Bomba - Refrigerante - Batería - Supercolector (desinstalación y sustitución)

Código de corrección

18401802 0.96

NOTA: Salvo que se indique lo contrario explícitamente en el procedimiento, el código de corrección anterior y el FRT reflejan todo el trabajo necesario para realizar este procedimiento, incluidos los procedimientos vinculados. No acumule códigos de corrección a menos que se le indique explícitamente que lo haga.

NOTA: Consulte Tiempos de tarifa plana (FRT) para obtener más información sobre los FRT y cómo se crean. Para enviar sus comentarios sobre los valores de FRT, escriba a ServiceManualFeedback@tesla.com.

NOTA: Consulte Protección personal para asegurarse de llevar el EPI adecuado al realizar el siguiente procedimiento.

Código de corrección

18401802 0.96

NOTA: Salvo que se indique lo contrario explícitamente en el procedimiento, el código de corrección anterior y el FRT reflejan todo el trabajo necesario para realizar este procedimiento, incluidos los procedimientos vinculados. No acumule códigos de corrección a menos que se le indique explícitamente que lo haga.

NOTA: Consulte Tiempos de tarifa plana (FRT) para obtener más información sobre los FRT y cómo se crean. Para enviar sus comentarios sobre los valores de FRT, escriba a ServiceManualFeedback@tesla.com.

NOTA: Consulte Protección personal para asegurarse de llevar el EPI adecuado al realizar el siguiente procedimiento.

- Log into Tesla Garage

- Enter vehicle VIN and select "Search"

-

Check Firmware version

NotaFirmware package installed must be 2021.36 or above for vehicle configuration update and Toolbox routine

- Navigate to "CFG" tab on "Vitals" page

-

Check the coolant pump GTW

configuration, and make sure the configuration is set to

DUAL_MIX.

PRECAUCIÓNThe Coolant Pump Identification will depend on this new configuration.NotaIf the configuration is set to DUAL or DUAL_SAN_P4, change the configuration to DUAL_MIX. If the gateway configuration is already set to DUAL_MIX, no further configuration is required.

- Open LH front door

- Lower LH front window

- Connect to vehicle using Toolbox 3.0

- Select "Dashboards" tab, and select "Infotainment Dashboard"

-

Select "Vehicle Configuration"

NotaConfiguration values should load automatically, if not select "Read Config" and "Run" to load

-

Select "Read Config" and select "Run" to

pull current vehicle configuration, Verify configuration change was performed

NotaRead config and verify configuration change was successful, Refresh page if required, Select ‘X’ at top right of window to close once complete

- Scroll down to "coolantPumpType" and change to "Two coolant pumps installed, mixed pole pair batches"

-

Select "Apply Changes" and select "Run"

to save updated configuration

NotaCenter display will reboot, Toolbox connection will be lost, Select ‘X’ at top right of window to close once complete

- Select ‘Actions/Autodiag’ and search for ‘Thermal’

-

Select "Start Thermal Fluid Fill/Drain

(Coolant only)", click Run and allow routine to complete

NotaSelect ‘X’ at top right of window to close once complete, Verify vehicle is in Series via Garage > Vitals > Thermal tab > Coolant loops, Thermal Fluid Fill/Drain routine has a 5 hour limit, After 5 hours routine must be performed again

-

Vehicle preparation

NotaEnsure vehicle is not charging before the repair

- Open hood

-

Remove rear apron

Nota14x clips

-

Power off vehicle from center

display

NotaVia Controls > Safety & Security > Vehicle Power > Power Off

-

Disconnect 12V negative terminal and

first responders loop

Nota1x nut, 10mm, 6 Nm, 1x connector, Ensure vehicle is in park, climate control system is off, and vehicle is not charging before disconnecting 12V, Negative terminal should be disconnected before FRL, Allow 2 minutes for all electrical circuits to fully discharge

-

Remove fresh air intake duct

Nota1x bolt, 10mm, 4 Nm, 2x clips, 1x pin, Remove bolt, Gently pry pin out from thermal beam, then remove from bulkhead studs

-

Disconnect powertrain coolant pump

connector

Nota1x locking electrical connector, Do not push down on Red tab, Pull red tab to disengage lock, Pull again to release connector

-

Disconnect battery coolant pump

connector

Nota1x locking electrical connector, Do not push down on Red tab, Pull red tab to disengage lock, Pull again to release connector

-

Raise vehicle fully and lower lift onto

locks

NotaSet vehicle to comfortable working height, Make sure there's an audible click of the locks on both sides before lowering, otherwise vehicle may tilt to the side

