Compresseur de climatisation, conduite de climatisation du supercollecteur et du compresseur au supercollecteur (retrait et remplacement)

Code de correction

18204012 1.92

REMARQUE : À moins d’indications explicites contraires dans la procédure, le code de correction et le temps forfaitaire ci-dessus représentent tout le travail à être fait pour cette procédure, notamment les procédures connexes. N’appliquez pas plusieurs codes de correction à la fois, à moins qu’il vous soit explicitement indiqué de le faire.

REMARQUE : Consultez Temps forfaitaires pour en apprendre plus à propos des temps forfaitaires et de leur création. Vous pouvez transmettre par courriel vos commentaires relatifs aux valeurs des temps forfaitaires à l'adresse ServiceManualFeedback@tesla.com.

REMARQUE : Consultez Protection individuelle pour vous assurer de porter l’équipement de protection individuelle adéquat lors vous effectuez la procédure ci-dessous. Voir Précautions ergonomiques pour consulter les pratiques de travail sécuritaires et saines.

Code de correction

18204012 1.92

REMARQUE : À moins d’indications explicites contraires dans la procédure, le code de correction et le temps forfaitaire ci-dessus représentent tout le travail à être fait pour cette procédure, notamment les procédures connexes. N’appliquez pas plusieurs codes de correction à la fois, à moins qu’il vous soit explicitement indiqué de le faire.

REMARQUE : Consultez Temps forfaitaires pour en apprendre plus à propos des temps forfaitaires et de leur création. Vous pouvez transmettre par courriel vos commentaires relatifs aux valeurs des temps forfaitaires à l'adresse ServiceManualFeedback@tesla.com.

REMARQUE : Consultez Protection individuelle pour vous assurer de porter l’équipement de protection individuelle adéquat lors vous effectuez la procédure ci-dessous. Voir Précautions ergonomiques pour consulter les pratiques de travail sécuritaires et saines.

- 2026-01-16: Mise à jour de la durée et de la quantité de réfrigérant requise pour la procédure de rinçage effectuée à l'aide de la machine de climatisation Snap-On.

- 2026-01-15: Taille de douille appropriée pour l'écrou qui fixe l'ensemble de conduite de climatisation reliant le supercollecteur au système CVAC au supercollecteur.

- 2025-12-10: Mise à jour de la procédure pour la réutilisation de la conduite de climatisation allant du supercollecteur au système CVC après le rinçage.

- 2025-11-14: Ajout des procédures de rinçage à l'aide de la machine Snap-on

- 2025-11-10: Ajout d'une étape pour vérifier la révision du numéro de pièce installé afin de déterminer si une procédure d'adaptation est nécessaire.

- 2025-10-27: Mise à jour du couple pour qu'il passe de 22 Nm à 28 Nm du côté CVC de la conduite de climatisation, et de 27 Nm à 36 Nm du côté du supercollecteur.

- 2025-08-14: Ajout d'étapes de configuration du type de pompe à liquide de refroidissement.

- 2025-03-27: Procédure de rinçage mise à jour.

- Le 17 juin 2024 : Ajout de l'étape de mise à jour de la configuration de la pompe de liquide de refroidissement.

- 29-05-2024 : Mise à jour de la procédure selon la dernière validation.

- 28-03-2024 : Correction du lien de mauvais affleurement.

- 06-03-2024 : Mise à jour des routines.

- 05-02-2024 : Ajout d'étapes pour serrer à la main les boulons qui fixent le supercollecteur et le compresseur au support de la tour d'amortisseur.

Équipement :

- 1838504-C0-A, 1838504-E0-A, 1838504-N0-A Adaptateur de rinçage de débris

- 1711245-00-A Machine de climatisation Dual GAS Ecotechnics Snap On, avec trousse d'adaptateur de rinçage R134A et R1234YF ou

- 1120026-01-A MACHINE DE SERVICE DE CLIMATISATION, WAECO, ASC5500 RPA

Retirer

- Mettez en place la machine de climatisation.

- Soulevez et soutenez le véhicule.

-

Ouvrez les quatre portes et abaissez les fenêtres.

RemarqueVerrouillez les portes arrière pour éviter toute fermeture accidentelle lorsque l'alimentation est coupée.

- Retirez l’unité de rangement qui se trouve sous le capot. Voir Unité de rangement sous le capot (retirez et remplacez),

- Retirez l’ensemble filtre HEPA. Voir Ensemble - filtre - HEPA (retirez et remplacez),

- Retirez le conduit HEPA. Voir Conduit - HEPA (retirez et remplacez),

- Placez le véhicule en mode « Service ». Voir Mode Entretien,

-

Consultez les alertes thermiques sur l'écran tactile en appuyant sur l'icône d'alerte.

Si une ou plusieurs des alertes suivantes sont présentes, effectuez une purge complète plus tard dans la procédure.

- VCFRONT_a161_compressorSelfFault

- VCFRONT_a163_compressorDisabledFSR

- VCFRONT_a460_hardIsentropicTdFailed

- VCFRONT_a467_lowPowerIndexFlagged

- VCFRONT_a531_lowPowerIndexFlaggedUserFacing

- VCFRONT_a543_compressorLowFlowDeliveryDetected

- Sur l'écran tactile, touchez et sélectionnez Exécuter pour commencer la routine « Démarrer la vidange du fluide thermique (liquide de refroidissement et réfrigérant) ».

- Avancez les sièges avant.

