2025-10-24

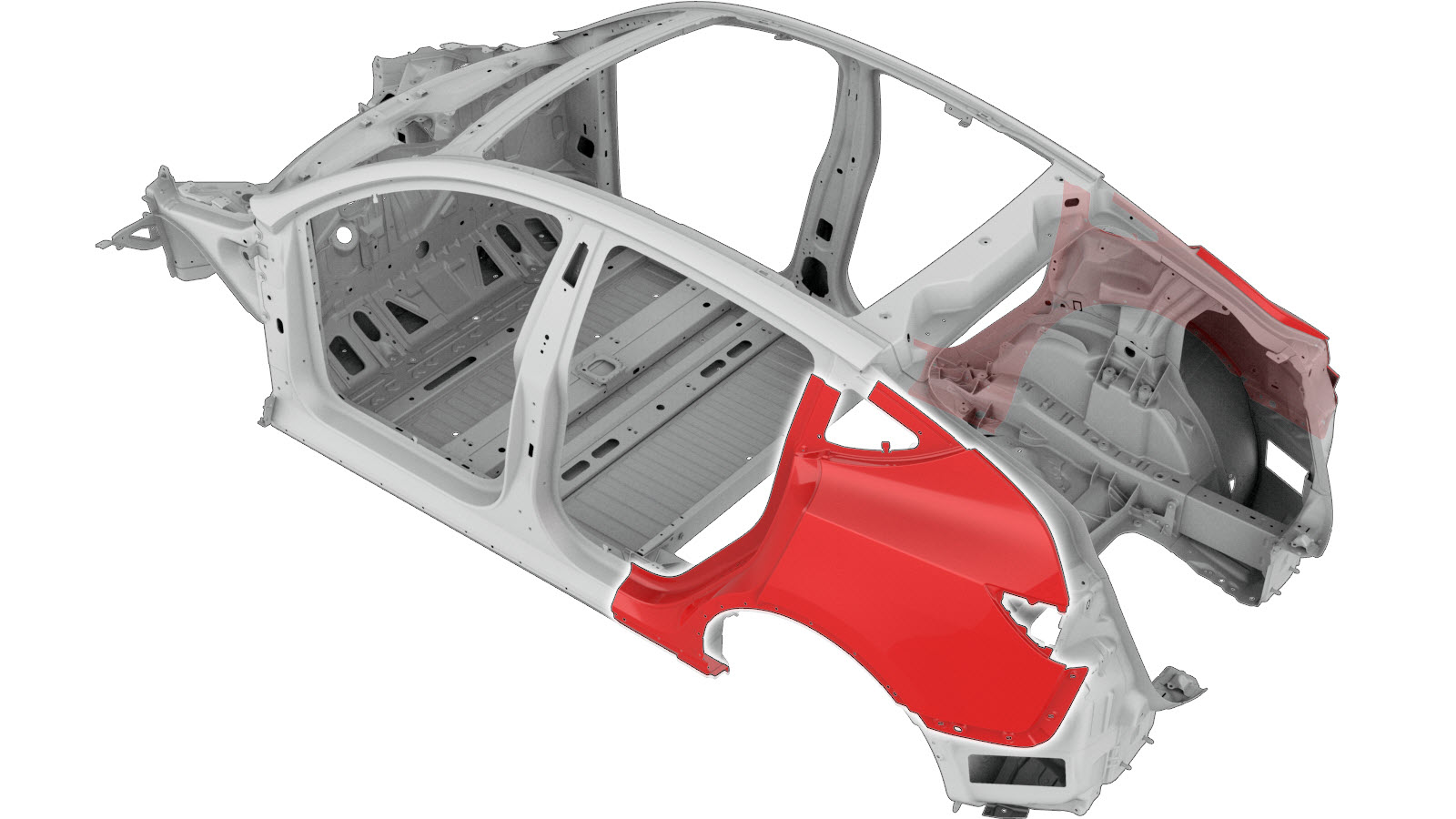

围板外壳

校正代码:

10100138602

10100138702

注意:除非本程序中有明确规定,否则上述校正代码涵盖执行本程序(包括关联碰撞维修程序)所需的所有碰撞维修工作。除非明确要求,否则请勿堆叠碰撞维修校正代码。添加执行此程序所需的任何关联机械程序。

校正代码:

