2025-09-12

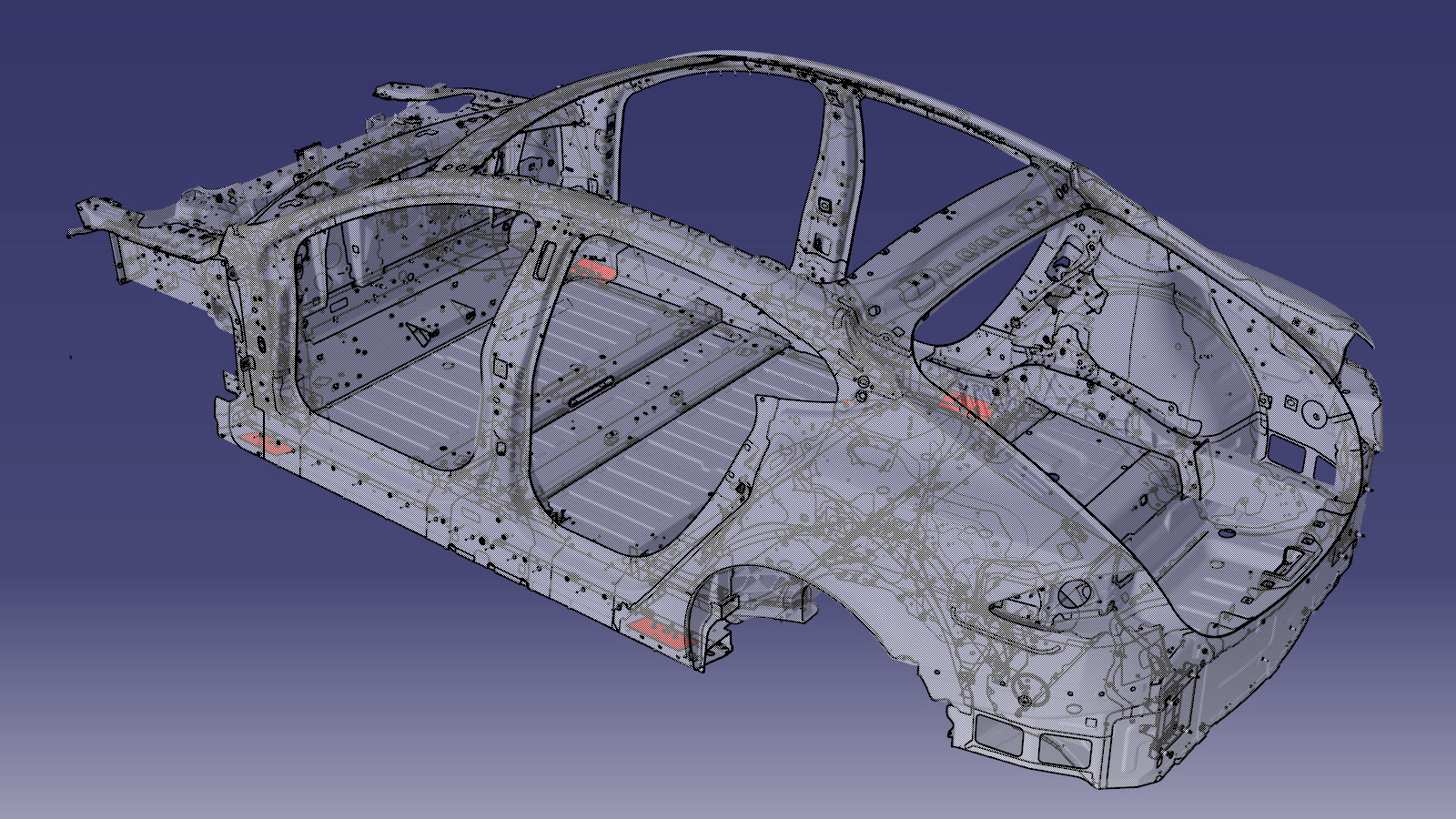

千斤顶垫支座维修

校正代码:

10102904002

注意:除非本程序中有明确规定,否则上述校正代码涵盖执行本程序(包括关联碰撞维修程序)所需的所有碰撞维修工作。除非明确要求,否则请勿堆叠碰撞维修校正代码。添加执行此程序所需的任何关联机械程序。

校正代码:

10102904002

注意:除非本程序中有明确规定,否则上述校正代码涵盖执行本程序(包括关联碰撞维修程序)所需的所有碰撞维修工作。除非明确要求,否则请勿堆叠碰撞维修校正代码。添加执行此程序所需的任何关联机械程序。

维修信息

- 在开始本程序之前,请查看所有碰撞维修一般实践和安全文档并佩戴适当的 PPE(个人防护装备)。

- 不使用车架工作台也可完成此程序。

零件清单

维修程序

-

拆卸原装部件。

防松螺母

- 维修通气孔区域的任何弯管。

-

如果维修区域的裂缝达到 10 毫米或更长,请执行 GMA 焊接。

警告未遵守包括使用个人防护装备在内的任何焊接安全注意事项,可能导致严重的人身伤害或财产损失。只有已完成 Tesla 认可的焊接培训课程的维修技师才有权在 Tesla 车辆上焊接结构组件。警告为保持车辆碰撞完整性,在采用 GMA 焊接法焊接 Tesla 车辆时,仅允许使用经批准的焊丝和 GMA 焊接器。请参阅已批准的气体保护金属极弧 (GMA) 焊接器和焊丝了解有关经批准的 GMA 焊接器和焊丝的信息。警告切勿在执行车辆电气绝缘程序前焊接 Tesla 车辆(请参阅车辆专用维修手册,了解有关车辆电气绝缘程序的更多信息)。在具有通电高压或低压系统的 Tesla 车辆上进行焊接可能会损坏车辆部件。注进行 GMA 焊接之前,使用规格和类型相同的材料执行焊接测试,以确保焊接设备的设置能保证满意的焊接效果。

- 需要时,打磨焊缝顶部表面,使焊缝与周围区域齐平。

-

安放维修板,标出通气孔(中间)和防松螺母孔的轮廓。

- 在每个标出的位置开一个 16 毫米的防松螺母钻孔。

- 在通气孔标记位置开一个 25 毫米的钻孔。

-

准备安装。

或 结构型沉头铆钉,6.5 毫米注以大约 35 毫米的间距标记沉头铆钉钻孔,与拐角、边缘、孔或障碍物距离至少 18 毫米,以便为 Microstop 锥口钻头罩总成提供足够的间隙。在需要安装多排沉头结构型铆钉的区域使每排铆钉上下错开(如图所示)。

防松螺母

- 在车辆接合面以及新部件上涂抹结构型粘合剂。

- 安装新部件。

- 执行任何必要的维修后操作。