- Débranchez l’alimentation 12 V/BT Voir Alimentation 12 V/BT (déconnectez et connectez),

- Retirez le panneau du bouclier aérodynamique avant. Voir Panneau - écran aérodynamique - avant (Ensemble non-structurel)(retirez et remplacez),

- Récupérez le réfrigérant du véhicule. Voir Fluide frigorigène de climatisation (récupération et recharge),

- Effectuez la procédure de désactivation HT du véhicule. Voir Procédure de désactivation HT du véhicule,

- Placez le liquide de refroidissement sous l'avant du véhicule.

- Retirez le bouchon de la bouteille de réfrigérant.

-

Débranchez le tuyau de dérivation du groupe motopropulseur du collecteur principal.

RemarqueCeci vidangera le réservoir de liquide de refroidissement.

-

Débranchez le flexible de sortie de radiateur du collecteur principal.

-

Débranchez le flexible d’entrée de radiateur du supercollecteur.

-

Posez trois prises mâles dans les orifices de liquide de refroidissement à l’avant du supercollecteur

-

Avant d'effectuer les deux prochaines étapes, inspectez les capteurs de température du flexible de liquide de refroidissement et les connecteurs.

RemarqueSi le véhicule est équipé d'un modèle de capteur de température d'une génération antérieure (image gauche), les connecteurs du nouveau supercollecteur pourraient ne pas convenir. Dans ce cas, le couvercle du connecteur électrique du nouveau supercollecteur doit être remplacé par celui du vieux supercollecteur. Effectuez Retravailler les connecteurs avant l'installation.

-

Débranchez le capteur du refroidisseur au flexible de batterie.

-

Débranchez le capteur du flexible d’alimentation du groupe motopropulseur.

-

Débranchez le flexible du refroidisseur à la batterie du supercollecteur.

-

Débranchez le flexible de contournement du groupe motopropulseur du supercollecteur.

-

Débranchez le flexible de retour de la batterie HT du super-collecteur.

-

Installez trois bouchons mâles dans les orifices de liquide de refroidissement à l'arrière du supercollecteur.

-

Débranchez le faisceau de câbles de supercollecteur du contrôleur avant.

- Retirez l’attache qui fixe le faisceau du sous-ensemble thermique au contrôleur avant.

- Retirez la batterie 12 V/BT. Voir 12 V /BT batterie (retirez et remplacez),

- Relâchez les attaches (x4) qui fixent le tuyau flexible de liquide de refroidissement au support du compresseur de climatisation.

- Retirez l’attache qui fixe le faisceau logique du compresseur de climatisation au support du faisceau HT du compresseur de climatisation.

-

Relâchez la languette de verrouillage du connecteur, puis débranchez le connecteur électrique basse tension du compresseur de CVC.

ATTENTIONN'APPUYEZ PAS sur la languette rouge de verrouillage. Tirez sur la languette jusqu’à ce que le connecteur se déverrouille, puis continuez à tirer la partie principale du connecteur pour le débrancher complètement.

-

Retirez le boulon qui fixe le support du faisceau de câbles HT au compresseur de climatisation.

TIpL'un ou plusieurs des outils suivants sont recommandés :

- Douille de 13 mm

- Clé à cliquet sans fil/Visseuse à percussion

- Clé à cliquet/Clé dynamométrique

-

Retirez le boulon qui fixe la tresse de masse au compresseur de climatisation, puis mettez la tresse de masse de côté.

TIpL'un ou plusieurs des outils suivants sont recommandés :

- Douille Torx T25

- Clé à cliquet sans fil/Visseuse à percussion

- Clé à cliquet/Clé dynamométrique

-

Relâchez l’attache qui fixe le tuyau de liquide de refroidissement au support du compresseur de CVC, près du point de fixation de la tresse de masse.

-

Tirez la languette de verrouillage noire du connecteur HT du compresseur de climatisation pour l’éloigner du compresseur de climatisation.

-

À l'aide d'un pic de 45 degrés, poussez simultanément sur la languette de verrouillage centrale tout en tirant sur la languette de verrouillage extérieure, puis retirez le connecteur HT du compresseur de climatisation.

-

Débranchez le connecteur électrique de la boîte de jonction HT (HVIL).

- Une fois la récupération de climatisation terminée, débranchez les tuyaux de climatisation du véhicule.

-

Retirez l'écrou qui fixe le conduit provenant du super-collecteur à l'aspiration du compresseur.

RemarqueL'un ou plusieurs des outils suivants sont recommandés :

- Douille longue de 13 mm

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

-

Retirez l'écrou qui fixe le supercollecteur à la conduite de refoulement du compresseur au compresseur.

