31/10/2024 08:34:05

Contactors - HV Battery (HV Battery 1.0/1.5) (Remove and Replace)

Correction Code 16302102

- 2024-07-24L Changed tool part number from 1046409-00-B – TIP, CONTACTOR-BUSBAR, L-SHAPED to 1046409-00-A – TIP, CONTACTOR-BUSBAR, L-SHAPED, REV 02.

- 2024-07-18: Added tool info for 1046409-00-B – TIP, CONTACTOR-BUSBAR, L-SHAPED.

- 2024-06-25: Added alternative sealants to replace Threebond 1216E due to non availability of Threebond in certain markets.

- 2024-06-24: Added warnings for high voltage awareness.

- 2024-05-29: Added parts lists.

Warning

Only technicians who have been trained in High Voltage Awareness and have completed all required certification courses (if applicable) are permitted to perform this procedure. Proper personal protective equipment (PPE) and insulating HV gloves with a minimum rating of class 0 (1000V) must be worn at all times a high voltage cable, busbar, or fitting is handled. Refer to Tech Note TN-15-92-003,

High Voltage Awareness Care Pointsfor additional safety information.

Warning

Remove all jewelry (watches, bracelets, rings, necklaces, earrings, ID tags, piercings, etc.) from your person, and all objects (keys, coins, pens, pencils, tools, fasteners, etc.) from your pockets before performing any procedure that exposes you to high voltage.

- 1084515-00-E – FIELD CTR KIT W/O FUSE PACK 1.0 1.5 – 1 pcs

- 1015753-00-C – ASY, RAPIDMATE PLATE, HVBAT,MDLS – 1 pcs

- 1130298-00-B – FIELD RAPIDMATE SEAL, FIELD REPAIR KIT – 1 pcs

- 1064696-01-B – CONTACTOR,INT CONNECTOR,TORX STUD,HVBAT – 2 pcs

- 1003195-00-E – ASY,HARNESS,HV SENSE,HVBAT,MDLS – 1 pcs

- 1004379-00-B – SCR,M5-0.8X16,R WSH,MPT,STL 8.8,ZN,PATCH – 20 pcs

- 1010395-00-B – CAP,0.5INX0.4IN,VINYL – 5 pcs

- 1004371-00-A – WSHR,FLAT,M8,21,1,STL,ZNC – 7 pcs

- 1004400-00-A – NUT,HX,SEMS,M8,[9],G0310,SEAL – 7 pcs

- 1011756-00-B – INSULATOR,CONTACTORS,HVBAT,MDLS – 1 pcs

- 1014467-00-B – ASY,INSLTR,MOD-CON BUS BR,PC1,MICA,HVBAT – 1 pcs

- 1020444-00-A – PLUG,1/8NPTF x 7.6MM,HEX SCKT,BRSS,NI – 1 pcs

- 1002773-00-A – BREATHER, INVERTER-MOTOR,JW – 1 pcs

- 1016496-00-E – CAP,VENT,FRONT – 1 pcs

- 1014884-00-B – ASY,INSLTR,MOD-CON BUS BR,PC2,MICA,HVBAT – 2 pcs

- 1009210-00-A – SCR,M6-1x16,HEX,w/WSHR,SEM,ST,BK,ZNC,PAT – 1 pcs

- 1012699-00-A – INSULATOR,OUTPUT BUSBARS,HVBAT,MDLS – 1 pcs

- 1004295-00-A – NUT,HF,M5-0.8,5,STL,ZNC,W/PATCH – 5 pcs

- 1023867-00-A – PLUG,RUBBER,EPDM,3/8ID,TAPERED – 1 pcs

- 1067510-00-A – ASY,HARNESS,CONTACTORS,HVBAT – 1 pcs

- 1046409-00-A – TIP, CONTACTOR-BUSBAR, L-SHAPED, REV 02.

- Threebond 1216E (1089956-00-A), Permatex Right Stuff (1031099-00-A), or Dowsil 7091 (1962594-00-A)

Remove

-

Remove the HV battery. See .

