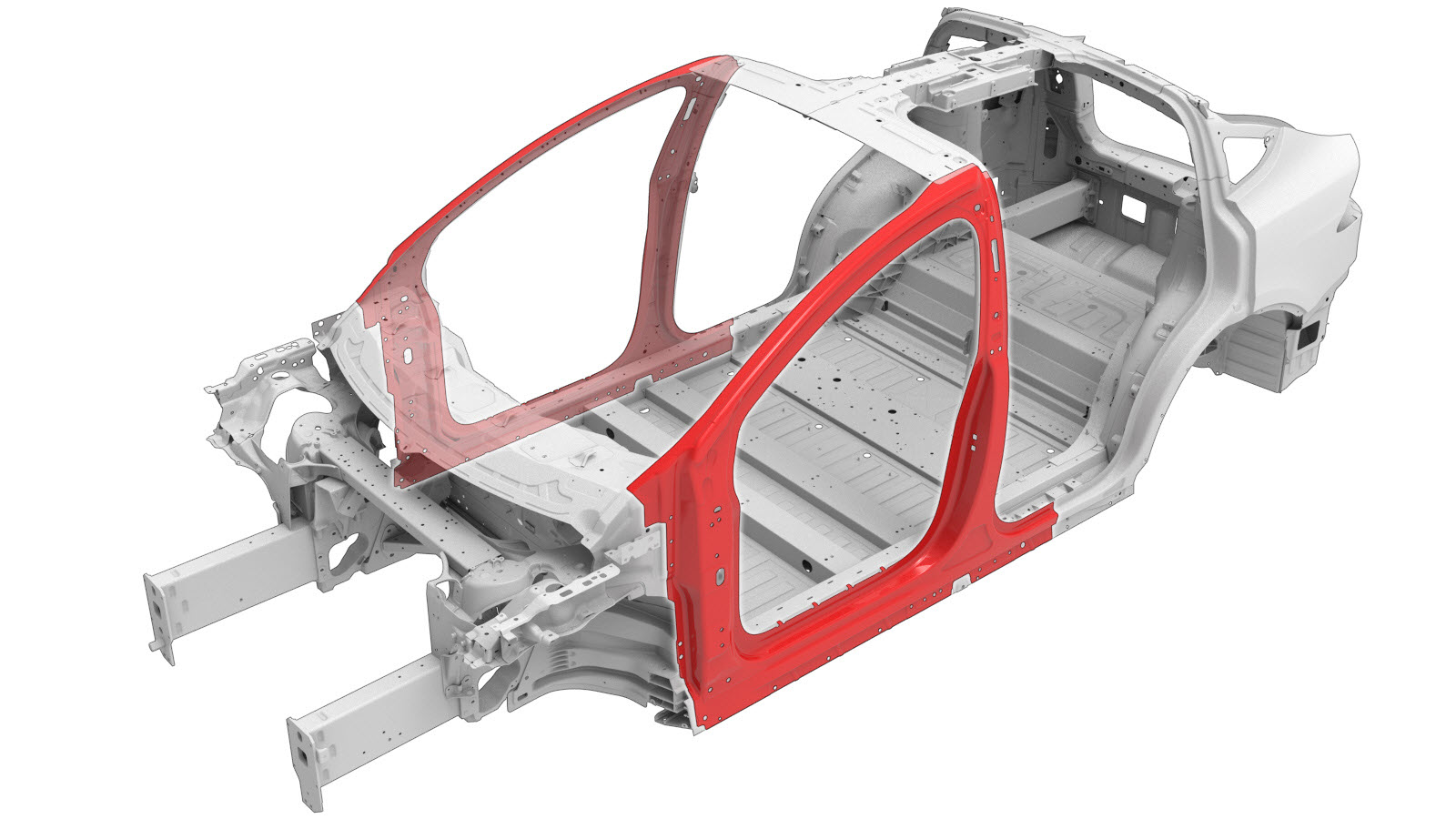

Body Side Outer

Correction code:

10100128702

10100128802

NOTE:

Unless explicitly stated in the procedure, the above

correction code includes all Collision Repair work required

to perform this procedure, including the linked Collision

Repair procedures. Do not stack Collision Repair

correction codes unless explicitly told to do

so. Add any associated mechanical procedures

needed to perform this procedure.