RemarqueL'un ou plusieurs des outils suivants sont recommandés :

- Douille longue de 13 mm

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

-

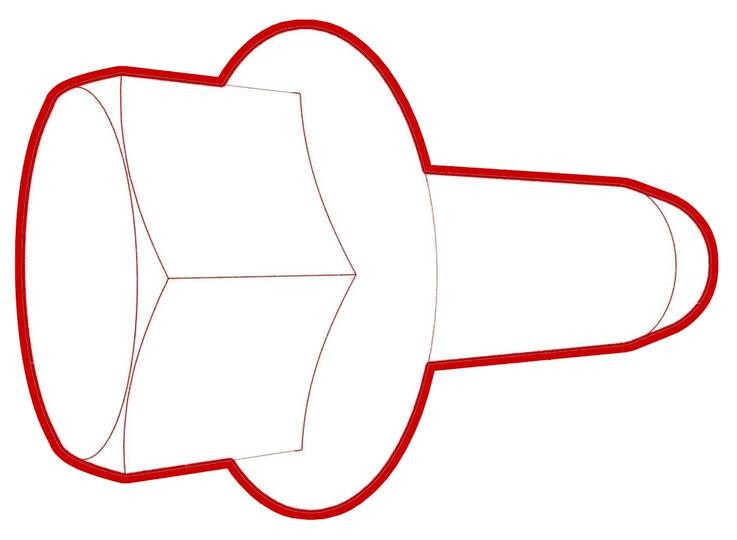

Retirez le boulon du collecteur de climatisation vers la conduite du compresseur du supercollecteur, puis retirez la conduite du collecteur de climatisation du véhicule.

TIpL'un ou plusieurs des outils suivants sont recommandés :

- Douille de 13 mm

- Rallonge de 6 po

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

-

Retirez les boulons (x2) qui fixent le conduit reliant le super-collecteur au système CVAC.

TIpL'un ou plusieurs des outils suivants sont recommandés :

- Douille de 13 mm

-

Retirez la sangle d'arrimage de la batterie arrière du support de la batterie BT/12 V.

RemarqueLe support de la batterie BT/12 V sert également de support au compresseur de climatisation.

-

Relâchez l’attache qui fixe le tube d'aération de la batterie 12 V/BT au support de la batterie.

-

Relâchez l’attache qui fixe le faisceau de câbles BT du compresseur de climatisation au renfort de faisceau de câbles HT du compresseur de climatisation.

-

Déplacez le renfort de faisceau de câbles HT vers l'avant et vers le haut pour dégager le renfort du compresseur de climatisation, puis mettez soigneusement le renfort de côté.

-

Relâchez les attaches de retenue qui fixent le faisceau de câbles HT du compresseur de climatisation au renfort de la tour d'amortisseur.

RemarqueTirez vers le haut sur l'attache pour faciliter le retrait. Ne tirez pas sur le câble HT.

-

Retirez les boulons gauche et droit qui fixent le renfort de la tour d'amortisseur à la carrosserie.

55 Nm (40.6 lbs-ft)

55 Nm (40.6 lbs-ft) 55 Nm (40.6 lbs-ft)TIpL'un ou plusieurs des outils suivants sont recommandés :

55 Nm (40.6 lbs-ft)TIpL'un ou plusieurs des outils suivants sont recommandés :- Douille de 15 mm

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

-

Retirez les boulons extérieurs gauche et droit qui fixent le renfort de la tour d'amortisseur à la carrosserie, puis retirez le renfort de la tour d'amortisseur du véhicule.

62 Nm (45.7 lbs-ft)TIpL'un ou plusieurs des outils suivants sont recommandés :

62 Nm (45.7 lbs-ft)TIpL'un ou plusieurs des outils suivants sont recommandés :- Douille de 15 mm

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

-

Avec de l'aide, retirez le renfort de la tour d'amortisseur ainsi que le supercollecteur et le compresseur du véhicule.

RemarqueFaites attention aux connecteurs et aux conduites de climatisation, puis soulevez lentement le renfort. Mettez-le sur un bloc de carton.

-

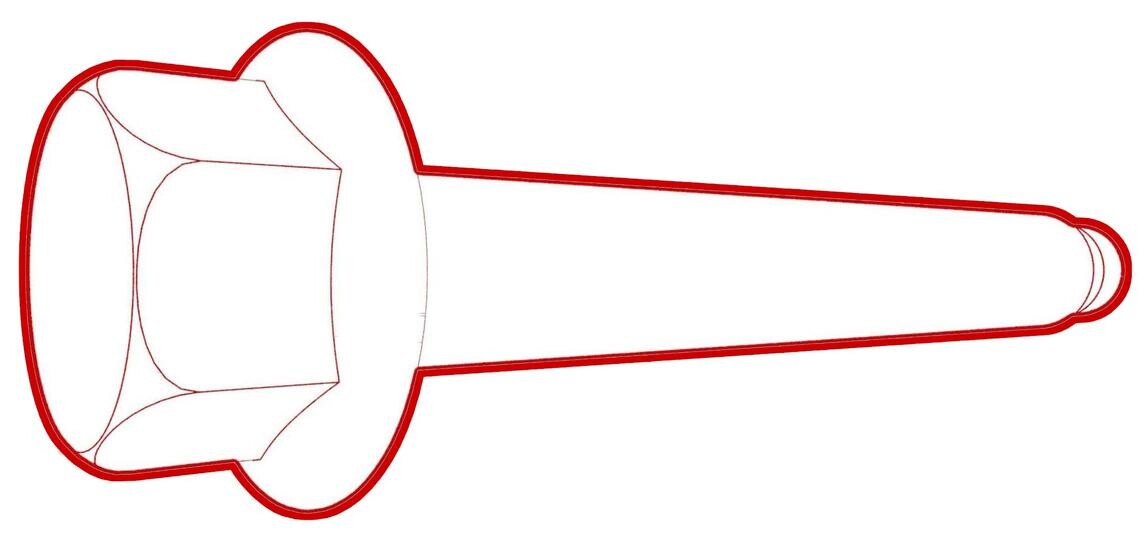

Retirez l'écrou qui fixe le supercollecteur à l'ensemble du conduit de climatisation reliant le super-collecteur au système CVAC, puis retirez le supercollecteur de l'ensemble de la conduite de climatisation du système CVAC.

