to the LH inner tie rod using the combination slip

joint pliers.

TIpNote the clamp orientation for installation later in this procedure.

-

Remove the clamp that attaches

the inner side of the bellows to the LH inner tie rod using a small flat head

screwdriver.

NoteUse a flat head screwdriver to remove the clamp off the retaining tab.

- Remove the bellows from the LH inner tie rod.

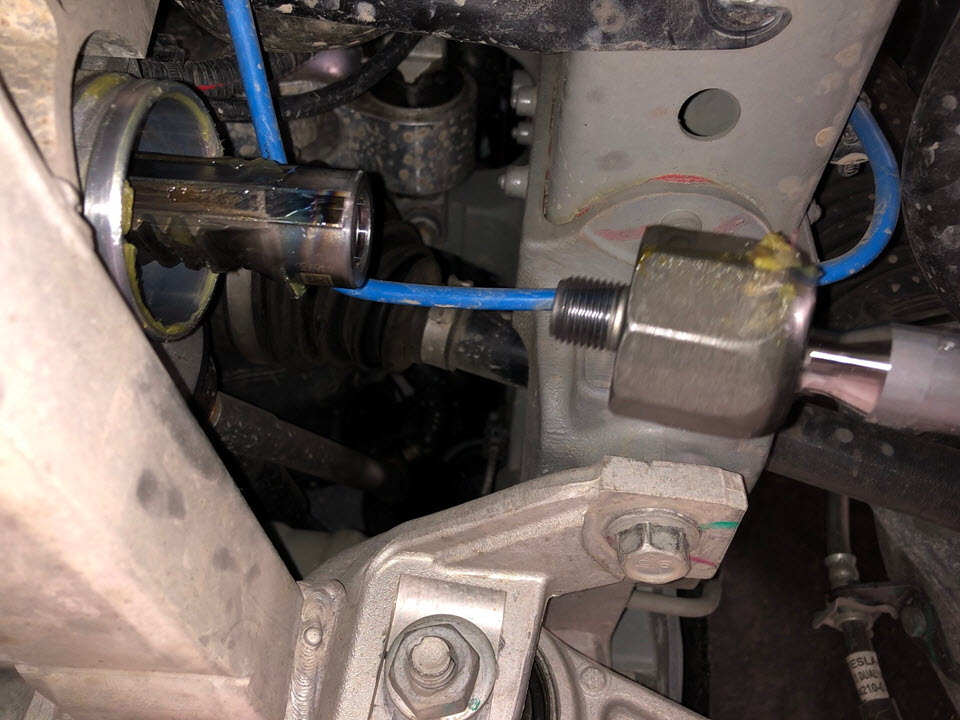

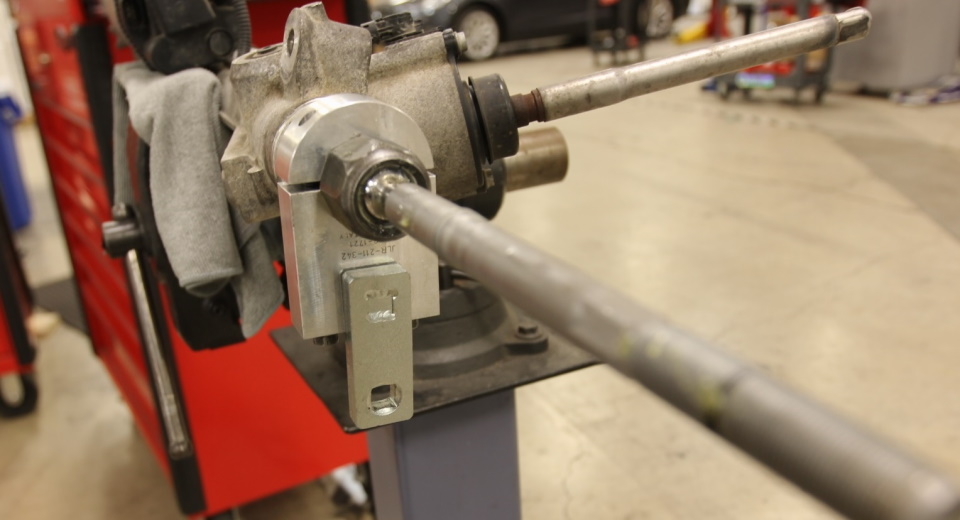

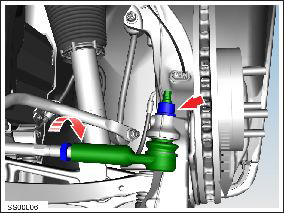

- Install the steering gear clamp tool, crawfoot socket, and the anti-rotation device tool on the LH inner tie rod.

-

Loosen the LH inner tie rod while

holding the inner gear to prevent it from rotating.

CAUTIONFailure to hold the inner gear may result in damage to the steering rack assembly.

- Remove the LH inner tie rod from the steering rack.

- Remove the steering rack clamp and anti-rotation device from the LH inner tie rod.

-

Remove and discard the RH nyloc nut that attaches the RH tie rod end to the

