2023-12-26

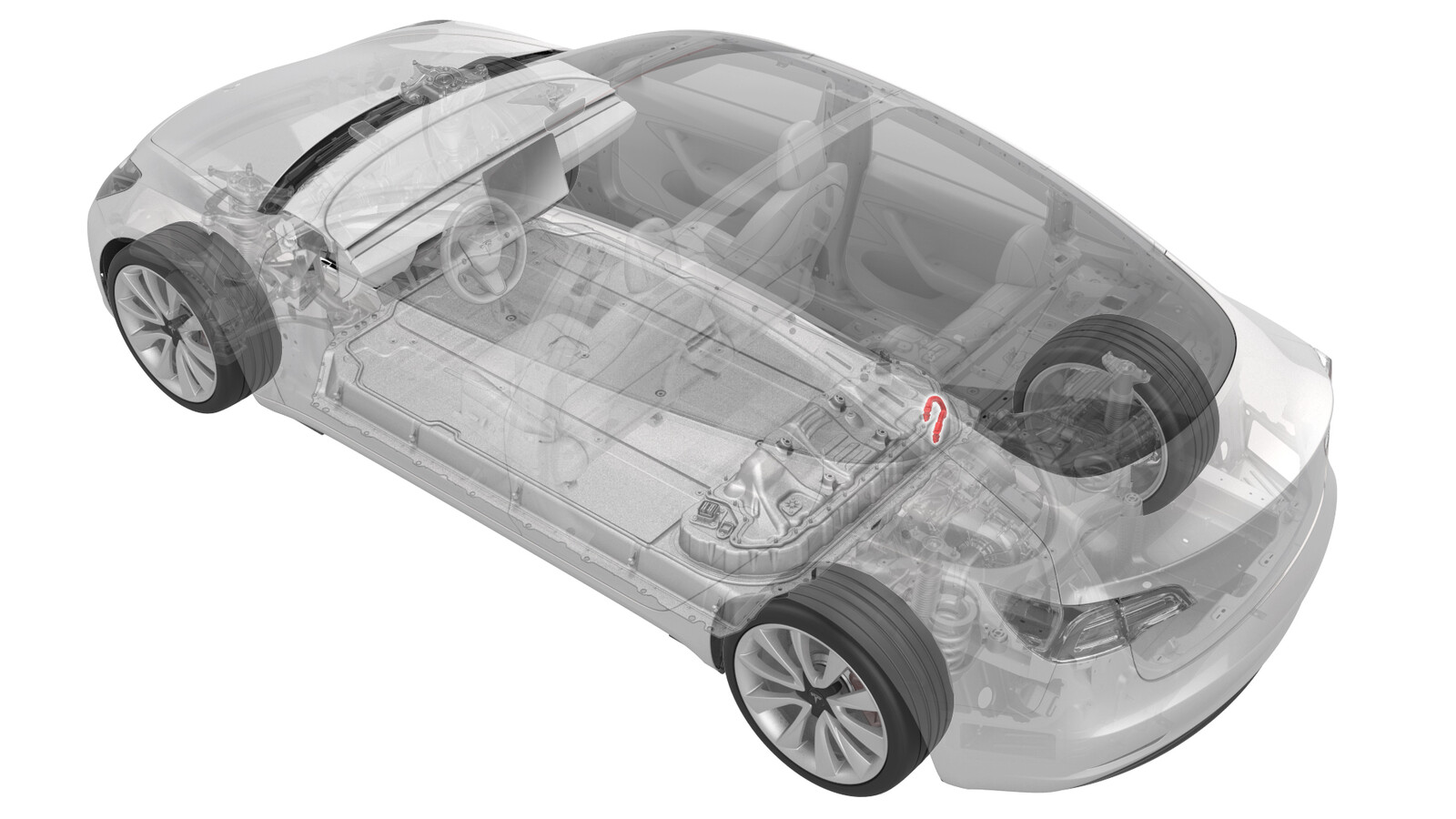

管 - 入口 - 冷却液 - 功率转换系统(拆卸和更换)

校正代码

16202002 2.94

注意:除非本程序中另有明确规定,否则上述校正代码和 FRT 反映的是执行本程序(包括关联程序)所需的所有工作。除非明确要求,否则请勿堆叠校正代码。

注意:请参阅平均维修工时,深入了解 FRT 及其创建方式。要提供有关 FRT 值的反馈,请发送电子邮件至 ServiceManualFeedback@tesla.com。。