TIpL'un ou plusieurs des outils suivants sont recommandés :

- 13 mm socket

- Clé à cliquet sans fil/Visseuse à percussion

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

-

Notez les anciens et nouveaux numéros de pièces et numéros de série.

RemarqueL'étiquette est située à l'avant de l'accumulateur.

-

Retirez les deux (2) boulons qui fixent le supercollecteur au renfort de la tour d’amortisseur et retirez le supercollecteur du véhicule.

TIpL'un ou plusieurs des outils suivants sont recommandés :

- Douille de 15 mm

- Clé à cliquet sans fil/Visseuse à percussion

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

-

Retirez les boulons (x2) qui fixent le support du compresseur de climatisation au renfort de la tour de suspension, puis retirez le compresseur de climatisation et l'ensemble du support du compresseur de climatisation.

RemarqueL'un ou plusieurs des outils suivants sont recommandés :

- Douille de 15 mm

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

-

Retirez le support du compresseur de climatisation du compresseur de climatisation.

RemarqueL'un ou plusieurs des outils suivants sont recommandés :

- Douille longue de 10 mm

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

- Documentez les numéros de pièce des nouveaux et anciens compresseurs pour mettre à jour la configuration lors d'une étape ultérieure.

Rincez le système CVC et préparez les composants pour la machine de climatisation Snap-on

-

Installez temporairement l'ancienne conduite reliant le supercollecteur au système CVC de climatisation et installez les boulons (x2) (couple de serrage de 28 Nm) qui fixent la conduite à l'ensemble CVC

-

Installez l'adaptateur de rinçage 1838504-E0-A sur la conduite reliant le supercollecteur au système CVC de climatisation.

Remarque1x écrou, 13 mm, 36 Nm

-

Branchez l'adaptateur de rinçage du boîtier CVC à la machine de climatisation.

RemarqueBranchez la conduite de pression rouge sur le côté gauche de l'adaptateur, boulonnez la conduite bleue provenant de la trousse de rinçage sur le côté droit de l'adaptateur.

-

Branchez les tuyaux de la machine de climatisation Snap-on aux adaptateurs de rinçage de climatisation et exécutez la procédure en sélectionnant .

RemarqueLa procédure de rinçage dure environ 90 minutes. Un minimum de 3,2 kg de fluide frigorigène est nécessaire dans le réservoir pour exécuter la procédure de rinçage du système.

-

Débranchez l'adaptateur de rinçage de l'appareil de climatisation.

- Retirez le conteneur de vidange de fluide frigorigène d’en dessous du véhicule.

-

Retirez les bouchons de la ligne de climatisation du nouveau supercollecteur.

-

Installez le bouchon dans les orifices de l'ancienne conduite reliant le supercollecteur au système CVC.

RemarqueEssayez d'éviter autant que possible les fuites d'huile.

-

Installez le bouchon dans l'orifice des anciennes conduites reliant le supercollecteur au compresseur de climatisation.

RemarqueEssayez d'éviter autant que possible les fuites d'huile.

-

Préparez la pièce pour l'expédition MRB à titre d'intérêt particulier.

RemarqueDébranchez tous les bouchons de liquide de refroidissement seulement du supercollecteur et vidangez autant de liquide de refroidissement que possible vers le récepteur de liquide à profil bas. Emballez-le soigneusement dans la boîte, de la même manière que la pièce neuve. Notez le numéro de session Toolbox, le modèle Tesla et les 6 derniers chiffres du VIN.

- Retirez la conduite de climatisation actuelle reliant le supercollecteur au système CVC du système CVC.

-

Installez de nouvelles rondelles d'étanchéité sur la conduite de climatisation reliant le supercollecteur existant au système CVC, côté supercollecteur.

Remarque1111740-00-A RONDELLE, 3/4, ACIER ZN, JOINT (x1), 1111738-00-A RONDELLE, 1/2, ACIER ZN, JOINT (x1), 1111737-00-A RONDELLE, 3/8, ACIER ZN, JOINT (x3).

-

Installez l'ensemble de conduite de climatisation allant du supercollecteur au système CVAC sur le supercollecteur et serrez l'écrou à la main.

Remarque1x écrou, 13 mm, 36 Nm Serrez à une étape ultérieure.

-

Retirez le support du compresseur de climatisation du compresseur de climatisation

Remarque3x boulons, 10 mm, 9 Nm

-

Retirez les bouchons de transport du nouveau compresseur de climatisation

-

Préparez la pièce pour l'expédition MRB à titre d'intérêt particulier

RemarqueInstallez les bouchons de transport du nouveau compresseur de climatisation sur l'ancien compresseur pour éviter les fuites d'huile pendant le transport

-

Installez le support du compresseur de climatisation sur le compresseur de climatisation

Remarque3x boulons, 10 mm, 9 Nm

-

Chevauchement de la procédure de rinçage du système de climatisation

RemarqueSoustrayez le temps passé sur d'autres opérations en attendant le rinçage du système de climatisation, le rinçage rapide dure 40 minutes, le rinçage complet dure 1 heure et 40 minutes.

