Compresor de aire acondicionado, supercolector y tubo de aire acondicionado que va del compresor al supercolector (Desinstalación y sustitución)

Código de corrección

18204012 1.92

NOTA: Salvo que se indique lo contrario explícitamente en el procedimiento, el código de corrección anterior y el FRT reflejan todo el trabajo necesario para realizar este procedimiento, incluidos los procedimientos vinculados. No acumule códigos de corrección a menos que se le indique explícitamente que lo haga.

NOTA: Consulte Tiempos de tarifa plana (FRT) para obtener más información sobre los FRT y cómo se crean. Para enviar sus comentarios sobre los valores de FRT, escriba a ServiceManualFeedback@tesla.com.

NOTA: Consulte Protección personal para asegurarse de llevar el EPI adecuado al realizar el siguiente procedimiento. Consulte Precauciones ergonómicas para ver prácticas de trabajo seguras.

Código de corrección

18204012 1.92

NOTA: Salvo que se indique lo contrario explícitamente en el procedimiento, el código de corrección anterior y el FRT reflejan todo el trabajo necesario para realizar este procedimiento, incluidos los procedimientos vinculados. No acumule códigos de corrección a menos que se le indique explícitamente que lo haga.

NOTA: Consulte Tiempos de tarifa plana (FRT) para obtener más información sobre los FRT y cómo se crean. Para enviar sus comentarios sobre los valores de FRT, escriba a ServiceManualFeedback@tesla.com.

NOTA: Consulte Protección personal para asegurarse de llevar el EPI adecuado al realizar el siguiente procedimiento. Consulte Precauciones ergonómicas para ver prácticas de trabajo seguras.

- 2025-12-10: Se ha actualizado el procedimiento para reutilizar el tubo del aire acondicionado que va del supercolector al climatizador después del enjuague.

- 2025-11-14: Se han añadido procedimientos de purga utilizando el equipo Snap-on.

- 2025-11-10: Se ha añadido un paso para comprobar la revisión del número de pieza instalada y verificar si es necesario realizar el procedimiento de actualización.

- 2025-10-27: Se ha actualizado el par de apriete del tubo del aire acondicionado en el lado del climatizador de 22 Nm a 28 Nm, y el par de apriete en el lado del supercolector de 27 Nm a 36 Nm.

- 2025-08-14: Se han añadido pasos sobre la configuración del tipo de bomba de refrigerante.

- 2025-03-27: Actualización del procedimiento de enjuague.

- 17/06/2024: Se ha añadido un paso para actualizar la configuración de la bomba de refrigerante.

- 29/05/2024: Se ha actualizado el procedimiento de acuerdo con la última validación.

- 28/03/2024: Se ha corregido un enlace de purga incorrecto.

- 06/03/2024: Se han actualizado las rutinas.

- 05/02/2024: Se han añadido pasos para apretar a mano los pernos que fijan el supercolector y el compresor al soporte de la torre del amortiguador.

- 1838504-C0-A, 1838504-E0-A, 1838504-N0-A Adaptador de enjuague de suciedad

- 1711245-00-A - Equipo de aire acondicionado Snap On Ecotechnics Dual Gas con kit de adaptador de enjuague R134A y R1234YF o

- 1120026-01-A EQUIPO DE SERVICIO DE AIRE ACONDICIONADO, WAECO, ASC5500 RPA

Retirar

- Configure el sistema de aire acondicionado.

- Eleve y apoye el vehículo.

-

Abra las cuatro puertas y baje las ventanillas.

NotaCierre las puertas traseras para evitar que se cierren accidentalmente cuando se desconecte la alimentación de 12 V/baja tensión.

- Extraiga la unidad de almacenamiento del vano del motor. Consulte Unidad de almacenamiento del vano del motor (Desinstalación y sustitución).

- Retire el conjunto del filtro HEPA. Consulte Conjunto - Filtro - HEPA (Desinstalación y sustitución).

- Retire el conducto HEPA. Consulte Conducto - HEPA (Desinstalación y sustitución).

- Coloque el vehículo en el Modo de servicio. Consulte Modo de servicio.

-

Compruebe las alertas térmicas a través de la pantalla táctil pulsando el icono de alerta.

Si aparecen alguna de las siguientes alertas, realice un enjuague completo más adelante en el procedimiento.

- VCFRONT_a161_compressorSelfFault

- VCFRONT_a163_compressorDisabledFSR

- VCFRONT_a460_hardIsentropicTdFailed

- VCFRONT_a467_lowPowerIndexFlagged

- VCFRONT_a531_lowPowerIndexFlaggedUserFacing

- VCFRONT_a543_compressorLowFlowDeliveryDetected

- En la pantalla táctil, toque y seleccione Ejecutar para iniciar la rutina "Iniciar llenado/drenaje de líquido térmico (refrigeración y refrigerante)".

- Mueva los asientos delanteros hacia delante.

- Desconecte la alimentación de baja tensión/12 V. Consulte Alimentación de 12 V/baja tensión (Desconexión y conexión).

- Desmonte el panel del deflector aerodinámico frontal. Consulte Panel - Deflector aerodinámico - Delantero (Sin paquete estructural)(Desinstalación y sustitución).

- Recupere el refrigerante del vehículo. Consulte Refrigerante del aire acondicionado (Recuperación y recarga).

- Realice el procedimiento de desactivación de la alta tensión del vehículo. Consulte Procedimiento de desactivación de la alta tensión del vehículo.

- Coloque el recipiente para refrigerante debajo de la parte delantera del vehículo.

- Retire el tapón de la botella de refrigerante.