CAUTIONInspect the HV battery for damage. If any dents, fluid leaks, or other signs of instability present, escalate a Toolbox session.

- Ensure the entire work area is clear and then place an HV Danger placard on the top of the battery.

- Place barricades around the work area.

- If the battery blanket in the 1st generation, replace it with a 2nd generation blanket. See .

- Remove the pyrotechnic fuse. See .

- Use an electrostatic discharge-safe (ESD-safe) vacuum to clean the area around the rear tray to make sure that there is no dust or debris that can enter the battery.

- Clean the area around the Rapid Mate plate with alcohol wipes.

- Put a piece of 3M vinyl tape 471 across the rear of the HV battery to prevent accidental removal of the crossmember bolts.

-

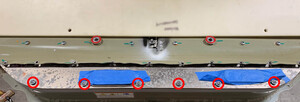

Remove the screws (x6) that

attach the Rapid Mate plate, the screws (x10) at the rear edge of the HV battery

top cover, and the rearmost side screws (x2) (Figure 6). Put these screws into the

designated container so that they can be accounted for before reinstalling

components.

CAUTIONDo not remove the forward side screws.TIpUse of the following tool(s) is recommended:

- Insulated Torx T25 socket

- Insulated Ratchet/torque wrench

-

Use the non-marring scraper and a

dead blow hammer to separate the sealant at the LH and RH rear corners where the

HV battery cover contacts the Rapid Mate plate.

CAUTIONDeform the HV battery cover as little as possible.CAUTIONDo not insert the scraper more than 20 mm into the battery cavity to avoid damaging internal components.

- Use the non-marring scraper and a dead blow hammer to separate the sealant across the rear of the HV battery cover where it contacts the Rapid Mate plate.

-

Center the plastic wedge between

the HV battery cover and the Rapid Mate plate.

NoteThe notch on the plastic wedge should be toward the right side of the HV battery.

- Gently tap the wedge with a mallet to make sure that the wedge is fully seated.

- Carefully bend the cover up to approximately 80 degrees.

-

Put on the HV-safe static control

wrist strap, and then clip the strap’s ground connection to a threaded hole on the

edge of the HV battery enclosure.

CAUTIONPut the static control wrist strap on as soon as the cover is opened. Otherwise, damage to sensitive electrical components might result.

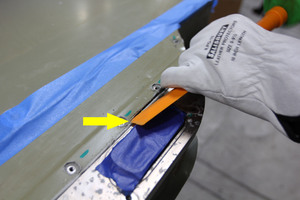

- Pull back the pack contactor paper insulator, and then tape it to the Rapid Mate plate to keep it out of the work area.

-

Use the insulation multimeter to

measure the voltage between the yellow contactor ring terminal (negative) and the

purple contactor ring terminal (positive) on the pack contactors:

- If the voltage is 50V or greater, make sure that the HV battery fuse has been removed. If the fuse has been removed, escalate the Toolbox session.

- If the voltage is less than 50V, continue to the next step.

-

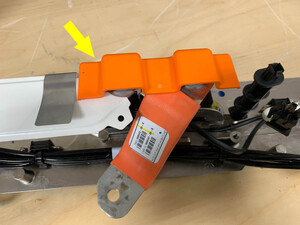

Remove the orange insulating cap

from the leftmost (white) pack contactor stud. Put this cap into the designated

container so that it can be accounted for before reinstalling components.

Warning: Remove only 1 insulating cap at a time to reduce the risk of a high voltage short circuit.

- Remove the nut and the washer, and then put them into the designated container so that they can be accounted for before reinstalling components.

- Repeat step 18 and 19 for each of the 3 remaining pack contactor studs.

-

Remove the bolt from the ground

strap on the left side of the pack contactors. Put this bolt into the designated

container so that it can be accounted for before reinstalling components.

TIpUse of the following tool(s) is recommended:

- Insulated 10 mm 12-point deep socket

- Insulated Ratchet/torque wrench

- Use an insulated blade to score the sealant between the battery enclosure and the Rapid Mate plate.