-

Débranchez le tuyau basse pression de la machine de climatisation au raccord rapide du filtre

-

Débranchez l'adaptateur de rinçage du boîtier CVC de la machine de climatisation

RemarqueDébranchez la conduite de pression rouge sur le côté gauche de l'adaptateur, déboulonnez la conduite bleue provenant de la trousse de rinçage sur le côté droit de l'adaptateur

-

Retirez l'adaptateur du véhicule.

Remarque1x écrou, 13 mm, 36 Nm

-

Retirez les boulons (x2) qui fixent la conduite reliant le supercollecteur au système CVC de climatisation à l'ensemble CVC, puis retirez la conduite de climatisation du véhicule.

Rincez le système de CVC et préparez les composants pour la machine de climatisation Waeco

-

Installez temporairement l'ancienne conduite reliant le supercollecteur au système CVC de climatisation et installez les boulons (x2) (couple de serrage de 28 Nm) qui fixent la conduite à l'ensemble CVC

-

Installez l'adaptateur de rinçage sur la conduite reliant le supercollecteur au système CVC de climatisation.

Remarque1x écrou, 13 mm, 36 Nm

-

Installez la trousse de rinçage sur la machine de climatisation.

RemarqueFixez la trousse de rinçage sur la machine de climatisation Waeco. 2x boulons de 8 mm, 1x écrou Nyloc

-

Inspectez le marquage du déshydrateur de filtre de la conduite de liquide.

RemarqueMarquez le filtre avant chaque rinçage avec un marqueur de peinture, remplacez le filtre après 10 rinçages.RemarqueSi le remplacement du filtre n’est pas encore nécessaire, passez à l’étape 7.

-

Retirez le déshydrateur de filtre de liquide en ligne

RemarqueRetirez le filtre du contenant (filtre gris fixé à l'unité de rinçage) PR052FM, Vous pouvez réutiliser le joint torique en cuivre, Utilisez la force manuelle, et pas d'outils

-

Remplacez le filtre déshydrateur de liquide en ligne (le filtre gris fixé à l'unité de rinçage) PR052FM

Remarque1x nouveau filtre, 2x nouvelles bagues d'étanchéité en cuivre, Portez un EPI approprié, Posez le mamelon de l'ancien filtre sur le nouveau filtre, Installez la bague d'étanchéité en cuivre entre les connexions, Ne serrez pas trop, serrez à la main, en raison de la conduite en cuivre, Assurez-vous que l'ancien joint a été retiré avant d'installer le nouveau filtre, utilisez un outil de prélèvement pour retirer la bague en cuivre si nécessaire

-

Branchez le tuyau flexible basse pression de la machine de climatisation au raccord rapide du filtre

-

Branchez l'adaptateur de rinçage du boîtier CVC à la machine de climatisation

RemarqueBranchez la conduite de pression rouge sur le côté gauche de l'adaptateur, boulonnez la conduite bleue provenant de la trousse de rinçage sur le côté droit de l'adaptateur

-

Branchez les tuyaux de la machine de climatisation aux adaptateurs de rinçage de climatisation et faites le rinçage du boîtier CVAC.

RemarqueSi une ou plusieurs des alertes mentionnées à l'étape 8 de la section « Supprimer » sont présentes, choisissez Rinçage complet. Si aucune alerte n'est présente, choisissez Rinçage rapide.RemarqueLa procédure de rinçage rapide du système dure environ 40 minutes. Si l'une des alertes illustrées est présente, effectuez un rinçage complet. Cela prend environ 1 heure et 40 minutes. Doit utiliser la machine de service de climatisation WAECO ASC 5500G RPA R1234YF. Un minimum de 6 kg de réfrigérant est nécessaire dans le réservoir pour effectuer la procédure de rinçage du système. Appuyez sur Entrée => Autres sélections => Entrée => Rinçage => Entrée => Entrée => Entrée => Rinçage complet => Entrée

- Retirez le conteneur de vidange de fluide frigorigène d’en dessous du véhicule.

-

Retirez les bouchons de la conduite de climatisation du nouveau supercollecteur

-

Installez le bouchon dans les trous de l'ancienne conduite reliant le supercollecteur au système CVC

RemarqueEssayez d'éviter autant que possible les fuites d'huile

-

Installez le bouchon dans les trous de l'ancienne conduite reliant le supercollecteur au compresseur de climatisation

RemarqueEssayez d'éviter autant que possible les fuites d'huile

-

Préparez la pièce pour l'expédition MRB à titre d'intérêt particulier

RemarqueDébranchez tous les bouchons de liquide de refroidissement seulement du supercollecteur et vidangez autant de liquide de refroidissement que possible vers le récepteur de liquide à profil bas, Emballez-le soigneusement dans la boîte de la même manière que le nouveau, Notez le numéro de session de Toolbox, le modèle Tesla, les 6 derniers chiffres du NIV

-

Installez l’ensemble conduite de climatisation, du supercollecteur au système CVAC, sur le supercollecteur, puis posez l’écrou à la main

Remarque1x écrou de 13 mm, couple de 36 Nm, Serrez au couple spécifié à une étape ultérieure

-

Retirez le support du compresseur de climatisation du compresseur de climatisation

Remarque3x boulons, 10 mm, 9 Nm

-

Retirez les bouchons de transport du nouveau compresseur de climatisation

-

Préparez la pièce pour l'expédition MRB à titre d'intérêt particulier

RemarqueInstallez les bouchons de transport du nouveau compresseur de climatisation sur l'ancien compresseur pour éviter les fuites d'huile pendant le transport

-

Installez le support du compresseur de climatisation sur le compresseur de climatisation

Remarque3x boulons, 10 mm, 9 Nm

-

Chevauchement de la procédure de rinçage du système de climatisation

RemarqueSoustrayez le temps passé sur d'autres opérations en attendant le rinçage du système de climatisation, le rinçage rapide dure 40 minutes, le rinçage complet dure 1 heure et 40 minutes.