-

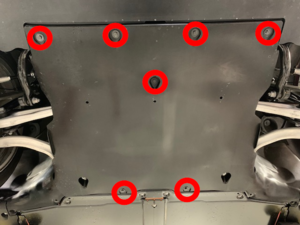

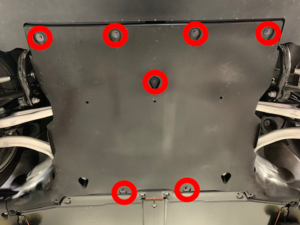

Remove outer fasteners from front aero

shield

Nota7x bolts, 10mm, 5 Nm

-

Remove remaining nuts and remove front

aero shield from vehicle

Nota2x nuts, 15mm, 5 Nm

- Position coolant drain container underneath battery coolant pump

-

Remove bolts securing battery coolant

pump to Supermanifold

Nota4x bolts, T20, 1.8 Nm

-

Remove battery coolant pump from

Supermanifold

NotaMake sure both o-rings (inner purple, and outer black) come off with old pump

-

Position battery coolant pump to

Supermanifold and install bolts hand tight

Nota4x bolts, T20, 1.8 Nm, Lubricate both o-rings with silicone o-ring lubricant, Refer to connector position and install coolant pump with connector tab facing up, Recommend installing upper right bolt with coolant pump for easier installation, Make sure the coolant pump is fully seated

- Remove coolant drain container from underneath vehicle

-

Position the front aero shield to

vehicle and install nuts

Nota2x nuts, 15mm, 5 Nm

-

Apply Loctite 222 onto front aero shield

bolts and install outer fasteners to front aero shield

Nota7x bolts, 10mm, 5 Nm

-

Lower vehicle until tires are touching

the ground

NotaRaise lift off locks, then hold lock release lever to keep locks free while vehicle is lowered

-

Torque bolts securing battery coolant

pump to supermanifold

Nota4x bolts, T20, 1.8 Nm

-

Connect battery coolant pump

connector

Nota1x locking electrical connector, Engage locking tab

-

Connect powertrain coolant pump

connector

Nota1x locking electrical connector, Engage locking tab

- Remove coolant bottle cap

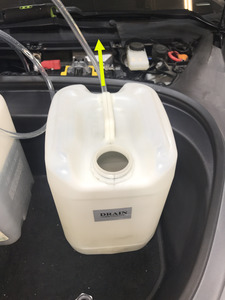

- Place empty coolant container into front storage area

- Fill container with at least 15L of coolant

- Place filled coolant container into front storage area

-

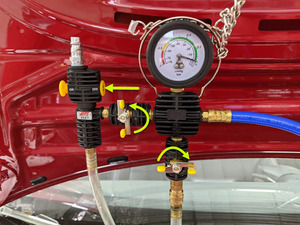

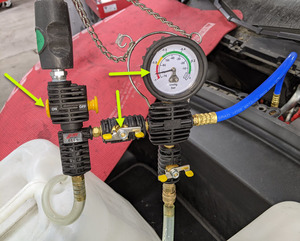

Setup vacuum refill tool

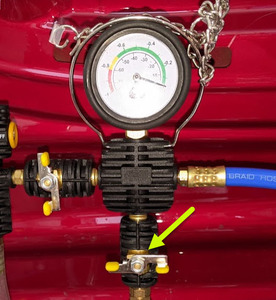

NotaVerify all valves on refill tool are in the closed position, See image for clarity

- Install vacuum refill cap onto coolant bottle assembly

-

Setup vacuum refill tool

NotaVerify all valves on refill tool are in the closed position, See image for clarity

-

Install vacuum refill hose into refill

cap on coolant bottle

NotaPerform push-pull-push test to verify hose is fully installed

- Position overflow hose into empty container

-

Connect shop air supply to coolant

refill tool

NotaIf not already done, Verify refill valve is set to off

-

Open air inlet valve to draw a vacuum,

Once gauge stabilizes, Fully close valve

NotaGauge stabilizes roughly (60-70 cmHg), Vacuum should not drop after the valves are closed

-

Slowly open the refill valve to allow

coolant to be drawn into the system

NotaMake sure hose end of refill hose is fully submerged during entire process

- Once the gauge reads zero, close the refill valve

- Once the gauge reads zero, close the refill valve

- Once the gauge reads zero, close the refill valve

- Once the gauge reads zero, close the refill valve

- Disconnect shop air supply from coolant refill tool

- Remove coolant refill hose from coolant container

- Remove coolant overflow hose from coolant container

- Remove vacuum refill hose from refill cap on coolant bottle

- Remove coolant refill tool from vehicle

- Remove both coolant containers from inside underhood area

-

Connect first responder loop and 12V

negative terminal

Nota1x nut, 10mm, 6 Nm, 1x connector, Engage locking tab, Connect FRL first before connecting 12V to avoid damage to car computer

-

Realice la siguiente rutina a través del modo de servicio o Toolbox (consulte 0005 - Modos de servicio):

PROC_VCFRONT_X_STOP-THERMAL-FILL-DRAINvia Toolbox: (link)via Service Mode:

