2025-09-11

软管总成,出口,PCS ((拆卸和更换))

校正代码

1630010142

FRT

2.04

注意:除非本程序中另有明确规定,否则上述校正代码和 FRT 反映的是执行本程序(包括关联程序)所需的所有工作。除非明确要求,否则请勿堆叠校正代码。

注意:请参阅平均维修工时,深入了解 FRT 及其创建方式。要提供有关 FRT 值的反馈,请发送电子邮件至ServiceManualFeedback@tesla.com。

注意:请参阅 人员保护,确保在执行以下程序时穿戴适当的个人防护装备 (PPE)。

注意:请参阅人体工程学注意事项查看安全健康的作业规程。

校正代码

1630010142

FRT

2.04

注意:除非本程序中另有明确规定,否则上述校正代码和 FRT 反映的是执行本程序(包括关联程序)所需的所有工作。除非明确要求,否则请勿堆叠校正代码。

注意:请参阅平均维修工时,深入了解 FRT 及其创建方式。要提供有关 FRT 值的反馈,请发送电子邮件至ServiceManualFeedback@tesla.com。

注意:请参阅 人员保护,确保在执行以下程序时穿戴适当的个人防护装备 (PPE)。

注意:请参阅人体工程学注意事项查看安全健康的作业规程。

| 描述 | 扭矩值 | 推荐工具 | 重复使用/更换 | 备注 |

|---|---|---|---|---|

| 用于固定母排罩检修盖板的螺栓 |

9 Nm (6.6 lbs-ft) |

|

重复使用 | |

| 将充电接口母排套件固定到高压接头的螺栓(2 个) |

9 Nm (6.6 lbs-ft) |

|

重复使用 | |

| 将快充母排直流链路侧负极固定到快充触点开关的螺纹胶螺栓 |

15 Nm (11.1 lbs-ft) - 180 degrees  5 Nm (3.7 lbs-ft) + 60 degrees |

|

更换 | |

| 将快充母排直流链路侧正极固定到快充触点开关的螺纹胶螺栓 |

15 Nm (11.1 lbs-ft) - 180 degrees  5 Nm (3.7 lbs-ft) + 60 degrees |

|

更换 | |

| 将快充母排输入侧负极固定到直流输入总成母排负极的螺纹胶螺栓 |

15 Nm (11.1 lbs-ft) - 180 degrees  5 Nm (3.7 lbs-ft) + 60 degrees |

|

更换 | |

| 将快充母排输入侧正极固定到直流输入总成母排正极的螺纹胶螺栓 |

15 Nm (11.1 lbs-ft) - 180 degrees  5 Nm (3.7 lbs-ft) + 60 degrees |

|

更换 | |