steering knuckle, and then disconnect the tie rod from the steering knuckle.

CAUTIONPrevent ball joint damage by holding the ball joint pin with another wrench to counterforce the tie rod end nut.

- Partially lower the vehicle.

-

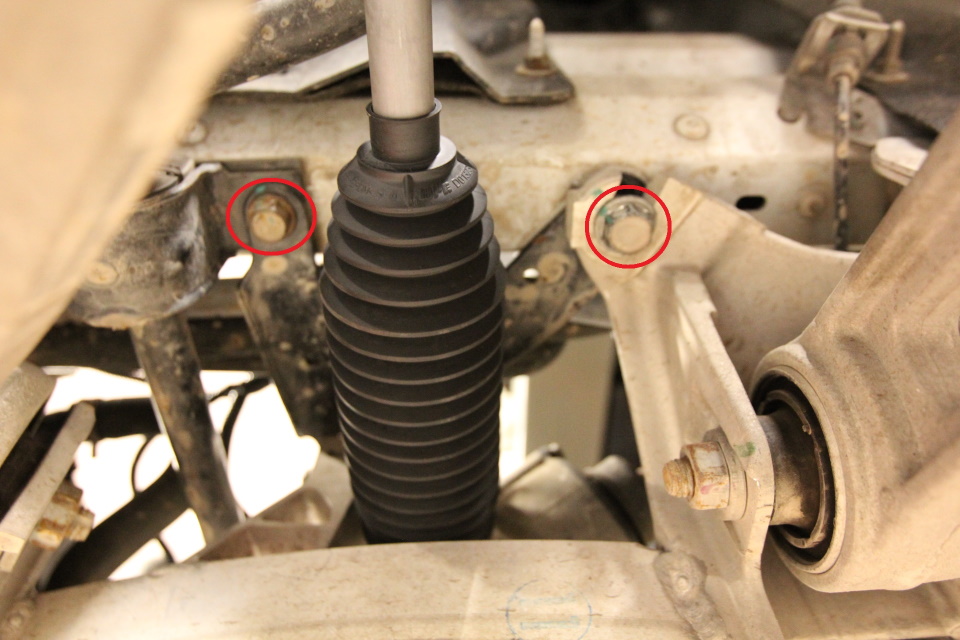

Remove and discard the bolts (x2) that attach the steering rack to the front

subframe.

NoteIf a washer was also installed between the steering rack bolt(s) and the front subframe, keep the washer(s) because it will be reinstalled during the installation process.

- Carefully lift up the LH side of the steering rack, and then remove the steering rack from the vehicle.

Installation

-

Place the new steering rack on a bench vise and tighten the vise.

NoteUse a shop tower between the steering rack and the bench vise to prevent marring.

-

Remove the LH inner tie rod outer

bellows clamp on the new steering rack using combination slip joint pliers.

NoteNote the clamp orientation for installation later in this section.