-

Desconecte del supercolector la manguera de derivación del tren de transmisión.

NotaSe vaciará el depósito de refrigerante.

-

Desconecte la manguera de salida del radiador del supercolector.

-

Desconecte la manguera de entrada del radiador del supercolector.

-

Coloque tres tapones macho en los puertos de refrigeración en la parte delantera del supercolector.

-

Antes de realizar los dos pasos siguientes, inspeccione los sensores de temperatura y los conectores de la manguera de refrigerante.

NotaSi el vehículo está equipado con un sensor de temperatura de un modelo anterior (imagen izquierda), es posible que los nuevos conectores del supercolector no encajen. En este caso, la cubierta del conector eléctrico debe cambiarse del supercolector antiguo al nuevo. Lleve a cabo el procedimiento Rectificación de los conectores antes de la instalación.

-

Desconecte el sensor de la manguera entre el enfriador y la batería.

-

Desconecte el sensor de la manguera de suministro del tren de transmisión.

-

Desconecte del supercolector la manguera que va del enfriador a la batería.

-

Desconecte del supercolector la manguera de alimentación del tren de transmisión.

-

Desconecte del supercolector la manguera de retorno de la batería de alta tensión.

-

Coloque tres tapones macho en los puertos de refrigerante en la parte trasera del supercolector.

-

Desenchufe el conector del mazo de cables del supercolector del controlador delantero.

- Suelte el clip que fija el mazo de cables del subconjunto del sistema térmico al controlador delantero.

- Extraiga la batería de baja tensión/12 V. Consulte Batería de 12 V/baja tensión (Desinstalación y sustitución).

- Suelte los clips (4 uds.) que fijan la manguera de refrigerante al soporte del compresor del aire acondicionado.

- Retire el clip que sujeta el mazo de cables lógico del compresor de aire acondicionado al soporte del mazo de cables de alta tensión del compresor de aire acondicionado.

-

Suelte la pestaña de bloqueo del conector y, a continuación, desenchufe del compresor del aire acondicionado el conector eléctrico de baja tensión.

PRECAUCIÓNNO presione la pestaña de bloqueo roja. Tire de la pestaña para sacarla del conector hasta que este se desbloquee y, a continuación, siga tirando del cuerpo principal del conector para desconectarlo por completo.

-

Retire el perno que fija el soporte del mazo de cables de alta tensión al compresor del aire acondicionado.

TIpSe recomienda utilizar las siguientes herramientas:

- Vaso de 13 mm

- Destornillador de impacto/carraca sin cable

- Llave de carraca/dinamométrica

-

Retire el perno que fija la toma de tierra al compresor de aire acondicionado y, a continuación, coloque la toma de tierra a un lado.

TIpSe recomienda utilizar las siguientes herramientas:

- Vaso Torx T25

- Destornillador de impacto/carraca sin cable

- Llave de carraca/dinamométrica

-

Suelte el clip que sujeta la manguera de refrigerante al soporte del compresor del aire acondicionado, cerca del punto de conexión de la toma de tierra.

-

Tire de la pestaña de bloqueo negra del conector de alta tensión del compresor del aire acondicionado para separarla del compresor del aire acondicionado.

-

Con una ganzúa de 45 grados, presione simultáneamente la pestaña de bloqueo central mientras tira de la pestaña de bloqueo exterior y retire el conector de alta tensión del compresor del aire acondicionado.

-

Desenchufe el conector eléctrico del HVIL.

- Una vez finalizada la recuperación del aire acondicionado, desconecte las mangueras del aire acondicionado del vehículo.

-

Retire la tuerca que fija al compresor el tubo de aspiración que va del supercolector al compresor.

NotaSe recomienda utilizar las siguientes herramientas:

- Vaso de 13 mm de cuello largo

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

-

Retire la tuerca que fija al compresor el tubo de descarga que va del supercolector al compresor.

NotaSe recomienda utilizar las siguientes herramientas:

- Vaso de 13 mm de cuello largo

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

-

Retire del supercolector el perno del tubo entre el colector del aire acondicionado y el compresor y, a continuación, retire el tubo del colector del aire acondicionado del vehículo.

TIpSe recomienda utilizar las siguientes herramientas:

- Vaso de 13 mm

- Extensión de 6 pulg.

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

-

Retire los pernos (2 uds.) que fijan al conjunto del climatizador el tubo del aire acondicionado que va del supercolector al climatizador.

TIpSe recomienda utilizar las siguientes herramientas:

- Vaso de 13 mm

-

Retire la correa de sujeción trasera de la batería del soporte de la batería de 12 V/baja tensión.

NotaEl soporte de la batería de 12 V/baja tensión también funciona como soporte del compresor del aire acondicionado.

-

Suelte el clip que fija el tubo de ventilación de la batería de baja tensión/12 V al soporte de la batería.

-

Suelte el clip que fija el mazo de cables de baja tensión del compresor del aire acondicionado al soporte del mazo de cables de alta tensión del compresor del aire acondicionado.

-

Mueva el soporte del mazo de cables de alta tensión hacia delante y hacia arriba para soltar el soporte del compresor del aire acondicionado y, a continuación, aparte el soporte con cuidado.

-

Retire los clips de sujeción que fijan el mazo de cables de alta tensión del compresor de aire acondicionado al brazo de apoyo de la torre del amortiguador.

NotaTire hacia arriba del clip para facilitar el desmontaje. No tire del cable de alta tensión.

-

Retire los pernos izquierdo y derecho que fijan el soporte de la torre del amortiguador a la carrocería.