-

Débranchez le tuyau basse pression de la machine de climatisation au raccord rapide du filtre

-

Débranchez l'adaptateur de rinçage du boîtier CVC de la machine de climatisation

RemarqueDébranchez la conduite de pression rouge sur le côté gauche de l'adaptateur, déboulonnez la conduite bleue provenant de la trousse de rinçage sur le côté droit de l'adaptateur

-

Retirez l'adaptateur du véhicule.

Remarque1x écrou, 13 mm, 36 Nm

Installer

-

Installez le recouvrement acoustique anti-bruit sur le nouveau compresseur.

RemarqueInstallez l'ancien recouvrement acoustique si l'adhésif est utilisable, ou un nouveau recouvrement acoustique dans le cas contraire.RemarqueRetirez le support adhésif, puis posez le recouvrement avec la face adhésive vers le haut. Alignez les découpes du recouvrement acoustique avec l'orifice d'aspiration sur le compresseur, installez le recouvrement autour de l'orifice d'aspiration, puis continuez d'envelopper le recouvrement autour du compresseur.

-

Placez le support du compresseur de climatisation sur le compresseur et installez les boulons qui fixent le renfort au compresseur.

9 Nm (6.6 lbs-ft)RemarqueL'un ou plusieurs des outils suivants sont recommandés :

9 Nm (6.6 lbs-ft)RemarqueL'un ou plusieurs des outils suivants sont recommandés :- Douille longue de 10 mm

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

-

Positionnez le compresseur de climatisation et le support du compresseur de climatisation sur le support de la tour d’amortisseur, puis serrez à la main les boulons (x2) pour les fixer.

-

Retirez les boulons (x2) qui fixent la conduite reliant le supercollecteur au système CVC de climatisation à l'ensemble CVC, puis retirez la conduite de climatisation du véhicule.

-

Remplacez les rondelles d'étanchéité de la conduite de climatisation actuelle reliant le supercollecteur au système CVC, du côté du supercollecteur.

Remarque1111740-00-A RONDELLE, 3/4, ACIER ZN, JOINT (x1), 1111738-00-A RONDELLE, 1/2, ACIER ZN, JOINT (x1), 1111737-00-A RONDELLE, 3/8, ACIER ZN, JOINT (x3).RemarqueLubrifiez les rondelles d'étanchéité avec de l'huile ND-11.

- Retirez les bouchons de la conduite de climatisation du nouveau supercollecteur.

-

Remplacez les rondelles d’étanchéité de l’ensemble de conduite de climatisation reliant le supercollecteur au système CVAC sur le côté système CVAC.

Remarque1111740-00-A RONDELLE, 3/4, ACIER ZN, JOINT (x1), 1111738-00-A RONDELLE, 1/2, ACIER ZN, JOINT (x1), 1111737-00-A RONDELLE, 3/8, ACIER ZN, JOINT (x3).RemarqueLubrifiez les rondelles d'étanchéité avec de l'huile ND-11.

-

Serrez à la main l'écrou qui fixe le conduit de climatisation reliant le super-collecteur au système CVAC au supercollecteur.

-

Serrez l'écrou qui fixe l'ensemble du conduit de climatisation reliant le super-collecteur au système CVAC au supercollecteur.

36 Nm (26.5 lbs-ft)RemarqueL'un ou plusieurs des outils suivants sont recommandés :

36 Nm (26.5 lbs-ft)RemarqueL'un ou plusieurs des outils suivants sont recommandés :- Douille de 13 mm

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

- Rallonge de 6 po

-

Positionnez l'ensemble du supercollecteur sur le renfort de la tour d'amortisseur, puis serrez à la main les boulons qui fixent l'ensemble du supercollecteur au renfort.

-

Serrez les boulons qui fixent le supercollecteur au renfort de la tour d’amortisseur.

31 Nm (22.9 lbs-ft)RemarqueL'un ou plusieurs des outils suivants sont recommandés :

31 Nm (22.9 lbs-ft)RemarqueL'un ou plusieurs des outils suivants sont recommandés :- Douille de 15 mm

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

- Rallonge de 6 po

-

Serrez les boulons (x2) qui fixent le compresseur au support de la tour d’amortisseur.

31 Nm (22.9 lbs-ft)RemarqueL'un ou plusieurs des outils suivants sont recommandés :

31 Nm (22.9 lbs-ft)RemarqueL'un ou plusieurs des outils suivants sont recommandés :- Douille longue de 15 mm

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

-

Avec de l'aide, installez le supercollecteur, le compresseur et le renfort de la tour d'amortisseur sur le véhicule.

RemarqueDeux techniciens sont nécessaires pour cette étape. Faites attention aux connecteurs et aux conduites de climatisation, soulevez lentement le renfort.

-

Posez les boulons gauche et droit qui fixent le renfort de la tour d'amortisseur à la carrosserie.