-

Remove the clamp that attaches the inner side of the bellows to the LH inner tie

rod on the new steering rack using a small flat head screwdriver.

NoteUse a flat head screwdriver to remove the clamp off the retaining tab.

- Remove the bellows from the LH inner tie rod on the new steering rack.

- Install the steering gear clamp tool, crawfoot socket, and the anti-rotation device tool on the LH inner tie rod of the new steering rack.

-

Loosen the LH inner tie rod while holding the inner gear to prevent it from

rotating.

CAUTIONFailure to hold the inner gear may result in damage to the steering rack assembly.

- Remove the LH inner tie rod from the new steering rack.

- Remove the steering gear clamp tool, crawfoot socket, and the anti-rotation device tool from the new steering rack.

-

Temporarily reinstall the LH bellow dust boot on the new steering rack to

prevent contamination.

CAUTIONDo not allow contaminants such as dirt or debris to enter the new steering rack, otherwise components will have to replaced.

- Put the new steering rack into position for installation: carefully position the RH side of the steering rack first, and then verify that the RH outer ball joint will be positioned correctly for installation before bolting the steering rack to the front subframe.

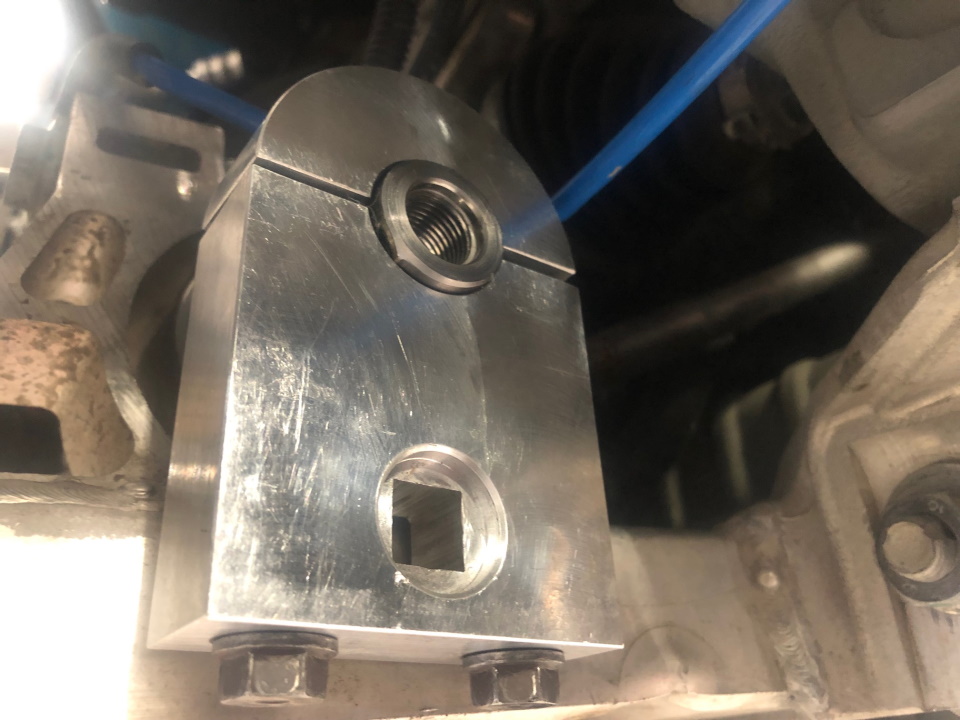

-

Hand tighten a new bolt that

attaches the RH side of the steering rack to the front subframe.

NoteInstall the washer between the steering rack and the front subframe, if equipped.

-

Install a new bolt that attaches the LH of the steering rack to the front

subframe (torque 175 Nm).

NoteInstall the washer between the steering rack and the front subframe, if equipped.

- Tighten the bolt that attaches the RH side of the steering rack to the front subframe (torque 175 Nm).

- Secure the clips (x2) that attach the front harness to the vehicle.

