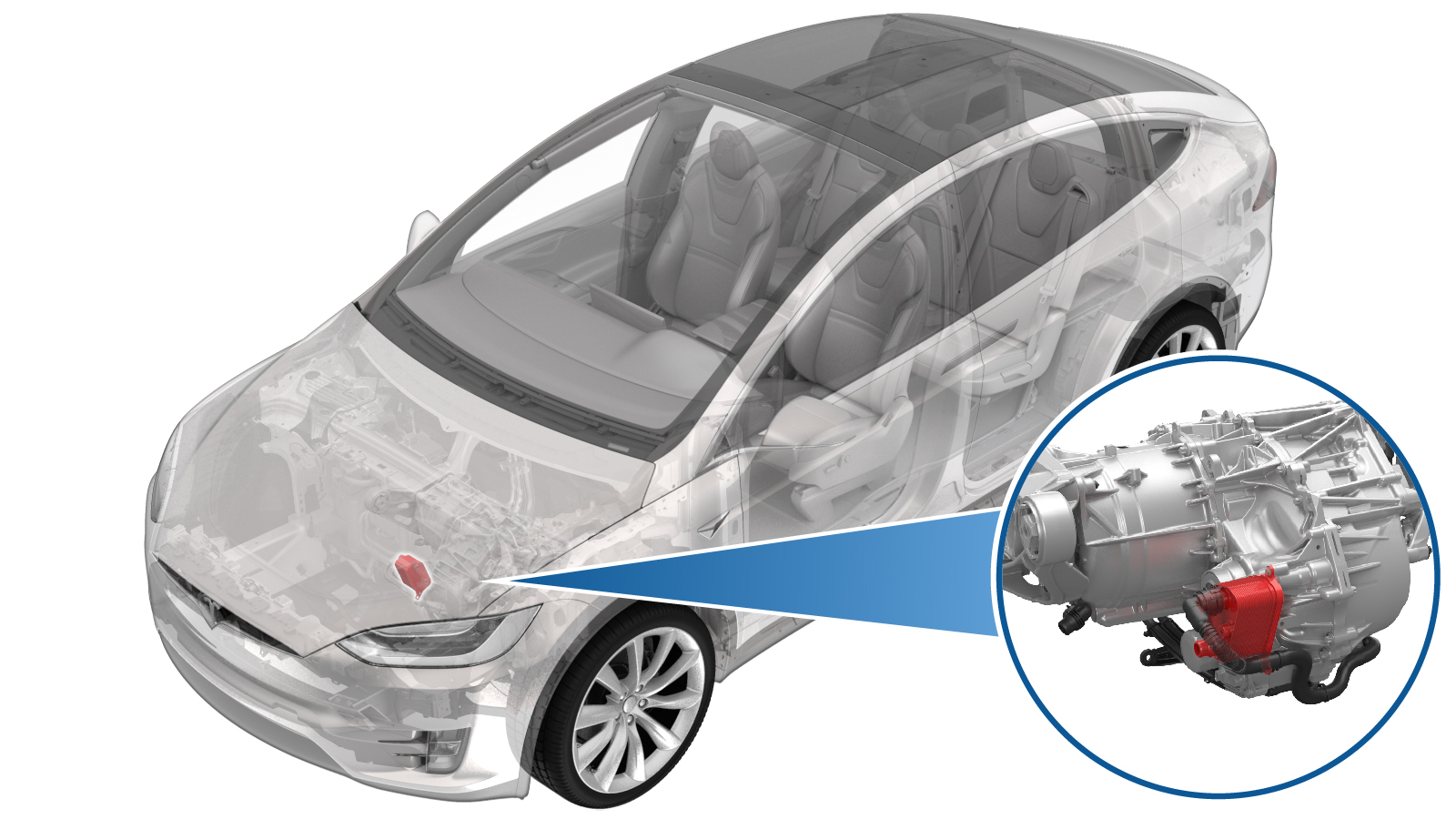

Heat Exchanger - Front Drive Unit (Remove and Install)

Correction code

39308512

1.20

NOTE: Unless

otherwise explicitly stated in the procedure, the correction code and FRT

listed above reflect all of the work required to perform this procedure,

including the linked procedures. Do not stack correction

codes unless explicitly told to do so.