Correction code:

10100128702

10100128802

NOTE:

Unless explicitly stated in the procedure, the above

correction code includes all Collision Repair work required

to perform this procedure, including the linked Collision

Repair procedures. Do not stack Collision Repair

correction codes unless explicitly told to do

so. Add any associated mechanical procedures

needed to perform this procedure.

Repair Information

- Review all collision repair general practices and safety documentation and wear the appropriate PPE (Personal Protective Equipment) before beginning this procedure.

- This procedure can be completed without using a frame bench.

Using this Document

- Body Side Outer Section Descriptions provides information on

where and how to section the Body Side Outer (or subassemblies) as

necessary to replace damaged areas of the Body Side Outer panel, or to

gain access to underlying parts of the vehicle structure. Use the

section descriptions to determine where to successfully section the Body

Side Outer as needed for the repair being performed.NoteSections of the Body Side Outer can be replaced individually or in any combination of sections so long as the referenced cut locations identified in this document are used.NoteMeasurements from bolt hole locations are from the center of the referenced holes unless stated differently in the section description.

- The Repair Procedure portion of this document contains the information necessary to replace the entire Body Side Outer. If replacing sections of the Body Side Outer (not the entire Body Side Outer Assembly), use the relevant portions of each step to determine which parts and fasteners are needed and the steps required to complete the repair.

Parts List

| Quantity | Description | Image / Notes |

|---|---|---|

| 1 | BODY SIDE OUTER COMPLETE (Body Side Outer) | |

| 4 | Countersunk Rivet, 4.8 mm Short | |

| 2 | Countersunk Rivet, 4.8 mm Long | |

| 4 | High Strength Structural Rivet, 6.5 mm | |

| 14 | Flow Form Rivet S18 | |

| 1 | Flow Form Rivet S28 | |

| 65 | Flow Form Rivet S38 | |

| 2 | Flow Form Rivet S48 | |

| 3 | Flow Form Rivet S58 | |

| 3 | Bolt, hex-head , M6x1.00x18 | Tesla part number 1006529-00-A. |

| 7 | Bolt, hex-head , M8-1.25x20 | Tesla part number 1007580-00-A. |

| 2 | Bolt, hex-head , HF M10x80 | Tesla part number 1053943-00-A. |

| 1 | Bolt, Torx-head , M8x20 | Tesla part number 1014747-00-B. |

When ordering parts, refer to the Parts Catalog and enter the VIN of the vehicle being repaired to find the correct parts (and the part numbers) for the vehicle. Alternatively, use the search function in the Parts Catalog to find a specific part for the vehicle.

Body Side Outer Section Descriptions

| Body Side Outer Sectioning | |

|---|---|

| The BODY SIDE OUTER COMPLETE (shown below) is a single assembly, and can be replaced as a single repair: | Alternatively, instead of replacing the whole BODY SIDE OUTER COMPLETE, areas of the Body Side Outer Complete can be replaced using the cut lines described in this document. |

| Body Side Outer Section Descriptions | |

|---|---|

|

A–Pillar Section Cut Line Reference Line/Point

Warning Do not cut bolt holes when cutting

sections. Note The cut can

be made within 350 mm of the specified cut line location to

allow sectioning of the Body Side Outer. Note Install a backing plate behind each butt joint if there is

sufficient space. Note The gap

between the adjacent panels of the butt joint for this

section should be as small as possible to maximize joint

strength.

or Aluminum Plug Welds

Note For these plug welds, drill a 9 mm hole in each of the

indicated locations.