- Connect the chiller bypass 3-way coolant valve electrical connector.

- Connect the steering rack electrical connector (x2).

- Connect the lower steering column intermediate shaft to the steering rack input shaft, and then install a new bolt (torque 50 Nm).

- Connect the 4 way coolant valve electrical connector.

- Partially raise the vehicle.

- Remove the LH inner tie rod bellows.

- Install the steering gear clamp tool, crawfoot socket, and the anti-rotation device tool on the LH inner tie rod (torque 10 Nm).

-

Install the LH inner tie rod to

the steering rack while holding the inner gear to prevent it from turning (torque

115 Nm).

CAUTIONFailure to hold the inner gear might result in internal steering rack damage.

- Remove the steering gear clamp and the anti rotation device tools from the LH inner tie rod.

- Install a new inner band clip on the LH tie rod bellows, but do not clamp the clip at this time.

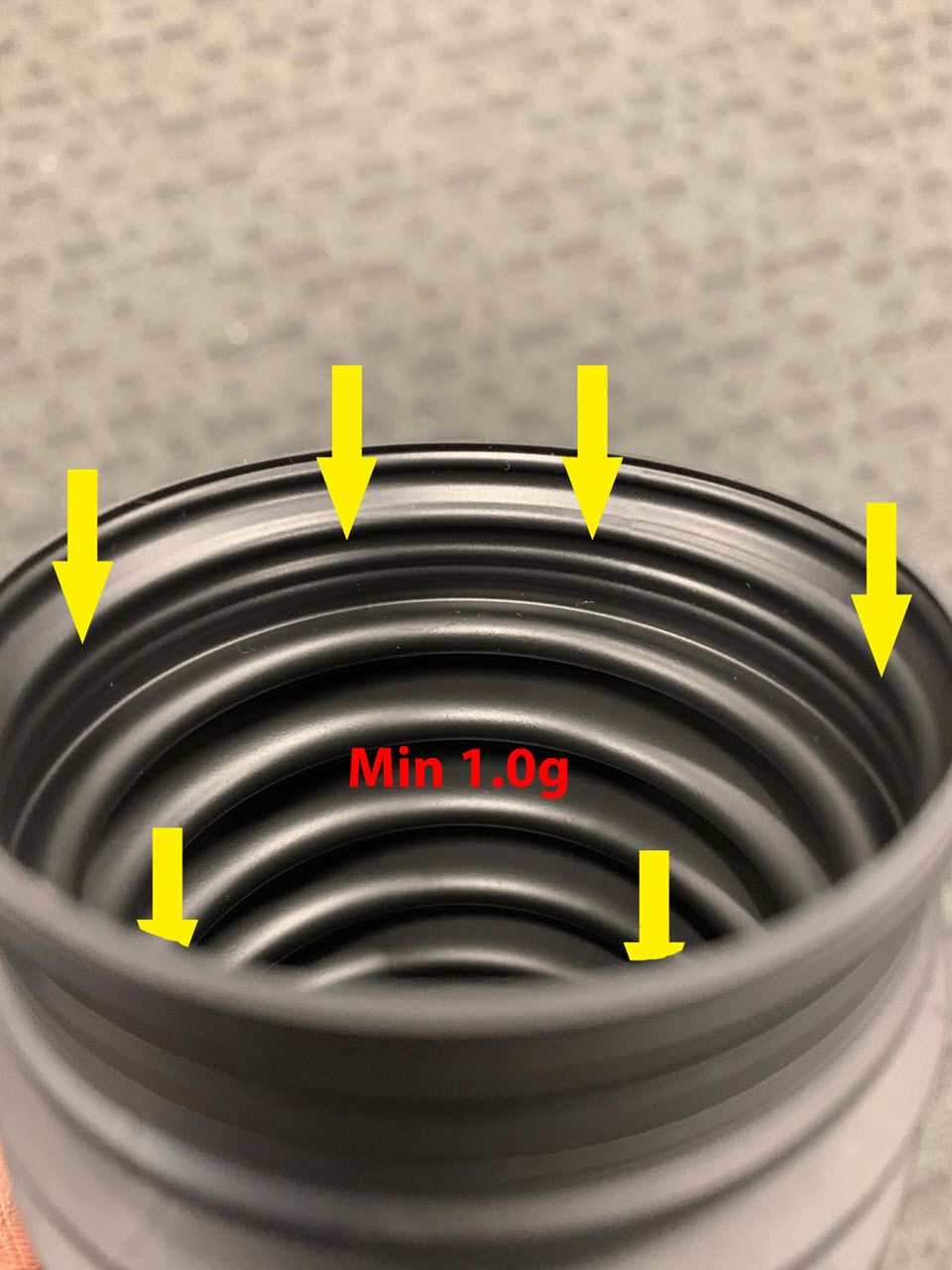

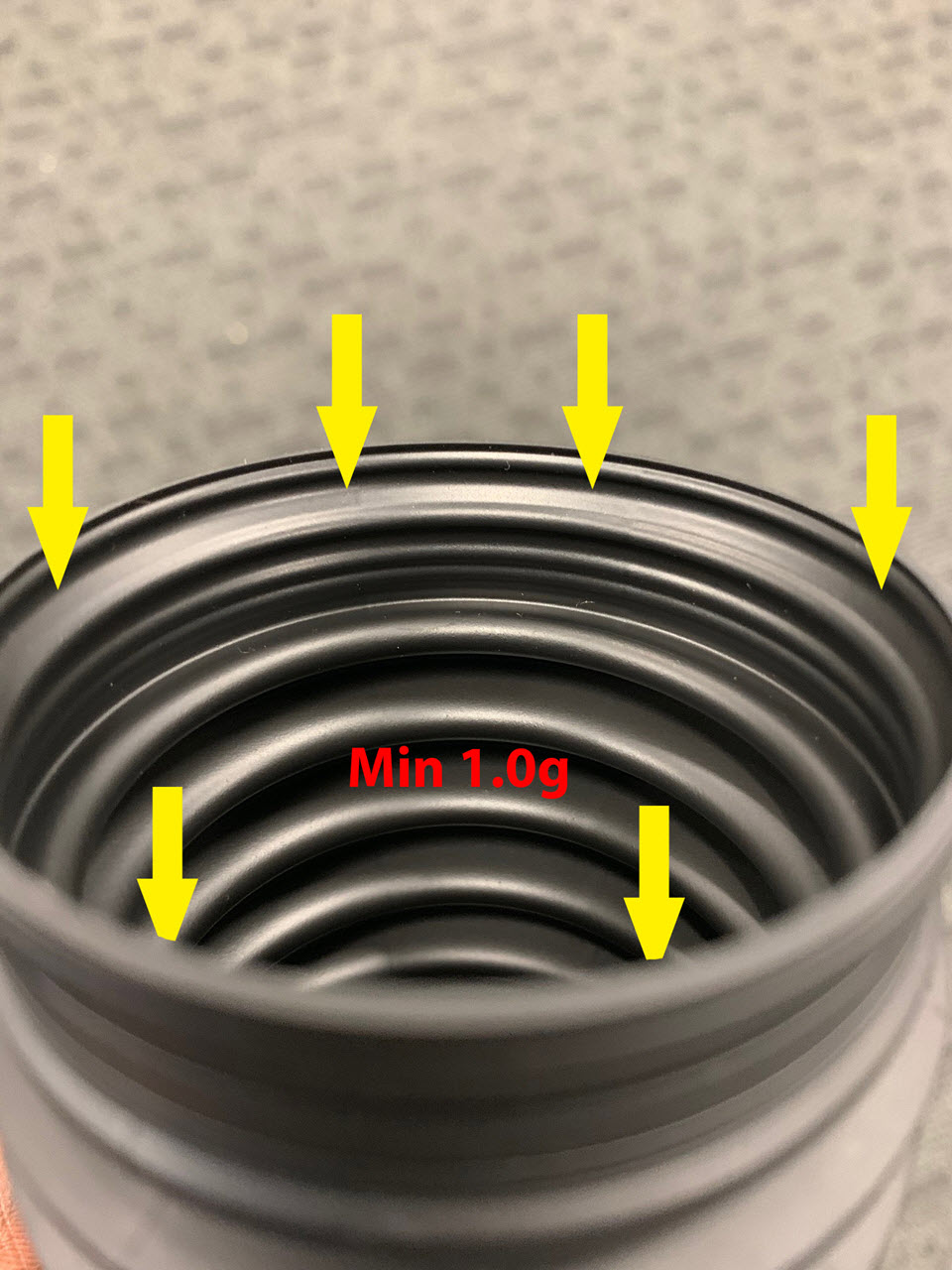

- Use the following amount of Renolit JP 1619 grease (included with the inner tie rod service kit) to lubricate the bellows before installation:

- Install the bellows into the LH inner tie rod.

- Lower the vehicle so that the tires are touching the ground.

-

Attach the LH inner tie rod band

clip by clamping the clip ear using the knipex ear clamp pliers.