55 Nm (40.6 lbs-ft)

55 Nm (40.6 lbs-ft) 55 Nm (40.6 lbs-ft)TIpSe recomienda utilizar las siguientes herramientas:

55 Nm (40.6 lbs-ft)TIpSe recomienda utilizar las siguientes herramientas:- Vaso de 15 mm

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

-

Retire los pernos exteriores izquierdo y derecho que fijan el soporte de la torre del amortiguador a la carrocería y, a continuación, desmonte el soporte de la torres del amortiguador del vehículo.

62 Nm (45.7 lbs-ft)TIpSe recomienda utilizar las siguientes herramientas:

62 Nm (45.7 lbs-ft)TIpSe recomienda utilizar las siguientes herramientas:- Vaso de 15 mm

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

-

Con ayuda de otra persona, retire del vehículo el soporte de la torre del amortiguador, junto con el supercolector y el compresor.

NotaTenga cuidado con los conectores y los tubos del aire acondicionado y, a continuación, levante lentamente el soporte. Colóquelo sobre una base de cartón.

-

Retire la tuerca que fija al supercolector el conjunto del tubo de aire acondicionado que va del supercolector al climatizador y, a continuación, retire el conjunto del tubo de aire acondicionado que va del supercolector al climatizador.

TIpSe recomienda utilizar las siguientes herramientas:

- Vaso de 15 mm

- Destornillador de impacto/carraca sin cable

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

-

Documente los números de pieza y de serie antiguos y nuevos.

NotaLa etiqueta se encuentra delante del acumulador.

-

Retire los pernos (2 uds.) que fijan el supercolector al soporte de la torre del amortiguador y, a continuación, retire el supercolector.

TIpSe recomienda utilizar las siguientes herramientas:

- Vaso de 15 mm

- Destornillador de impacto/carraca sin cable

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

-

Retire los pernos (2 uds.) que sujetan el soporte del compresor del aire acondicionado al soporte de la torre del amortiguador y, a continuación, retire el compresor del aire acondicionado y el conjunto de soporte del compresor del aire acondicionado.

NotaSe recomienda utilizar las siguientes herramientas:

- Vaso de 15 mm

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

-

Retire del compresor del aire acondicionado el soporte del compresor del aire acondicionado.

NotaSe recomienda utilizar las siguientes herramientas:

- Vaso de 10 mm de cuello largo

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

- Documente los números de pieza de los compresores nuevos y antiguos para actualizar la configuración en un paso posterior.

Purgue el sistema de climatización y prepare los componentes para el equipo Snap-on de aire acondicionado

-

Instale temporalmente el tubo que va del antiguo supercolector al climatizador e instale los pernos (2 uds.) (apriete 28 Nm) para fijarlo al conjunto del climatizador

-

Instale el adaptador de enjuague 1838504-E0-A en el tubo del aire acondicionado que va del supercolector al climatizador.

Nota1 tuerca, 13 mm, 36 Nm

-

Conecte el adaptador de enjuague del compartimento del climatizador al equipo de aire acondicionado.

NotaConecte el tubo de presión rojo al lado izquierdo del adaptador y enrosque el tubo azul procedente del kit de enjuague en el lado derecho del adaptador.

-

Conecte las mangueras del equipo del aire acondicionado Snap-on a los adaptadores de enjuague del aire acondicionado y ejecute el procedimiento de enjuague seleccionando .

NotaEl procedimiento de enjuague dura aproximadamente 40 minutos. Se necesita un mínimo de 6 kg de refrigerante en el depósito para ejecutar el procedimiento de enjuague del sistema.

-

Desconecte el adaptador de enjuague al equipo de aire acondicionado.

- Retire el recipiente de drenaje de refrigerante de debajo del vehículo.

-

Retire los tapones de los tubos del aire acondicionado del nuevo supercolector.

-

Coloque los tapones en los orificios de los tubos que van del antiguo supercolector al climatizador.

NotaEvite las fugas de aceite en la medida de lo posible.

-

Coloque los tapones en los orificios de los tubos que van del antiguo supercolector al compresor de aire acondicionado.

NotaEvite las fugas de aceite en la medida de lo posible.

-

Prepare la pieza para enviarla a MRB como encargo especial.

NotaQuite todos los tapones de refrigerante del supercolector y drene todo el refrigerante que pueda al receptor de líquido de perfil bajo. Empaquételo todo con cuidado en la caja como si fuera nuevo. Escriba el número de sesión de Toolbox, el modelo de Tesla y los últimos 6 dígitos del VIN.

- Retire del climatizador el tubo del aire acondicionado que va del supercolector actual al climatizador.

-

Instale arandelas de sellado nuevas en el tubo del aire acondicionado que va del supercolector actual al climatizador en el lado del supercolector.

NotaARANDELA 1111740-00-A, 3/4, ACERO ZN, JUNTA (1 UDS.), ARANDELA 1111738-00-A, 1/2, ACERO ZN, JUNTA (1 UDS.), ARANDELA 1111737-00-A, 3/8, ACERO ZN, JUNTA (3 UDS.).

-

Coloque en el supercolector el conjunto del tubo del aire acondicionado que va del supercolector al climatizador e instale la tuerca apretándola a mano.

Nota1 tuerca, 13 mm, 36 Nm. No los apriete todavía.

-

Retire del compresor del aire acondicionado el soporte del compresor del aire acondicionado.

Nota3 pernos, 10 mm, 9 Nm

-

Quite los tapones de transporte del nuevo compresor del aire acondicionado

-

Prepare la pieza para enviarla a MRB como encargo especial

NotaColoque los tapones de transporte del nuevo compresor de aire acondicionado en el compresor antiguo para evitar fugas de aceite durante el transporte

-

Coloque el soporte del compresor del aire acondicionado en dicho compresor.