GMA Weld

Warning Do not weld a panel where it directly

contacts underlying structural components (the heat

affect zone from welding can weaken the strength of

underlying structural components). Use structural

adhesive to fill gaps behind panels and underlying

components. |

|

|

B-Pillar Section Cut Line Reference Line/Point

Warning Do not cut bolt holes when cutting

sections. Note The cut can be made within 10 mm of the specified cut line

location to allow sectioning of the Body Side Outer. Note Install a backing plate behind each butt joint

if there is sufficient space. Note The gap

between the adjacent panels of the butt joint for this

section should be as small as possible to maximize joint

strength.

or Aluminum Plug Welds

Note For these plug welds, drill a 9 mm hole in each

of the indicated locations.

GMA Weld

Warning Do not weld a panel where it

directly contacts underlying structural components (the

heat affect zone from welding can weaken the strength of

underlying structural components). Use structural

adhesive to fill gaps behind panels and underlying

components. |

|

|

Sill Section Cut Line Reference Line/Point

Warning Do not weld a panel where it directly

contacts underlying structural components (the heat affect

zone from welding can weaken the strength of underlying

structural components). Use structural adhesive to fill gaps

behind panels and underlying components. Warning Do not cut bolt holes when cutting

sections. Note The cut can

be made within 235 mm of the specified cut line location to

allow sectioning of the Body Side Outer. Note Install a backing plate behind each butt joint if there is

sufficient space. Note The gap

between the adjacent panels of the butt joint for this

section should be as small as possible to maximize joint

strength.

or Aluminum Plug Welds

Note For these plug welds, drill a 9 mm hole in each

of the indicated locations. GMA Weld |

|

Repair Procedure

-

Remove the necessary portion

of the A–Pillar Outer to expose the underlying component being repaired.

-

Remove the original component.

-

Prepare for installation.

NoteA red X indicates a location where a factory-installed fastener is not being replaced.

or Countersunk Rivets, 4.8 mm Short

or Countersunk Rivets, 4.8 mm Long

or High Strength Structural Rivets, 6.5 mm- A = 35 mm.

- B = 12 mm.

or Flow Form Rivets, S38- C = 8 mm.

- D = 9 mm.

- E = 13 mm.

- F = 5 mm.

or Flow Form Rivets, S58- D = 9 mm.

- G = 15 mm.

- Apply structural adhesive to the mating surfaces on the vehicle and the new component or components.

-

Install the new component or components.

Torque the bolts as follows:

- or Bolts, hex-head, M6x1.00x18, Tesla part number 1006529-00-A: Torque 12 Nm.

- or Bolts, hex-head, M8-1.25x20, Tesla part number 1007580-00-A: Torque 24 Nm.

- or Bolts, hex-head, HF M10x80, Tesla part number 1053943-00-A: Torque 45 Nm.

- or Bolt, Torx-head, M8x20, Tesla part number 1014747-00-B: Torque 24 Nm.

-

If replacing a section of

the Body Side Outer only:

Perform GMA welding on the butt joints between sections.

or Aluminum Plug Welds

GMA Weld

NoteDo not weld a panel where it directly contacts a structural panel underneath. The heat from welding might weaken the strength of the underlying panel. Instead of welding, use structural adhesive to fill gaps between a panel and underlying panels.WarningFailure to follow all welding safety precautions, including the use of personal protective equipment, could result in serious injury or property damage. Only technicians who have completed Tesla’s approved welding training are authorized to weld structural components on Tesla vehicles.WarningTo maintain vehicle crash integrity, use only approved welding wire and an approved GMA welder to perform GMA welding on Tesla vehicles. Refer to Approved Gas Metal Arc (GMA) Welders and Welding Wire for information on approved GMA welders and welding wire.CAUTIONDo not weld on a Tesla vehicle before performing the Vehicle Electrical Isolation Procedure (refer to the vehicle-specific Service Manual for more information on the Vehicle Electrical Isolation Procedure). Welding on a Tesla vehicle with an energized high or low voltage system might damage vehicle components.NoteBefore GMA welding, a test weld using material of the same gauge and type should be performed to make sure that the welding equipment settings produce a satisfactory joint. -

Install the necessary

portion of the A–Pillar Outer to cover the

underlying component.

-

Install the Fender Brackets (Upper/Middle).

-

Install the Fender Bracket (Lower).

- Perform any necessary post-repair operations.