NoteThe tie rod band clip can be secured from the underhood storage unit area.NoteRotate the tie rod band to properly access the ear clip.

- Place the LH front subframe brace for installation, and then hand tighten the bolt.

- Raise the vehicle fully.

-

Install the lower bolts (x2)

attach the LH subframe brace to the body (torque 15 mm bolt: 26 Nm, 18 mm bolt: 76

Nm).

NoteSlide the LH subframe brace out from in between the LH subframe.

- Install the front aero shield panel. See .

- Lower the vehicle partially to a comfortable working height.

-

Install the outer hose clip on

the LH inner tie rod bellows using the combination slip joint pliers.

NoteInstall the clip in the original orientation.

- Install the LH jam nut onto the inner tie rod.

-

Install the LH tie rod end, and

then snug the jam nut. Repeat this step for the RH tie rod.

NoteUse the recorded number of turns to put the tie rod end back on.

- Install a new nut that attaches the LH tie rod end to the knuckle (torque 103 Nm). Repeat this step for the RH tie rod.

-

Tighten the LH tie rod end jam

nut (torque 70 Nm). Repeat this step for the RH tie rod.

NoteSet the Tohnichi torque wrench to 80 Nm with the adapter.

- Install the LH and RH front wheels. See .

- Tighten the upper bolt for the LH front subframe brace (torque 26 Nm).