Nota3 pernos, 10 mm, 9 Nm

-

Siga el mismo procedimiento que para el enjuague del sistema de aire acondicionado

NotaReste el tiempo empleado en otras operaciones mientras espera a que se drene el sistema de aire acondicionado. El enjuague rápido dura 40 minutos; el enjuague completo, 1 hora y 40 minutos

-

Desconecte la manguera de baja presión que va del equipo de aire acondicionado al conector rápido del filtro

-

Desconecte el adaptador de enjuague del compartimento del climatizador del equipo de aire acondicionado

NotaDesconecte el tubo de presión rojo del lado izquierdo del adaptador y desenrosque el tubo azul procedente del kit de enjuague del lado derecho del adaptador

-

Retire el adaptador del vehículo

Nota1 tuerca, 13 mm, 36 Nm

-

Retire los pernos (2 uds.) que sujetan el tubo que va del supercolector al climatizador y, a continuación, extraiga el tubo de aire acondicionado del vehículo.

Purgue el sistema HVAC y prepare los componentes para el equipo de aire acondicionado Waeco

-

Instale temporalmente el tubo que va del antiguo supercolector al climatizador e instale los pernos (2 uds.) (apriete 28 Nm) para fijarlo al conjunto del climatizador

-

Instale el adaptador de enjuague en el tubo que va del supercolector al climatizador.

Nota1 tuerca, 13 mm, 36 Nm

-

Conecte el kit de enjuague al equipo de aire acondicionado.

NotaConecte el kit de enjuague al equipo de aire acondicionado Waeco. 2 pernos, 8 mm, 1 tuerca Nyloc

-

Revise las marcas del secador del filtro en línea de líquido.

NotaMarque el filtro con un rotulador cada vez que lo enjuague y sustitúyalo tras 10 enjuagues.NotaSi todavía no es necesario sustituir el filtro, vaya al paso 7.

-

Retire el secador del filtro en línea de líquido

NotaRetire el filtro del contenedor (el filtro gris conectado a la unidad de enjuague) PR052FM. La junta tórica de cobre puede reutilizarse. Aplique solo la fuerza manual, sin usar herramientas

-

Sustituya el secador del filtro en línea de líquido (el filtro gris conectado a la unidad de enjuague) PR052FM

Nota1 filtro nuevo, 2 juntas de sellado de cobre nuevas. Lleve los EPI adecuados. Quite la boquilla del filtro antiguo y colóquela en el nuevo. Instale las juntas de sellado de cobre entre las conexiones. No las apriete en exceso; apriételas solo a mano, ya que el tubo es de cobre. Antes de instalar el filtro nuevo, asegúrese de que se ha retirado la junta antigua. Utilice una ganzúa si es necesario para extraer la junta de cobre

-

Conecte la manguera de baja presión del equipo de aire acondicionado al conector rápido del filtro

-

Conecte el adaptador de enjuague del compartimento del climatizador al equipo de aire acondicionado

NotaConecte el tubo de presión rojo al lado izquierdo del adaptador y enrosque el tubo azul procedente del kit de enjuague en el lado derecho del adaptador

-

Conecte las mangueras del equipo de acondicionado a los adaptadores de enjuague de aire acondicionado y enjuague del compartimento del climatizador.

NotaSi hay alguna de las alertas mencionadas en el paso 8 de la sección "Retirar", elija Full flushing (Enjuague completo). Si no hay alertas, elija Fast flushing (Enjuague rápido).NotaEl procedimiento de enjuague rápido del sistema dura aproximadamente 40 minutos. Si se produce alguna de las alertas ilustradas, ejecute el enjuague completo. Esto tarda aproximadamente 1 hora y 40 minutos. Debe utilizar el equipo de servicio del aire acondicionado WAECO ASC 5500G RPA R1234YF. Se necesita un mínimo de 6 kg de refrigerante en el depósito para ejecutar el procedimiento de enjuague del sistema. Pulse Enter => Other Selections => Enter => Flushing => Enter => Enter => Enter =>=> Full Flushing => Enter

- Retire el recipiente de drenaje de refrigerante de debajo del vehículo.

-

Retire los tapones de los tubos del aire acondicionado del nuevo supercolector

-

Coloque los tapones en los orificios de los tubos que van del antiguo supercolector al climatizador

NotaEvite las fugas de aceite en la medida de lo posible

-

Coloque los tapones en los orificios de los tubos que van del antiguo supercolector al compresor de aire acondicionado

NotaEvite las fugas de aceite en la medida de lo posible

-

Prepare la pieza para enviarla a MRB como encargo especial

NotaQuite del supercolector todos los tapones del procedimiento de "Solo refrigerante" y drene tanto refrigerante como sea posible en el receptor de fluidos de perfil bajo. Devuelva el componente con cuidado a la caja colocándolo en su disposición original. Escriba el número de sesión de Toolbox, el modelo Tesla y los últimos 6 dígitos del VIN

-

Instale el conjunto del tubo que va del supercolector al climatizador en el supercolector, coloque la tuerca y apriétela a mano

Nota1 tuerca, 13mm, 36 Nm. El apriete con llave se realiza en un paso posterior

-

Retire del compresor del aire acondicionado el soporte del compresor del aire acondicionado.