55 Nm (40.6 lbs-ft)

55 Nm (40.6 lbs-ft) 55 Nm (40.6 lbs-ft)RemarqueL'un ou plusieurs des outils suivants sont recommandés :

55 Nm (40.6 lbs-ft)RemarqueL'un ou plusieurs des outils suivants sont recommandés :- Douille de 15 mm

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

-

Posez les boulons extérieurs gauche et droit qui fixent le renfort de la tour d’amortisseur à la carrosserie.

62 Nm (45.7 lbs-ft)RemarqueL'un ou plusieurs des outils suivants sont recommandés :

62 Nm (45.7 lbs-ft)RemarqueL'un ou plusieurs des outils suivants sont recommandés :- Douille de 15 mm

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

-

Installez les boulons (x2) qui fixent le conduit reliant le supercollecteur au système CVAC.

28 Nm (20.6 lbs-ft)TIpL'un ou plusieurs des outils suivants sont recommandés :

28 Nm (20.6 lbs-ft)TIpL'un ou plusieurs des outils suivants sont recommandés :- Douille de 13 mm

-

Branchez le flexible d’entrée de radiateur sur le supercollecteur.

RemarqueEffectuez un test de solidité en poussant et en tirant pour vous assurer que le tuyau est solidement fixé.

-

Branchez le flexible de sortie de radiateur sur le supercollecteur.

RemarqueEffectuez un test de solidité en poussant et en tirant pour vous assurer que le tuyau est solidement fixé.

-

Branchez le flexible de contournement du groupe motopropulseur sur le supercollecteur.

RemarqueEffectuez un test de solidité en poussant et en tirant pour vous assurer que le tuyau est solidement fixé.

-

Branchez le flexible de retour de la batterie HT sur le super-collecteur.

RemarqueEffectuez un test de solidité en poussant et en tirant pour vous assurer que le tuyau est solidement fixé.

-

Branchez le flexible d’alimentation du groupe motopropulseur sur le super-collecteur.

RemarqueEffectuez un test de solidité en poussant et en tirant pour vous assurer que le tuyau est solidement fixé.

-

Branchez le flexible du refroidisseur à la batterie sur le supercollecteur.

RemarqueEffectuez un test de solidité en poussant et en tirant pour vous assurer que le tuyau est solidement fixé.

-

Branchez le capteur du flexible d’alimentation du groupe motopropulseur.

RemarqueLe faisceau et le flexible de liquide de refroidissement sont codés par couleur. Faites correspondre la couleur du faisceau à celle du tuyau de liquide refroidissement.

-

Branchez le capteur du flexible du refroidisseur à la batterie.

RemarqueLe faisceau et le flexible de liquide de refroidissement sont codés par couleur. Faites correspondre la couleur du faisceau à celle du tuyau de liquide refroidissement.

- Installez l’attache qui fixe le faisceau du sous-ensemble thermique au contrôleur avant.

-

Branchez le connecteur du sous-faisceau thermique au contrôleur avant.

-

Placez le renfort de faisceau de câbles HT du compresseur de climatisation sur le compresseur.

RemarqueAssurez-vous que le renfort de faisceau de câbles HT s'engage dans le renfort de montage du faisceau situé sur le dessus du compresseur de climatisation.

-

Installez le boulon fixant le support du faisceau de câbles HT au compresseur de climatisation.

9 Nm (6.6 lbs-ft)TIpL'un ou plusieurs des outils suivants sont recommandés :

9 Nm (6.6 lbs-ft)TIpL'un ou plusieurs des outils suivants sont recommandés :- Douille longue de 13 mm

- Clé à cliquet/Clé dynamométrique

TIp -

Branchez le connecteur électrique de la boîte de jonction HT (HVIL).

-

Enfoncez solidement le connecteur HT du compresseur de climatisation sur le compresseur de climatisation, puis engagez la languette de verrouillage en la poussant vers le compresseur de climatisation.

RemarquePoussez et tirez sur les connecteurs pour vérifier qu’ils sont bien fixés.

-

Installez les attaches de fixation qui fixent le faisceau HT du compresseur de climatisation au renfort de la tour d'amortisseur.

-

Installez l’attache qui fixe le tuyau de liquide de refroidissement au support du compresseur de CVC, près du point de fixation de la tresse de masse.

-

Placez la tresse de masse sur le compresseur de climatisation et installez le boulon qui fixe la tresse de masse au compresseur de climatisation.

7 Nm (5.2 lbs-ft)RemarqueCe boulon est auto-taraudeur. Il n'est pas nécessaire de tarauder le trou du boulon de compresseur.TIpL'un ou plusieurs des outils suivants sont recommandés :

7 Nm (5.2 lbs-ft)RemarqueCe boulon est auto-taraudeur. Il n'est pas nécessaire de tarauder le trou du boulon de compresseur.TIpL'un ou plusieurs des outils suivants sont recommandés :- Douille Torx T25

- Clé à cliquet sans fil/Visseuse à percussion

- Clé à cliquet/Clé dynamométrique

-

Installez l’attache qui fixe le faisceau de câbles BT du compresseur de climatisation au renfort de faisceau de câbles HT du compresseur de climatisation.

-

Branchez le connecteur électrique BT au compresseur de climatisation, puis serrez la languette de verrouillage.

ATTENTIONPoussez la languette de verrouillage rouge vers le connecteur pour engager le mécanisme de verrouillage. N'APPUYEZ PAS et NE TIREZ PAS sur la languette rouge de verrouillage.

-

Retirez les bouchons de transport du nouveau compresseur de climatisation.