- Use the non-marring scraper to separate the sealant at the rear edge of the Rapid Mate plate, and then separate the Rapid Mate plate from the ancillary bay.

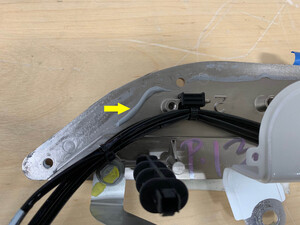

- Release the rightmost fir tree clip for the low voltage communication harness.

- Lift up the Rapid Mate plate, and release the edge clip.

- Move the Rapid Mate plate back and remove the edge clips (x2).

-

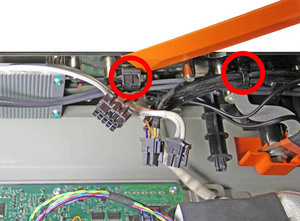

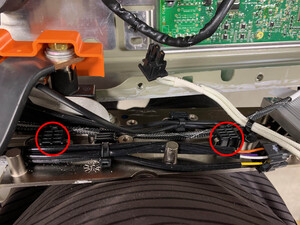

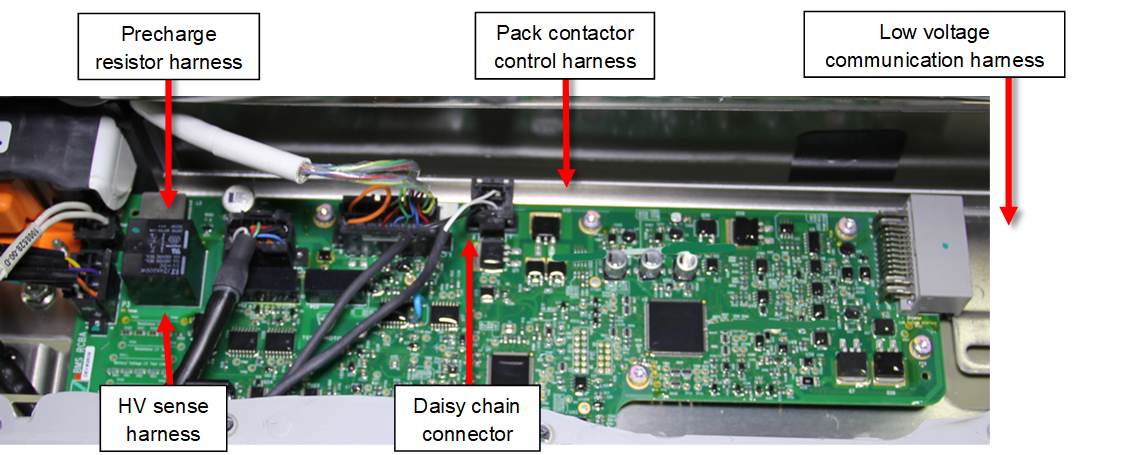

Disconnect the following

harnesses from the battery management system (BMS) circuit board:

- Pre-charge resistor harness

- HV sense harness

- Pack contactor control harness

- Low voltage communication harness

- Remove Rapid Mate plate from HV battery.

-

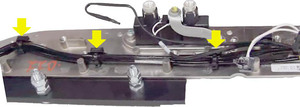

Remove the nuts (x4) that attach

the pack contactors to the ancillary bay (Figure 22). Put these nuts into the

designated container so that they can be accounted for before reinstalling

components.

TIpUse of the following tool(s) is recommended:

- Insulated 8 mm socket

- Insulated Ratchet/torque wrench

-

Lift the busbars up slightly to

allow clearance for the pack contactors, and then remove the pack contactors from

the ancillary bay.

NoteA popping sound is normal as the orange plastic shunt insulator separates. The insulator halves snap back together when the new pack contactors are installed.

-

Use the non-marring scraper to

clean the old sealant from the Rapid Mate plate and the ancillary bay.

NoteThe sealing surface should be smooth and consistent. The sealant does not need to be completely removed.

- Use a small pick to remove any old sealant from screw holes, if necessary.

- Use the ESD-safe vacuum to clean the areas that were covered by sealant, the Rapid Mate plate, and inside the ancillary bay.