Nota3 pernos, 10 mm, 9 Nm

-

Quite los tapones de transporte del nuevo compresor del aire acondicionado

-

Prepare la pieza para enviarla a MRB como encargo especial

NotaColoque los tapones de transporte del nuevo compresor de aire acondicionado en el compresor antiguo para evitar fugas de aceite durante el transporte

-

Coloque el soporte del compresor del aire acondicionado en dicho compresor.

Nota3 pernos, 10 mm, 9 Nm

-

Siga el mismo procedimiento que para el enjuague del sistema de aire acondicionado

NotaReste el tiempo empleado en otras operaciones mientras espera a que se drene el sistema de aire acondicionado. El enjuague rápido dura 40 minutos; el enjuague completo, 1 hora y 40 minutos

-

Desconecte la manguera de baja presión que va del equipo de aire acondicionado al conector rápido del filtro

-

Desconecte el adaptador de enjuague del compartimento del climatizador del equipo de aire acondicionado

NotaDesconecte el tubo de presión rojo del lado izquierdo del adaptador y desenrosque el tubo azul procedente del kit de enjuague del lado derecho del adaptador

-

Retire el adaptador del vehículo

Nota1 tuerca, 13 mm, 36 Nm

Instalar

-

Coloque la cubierta acústica NVH en el nuevo compresor.

NotaInstale una cubierta nueva o reutilice la antigua si el adhesivo está en buen estado y no dispone de una cubierta nueva.NotaRetire la protección del adhesivo y coloque la cubierta hacia abajo con la cara adhesiva hacia arriba. Alinee los recortes con el puerto de aspiración del compresor, instale la cubierta alrededor del puerto de aspiración y, a continuación, continúe enrollando la cubierta alrededor del compresor.

-

Coloque el soporte del compresor del aire acondicionado en el compresor del aire acondicionado y coloque los pernos que sujetan el soporte al compresor.

9 Nm (6.6 lbs-ft)NotaSe recomienda utilizar las siguientes herramientas:

9 Nm (6.6 lbs-ft)NotaSe recomienda utilizar las siguientes herramientas:- Vaso de 10 mm de cuello largo

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

-

Coloque el compresor de aire acondicionado y el conjunto de soporte del compresor de aire acondicionado en el soporte de la torre del amortiguador y apriete a mano los pernos (2 uds.) para fijarlos.

-

Retire los pernos (2 uds.) que sujetan el tubo que va del supercolector al climatizador y, a continuación, extraiga el tubo de aire acondicionado del vehículo.

-

Sustituya las arandelas de sellado del tubo del aire acondicionado que va del supercolector actual al climatizador en el lado del supercolector.

NotaARANDELA 1111740-00-A, 3/4, ACERO ZN, JUNTA (1 UDS.), ARANDELA 1111738-00-A, 1/2, ACERO ZN, JUNTA (1 UDS.), ARANDELA 1111737-00-A, 3/8, ACERO ZN, JUNTA (3 UDS.).NotaLubrique las arandelas de sellado con aceite ND-11.

- Retire los tapones de los tubos del aire acondicionado del nuevo supercolector.

-

Sustituya las arandelas de sellado del conjunto del tubo de aire acondicionado que va del supercolector al climatizador en el lado del climatizador.

NotaARANDELA 1111740-00-A, 3/4, ACERO ZN, JUNTA (1 UDS.), ARANDELA 1111738-00-A, 1/2, ACERO ZN, JUNTA (1 UDS.), ARANDELA 1111737-00-A, 3/8, ACERO ZN, JUNTA (3 UDS.).NotaLubrique las arandelas de sellado con aceite ND-11.

-

Apriete a mano la tuerca que fija en el supercolector el tubo de aire acondicionado que va del supercolector al climatizador.

-

Apriete la tuerca que fija en el supercolector el conjunto del tubo de aire acondicionado que va del supercolector al climatizador.

36 Nm (26.5 lbs-ft)NotaSe recomienda utilizar las siguientes herramientas:

36 Nm (26.5 lbs-ft)NotaSe recomienda utilizar las siguientes herramientas:- Vaso de 13 mm

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

- Extensión de 6 pulg.

-

Coloque el conjunto del supercolector en el soporte de la torre de amortiguadores y apriete a mano los pernos que fijan el conjunto del supercolector al soporte.

-

Apriete los pernos que fijan el conjunto del supercolector al soporte de la torre del amortiguador.

31 Nm (22.9 lbs-ft)NotaSe recomienda utilizar las siguientes herramientas:

31 Nm (22.9 lbs-ft)NotaSe recomienda utilizar las siguientes herramientas:- Vaso de 15 mm

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

- Extensión de 6 pulg.

-

Apriete los pernos (2 uds.) que fijan el compresor al soporte de la torre del amortiguador.

31 Nm (22.9 lbs-ft)NotaSe recomienda utilizar las siguientes herramientas:

31 Nm (22.9 lbs-ft)NotaSe recomienda utilizar las siguientes herramientas:- Vaso de 15 mm de cuello largo

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

-

Con ayuda de otra persona, instale en el vehículo el supercolector y el compresor, junto con el soporte de la torre del amortiguador.

NotaSe necesitan 2 técnicos para este paso. Tenga en cuenta los conectores y los tubos del aire acondicionado. Levante lentamente el soporte.

-

Coloque los pernos izquierdo y derecho que fijan el apoyo de la torre del amortiguador a la carrocería.

55 Nm (40.6 lbs-ft)

55 Nm (40.6 lbs-ft) 55 Nm (40.6 lbs-ft)NotaSe recomienda utilizar las siguientes herramientas:

55 Nm (40.6 lbs-ft)NotaSe recomienda utilizar las siguientes herramientas:- Vaso de 15 mm

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

-

Coloque los pernos exteriores izquierdo y derecho que sujetan el apoyo de la torre del amortiguador a la carrocería.

