A/C Refrigerant Recovery & Recharge

FRT No: 18033302

Set Up HVAC Machine

- Perform a calibration check of the HVAC machine. Refer to the HVAC machine operator’s manual for instructions on how to perform a calibration check of the HVAC machine. If a machine fails the calibration check, do not perform the service until a service representative calibrates the HVAC machine.

- Check the full length of the service lines and service ports for damage or degradation. Ensure that there are no obvious signs of damage or degradation that could cause a leak when servicing the vehicle.

- Check the HVAC machine’s power supply cord before servicing the vehicle. Ensure it is not damaged and the insulation has not been compromised in any way.

- Verify that the oil is PVE for Roadster 1.5 or POE for Roadster 2.0.

| CAUTION: Do not mix different types of A/C system oil. If the HVAC machine is not solely dedicated to Roadster use, perform internal self-flushing of the A/C lines in the machine before every service to prevent cross-contamination. |

- Press the MENU button on the keypad.

- Press the UP or DOWN arrow key to scroll to "HOSE FLUSH". Press START/YES or OK.

- Connect the hoses to the unit's storage port connections.

- Open the coupler valves.

- Press START/YES or OK to begin the hose flush process. If the procedure has started correctly, a three minute countdown begins. The machine automatically starts and finishes the recovery from the hoses after the flush procedure is completed.

- When the entire procedure has been completed, the screen displays "FLUSH COMPLETE CONNECT SERVICE HOSES TO VEHICLE, START TO CONTINUE".

- Close the coupler valves and press START/YES or OK.

- Press STOP/NO or OK to exit the hose flush menu.

- Connect the appropriate refrigerant oil bottle.

NOTE: The hoses have now been flushed and may be connected to the vehicle for service.

Recover/Recharge

- Remove the dust caps from the high and low pressure charge port connectors.

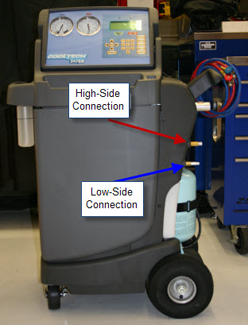

- Connect the high and low pressure hoses from the R134a recovery/charging station to the connectors on the vehicle.

| WARNING: Servicing must only be carried out by personnel familiar with both the vehicle system and the charging and testing equipment. All operations must be carried out in a well-ventilated

area away from open flame and heat sources. |

| WARNING: R134a is a hazardous liquid and if handled incorrectly can cause serious injury. Suitable protective clothing, consisting of face protection, heat-proof gloves, rubber boots and apron or waterproof overalls, must be worn when carrying out operations on the air conditioning system. |

- Check and mark existing level of recovered A/C oil.

- Activate the HVAC service mode. Refer to the GENERAL INFORMATION section.

NOTE: Because the Tesla Roadster uses two separate A/C circuits (one for the cabin environment, and another for the battery cooling system), it is necessary to activate the HVAC service mode to ensure that all the refrigerant is recovered and recharged in both circuits.

- Only when the HVAC system is in service mode, should you continue with the refrigerant recovery and recharge process.

- Due to the position of the receiver drier, it is necessary to use a heated air supply to warm the canister and prevent it from internally freezing up during the recovery and recharging process:

| CAUTION: Do not concentrate excessive heat to one point. Move the heat gun around to distribute heated air evenly. |

| WARNING: Do not leave the heat gun unattended. |

a. Use a heat gun set to the lowest setting to direct heat to the receiver drier. Attempt to heat the receiver drier to approximately 40 degrees C (104 degrees F).

b. Follow the HVAC machine instructions for recovering refrigerant from the vehicle.

c. Continue to heat the receiver drier while the machine is recovering refrigerant.

d. When the system is evacuated, note the reading on the low side gauge.

e. Continue to heat the receiver drier bottle for 5 minutes, then check the low side gauge again. If the pressure has increased, repeat the refrigerant recovery procedure.

- Measure and record the quantity of refrigerant oil recovered from the system.

- Carry out any required service procedure now that the refrigerant has been recovered from the system.

- If any part of the system has been opened during the course of a service procedure, a refrigerant recovery (evacuate) process must be carried out prior to recharging the system.

NOTE: In order to fully purge refrigerant and remove air, moisture, and contaminants, it is important to apply the appropriate vacuum for 30-45 minutes

- If required, activate the HVAC service mode.

- Ensure that the R134a recovery/recharging station has enough refrigerant to allow the system to be fully charged.

- Add the required quantity of recommended refrigerant oil to the oil charger on R134a station.

| CAUTION: Do not mix different types of A/C system oil. Model S and Model X use ND-11 spec POE oil, while Roadster 1.5 and 2.0 use different oils (PVE for 1.5 cars and POE for 2.0/2.5 cars). |

- Following the instructions supplied with the R134a recovery/charging station, recharge the HVAC system with the correct quantity of refrigerant.

NOTE: When recharging the HVAC system, always allow additional weight of refrigerant to fill the charging line between refrigerant station and vehicle. Calculate the additional refrigerant weight required at 30 grammes per metre of charging hose.

- Once charging is complete, disconnect the high and low pressure hoses from the charge port connectors.

- Fit dust caps to charge port connectors.