2025-09-12

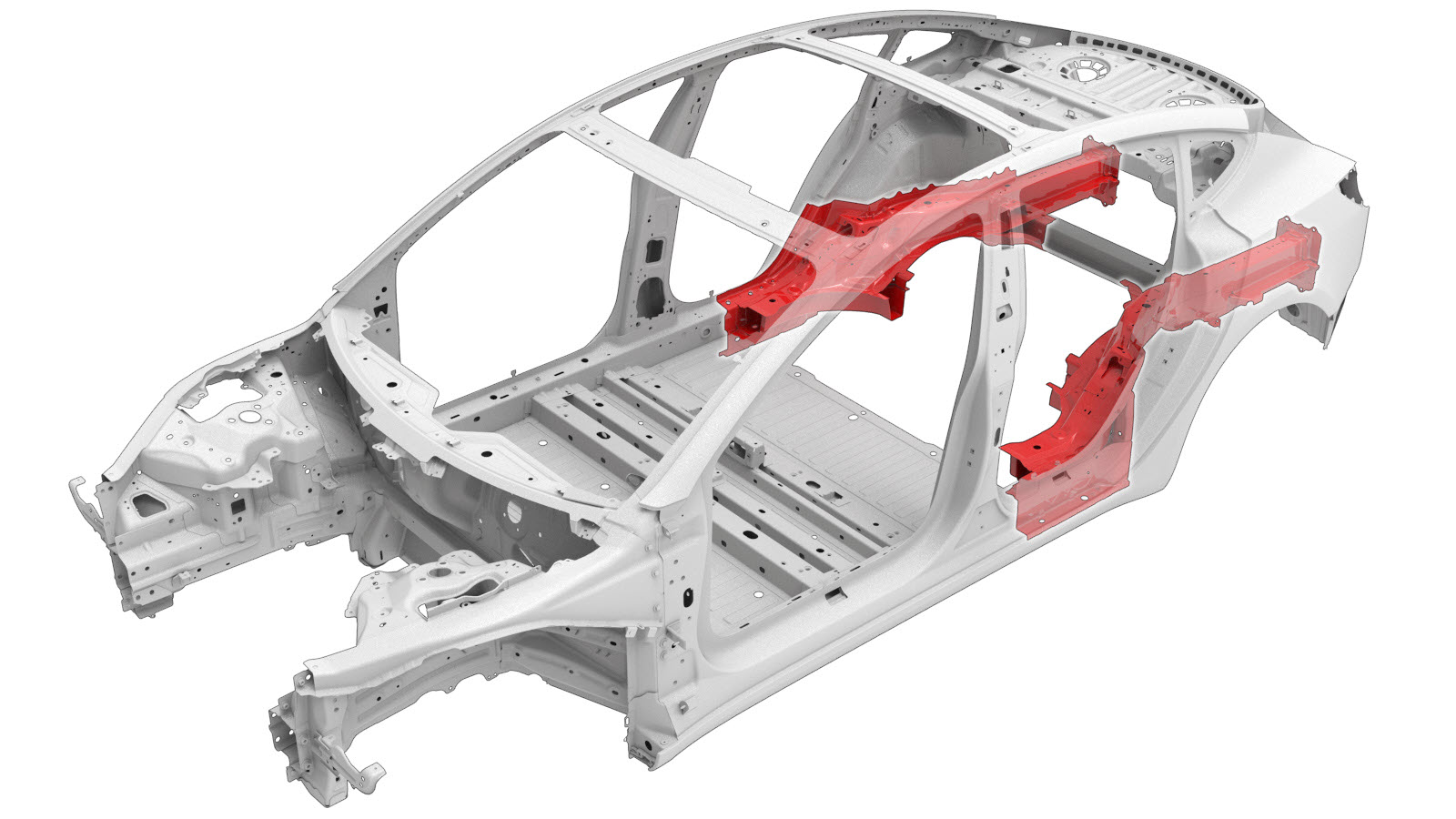

后节点(整体)

校正代码:

10101810602

10101810702

注意:除非本程序中有明确规定,否则上述校正代码涵盖执行本程序(包括关联碰撞维修程序)所需的所有碰撞维修工作。除非明确要求,否则请勿堆叠碰撞维修校正代码。添加执行此程序所需的任何关联机械程序。