| 将直流输入母排总成固定到高压电池仓的螺栓(4 个) |

10 Nm (7.4 lbs-ft) |

|

更换 | |

| 将快充总成固定到高压电池仓的螺栓(2 个) |

5.5 Nm (4.1 lbs-ft) |

|

重复使用 | |

| 将快充母排直流链路侧负极固定到快充触点开关的螺纹胶螺栓 |

15 Nm (11.1 lbs-ft) - 180 degrees  5 Nm (3.7 lbs-ft) + 60 degrees |

|

更换 |

拆卸

- 打开所有车门,降下所有车窗。

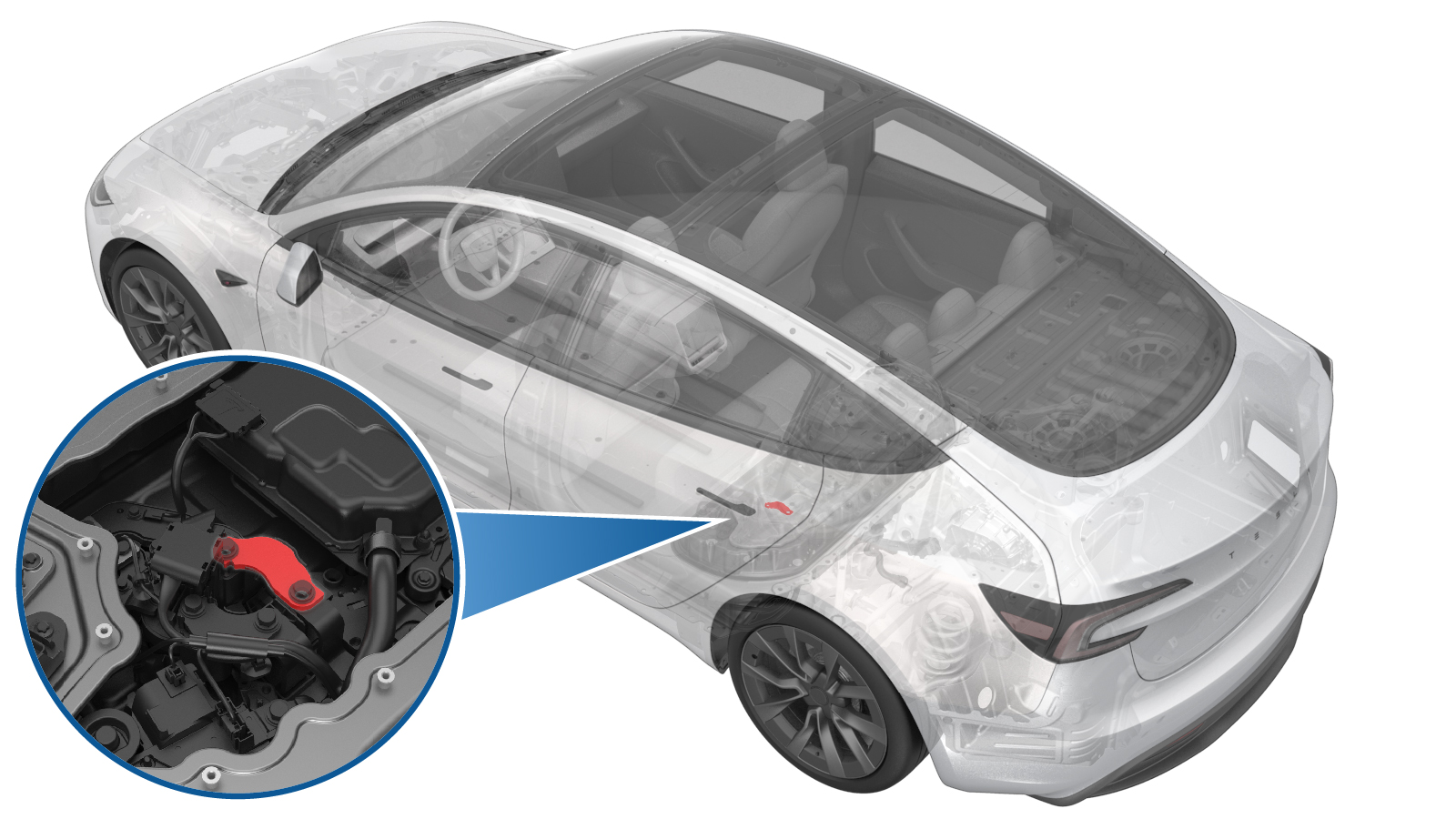

- 断开低压电源。请参阅 低压电池 - 锂离子(断开和连接)。

- 拆卸第二排左侧座垫支架。请参阅 第二排座椅坐垫支架 ((拆卸和更换))。

- 执行车辆高压禁用程序。请参阅 车辆电气绝缘程序 (Test/Adjust)。

-

拆卸用于固定母排罩检修盖板的螺栓。

TIp推荐使用以下工具

- 绝缘工具:

- 棘轮/扭矩扳手 - 1057602-00-A

- 10 毫米 12 角深套筒 - 1133768-00-C

- 1/4 英寸钻头加长件,摆角 10.5"

- 电工保护手套

- 棘轮/扭矩扳手

- 绝缘工具:

-

拆下将充电接口母排套件固定到高压接头的螺栓(2 个)。

TIp推荐使用以下工具

- 绝缘工具:

- 1/4 英寸钻头加长件,摆角 10.5"

- 棘轮/扭矩扳手 - 1057602-00-A

- 10 毫米 12 角深套筒 - 1133768-00-C

- 电工保护手套

- 棘轮/扭矩扳手

- 绝缘工具:

-

松开交流充电接口输入线束夹。

-

抬起母排套件连接器,将母排总成后端向上移动,将铝制连接器罩从高压接头上拆下。

-

将充电接口母排连接器放置在高压电池仓前方横梁上,以便操作。

- 拆下高压电池仓盖板。请参阅 高压电池仓盖总成 ((拆卸和更换))。

- 拆下烟火电池断接开关。请参阅 电池烟火断开装置 ((拆卸和更换))。

- 拆卸高压电池负极触点开关。请参阅 母排 - 快充接触器到直流母排 - 负极 ((拆卸和更换))。

-

用手按压两侧锁片,向上提起连接器,以断开低压快充触点开关连接器。

-

断开功率转换系统至交流线束连接器。

注向上拉动红色锁片以松开。如有必要,可使用塑料饰板工具辅助向上提起连接器。

-

松开锁片,然后将交流滤波器线束从快充触点开关盖板上断开。

-

松开快充触点开关盖板上的线束夹(2 个),然后将快充触点开关盖板附近的接线线束置于一旁。

-

拆下高压电池仓左侧端子盖。

-

拆下并弃置用于固定直流链路侧负极快充母排的螺纹胶螺栓。

TIp推荐使用以下工具

- 绝缘工具:

- 4 英寸加长件

- 棘轮/扭矩扳手

- 13 毫米套筒

- 油性记号笔

- 带角度测量的扭矩扳手

- 绝缘工具:

-

拆下并弃置用于固定直流链路侧正极快充母排的螺纹胶螺栓。

TIp推荐使用以下工具

- 绝缘工具:

- 4 英寸加长件

- 棘轮/扭矩扳手

- 13 毫米套筒

- 油性记号笔

- 带角度测量的扭矩扳手

- 绝缘工具:

-

将超级线束连接器从直流输入总成上断开。

-

拆下直流输入总成至两个输入侧快充母排的绝缘体。

-

拆下并弃置用于固定输入侧负极快充母排和负极直流输入母排总成的螺纹胶螺栓。

TIp推荐使用以下工具

- 绝缘工具:

- 4 英寸加长件

- 棘轮/扭矩扳手

- 13 毫米套筒

- 电工保护手套

- 油性记号笔

- 带角度测量的扭矩扳手

- 绝缘工具:

-

拆下并弃置用于固定输入侧正极快充母排和正极直流输入母排总成的螺纹胶螺栓。

TIp推荐使用以下工具

- 绝缘工具:

- 4 英寸加长件

- 棘轮/扭矩扳手

- 13 毫米套筒 - 1057606-00-A

- 电工保护手套

- 油性记号笔

- 棘轮/扭矩扳手

- 带角度测量的扭矩扳手

- 绝缘工具:

-

拆下并弃用将直流输入母排总成固定到高压电池仓的螺栓(4 个),然后将直流输入母排总成从高压电池仓上拆下。

TIp推荐使用以下工具

- 绝缘工具:

- 4 英寸加长件

- 棘轮/扭矩扳手

- 电工保护手套

- 棘轮/扭矩扳手

- 外梅花五角套筒 E10 - 1059330-00-B

- 油性记号笔

- 1/4 英寸至 3/8 英寸适配器

- 绝缘工具:

-

拆下将快充总成固定到高压电池仓的螺栓(2 个)。

TIp推荐使用以下工具

- 绝缘工具:

- 4 英寸加长件

- 棘轮/扭矩扳手

- 10 毫米套筒

- 电工保护手套

- 油性记号笔

- 绝缘工具:

-

将快充总成从高压电池仓上拆下。

-

将快充绝缘体盖从快充总成上拆下并弃置。

注向上拉动绝缘体盖,使其从卡子(8 个)和定位销上松开。

-

拆下并弃用将直流链路侧负极快充母排固定到快充触点开关的螺纹胶螺栓,然后将直流链路侧负极快充母排从快充触点开关上拆下。

TIp推荐使用以下工具

- 绝缘工具:

- 4 英寸加长件

- 棘轮/扭矩扳手

- 13 毫米套筒

- 油性记号笔

- 带角度测量的扭矩扳手

- 绝缘工具:

安装

-

安装新的螺纹胶螺栓,将直流链路侧负极快充母排固定到快充触点开关上。

15 Nm (11.1 lbs-ft) - 180 degrees

15 Nm (11.1 lbs-ft) - 180 degrees 5 Nm (3.7 lbs-ft) + 60 degrees注先将螺栓紧固至 15 Nm,然后回退 180 度,最后再紧固至 5 Nm + 60 度。紧固后进行标记。TIp推荐使用以下工具

5 Nm (3.7 lbs-ft) + 60 degrees注先将螺栓紧固至 15 Nm,然后回退 180 度,最后再紧固至 5 Nm + 60 度。紧固后进行标记。TIp推荐使用以下工具- 绝缘工具:

- 4 英寸加长件

- 棘轮/扭矩扳手

- 13 毫米套筒

- 油性记号笔

- 带角度测量的扭矩扳手

- 绝缘工具:

-

将新的快充绝缘体盖安装到快充总成上。

-

将快充总成放置在高压电池仓上,以备安装。

-

安装将快充总成固定到高压电池仓的螺栓(2 个)。

5.5 Nm (4.1 lbs-ft)TIp推荐使用以下工具

5.5 Nm (4.1 lbs-ft)TIp推荐使用以下工具- 绝缘工具:

- 4 英寸加长件

- 棘轮/扭矩扳手

- 10 毫米套筒

- 电工保护手套

- 油性记号笔

- 绝缘工具:

-

将直流输入母排总成安装到高压电池仓上。

注确保密封件未损坏且已正确就位。

-

安装新的螺栓(4 个),将直流输入母排总成固定到高压电池仓上。

10 Nm (7.4 lbs-ft)注紧固后进行标记。TIp推荐使用以下工具

10 Nm (7.4 lbs-ft)注紧固后进行标记。TIp推荐使用以下工具- 绝缘工具:

- 4 英寸加长件

- 棘轮/扭矩扳手

- 电工保护手套

- 棘轮/扭矩扳手

- 外梅花五角套筒 E10 - 1059330-00-B

- 油性记号笔

- 1/4 英寸至 3/8 英寸适配器

- 绝缘工具:

-

安装新的螺纹胶螺栓,将输入侧负极快充母排和负极直流输入母排总成固定好。

15 Nm (11.1 lbs-ft) - 180 degrees

15 Nm (11.1 lbs-ft) - 180 degrees 5 Nm (3.7 lbs-ft) + 60 degrees注先将螺栓紧固至 15 Nm,然后回退 180 度,最后再紧固至 5 Nm + 60 度。紧固后进行标记。TIp推荐使用以下工具

5 Nm (3.7 lbs-ft) + 60 degrees注先将螺栓紧固至 15 Nm,然后回退 180 度,最后再紧固至 5 Nm + 60 度。紧固后进行标记。TIp推荐使用以下工具- 绝缘工具:

- 4 英寸加长件

- 棘轮/扭矩扳手

- 13 毫米套筒

- 电工保护手套

- 油性记号笔

- 带角度测量的扭矩扳手

- 绝缘工具:

-

安装新的螺纹胶螺栓,将输入侧正极快充母排和正极直流输入母排总成固定好。

15 Nm (11.1 lbs-ft) - 180 degrees

15 Nm (11.1 lbs-ft) - 180 degrees 5 Nm (3.7 lbs-ft) + 60 degrees注先将螺栓紧固至 15 Nm,然后回退 180 度,最后再紧固至 5 Nm + 60 度。紧固后进行标记。TIp推荐使用以下工具

5 Nm (3.7 lbs-ft) + 60 degrees注先将螺栓紧固至 15 Nm,然后回退 180 度,最后再紧固至 5 Nm + 60 度。紧固后进行标记。TIp推荐使用以下工具- 绝缘工具:

- 4 英寸加长件

- 棘轮/扭矩扳手

- 13 毫米套筒 - 1057606-00-A

- 电工保护手套

- 油性记号笔

- 棘轮/扭矩扳手

- 带角度测量的扭矩扳手

- 绝缘工具:

-

在直流输入母排总成的两个高压接头处执行 Hioki 电阻测试。

注电阻值应为 60 微欧或更低。分别测试快充母排负极至直流输入母排负极以及快充母排正极至直流输入母排正极的电阻。

-

安装直流输入总成至两个输入侧快充母排的绝缘体。

-

将超级线束连接器连接到直流输入总成。

-

安装新的螺纹胶螺栓,以紧固直流链路正极快充母排。

15 Nm (11.1 lbs-ft) - 180 degrees

15 Nm (11.1 lbs-ft) - 180 degrees 5 Nm (3.7 lbs-ft) + 60 degrees注先将螺栓紧固至 15 Nm,然后回退 180 度,最后再紧固至 5 Nm + 60 度。紧固后进行标记。注推荐使用以下工具

5 Nm (3.7 lbs-ft) + 60 degrees注先将螺栓紧固至 15 Nm,然后回退 180 度,最后再紧固至 5 Nm + 60 度。紧固后进行标记。注推荐使用以下工具- 绝缘工具:

- 4 英寸加长件

- 棘轮/扭矩扳手

- 13 毫米套筒

- 油性记号笔

- 带角度测量的扭矩扳手

- 绝缘工具:

-

在直流链路侧快充母排的正极高压接头处执行 Hioki 电阻测试。

注电阻值应为 25 微欧或更低。

-

安装新的螺纹胶螺栓,以紧固直流链路负极快充母排。

15 Nm (11.1 lbs-ft) - 180 degrees

15 Nm (11.1 lbs-ft) - 180 degrees 5 Nm (3.7 lbs-ft) + 60 degrees注先将螺栓紧固至 15 Nm,然后回退 180 度,最后再紧固至 5 Nm + 60 度。紧固后进行标记。注推荐使用以下工具