-

Clean the Rapid Mate plate to

ancillary bay surfaces with an alcohol wipe, and allow the alcohol to dry for 1

minute.

CAUTIONDo not use anything other than isopropyl alcohol (IPA) to clean the HV battery enclosure. Using other chemicals, such as brake cleaner, might corrode the coating on the HV battery enclosure.

Busbar Inspection and Refurbishment

Warning

Make sure that the

green fuse flag has been installed and both HV insulating gloves and leather glove

protectors are on before performing this procedure.

-

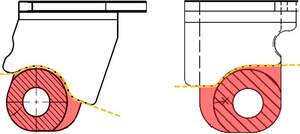

Inspect the top and bottom of the

busbars within the ancillary bay. Use the insulated mirror to evaluate the bottom

of the busbars:

- If any metallic material transfer has occurred, the busbar is not repairable. Return the HV battery to the remanufacturing center.

- If the metal of either busbar has melted or deformed in any way, the busbar is not repairable. Return the HV battery to the remanufacturing center.

- Inspect the top and bottom of the white busbar insulation for damage. If the insulation is damaged, or peeled more than 5 mm beyond the first bend of the busbar, the busbar is not repairable. Return the HV battery to the remanufacturing center.

- Glue seepage or melted plastic is repairable.

- Use the plastic pry tool to scrape off any non-metallic contamination (such as glue, melted plastic, burned insulation, or melted insulation) from the tops of the busbars.

-

Firmly wipe the top and bottom of

the busbars with an alcohol wipe to remove any loose debris, and allow the alcohol

to dry for 1 minute.

Warning: Do not clean both busbars at the same time.

- Wipe the top and bottom of the white insulation with an alcohol wipe, and allow the alcohol to dry for 1 minute.

- Repeat step 3 and 4 with another alcohol wipe.

- Use the insulated mirror to check the bottom of the busbar for any remaining debris or lint from the alcohol wipe.

- Use an ESD-safe vacuum to remove all debris.

-

Inspect the condition of the

busbars.

CAUTIONDo not remove any damaged insulation.

- If all busbar insulation is in good condition, skip to step 11.

- If the busbar insulation is damaged or peeled back less than 5 mm beyond the first bend of the busbar, continue to the next step.

- If the busbar insulation is damaged or peeled back more than 5 mm beyond the first bend of the busbar, the busbar is not repairable. Return the HV battery to the remanufacturing center.

- Make sure that the busbar insulation is completely dry.

-

Tightly wrap the damaged

insulation with polyimide tape. Wrap the insulation 2-3 times, pressing firmly on

the end of the tape for proper adhesion.

CAUTIONThe tape must not extend onto the nut and washer area on the top and the bottom of the busbar.

- Inspect the busbar mica, and replace the mica if it is broken or damaged.

- Use an ESD-safe vacuum to remove all debris. Make sure that there are no metal shavings inside the ancillary bay or on top of the BMS circuit board.

- Disconnect the ESD wrist strap.

- Remove HV insulating gloves.

Rapid Mate Plate Inspection and Refurbishment

Warning

: Perform this

procedure away from the HV battery, but still within the designated safe area.

Note

Mark each fastener with a paint pen

after torquing it:

- Orange: Structural fasteners, rework or reinstallation mark

- Pink or Violet: HV fasteners, rework mark

- Green: Structural fasteners, original production mark (for reference only)

- Yellow: HV fasteners, original production mark (for reference only)

- Scrape off any large chunks or beads of sealant from Rapid Mate plate.

- Remove the covers or tape from the high voltage and low voltage Rapid Mate connectors.

- Vacuum the Rapid Mate plate to remove any debris.

- Clean the Rapid Mate plate with an alcohol wipe, and allow the Rapid Mate plate to fully dry before continuing.

- Check the high voltage and low voltage Rapid Mate connectors on the Rapid Mate plate for damage or excessive wear. If either connector is damaged, replace the Rapid Mate plate altogether.

- Install protective covers on (or apply tape to) the high voltage and low voltage Rapid Mate connectors.