NOTE: See Flat Rate Times

to learn more about FRTs and how they are created.

NOTE: See Personal Protection

to make sure you are wearing proper PPE when performing the procedure

below.

NOTE:

See Ergonomic Precautions for

safe and healthy working practices.

Correction code

39308512

1.20

NOTE: Unless

otherwise explicitly stated in the procedure, the correction code and FRT

listed above reflect all of the work required to perform this procedure,

including the linked procedures. Do not stack correction

codes unless explicitly told to do so.

NOTE: See Flat Rate Times

to learn more about FRTs and how they are created.

NOTE: See Personal Protection

to make sure you are wearing proper PPE when performing the procedure

below.

NOTE:

See Ergonomic Precautions for

safe and healthy working practices.

- 2025-06-06: Updated procedure without compressor removal.

- 2025-01-28: Revised procedure and added references.

Removal

- Remove the underhood storage unit. See Underhood Storage Unit (Remove and Replace).

- Remove the HEPA filter. See Filter - HEPA (Remove and Replace).

- Disconnect 12V power. See Disconnect 12V Power.

-

Clamp the coolant hose.

-

Move coolant hose to create additional

clearance.

NoteUse a clip pry tool to remove the clip holding the coolant hose, then lower the hose to allow for additional clearance.

-

Remove the upper bolt that attaches

the heat exchanger to the FDU.

- Remove the front aero shield panel. See Panel - Aero Shield - Front (Remove and Replace).

-

Remove the bolts that attach the front

bash plate extrusion.

-

Remove and discard the bolts (x2) that

attach the front of the HV battery.

-

Remove and discard the front HV

battery bolts (x4).

-

Remove the bolts (x2) that attach the

skid plate to the front subframe.

-

Position an oil drain container under

the oil pump area.

-

Disconnect the front drive unit oil

pump connector.

-

Remove the bolts (x2) that attach the

oil pump to the FDU.

-

Remove the oil pump from the

FDU.

NotePry the pump away from the FDU with a pry tool or flat blade screwdriver. Make sure that the FDU casting is not damaged. Allow the oil to drain from the FDU.

-

Position a foldable funnel under the

FDU.

-

Remove the oil filter from the

FDU.

-

Remove foldable funnel

- Remove the oil drain container from under the vehicle.

-

Position coolant drain container under

the LH front corner of the vehicle to catch vehicle coolant

-

Release the FDU outlet hose from the

heat exchanger and plug the heat exchanger.

Note1x spring clip. Allow excess coolant to fully drain.

-

Release the upper coolant hose from

the heat exchanger and plug the heat exchanger.

Note1x spring clip. Allow excess coolant to fully drain.

-

Remove the fir tree clip from the heat

exchanger and move hose aside

-

Remove the lower bolt that attaches

the heat exchanger to the FDU.

-

Remove the heat exchanger from the FDU

assembly.

NoteSome oil will spill out of the FDU after removal

Installation

-

Inspect seals of the new heat

exchanger

NoteReplace any damaged seals. Lubricate with drive unit oil before installation

-

Position the heat exchanger onto the

FDU assembly.

-

Install the lower fastener securing

the heat exchanger to the FDU.

5 Nm (3.7 lbs-ft) + 30degNote1x bolt, EP10, 5 Nm + 30 degrees

5 Nm (3.7 lbs-ft) + 30degNote1x bolt, EP10, 5 Nm + 30 degrees -

Install the clip securing the upper

coolant hose to the heat exchanger

Note1x fir tree clip

-

Install the upper coolant hose onto

the heat exchanger .