5 Nm (3.7 lbs-ft) + 60 degrees注先将螺栓紧固至 15 Nm,然后回退 180 度,最后再紧固至 5 Nm + 60 度。紧固后进行标记。注推荐使用以下工具- 绝缘工具:

- 4 英寸加长件

- 棘轮/扭矩扳手

- 13 毫米套筒

- 油性记号笔

- 带角度测量的扭矩扳手

- 绝缘工具:

-

在直流链路侧快充母排的负极高压接头处执行 Hioki 电阻测试。

注电阻值应为 55 微欧或更低。

-

安装高压电池仓左侧端子盖。

-

将线束夹(2 个)安装到快充触点开关盖板上。

-

连接低压快充连接器。

-

紧固锁片,将交流滤波器线束安装到快充触点开关盖板上。

-

连接功率转换系统至交流线束连接器。

注先向下推动连接器,再向下推动锁片以安装连接器。确保连接器完全就位。

- 安装高压电池负极触点开关。请参阅 母排 - 快充接触器到直流母排 - 负极 ((拆卸和更换))。

- 安装烟火电池断接开关。请参阅 电池烟火断开装置 ((拆卸和更换))。

-

将高压电池仓盖板放置到高压电池上,以备安装。

注检查所有绝缘体,确保均已就位。

-

使用异丙醇 (IPA) 湿巾清洁高压连接器接触面和高压连接器母排接触面上残留的 Penetrox。

注等待各表面风干 1 分钟。新母排高压接头上已涂抹 Penetrox。重新使用母排时,必须清洁高压连接器。

- 向两条高压连接器接头引线上孔的任意一侧涂抹 2 滴直径约 5 毫米的 Penetrox A-13,然后均匀铺开,确认接触面被完全覆盖。

-

放置母排套件连接器,然后将其降至高压接头上。

注抬起母排总成后端,以便安装。安装母排时如果需要过度用力,则母排可能已弯曲。检查母排是否损坏,必要时进行更换。

-

安装交流充电接口输入线束夹。

-

安装将充电接口母排套件固定到高压接头的螺栓(2 个)。

9 Nm (6.6 lbs-ft)推荐使用以下工具

9 Nm (6.6 lbs-ft)推荐使用以下工具- 绝缘工具:

- 1/4 英寸钻头加长件,摆角 10.5"

- 棘轮/扭矩扳手 - 1057602-00-A

- 10 毫米 12 角深套筒 - 1133768-00-C

- 电工保护手套

- 棘轮/扭矩扳手

- 绝缘工具:

-

在高压母排引线至螺栓头的每个高压接头处进行 Hioki 电阻测试。

注可接受的电阻为 0.050 毫欧(50 微欧)至 0.195 毫欧(195 微欧)。

- 如果电阻值高于 0.195 毫欧(195 微欧),说明高压接头电阻过大。拆下紧固件,使用异丙醇清洁接触区域,重新安装紧固件,再次测试。

- 如果电阻值低于 0.050 毫欧(50 微欧),请重新放置探针并再次测量。

- 如果电阻值反复在 0.00 毫欧和 0.050 毫欧(50 微欧)之间变化,表明已通过 Hioki 测试,请执行下一步骤。

-

安装用于固定母排罩检修盖板的螺栓。

9 Nm (6.6 lbs-ft)TIp推荐使用以下工具

9 Nm (6.6 lbs-ft)TIp推荐使用以下工具- 绝缘工具:

- 棘轮/扭矩扳手 - 1057602-00-A

- 10 毫米 12 角深套筒 - 1133768-00-C

- 1/4 英寸钻头加长件,摆角 10.5"

- 电工保护手套

- 棘轮/扭矩扳手

- 绝缘工具:

-

安装高压电池仓盖板。请参阅 高压电池仓盖总成 ((拆卸和更换))。

注安装高压电池仓盖板前,检查高压电池仓盖板密封件,确认无可视损坏。如果密封件已破损和/或出现分层现象,请更换高压电池仓盖板。

- 安装第二排左侧座椅座垫支架。请参阅 第二排座椅坐垫支架 ((拆卸和更换))。

- 连接低压电源。请参阅 低压电池 - 锂离子(断开和连接)。

- 升起所有车窗,关闭所有车门。