- Remove and discard the black plastic Rapid Mate plate support posts, if equipped.

- Remove the white contactor insulator sheet from the Rapid Mate plate. Make sure all of the old adhesive is removed from the plate.

- Remove and inspect the output busbar insulator. A new insulator is required if there is any evidence of damage.

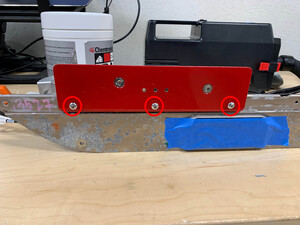

- Align the two output busbar holes with the posts of the busbar locating fixture, and then attach the fixture to the Rapid Mate plate using M5 fasteners (x3).

- Remove the thermistor and clip from the white output busbar. Put the clip into the designated container so that it can be accounted for before reinstalling components.

-

Remove the M8 bolts (x2) that

attach the output busbars to the HV Rapid Mate connector, and then remove the

busbars.

NotePut the bolts into the designated container temporarily so that they can be accounted for before reinstalling components.

- If the vehicle is rear wheel drive, discard the fasteners and the busbars.

- If the vehicle is dual

motor, discard the fasteners and inspect the busbars:

- If there are any signs of delamination, discard the busbars.

- If there are no signs of delamination, the busbars can be reused.

- Release the edge clips (x2) to remove and discard the HV sense harness from the Rapid Mate plate.

-

Inspect the container that was

designated to hold the removed fasteners. Make sure that all of the fasteners

listed below are present.

CAUTIONCheck the fasteners that were removed from the HV battery and compare to any remaining new fasteners. Make sure that all fasteners have been accounted for. If any of the removed fasteners are missing, they might have dropped inside the ancillary bay area. If they cannot be located, escalate the Toolbox session.

- Set the thermistor clip and two M5 screws aside, and then discard the remaining fasteners and orange insulating caps.

- Install the new HV sense harness to the Rapid Mate plate in the position and orientation shown.

-

Use the installed busbar locating

fixture to properly position the busbars.

- Rear Wheel Drive: Install 2 new busbars.

- Dual Motor: Install the 2 old busbars, unless there are signs of delamination. In this situation install new busbars.

-

Install new M8 bolts (x2)

(1004392-00-B) to attach the busbars. Use a pink or violet paint pen to mark the

head of each bolt after it is torqued.

9 Nm (6.6 lbs-ft)TIpUse of the following tool(s) is recommended:

9 Nm (6.6 lbs-ft)TIpUse of the following tool(s) is recommended:- 13 mm socket

- Micrometer Ratchet/torque wrench

- Flex head ratchet/flex head torque wrench

-

Reinstall the thermistor and

thermistor clip onto the white output busbar in the position and orientation as

shown.

NoteMake sure that the end of the thermistor does not protrude from the clip.

- Remove the busbar locating fixture (4mm).

-

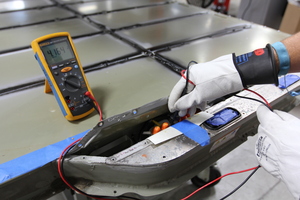

Use the Hioki resistance meter to

measure the resistance between the busbars and the Rapid Mate studs.

WarningThe acceptable resistance is between 0.080 mΩ (80 μΩ) and 0.150 mΩ (150 μΩ). If the resistance is lower than 0.080 mΩ (80 μΩ), reposition the probes and measure again. If the resistance is greater than 0.150 mΩ (150 μΩ), there is too much resistance in the High Voltage joint. Remove the fastener, clean areas with isopropyl alcohol, install fastener back and test again.

-

Install the output busbar

insulator.

CAUTIONBefore continuing this procedure, make sure that the thermistor and thermistor clip are properly installed.

- Install a new contactor insulator sheet, and then gently tape the sheet out of the way.