-

Lubrifiez les joints toriques des raccords de tuyau flexible haute et basse pression reliant le super-collecteur au compresseur de climatisation de la nouvelle conduite de climatisation avec l'huile de climatisation appropriée. Voir Liquides et contenances pour les spécifications relatives à l’huile du système de climatisation appropriée.

Figure 1. Raccord basse pression illustré; raccord haute pression similaire -

Placez le raccord haute pression, situé entre le super-collecteur et le compresseur de climatisation, sur le compresseur et installez l'écrou qui fixe le raccord au compresseur de climatisation.

22 Nm (16.2 lbs-ft)TIpL'un ou plusieurs des outils suivants sont recommandés :

22 Nm (16.2 lbs-ft)TIpL'un ou plusieurs des outils suivants sont recommandés :- Douille longue de 13 mm

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

- Placez le conduit provenant du compresseur de climatisation sur super-collecteur, puis serrez à la main le boulon qui fixe le conduit de climatisation au super-collecteur.

-

Serrez le boulon qui fixe la conduite de climatisation, qui va du supercollecteur au compresseur, au supercollecteur.

22 Nm (16.2 lbs-ft)RemarqueL'un ou plusieurs des outils suivants sont recommandés :

22 Nm (16.2 lbs-ft)RemarqueL'un ou plusieurs des outils suivants sont recommandés :- Douille de 13 mm

- Clé à cliquet à tête flexible/clé dynamométrique à tête flexible

- Rallonge de 6 po

-

Placez le raccord basse pression, entre le super-collecteur et le compresseur de climatisation, sur le compresseur, puis installez l'écrou qui fixe le raccord au compresseur de climatisation.

22 Nm (16.2 lbs-ft)TIpL'un ou plusieurs des outils suivants sont recommandés :

22 Nm (16.2 lbs-ft)TIpL'un ou plusieurs des outils suivants sont recommandés :- Douille longue de 13 mm

- Installez les attaches (x4) qui fixent le tuyau flexible de liquide de refroidissement au support du compresseur de climatisation.

-

Installez la sangle d'arrimage de la batterie arrière sur le renfort de batterie 12 V.

-

Fixez l’attache qui fixe le tube d'aération de la batterie 12 V au renfort de la batterie 12 V.

- Installez la batterie auxiliaire BT de 12 V. Voir 12 V /BT batterie (retirez et remplacez),

- Connectez la boucle de premier intervenant et la batterie basse tension.

- Sur l'écran tactile, touchez et sélectionnez Exécuter pour commencer la routine « Démarrer la vidange du fluide thermique (liquide de refroidissement et réfrigérant) ».

- Débranchez l’alimentation 12 V/BT Voir Alimentation 12 V/BT (déconnectez et connectez),

- Faites un test d'étanchéité sous vide de la climatisation. Voir Fluide frigorigène de climatisation (récupération et recharge),

- Effectuez la recharge du réfrigérant de la climatisation. Voir Fluide frigorigène de climatisation (récupération et recharge),

- Effectuez un remplissage sous vide du système de refroidissement. Voir Système de refroidissement (remplissage sous vide),

- Connectez la boucle de premier intervenant, mais laissez la batterie BT débranchée.

- Connectez un mainteneur BT. Voir Mainteneur BT (connecter et déconnecter),

-

Effectuez une mise à jour de la configuration du compresseur :

- Réinstallez le micrologiciel. Voir Réinstallation du logiciel – Écran tactile,

- Sur l’écran tactile, touchez l’icône de clé du mode Entretien (dans le bas de l’interface utilisateur de l’écran tactile) et touchez , puis laissez la routine se terminer.

- Touchez pour inspecter la configuration actuelle de la pompe de liquide de refroidissement. Si la configuration n'est pas DUAL_MIX, changez-la à DUAL_MIX.

- Touchez , puis fermez une fois que la routine est terminée.

- Touchez pour inspecter la configuration actuelle du supercollecteur. Si la configuration n'est pas TYPE1, changez-la à TYPE1.

- Touchez , puis fermez une fois que la routine est terminée.

- Touchez , puis fermez une fois que la routine est terminée.

- Touchez et fermez une fois la routine terminée.

- Installez le coussin de siège inférieur de la deuxième rangée. Voir Coussin de siège - inférieur - appuie-tête - 2e rangée (retirez et remplacez),

- Installez le bouclier aérodynamique avant. Voir Panneau - écran aérodynamique - avant (Ensemble non-structurel)(retirez et remplacez),

- Une fois la purge de l'air de refroidissement terminée, inspectez le niveau du liquide de refroidissement et assurez-vous que le niveau de liquide est à la ligne Max.

- Touchez , puis fermez une fois que la routine est terminée.

- Touchez , puis fermez une fois que la routine est terminée.

- Sur l'écran tactile, maintenez enfoncé le bouton Quitter le mode entretien pour quitter le mode Entretien Plus.

- Débranchez le mainteneur BT. Voir Mainteneur BT (connecter et déconnecter),

- Branchez l’alimentation à basse tension. Voir Alimentation 12 V/BT (déconnectez et connectez),

- Installez le conduit HEPA. Voir Conduit - HEPA (retirez et remplacez),

- Installez le couvercle de l’ensemble filtre HEPA. Voir Ensemble - filtre - HEPA (retirez et remplacez),

- Installez l’unité de rangement sous le capot Voir Unité de rangement sous le capot (retirez et remplacez),