62 Nm (45.7 lbs-ft)NotaSe recomienda utilizar las siguientes herramientas:

62 Nm (45.7 lbs-ft)NotaSe recomienda utilizar las siguientes herramientas:- Vaso de 15 mm

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

-

Coloque los pernos (2 uds.) que fijan al conjunto del climatizador el tubo del aire acondicionado que va del supercolector al climatizador.

28 Nm (20.6 lbs-ft)TIpSe recomienda utilizar las siguientes herramientas:

28 Nm (20.6 lbs-ft)TIpSe recomienda utilizar las siguientes herramientas:- Vaso de 13 mm

-

Instale la manguera de entrada del radiador en el supercolector.

NotaRealice una prueba de empuje y tracción para asegurarse de que la manguera está totalmente asentada.

-

Instale la manguera de salida del radiador en el supercolector.

NotaRealice una prueba de empuje y tracción para asegurarse de que la manguera está totalmente asentada.

-

Instale la manguera de derivación del tren de transmisión en el supercolector.

NotaRealice una prueba de empuje y tracción para asegurarse de que la manguera está totalmente asentada.

-

Conecte la manguera de retorno de la batería de alta tensión al supercolector.

NotaRealice una prueba de empuje y tracción para asegurarse de que la manguera está totalmente asentada.

-

Conecte la manguera de alimentación del tren de transmisión al supercolector.

NotaRealice una prueba de empuje y tracción para asegurarse de que la manguera está totalmente asentada.

-

Conecte al supercolector la manguera que va del enfriador a la batería.

NotaRealice una prueba de empuje y tracción para asegurarse de que la manguera está totalmente asentada.

-

Conecte el sensor de la manguera de suministro del tren de transmisión.

NotaEl mazo de cables y la manguera de refrigerante están codificados por colores. Haga coincidir el color del mazo de cables con el color de la manguera de refrigerante.

-

Conecte el sensor del enfriador a la manguera de la batería.

NotaEl mazo de cables y la manguera de refrigerante están codificados por colores. Haga coincidir el color del mazo de cables con el color de la manguera de refrigerante.

- Coloque el clip que fija el mazo de cables del subconjunto del sistema térmico al controlador delantero.

-

Enchufe el conector del mazo de cables secundario del sistema térmico al controlador delantero.

-

Coloque el soporte del mazo de cables de alta tensión del compresor del aire acondicionado en el compresor del aire acondicionado.

NotaAsegúrese de que el soporte del mazo de cables de alta tensión se acopla al soporte del mazo de cables en la parte superior del compresor del aire acondicionado.

-

Coloque el perno que fija el soporte del mazo de cables de alta tensión al compresor del aire acondicionado.

9 Nm (6.6 lbs-ft)TIpSe recomienda utilizar las siguientes herramientas:

9 Nm (6.6 lbs-ft)TIpSe recomienda utilizar las siguientes herramientas:- Vaso de 13 mm de cuello largo

- Llave de carraca/dinamométrica

TIp -

Enchufe el conector eléctrico del HVIL.

-

Fije completamente el conector de alta tensión al compresor del aire acondicionado y, a continuación, acople la pestaña de bloqueo empujándola hacia el compresor del aire acondicionado.

NotaHaga una prueba de empuje y tracción para comprobar que el conector está correctamente conectado.

-

Instale los clips de sujeción que fijan el mazo de cables de alta tensión del compresor de aire acondicionado al soporte de la torre del amortiguador.

-

Instale el clip que sujeta la manguera de refrigerante al soporte del compresor del aire acondicionado, cerca del punto de conexión de la toma de tierra.

-

Coloque la toma de tierra en el compresor de aire acondicionado y, a continuación, instale el perno que fija la toma de tierra al compresor.

7 Nm (5.2 lbs-ft)NotaEste perno es autorroscante. No es necesario perforar el orificio del perno del compresor.TIpSe recomienda utilizar las siguientes herramientas:

7 Nm (5.2 lbs-ft)NotaEste perno es autorroscante. No es necesario perforar el orificio del perno del compresor.TIpSe recomienda utilizar las siguientes herramientas:- Vaso Torx T25

- Destornillador de impacto/carraca sin cable

- Llave de carraca/dinamométrica

-

Coloque el clip que fija el mazo de cables de baja tensión del compresor del aire acondicionado al soporte del mazo de cables de alta tensión del compresor del aire acondicionado.

-

Enchufe el conector eléctrico de baja tensión al compresor del aire acondicionado y, a continuación, acople la pestaña de bloqueo.

PRECAUCIÓNPresione la pestaña de bloqueo roja en dirección al conector para acoplar el mecanismo de bloqueo. NO presione ni tire hacia arriba de la pestaña de bloqueo roja.

-

Quite los tapones de transporte del nuevo compresor del aire acondicionado.

-

Lubrique las nuevas juntas tóricas de los racores de las mangueras de alta y baja presión que van del supercolector al compresor de aire acondicionado con aceite adecuado para aire acondicionado. Consulte Líquidos y capacidades para conocer las especificaciones del aceite del aire acondicionado.