Install

-

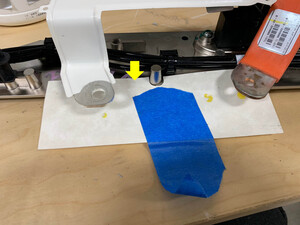

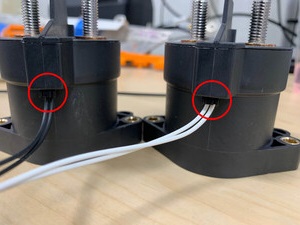

Attach the new pack contactor

harnesses to the new pack contactor connectors.

NotePerform a push-pull-push test to make sure that the electrical connectors are fully seated.

- Inspect HV insulating gloves, and then put on the HV insulating gloves and leather over gloves.

- Wear an ESD wrist strap and ground the strap to the HV battery enclosure.

- Clean inside the ancillary bay with an ESD-safe vacuum.

-

Use appropriate insulation tools

to gently lift the busbars and set the new pack contactors into position.

CAUTIONDo not lift the contactors by the wire harnesses.CAUTIONThe pack contactor with the black wire is on the left, and the pack contactor with the white wire is on the right.

-

Attach the pack contactors to the

ancillary tray with new M5 nuts (x4). Use an orange paint pen to mark the nuts

after they are torqued.

2.8 Nm (2.1 lbs-ft)TIpUse of the following tool(s) is recommended:

2.8 Nm (2.1 lbs-ft)TIpUse of the following tool(s) is recommended:- Insulated 8 mm socket

- Insulated Ratchet/torque wrench

-

Reconnect the top half of the

orange shunt cover to the lower half by re-engaging the plastic clips.

NoteThe shunt cover is properly installed when the tabs bend upward from the top of the cover and the lower plastic clips are engaged. If the tabs are flush with the top of the cover, the shunt cover is not installed properly.

- Position the Rapid Mate plate slightly above its normal location at the rear of the HV battery.

- Route the pack contactor control harness above the white output busbar, then above the orange HV busbar, in front of the Rapid Mate assembly.

-

Connect the edge clips (x3) to

the Rapid Mate plate.

NoteThe pack contactor harness uses the 3 thicker edge clips.

-

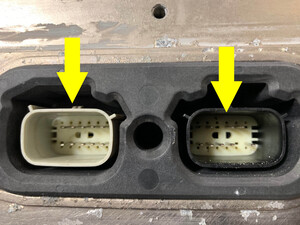

Starting from the outside and

working inwards, attach the BMS harnesses to the BMS circuit board

connectors.

CAUTIONMake sure that the daisy chain connector is still properly installed, and was not accidentally disconnected.NotePerform a “push-pull-push” check at the connectors to make sure that they are properly secured.

- Connect the low voltage communications harness fir tree clip on the right side of ancillary tray.

-

Install a new M6 ground strap

bolt. Use a pink or violet paint pen to mark the head of the screw after it is

torqued.

4.5 Nm (3.3 lbs-ft)NoteMake sure that the torque wrench is not pressed against the HV battery enclosure while the ground strap bolt is being tightened. This can cause an inaccurately high torque reading, leading to an under-torqued bolt.TIpUse of the following tool(s) is recommended:

4.5 Nm (3.3 lbs-ft)NoteMake sure that the torque wrench is not pressed against the HV battery enclosure while the ground strap bolt is being tightened. This can cause an inaccurately high torque reading, leading to an under-torqued bolt.TIpUse of the following tool(s) is recommended:- Insulated 10 mm 12-point deep socket

- Insulated Ratchet/torque wrench

-

Loosely reinstall old M5 screws

(x2) at the LH and RH ends of the Rapid Mate plate to the ancillary bay.

NoteDo not install new fasteners at this time.

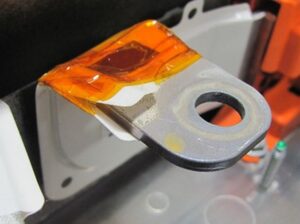

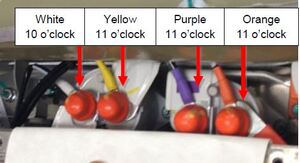

- Place the orange contactor ring terminal onto the rightmost contactor stud, wire side up.

-

Make sure that the terminal is

oriented properly as shown. The orange terminal should be in the 11 o’clock

position.