- Thermal ➜ Actions ➜ Stop Thermal Fill/Drain

- Thermal ➜ Coolant System ➜ Stop Coolant Fill/Drain

- Thermal ➜ Refrigerant System ➜ Stop Refrigerant Fill/Drain

- Drive Inverter ➜ Front Drive Inverter Replacement ➜ Stop Fluid Fill/Drain

- Drive Inverter ➜ Rear Drive Inverter Replacement ➜ Stop Fluid Fill/Drain

- Drive Inverter ➜ Rear Left Drive Inverter Replacement ➜ Stop Fluid Fill/Drain

- Drive Inverter ➜ Rear Right Drive Inverter Replacement ➜ Stop Fluid Fill/Drain

- Drive Unit ➜ Front Drive Unit Replacement ➜ Stop Coolant Fill/Drain

- Drive Unit ➜ Rear Drive Unit Replacement ➜ Stop Coolant Fill/Drain

NotaSelect ‘X’ at top right of window to close once complete -

Realice la siguiente rutina a través del modo de servicio o Toolbox (consulte 0005 - Modos de servicio):

TEST_VCFRONT_X_THERMAL-COOLANT-AIR-PURGEvia Toolbox: (link)via Service Mode:

- Thermal ➜ Actions ➜ Coolant Purge Stop or Coolant Purge Start

- Thermal ➜ Coolant System ➜ Coolant Purge Start

- Drive Inverter ➜ Front Drive Inverter Replacement ➜ Coolant Air Purge

- Drive Inverter ➜ Rear Drive Inverter Replacement ➜ Coolant Air Purge

- Drive Inverter ➜ Rear Left Drive Inverter Replacement ➜ Coolant Air Purge

- Drive Inverter ➜ Rear Right Drive Inverter Replacement ➜ Coolant Air Purge

- Drive Unit ➜ Front Drive Unit Replacement ➜ Coolant Air Purge

- Drive Unit ➜ Rear Drive Unit Replacement ➜ Coolant Air Purge

NotaMake sure vehicle is not in drive state, Plan is still running despite the stop message, Coolant pumps will be audible, Test lasts approximately 10 mins, Speeds can be monitored in garage under PT Thermal tab, Idle speed = ~1500 RPM, Test will vary speeds from 3500-6500 RPM and actuate valve between SERIES and PARALLEL, Putting vehicle into drive state will stop this routine, If speeds hover at 7000 RPM, that means the pumps are air locked, perform vacuum fill again, Continue to add coolant and purge until the coolant level reaches between the NOM and MAX Lines on the bottle, Select ‘X’ at top right of window to close once complete -

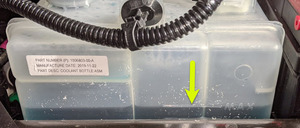

Inspect coolant level and top off as

necessary

NotaEnsure that the fluid level is at the Max line

- Install coolant bottle cap

-

Realice la siguiente rutina a través del modo de servicio o Toolbox (consulte 0005 - Modos de servicio):

TEST-SELF_VCFRONT_X_COOLANT-PUMPS-IDENTIFICATIONvia Toolbox: (link)via Service Mode:

- Thermal ➜ Actions ➜ Run Coolant Pumps Identification

- Thermal ➜ Coolant System ➜ Pump Identification

NotaSelect ‘X’ at top right of window to close once complete, Ensure VCFRONT_a490_coolantPumpsNotIdentified has cleared -

Realice la siguiente rutina a través del modo de servicio o Toolbox (consulte 0005 - Modos de servicio):

TEST-SELF_VCFRONT_X_THERMAL-PERFORMANCEvia Toolbox: (link)via Service Mode: Thermal ➜ Actions ➜ Test Thermal Performancevia Service Mode Plus:

- Drive Inverter ➜ Front Drive Inverter Replacement ➜ Thermal System Test

- Drive Inverter ➜ Rear Drive Inverter Replacement ➜ Thermal System Test

- Drive Inverter ➜ Rear Left Drive Inverter Replacement ➜ Thermal System Test

- Drive Inverter ➜ Rear Right Drive Inverter Replacement ➜ Thermal System Test

- Drive Unit ➜ Front Drive Unit Replacement ➜ Thermal System Test

- Drive Unit ➜ Rear Drive Unit Replacement ➜ Thermal System Test

NotaSelect ‘X’ at top right of window to close once complete. -

Install fresh air intake duct

Nota1x bolt, 10mm bolt, 4 Nm, 2x clips, 1x pin, Set clips on bulkhead studs, Secure to thermal bar

-

Install rear apron

Nota14x clips, Hold rear wall of frunk to keep from flexing while engaging front clips

- Close hood

-

Remove vehicle from lift

NotaLower rack arms fully and remove from under vehicle if necessary, Remove air suspension from "Jack Mode" if equipped