10100138602

10100138702

注意:除非本程序中有明确规定,否则上述校正代码涵盖执行本程序(包括关联碰撞维修程序)所需的所有碰撞维修工作。除非明确要求,否则请勿堆叠碰撞维修校正代码。添加执行此程序所需的任何关联机械程序。

维修信息

- 在开始本程序之前,请查看所有碰撞维修一般实践和安全文档并佩戴适当的 PPE(个人防护装备)。

- 不使用车架工作台也可完成此程序。

零件清单

分割指南

一般分割指南:

- 如果某区块维修需要拆除或安装额外的面板或总成,请参考适用于各面板或总成的特定维修程序执行必要的步骤。

- 如果在车顶行李架区域进行分割,请勿切割车顶行李架支架。

- 如下所述,可以切开间隙孔或非功能孔(外饰孔)。

- 切勿在螺栓孔中心 25 毫米范围内进行切割。

- 除非特别说明,否则区块在对接接头处无需紧固件。

- 衬垫板可安装在区块之间的对接接头处(如创建和安装衬垫板中所述)。

- 对接接头面板之间的缝隙应尽可能小,以最大限度地提高接头强度。

- GMA 焊接区块对接接头。

- 焊接后密封所有外露的焊缝。

- 如果对接接头包括法兰,请勿在法兰上焊接(法兰仅使用结构型粘合剂固定)。

注

在分割围板外壳时,请勿切割下方面板。

下图所示为围板外壳。彩色区域表示是否允许分割。将车辆围板外壳的损坏区域与下图进行比较,然后根据与突出显示区域的颜色对应的维修条件确定用于判断该组件损坏区域是否可分割的条件。

| 围板外壳分区 | |

|---|---|

根据上图中使用的颜色,允许进行如下维修:

| 区域颜色 | 区域可维修性 |

|---|---|

| 绿色区域: | 允许在这些区域进行分割。 |

| 黄色区域: | 允许在这些区域进行分割。 泡沫位于面板后方。 注 如果要在此区域进行分割,请取出泡沫,然后清洁该区域以免污染焊缝。 |

| 红色区域: | 不允许进行分割。 |

维修程序

-

拆卸原装部件。

或 原厂 SPR

或 原厂点焊焊缝

-

准备安装。

-

在充电端口外壳支架与围板外壳和原厂泡沫隔板直接接触的区域涂抹接缝密封剂。

警告本程序要求接缝密封剂的凝固延展率高于 150%。这可避免围板外表面——充电端口外壳支架粘合到面板内侧的位置——出现肉眼可见的变形。警告如果使用的接缝密封剂不适用于裸露金属表面,那么围板内侧的接合面首先需要进行表面修整,再安装充电端口外壳总成。请参阅所使用的接缝密封剂的技术数据表。

- 在车辆接合面以及新部件上涂抹结构型粘合剂。

- 安装新部件。

-

执行电阻点焊。

或 安装点焊焊缝警告未遵守包括使用个人防护装备在内的任何焊接安全注意事项,可能导致严重的人身伤害或财产损失。只有已完成 Tesla 认可的焊接培训课程的维修技师才有权在 Tesla 车辆上焊接结构组件。警告切勿在执行车辆电气绝缘程序前焊接 Tesla 车辆(请参阅车辆专用维修手册,了解有关车辆电气绝缘程序的更多信息)。在具有通电高压或低压系统的 Tesla 车辆上进行焊接可能会损坏车辆部件。

-

执行 GMA 焊接。

或 钢塞焊焊缝

GMA 焊缝

警告未遵守包括使用个人防护装备在内的任何焊接安全注意事项,可能导致严重的人身伤害或财产损失。只有已完成 Tesla 认可的焊接培训课程的维修技师才有权在 Tesla 车辆上焊接结构组件。警告为保持车辆碰撞完整性,在采用 GMA 焊接法焊接 Tesla 车辆时,仅允许使用经批准的焊丝和 GMA 焊接器。请参阅已批准的气体保护金属极弧 (GMA) 焊接器和焊丝了解有关经批准的 GMA 焊接器和焊丝的信息。警告切勿在执行车辆电气绝缘程序前焊接 Tesla 车辆(请参阅车辆专用维修手册,了解有关车辆电气绝缘程序的更多信息)。在具有通电高压或低压系统的 Tesla 车辆上进行焊接可能会损坏车辆部件。注进行 GMA 焊接之前,使用规格和类型相同的材料执行焊接测试,以确保焊接设备的设置能保证满意的焊接效果。 - 执行任何必要的维修后操作。