注意:请参阅人员保护,确保在执行以下程序时穿戴适当的个人防护装备 (PPE)。请参阅人体工程学注意事项查看安全健康的作业规程。

校正代码

16202002 2.94

注意:除非本程序中另有明确规定,否则上述校正代码和 FRT 反映的是执行本程序(包括关联程序)所需的所有工作。除非明确要求,否则请勿堆叠校正代码。

注意:请参阅平均维修工时,深入了解 FRT 及其创建方式。要提供有关 FRT 值的反馈,请发送电子邮件至 ServiceManualFeedback@tesla.com。。

注意:请参阅人员保护,确保在执行以下程序时穿戴适当的个人防护装备 (PPE)。请参阅人体工程学注意事项查看安全健康的作业规程。

设备:

- 1111868-00-B Connector Removal, Coolant, PCS, M3

- 1135762-00-A 冷却软管维修堵头套件,Model 3

警告

只有完成全部所需认证的技术人员才能执行此程序。Tesla 特斯拉建议第三方服务提供商技术人员在执行此程序之前接受同等培训。有关 Tesla 技术人员要求的更多信息,或第三方主题说明,请参阅高压认证要求。处理高压线缆、母排或接头时,务必全程穿戴最低防护等级为 0(1000V) 的适当个人防护装备 (PPE)及高压绝缘手套。有关其他安全信息,请参阅技术注意事项 TN-15-92-003,高压安全意识注意事项

。

拆卸

- 排放功率转换系统中的冷却液。请参阅高压电池仓冷却液(排放和重新加注)。

- 拆下烟火电池隔离开关。请参阅烟火电池断接开关(拆卸和更换)。

- 拆卸高压控制器。请参阅控制器 - 高压(拆卸和更换)。

- 松开将线束固定到铰链托盘和铰链的夹子。

- 抬高铰链托盘,从铰链上拆下铰链托盘。

- 切割两块吸收垫至一半以形成狭缝,接着使用垫片围绕每一处冷却液输入管道接头。

-

使用冷却液连接器拆卸工具,阔开管道接头夹,使其宽于功率转换系统上的钩锁。

注本视频演示如何从功率转换系统上断开冷却液软管并插上接头。

图 1. 冷却液连接器拆卸工具示例 - 向上拉动工具和管道接头,使接头从功率转换系统上断开。

-

重复执行第7和第8步,处理电池法兰处的其他管道接头。

注请参阅上一步中的视频。

-

将管道从车辆上拆下。

- 将插头安装到功率转换系统和电池法兰中。

-

擦除迸溅的冷却液。

警告迸溅出的冷却液可能形成电路。

安装

-

擦除迸溅的冷却液。

警告迸溅出的冷却液可能形成电路。

-

在将管道插入功率转换系统前,应确保 O 型环未损坏,且稳妥固定在连接器卡槽中。按需更换组件。

O 型环状况良好

O 型环情况不佳

- 使用 Krytox 203 润滑剂对冷却液输入管道 O 型环进行润滑。

- 从功率转换系统和电池法兰上拆下堵头。

-

将冷却液输入管道安装到功率转换系统和电池法兰上。

-

稳妥下压管道接头,确保接头牢固连接。

警告验证两处夹子已将功率转换系统上的钩锁和电池法兰完全锁紧,然后向上拉动接头以检查牢固性。

图 2. 稳妥连接示例 -

从冷却液输入管道接头周围取走吸水垫,然后擦除迸溅的冷却液。

警告迸溅出的冷却液可能形成电路。

- 执行高压电池仓冷却液泄漏测试。请参阅高压电池仓冷却液泄漏测试。

-

仅连接 12V 辅助电池负极端子。

6 Nm (4.4 lbs-ft)警告此时切勿按照程序连接 12V 电源。

6 Nm (4.4 lbs-ft)警告此时切勿按照程序连接 12V 电源。 - 将 12V 充电器连接到 12V 辅助电池端子上。

- 重新加注冷却液。请参阅高压电池仓冷却液(排放和重新加注)。

- 在触摸屏上,点击。

- 断开 12V 充电器与 12V 辅助电池端子的连接。

- 断开 12V 辅助电池负极端子。

- 将铰链托盘安装到铰链上,然后降下铰链托盘。

- 紧固将线束固定到铰链托盘和铰链的夹子。

- 安装高压控制器。请参阅控制器 - 高压(拆卸和更换)。

- 测量烟火电池隔离开关安装点间的电压,然后安装烟火电池隔离开关。请参阅烟火电池断接开关(拆卸和更换)。