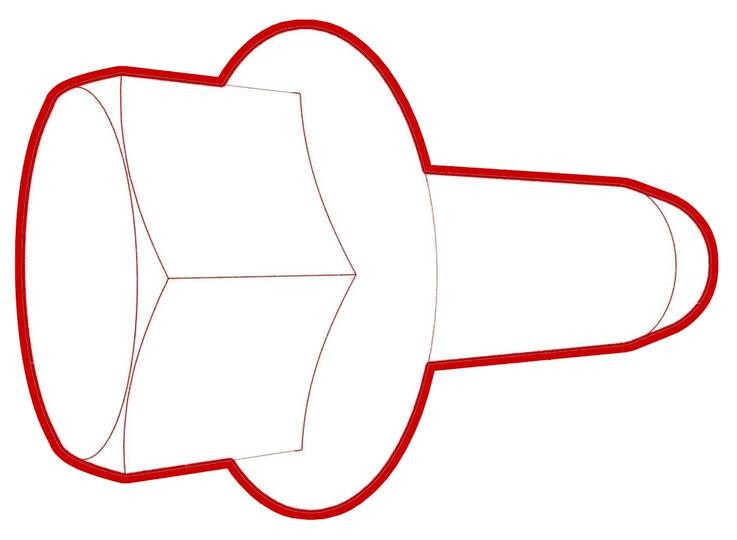

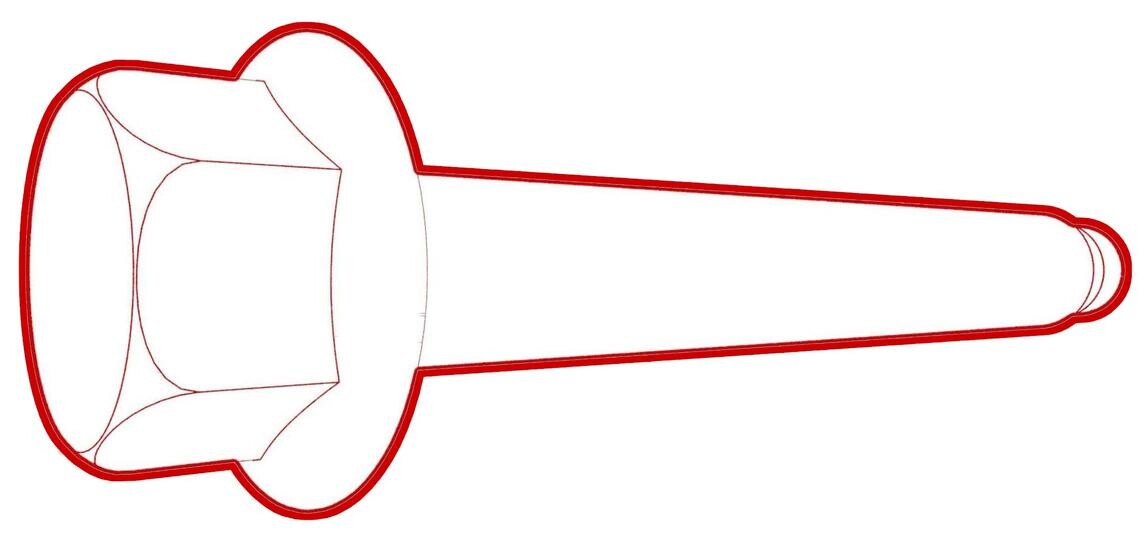

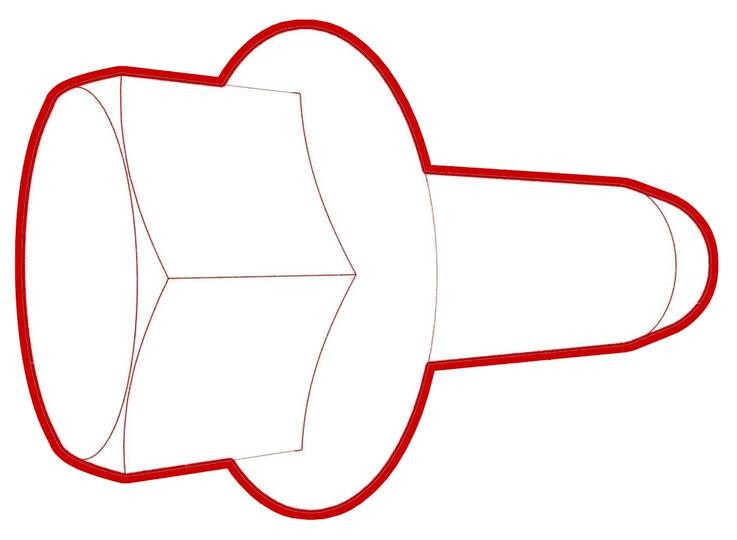

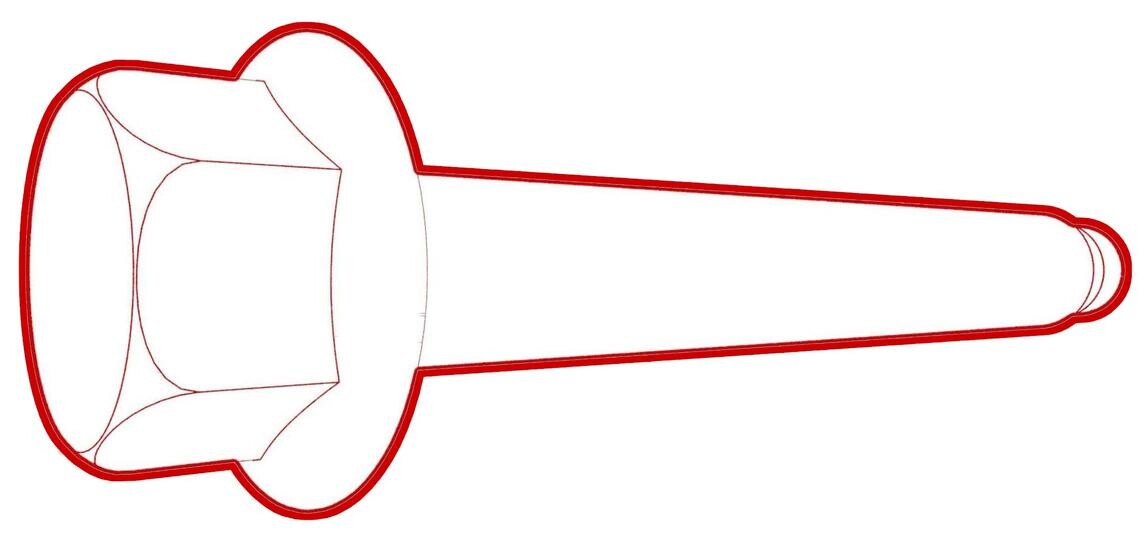

Figura 1. Se muestra el racor de baja presión, pero el racor de alta presión es similar -

Coloque el racor de alta presión que va del supercolector al compresor de aire acondicionado y, a continuación, coloque la tuerca que fija el racor al compresor de aire acondicionado.

22 Nm (16.2 lbs-ft)TIpSe recomienda utilizar las siguientes herramientas:

22 Nm (16.2 lbs-ft)TIpSe recomienda utilizar las siguientes herramientas:- Vaso de 13 mm de cuello largo

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

-

Coloque el racor de baja presión que va del supercolector al compresor de aire acondicionado y, a continuación, coloque la tuerca que fija el racor al compresor de aire acondicionado.

22 Nm (16.2 lbs-ft)TIpSe recomienda utilizar las siguientes herramientas:

22 Nm (16.2 lbs-ft)TIpSe recomienda utilizar las siguientes herramientas:- Vaso de 13 mm de cuello largo

- Llave dinamométrica de carraca de cabezal flexible/cabezal flexible

- Instale los clips (4 uds.) que fijan la manguera de refrigerante al soporte del compresor de aire acondicionado.

-

Instale la correa de sujeción trasera en la batería del soporte de la batería de 12 V.

-

Coloque el clip que fija el tubo de ventilación de la batería de 12 V al soporte de la batería de 12 V.

- Instale la batería auxiliar de 12 V/baja tensión. Consulte Batería de 12 V/baja tensión (Desinstalación y sustitución).

- Conecte el bucle de primera respuesta y la batería de baja tensión.

- En la pantalla táctil, toque y seleccione Ejecutar para iniciar la rutina "Iniciar llenado/drenaje de líquido térmico (refrigeración y refrigerante)".

- Desconecte la alimentación de baja tensión/12 V. Consulte Alimentación de 12 V/baja tensión (Desconexión y conexión).

- Realice la prueba de fugas de vacío del aire acondicionado. Consulte Refrigerante del aire acondicionado (Recuperación y recarga).

- Realice la recarga de refrigerante del aire acondicionado. Consulte Refrigerante del aire acondicionado (Recuperación y recarga).

- Realice un llenado en vacío del sistema de refrigeración. Consulte Sistema de refrigeración (Llenado por vacío).