- Secure the clips (x2) that attach the coolant hoses to the LH front subframe brace.

- Reconnect 12V power. See .

- Install the underhood storage unit. See .

- Install the underhood storage carpet. See Carpet - Underhood Storage (Remove and Install).

- Install the LH and RH underhood aprons. See Underhood Apron - LH (Remove and Replace) .

- Install the rear underhood apron. See Underhood Apron - Center - Rear (Remove and Replace).

- Update the vehicle firmware. See Firmware Update.

- Connect a laptop with Toolbox 3 to the vehicle. See Toolbox 3 (Connect and Disconnect).

- Unlock the vehicle gateway. See Gateway Unlock.

-

Using Toolbox 3:

- Select the Actions tab and search for "EPAS Post Replacement"

- Select the ODIN routine PROC_EPAS_X_POST-REPLACEMENTvia Toolbox: (link)via Service Mode: Chassis ➜ Steering ➜ Post Steering Rack Replacement, and then click the link of the routine.

- Click RUN, and allow the routine to complete.

- Perform a Lock To Lock-Angle test. See Lock To Lock-Angle Test.

- Disconnect the laptop with Toolbox 3 from the vehicle. See Toolbox 3 (Connect and Disconnect).

- Refer to the Alignment Requirement tables to determine whether an EPAS alignment check (EC) or four wheel alignment check (AC) is necessary. If performed, add the alignment check/adjust as a separate activity. See Alignment Requirement - Suspension.