校正代码:

10101810602

10101810702

注意:除非本程序中有明确规定,否则上述校正代码涵盖执行本程序(包括关联碰撞维修程序)所需的所有碰撞维修工作。除非明确要求,否则请勿堆叠碰撞维修校正代码。添加执行此程序所需的任何关联机械程序。

维修信息

- 在开始本程序之前,请查看所有碰撞维修一般实践和安全文档并佩戴适当的 PPE(个人防护装备)。

- 执行本程序时,请将车辆正确固定到车架工作台上。

零件清单

| 数量 | 描述 | 图片/备注 |

|---|---|---|

| 1 |

ASSEMBLY - REAR FRAMERAIL COMPLETE(后节点 - 整体) |

|

| 10 | 高强度结构型铆钉,6.5 毫米 | |

| 5 | 结构型灯笼铆钉,6.5 mm | |

| 2 | 结构型沉头铆钉,6.5 mm | |

| 11 | 铆钉,4.8 mm | |

| 2 | 沉头铆钉,4.8 毫米短款 | |

| 11 | 结构型法兰铆钉 | |

| 15 | 流型铆钉 S18 | |

| 2 | 流型铆钉 S28 | |

| 5 | 流型铆钉 S38 | |

| 1 | 流型铆钉 S58 | |

| 4 | 六角头螺栓,SEMS,[FL],HX,M8X23.5,[109],G1009,PTC | Tesla 零件号 1063260-00-C。 |

| 2 | 六角头螺栓,HH M8X29 109 G1009 B M | Tesla 零件号 1623708-00-A。 |

如需订购零件,请参阅零件目录,输入需维修车辆 VIN,查找车辆正确零件(以及零件号)。或者,也可以在零件目录中搜索,查找车辆专用零件。

维修程序

-

拆下后车身面板。

-

拆卸行李箱底板总成(整体)。

-

拆下后车架纵梁至下部围板加长板。

-

拆下第三排座椅横梁(下部)。

-

拆下踵板横梁(后)。

-

拆卸原装部件。

-

准备安装。

注红色 X 表示此处工厂安装的紧固件未进行更换。

或 流型铆钉,S18

或 流型铆钉,S28

或 流型铆钉,S38

或 流型铆钉,S58

或 六角头螺栓

GMA 焊缝注每处 GMA 焊缝为 20 毫米长。 - 在车辆接合面以及新部件上涂抹结构型粘合剂。

-

安装新部件。

按如下所示拧紧螺栓:

- 六角头螺栓:SEMS,[FL],HX,M8X23.5,[109],G1009,PTC,零件号 1063260-00-C:24 Nm。

- 六角头螺栓:HH M8X29 109 G1009 B M,零件号 1623708-00-A:19 Nm。

-

执行 GMA 焊接。

GMA 焊缝注每处 GMA 焊缝为 20 毫米长。警告未遵守包括使用个人防护装备在内的任何焊接安全注意事项,可能导致严重的人身伤害或财产损失。只有已完成 Tesla 认可的焊接培训课程的维修技师才有权在 Tesla 车辆上焊接结构组件。警告为保持车辆碰撞完整性,在采用 GMA 焊接法焊接 Tesla 车辆时,仅允许使用经批准的焊丝和 GMA 焊接器。请参阅已批准的气体保护金属极弧 (GMA) 焊接器和焊丝了解有关经批准的 GMA 焊接器和焊丝的信息。警告切勿在执行车辆电气绝缘程序前焊接 Tesla 车辆(请参阅车辆专用维修手册,了解有关车辆电气绝缘程序的更多信息)。在具有通电高压或低压系统的 Tesla 车辆上进行焊接可能会损坏车辆部件。注进行 GMA 焊接之前,使用规格和类型相同的材料执行焊接测试,以确保焊接设备的设置能保证满意的焊接效果。

-

安装踵板横梁(后)。

-

安装第三排座椅横梁(下部)。

-

安装后车架纵梁端板。

-

安装后车架纵梁至下部围板加长板。

-

安装行李箱底板总成(整体)。

-

安装后车身面板。

- 执行任何必要的维修后操作。