- Conecte el bucle de primera respuesta y deje la batería de baja tensión desconectada.

- Conecte un dispositivo de mantenimiento de baja tensión. Consulte Dispositivo de mantenimiento de baja tensión (Conexión y desconexión).

-

Actualice la configuración del compresor:

- Reinstale el firmware. Consulte Reinstalación de software - Pantalla táctil.

- En la pantalla táctil, toque la "llave" del modo de servicio (en la parte inferior de la interfaz de usuario) y, a continuación, toque y deje que finalice la rutina.

- Toque para inspeccionar la configuración actual de la bomba de refrigerante. Si la configuración no es DUAL_MIX, cámbiela a DUAL_MIX.

- Toque y cierre cuando la rutina haya finalizado.

- Toque para examinar la configuración actual del supercolector. Si la configuración no es TYPE1, cámbiela a TYPE1.

- Toque y cierre cuando la rutina haya finalizado.

- Toque y cierre cuando la rutina haya finalizado.

- Toque y cierre cuando la rutina haya finalizado.

- Instale el cojín inferior del asiento de la 2.ª fila. Consulte Cojín del asiento - Parte inferior - 2.ª fila (Desinstalación y sustitución).

- Instale el panel del deflector aerodinámico delantero. Consulte Panel - Deflector aerodinámico - Delantero (Sin paquete estructural)(Desinstalación y sustitución).

- Una vez finalizada la purga de aire del refrigerante, inspeccione el nivel de refrigerante y asegúrese de que el nivel de líquido está en la línea Max.

- Toque y cierre cuando la rutina haya finalizado.

- Toque y cierre cuando la rutina haya finalizado.

- En la pantalla táctil, mantenga pulsado el botón Salga del modo de servicio para salir del Modo Servicio Plus.

- Desconecte el dispositivo de mantenimiento de baja tensión. Consulte Dispositivo de mantenimiento de baja tensión (Conexión y desconexión).

- Conecte la alimentación de baja tensión. Consulte Alimentación de 12 V/baja tensión (Desconexión y conexión).

- Instale el conducto HEPA. Consulte Conducto - HEPA (Desinstalación y sustitución).

- Instale el conjunto del filtro HEPA. Consulte Conjunto - Filtro - HEPA (Desinstalación y sustitución).

- Instale la unidad de almacenamiento del vano del motor. Consulte Unidad de almacenamiento del vano del motor (Desinstalación y sustitución).