Note1x spring clip. Perform a push-pull-push test.

-

Install the FDU outlet hose onto the

heat exchanger.

Note1x spring clip. Perform a push-pull-push test.

-

Install the clip that attaches the oil

pump harness pigtail to the heat exchanger.

- Remove the coolant drain container from under the LH front of the vehicle.

-

Position an oil drain container under

the oil pump area.

-

Remove the fill plug from the

FDU.

-

Inspect seals and o-rings

NoteInspect O-rings on removed parts, 3 O-rings on pump, one O-ring on fill plug. if missing O-ring on pump, ensure it is not left in housing. If damaged O-ring on plug, replace plug. Replace all O-rings on oil pump if damaged. Check seal on oil filter; if missing, check if still on housing and remove before installing.

-

Install the new oil filter.

NoteSpin clockwise, 3 Nm and 135 degrees. Lubricate seal prior to installation.

-

Install the oil pump into the

FDU

NoteUse residual oil in the oil pump cavity to lubricate the seals of the oil pump before installation, Align bolt holes with housing

-

Install the bolts (x2) that attach the

oil pump to the FDU.

5 Nm (3.7 lbs-ft) + 20 deg

5 Nm (3.7 lbs-ft) + 20 deg -

Set up fill kit.

NoteSet fluid level to 2000 ml in measuring container

-

Install fluid transfer pump

NoteTrim both input and output hoses to 26". Insert output hose into the fill hole until fully seated, then pull back 5 mm.

-

Set up the fill process.

NotePlace measured fluid container in drain basket, fully submerge input hose, prime pump with ATF fluid.

-

Connect the 12V power supply tool

connector to the oil pump.

-

Pump ATF fluid into the front drive

unit

NoteAssistant required. Pump 5 full strokes from the fluid container, then run the pump via the switch box for entire fill and keep running until drain plug installed. Do not run pump when dry. If pump is not running and drain plug not installed, fluid will drain from the plug within 10 seconds.

-

Install the fill plug into the

FDU.

15 Nm (11.1 lbs-ft)

15 Nm (11.1 lbs-ft) -

Disconnect the 12V power supply tool

from oil pump

Note1x electrical connector

-

Connect the front drive unit oil pump

connector

Note1x electrical connector

- Clean area with brake cleaner and wipe residual fluid off with a towel.

- Remove the oil drain container from under the vehicle.

-

Install the skid plate between the

battery pack and subframe.

-

Install the bolts (x2) to attach the

skid plate to the subframe.

10 Nm (7.4 lbs-ft)

10 Nm (7.4 lbs-ft) -

Install new patch bolts (x4) at the

front of the HV battery with battery powered drill

Note4x patch bolts, 30 Nm. Install new patch bolts, Do not over tighten bolts. Torque at a later step.

-

Torque the front bolts of the HV

battery to 30 Nm.

-

Install new 21mm bolts (x2) at the

front of HV battery with battery powered drill.

NoteDo not over tighten the bolts. Torque at a later step.

-

Torque the bolts (x2) that attach the

front of HV battery to the vehicle to 115 Nm.

-

Install the bolts (x2) that attach the

front bash plate extrusion.

16 Nm (11.8 lbs-ft)

16 Nm (11.8 lbs-ft) - Install the front aero shield. See Panel - Aero Shield - Front (Remove and Replace).

-

Install the upper fastener that

attaches the heat exchanger to the FDU.

5 Nm (3.7 lbs-ft) + 30 deg

5 Nm (3.7 lbs-ft) + 30 deg -

Install the clip to hold the coolant hose in place.

-

Remove the coolant hose clamp.

- Reconnect 12V power. See Disconnect 12V Power.

- Perform a coolant air purge. See Cooling System - Partial Refill and Bleed.

- Install the HEPA filter. See Filter - HEPA (Remove and Replace).

- Install the underhood storage unit. See Underhood Storage Unit (Remove and Replace).