CAUTIONMake sure that the terminals do not rest on top of the plastic posts.

- Install a new M8 washer with the flat side facing down.

-

Install a new M8 nut.

9 Nm (6.6 lbs-ft)TIpUse of the following tool(s) is recommended:

9 Nm (6.6 lbs-ft)TIpUse of the following tool(s) is recommended:- Insulated 13 mm socket

- Insulated Ratchet/torque wrench

- Use a pink or violet paint pen to mark only the nut after it is torqued. Do not mark the stud.

- Repeat steps 15 through 19 for the purple, yellow, and white contactor ring terminals, working right to left.

-

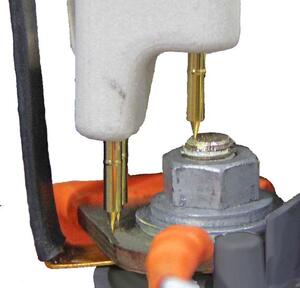

Connect the 3+1 probe leads to

the Hioki resistance meter.

CAUTIONThe probes must contact bare metal surfaces. Do not contact paint marks.

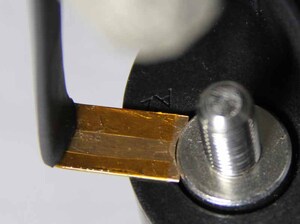

-

Measure the resistance value at

the contactor stud having the white contactor ring terminal.

- The upper probe must press against the top of the pack contactor stud, not on top of the nut.

- The lower probes must press against the busbar, not on the contactor ring terminal.

- The curved edge of the L-shaped probe must press against the side of the stud shoulder.

WarningThe acceptable resistance is 0.050 mΩ (50 μΩ) or less. If the resistance is greater than 0.050 mΩ (50 μΩ), there is too much resistance in the High Voltage joint. Remove the fastener, clean areas with isopropyl alcohol, install fastener back and test again. - Repeat step 22 for the contactor studs having the yellow, purple, and orange contactor ring terminals.

- Clean inside the ancillary bay with an ESD-safe vacuum.

-

Install a new orange insulating cap on each pack contactor terminal. Mark the

top of each cap with a pink or violet paint pen as confirmation that:

- Each terminal joint is properly assembled; each flat washer is present and oriented properly.

- The terminals are properly positioned on the contactor studs.

- The joint is properly torqued and marked.

- A passing resistance value is measured and recorded.

- Remove the tape that held the pack contactor insulator sheet out of the way.

- Remove and discard the old M5 screws (x2) that loosely attached the Rapid Mate plate to the ancillary tray.

- Check that the shunt insulator cover is properly snapped into position.

-

Clean inside the ancillary bay with an ESD-safe vacuum.

NoteThis is the last opportunity to remove any debris remaining inside the HV battery.

- Remove the ESD strap and disconnect it from the HV battery enclosure.

- Clean all sealing surfaces with alcohol wipes.

- Center the long plastic wedge against the HV battery cover on the fold side.

-

Bend the HV battery top cover down smoothly and evenly.

CAUTIONDo not use a hammer to bend the HV battery cover.

- Make sure that the bend radius is fully worked out of the HV battery top cover so it sits flat when in position. Do not allow a large downward dent to remain in the section of the HV battery cover, as this might press down onto the pack contactor studs.

- Partially install the new M5 screws (x6) along the rear of the Rapid Mate plate. Engage no more than approximately 2 threads.

- Load the sealant in the caulking gun, and then cut the nozzle approximately 15 mm from the tip.

- Hold the Rapid Mate plate up slightly with a non-conductive wedge tool and apply a bead of sealant inside the gap. Make sure that the sealant bleeds out of the LH and RH ends of the Rapid Mate plate. Use a flashlight or shop light to check the sealing area for complete coverage. Apply additional sealant as needed.

-

Working from the center outward, tighten the M5 screws (x6) to attach the Rapid

Mate plate (torque 6 Nm). Use an orange paint pen to mark the heads of the screws

after they are torqued.

6 Nm (4.4 lbs-ft)TIpUse of the following tool(s) is recommended:

6 Nm (4.4 lbs-ft)TIpUse of the following tool(s) is recommended:- Insulated Torx T25 socket

- Insulated Ratchet/torque wrench

- Use the non-marring scraper to smooth any sealant along the rear of the HV battery enclosure. Wipe off any sealant that gets on top of the HV warning label.

-

Apply a thick bead of sealant to the

forward flange on the Rapid Mate plate and along the LH and RH sides of the ancillary

tray.

CAUTIONThe surfaces near where the HV battery top cover bends up are the most prone to leakage. Make sure that adequate sealant is applied to these areas. Do not loosen the adjacent screw in an attempt to inject more sealant into this area.

- Bend the HV battery top cover down. Working from the center outward, hold the HV battery top cover down while installing the M5 screws (x12) loosely. The HV battery top cover does not need to be perfectly flat or smooth at this time.

- Working from the center outward, partially tighten the HV battery top cover mounting screws.

-

Working from the center outward, tighten the HV battery top cover mounting

screws. Mark each bolt with an orange paint pen as it is torqued.

6 Nm (4.4 lbs-ft)TIpUse of the following tool(s) is recommended:

6 Nm (4.4 lbs-ft)TIpUse of the following tool(s) is recommended:- Insulated Torx T25 socket

- Insulated Ratchet/torque wrench

-

If any part of the battery top cover is not flat, gently press it down with the

handle of a mallet or other heavy tool.

Note:It is especially important to flatten the HV battery top cover where it was bent.

- If sealant touches any part of either Rapid Mate connector, use isopropanol on a lint-free cloth to remove the sealant.

- Use a flashlight or shop light to check the HV battery sealing area for complete coverage. Apply additional sealant as needed.

- Remove the tape from across the rear of the HV battery.

- Record part and serial number of HV battery pyro fuse.

- Connect the ESD ground strap to the HV battery fuse case.

- Put on the HV-safe static control wrist strap and clip the strap’s ground connection to a suitable ground.

- Install the pyrotechnic fuse. See .

-

Install the HV battery. See .

NotePause connecting the LV power.

- Connect the first responder loop and connect the 12V battery negative terminal. See .

- Connect the 12V charger while the vehicle 12V system remain supported.

-

Remove the coolant reservoir cap, inspect the coolant level and top off as

needed.

NoteFill the reservoir to the "NOM" line with G-48 coolant.

- Locally connect a laptop with Toolbox 3 to the vehicle. See .

- Unlock the vehicle gateway. See .

-

On the laptop, select

Actions

tab and search for "Contactor Replacement", click on PROC_BMS_X_CONTACTOR-REPLACEMENTvia Toolbox: (link)via Service Mode Plus: High Voltage Battery ➜ Pack Contactor Replacement ➜ Pack Contactor Replacement Routine, clickRun

, and allow the routine to complete. -

If the pyro fuse was replaced, write the pyro fuse data into the BMS through

Toolbox 3. Select

Actions

tab and search forWrite or Read BMS Pyro Fuse Type

, click on PROC_BMS_X_PYROFUSE-READWRITE-TYPE-YEAR-MONTHvia Toolbox: (link)via Service Mode: High Voltage ➜ HV Battery ➜ Read/Write Fuse Type, select the correctPyro Fuse Type

based on what was determined earlier, selectWrite

from theWrite or Read Pyro Fuse Data

section, then clickRun

, and allow the routine to complete. -

Search for

Coolant Air Purge

in theActions

tab, click on PROC_THC_X_COOLANT-AIR-PURGEvia Toolbox: (link)via Service Mode: Thermal ➜ Actions ➜ Coolant Air Purge, clickRun

, and allow the routine to complete. - Top off the reservoir to "NOM" line with G-48 coolant.

- Install coolant reservoir cap.

- Disconnect the laptop.

- Disconnect the 12V charger from vehicle.

- Finish the remaining steps of installing the HV battery. See .

- Charge the vehicle for at least 10 minutes.

- Perform vehicle test drive to verify no BMS alerts are present.